18+ SAMPLE Food Safety Inspection Checklist

-

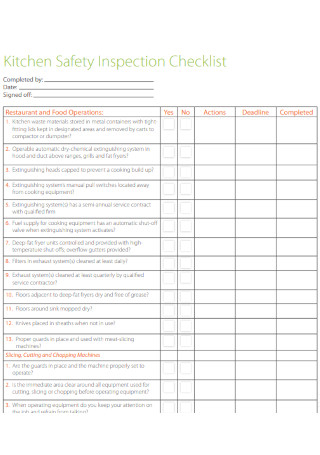

Food Safety Inspection Checklist

download now -

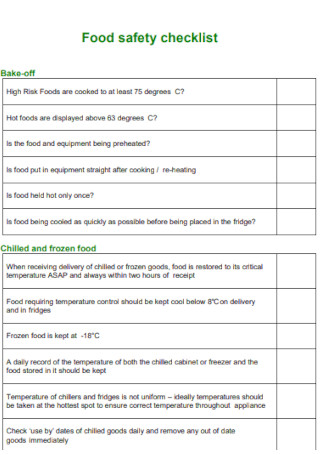

Sample Food Safety Inspection Checklist

download now -

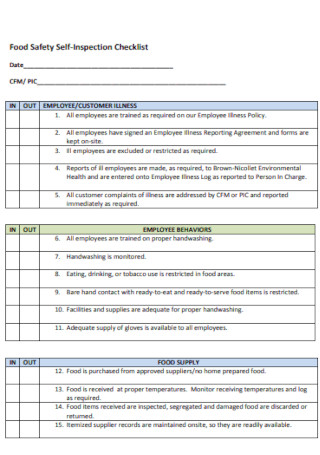

Food Safety Self Inspection Checklist

download now -

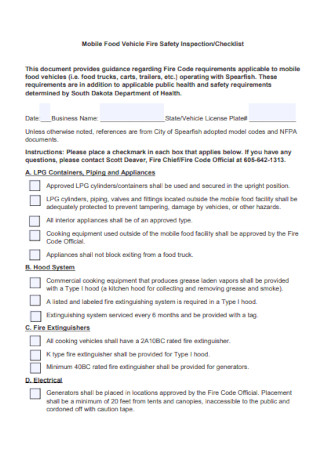

Food Vehicle Safety Inspection Checklist

download now -

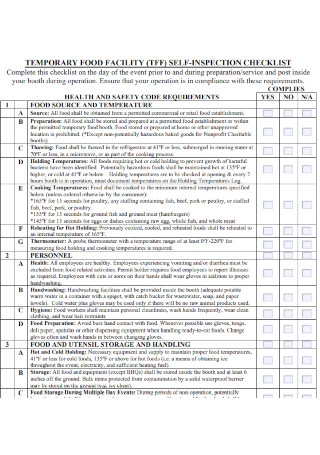

Food Facility Safety Inspection Checklist

download now -

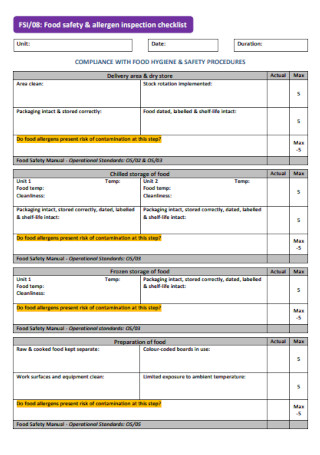

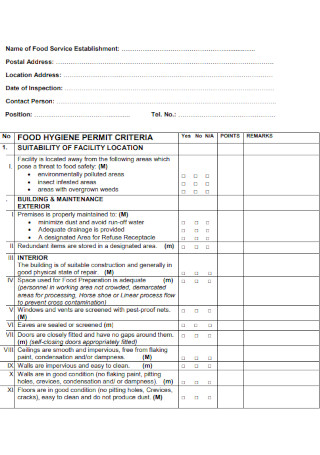

Food Hygiene Safety Inspection Checklist

download now -

Food Safety Establishment Inspection Checklist

download now -

Food Safety Management Inspection Checklist

download now -

Food Health and Safety Inspection Checklist

download now -

Kitchen Food Safety Inspection Checklist

download now -

Food Safety Group Inspection Checklist

download now -

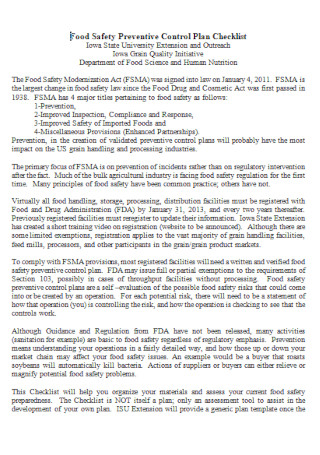

Food Safety Control Plan Inspection Checklist

download now -

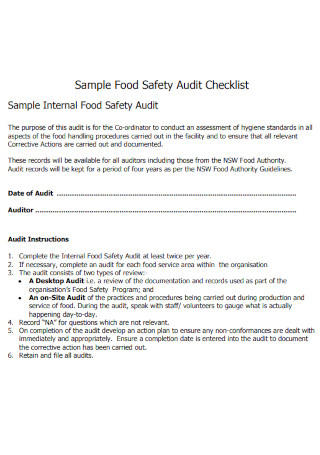

Food Safety Audit Inspection Checklist

download now -

Food Safety Inspection Checklist Form

download now -

Food Service Safety Inspection Checklist

download now -

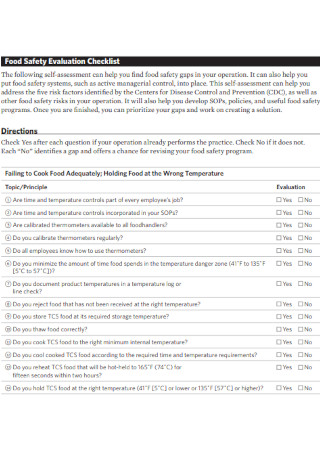

Food Safety Inspection Evaluation Checklist

download now -

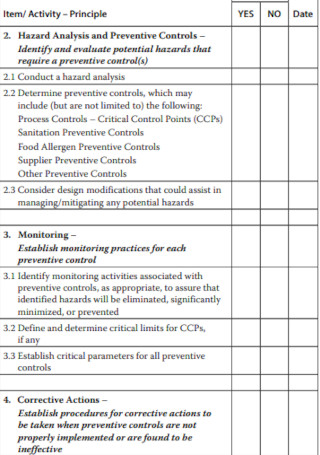

Food Safety Inspection Plan Checklist

download now -

Pre Season Food Safety Inspection Checklist

download now -

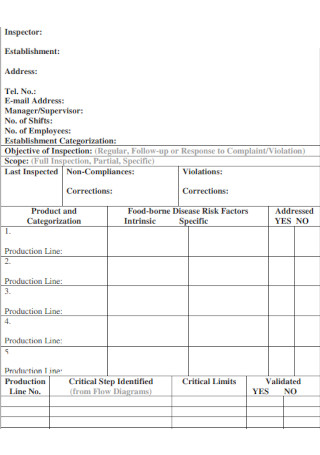

Risk Based Food Safety Inspection Checklist

download now

FREE Food Safety Inspection Checklist s to Download

18+ SAMPLE Food Safety Inspection Checklist

What is a food safety inspection checklist?

Food Safety Inspection Key Points

How to Prepare for a Food Safety Inspection

What is the biggest threat to food safety?

What are the 4 types of food hazards?

What powers do food safety inspectors have?

What is a food safety inspection checklist?

A food safety inspection checklist is a guide for food inspectors to make sure that the important aspects of gauging the cleanliness of a certain restaurant’s menu are looked into. These food safety inspectors examine the raw food, or the venue wherein food is prepared, and see to it if they are free from disease-inducing microbes, for instance, chemical contamination, harmful substances, unsafe processing and production, and a lot more that involve food, and the making of it. This is in compliance with health and safety protocols by the state to prevent harm and possible sickness to the general public. This record can be used by the food company or the restaurant itself to prove its credibility to their customers that they are officially approved as a clean and legitimate company that ensures safety of people who consume their products. Using the food safety inspection checklist, the company can even be preemptive and make sure that they follow these standards, based on the coverage of key things that the checklist specifically calls for.

Food Safety Inspection Key Points

They key points serve as the specifics of where the food inspector should look into in order to determine whether or not your food company passes the standards of health and hygiene protocols, and may even very possibly determine the continuance of your business, since unsafe products are a great threat to people in general. Hence, the preparation, storing, and managing of food products are meticulously checked by food safety inspectors, or Environmental Health Officers. These are the things that Environmental Health Officers will inspect when conducting an assessment in your area.

How to Prepare for a Food Safety Inspection

When health and safety risks arise in a food business, so do their liabilities as a company. This is why it is very important for them to prepare for food safety inspections. Not only do they gain their credibility as part of the food business industry, but they also secure their investment to be something sustainable and profitable in the long run. One way to make sure that you do not fail the inspection is to conduct regular inspections of your own. After all, making sure that your products are safe is not only to pass an inspection, but to also guarantee the well-being of your consumers to begin with. With that, here are the important steps to follow in preparing for a food safety inspections.

Step 1: Required certification

You need a lot of government certifications before you can even begin a food business. Make sure to prepare all the needed certifications that are not expired for the food safety inspector to evaluate. This is to guarantee that your business is legal, and has gone through the required process to commence. This is also a requirement for a food safety inspection to start examining your area.

Step 2: Staff Orientation

Aside from making personal hygiene a necessity in the workplace, you also need to ensure that your staff knows the important information regarding the handling of food in your business. They need to know the answers to questions regarding their positions in food management, and how they regulate their work station in terms of health and safety. These may be things your staff knows in pragmatics, but may be things they do not exactly have the words for, hence it would be strategic for you to have a recap of some sort.

Step 3: Maintenance and Repairs

Some tools or equipment in the work station may be old, or close to deteriorating, hence, it is important for you to have maintenance for these objects, and make calls for the necessary reparations to be done to your kitchenware or appliances. This is to avoid future malfunction that may greatly affect your business, and also to make sure that your tools are kept up-to-date.

Step 4: Food Temperature Control

Food temperature is one of the main things to be checked during inspections. The attention you give it should be directly proportional to that. Make sure to prepare the food temperature log as backing document to show the clear maintenance of the temperature, and check your local health regulation requirements to see if your practices fit their standards.

What is the biggest threat to food safety?

There are a lot of things that are threatening to food safety, especially because we are talking about health. But generally, harmful microbes or bacteria are the biggest of which, since they are present within the food itself, and consumption of which can surely directly affect the humans coming in contact with them. This is why there are a lot of preemptive measures present in the food safety inspection checklist to safeguard food from this threat, such as the meticulous maintenance of food temperature, as well as their respective containers having to be tightly intact.

What are the 4 types of food hazards?

The four types of food hazards are physical, allergen, microbiological, and chemical hazards. Physical hazards pertain to the type of packaging the food has, which has a direct effect to the product in and of itself, as well as pest droppings, and a lot more accidental remnants coming from external things. Allergens are more contingent on the individuals, whether or not they are allergic to certain food. This is why checking the components and ingredients of a certain dish is so important since it makes sure that your consumption is still in line with your health. Microbiological hazards pertain to food borne pathogens that are mostly present in raw food, or perhaps yeast, viruses, and other harmful organisms that live inside food itself but are invisible to the eye, while chemical hazards are artificial substances that homogenized with food, despite being not supposed to.

What powers do food safety inspectors have?

Food safety inspectors have the power to document your food management, detain and seize a few unsafe products, and file reports or call authorities if there are any malicious practices within your business. They have direct control to the continuance of your business, since leaving an unsatisfactory impression to your food safety inspector may result to them failing your company in the check-up.

It is a long process to have that savory-smelling scrumptious dish on your dining table, because of the existing hazards present in preparing it in the first place. It is important for businesses to comply with health standards, since these are made to guarantee the safety of customers at the end of the day. Their credibility and ability to sustain their business are also contingent on them passing this inspection, which is why they are very much encouraged to regularly check their manufacturing and food management.