25+ SAMPLE New Construction Checklist

-

New Home Construction Checklist Template

download now -

New Construction Final Work Checklist Template

download now -

New Construction Renovation Cleaning Checklist Template

download now -

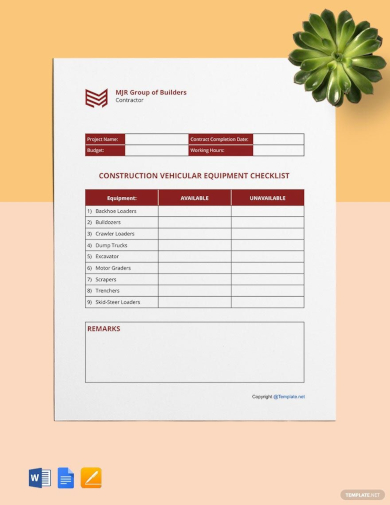

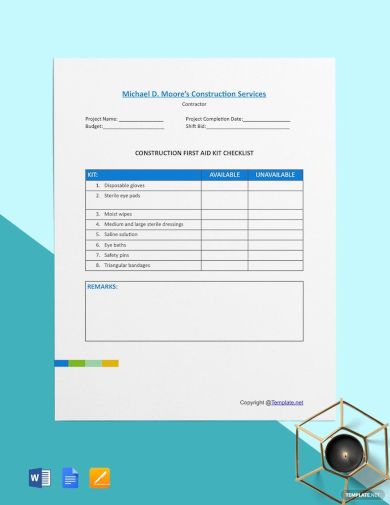

Sample Construction Checklist Template

download now -

Basic Construction Checklist Template

download now -

New Building Construction Checklist

download now -

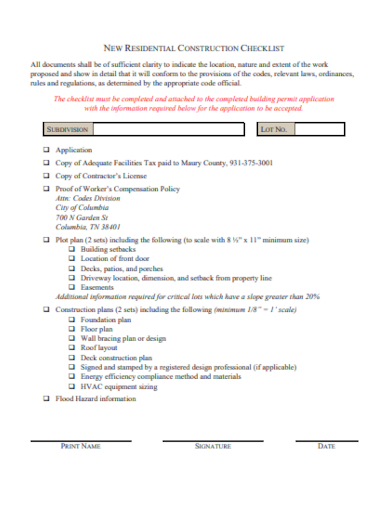

New Residential Construction Checklist

download now -

Printable New Construction Checklist

download now -

Checklist for New Construction

download now -

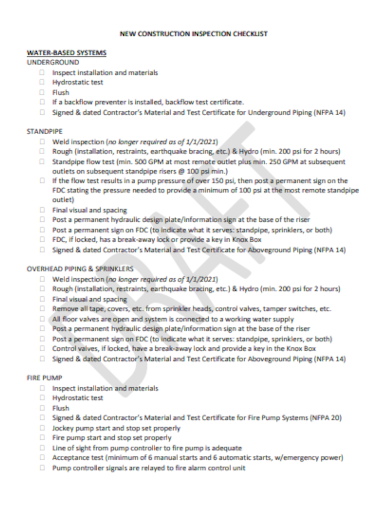

New Construction Inspection Checklist

download now -

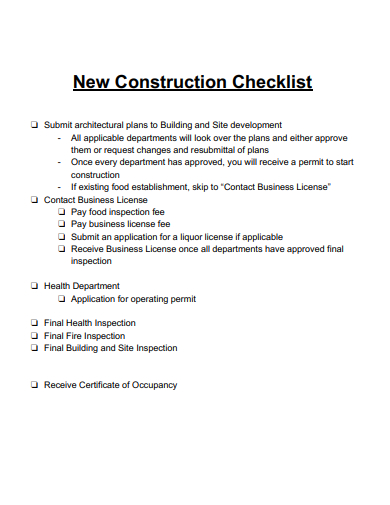

New Construction Checklist in PDF

download now -

New Construction Project Checklist

download now -

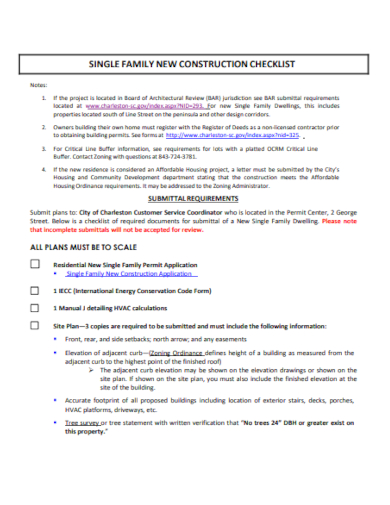

Single Family New Construction Checklist

download now -

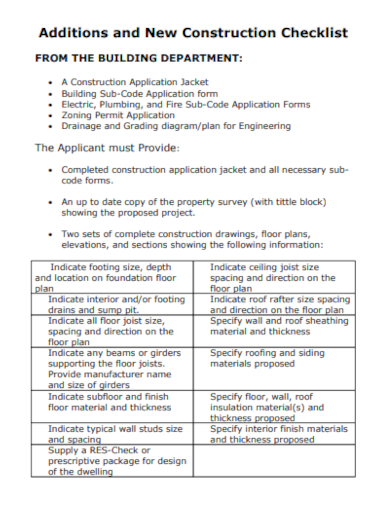

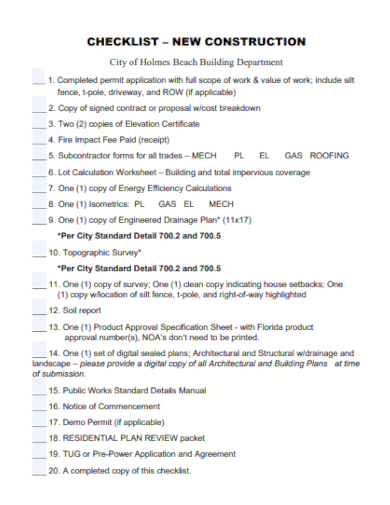

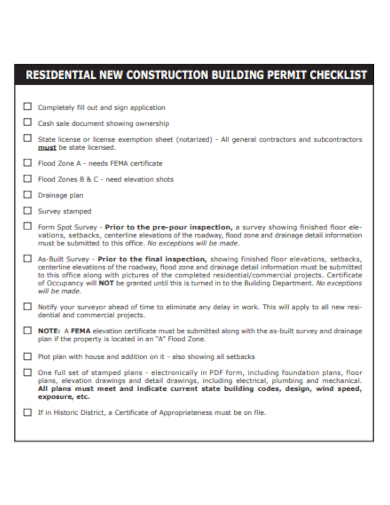

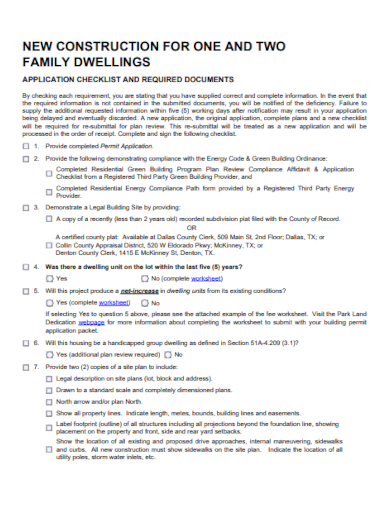

New Construction Permit Checklist

download now -

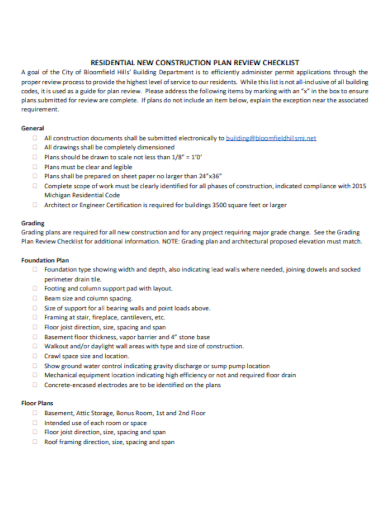

New Construction Plan Checklist

download now -

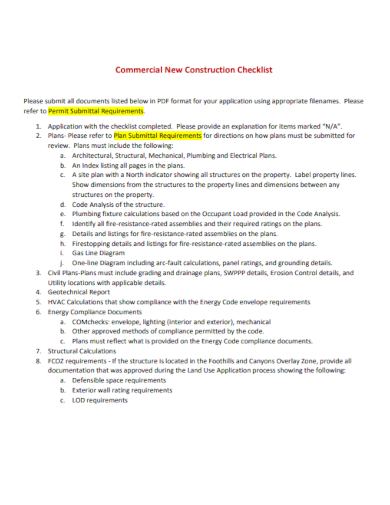

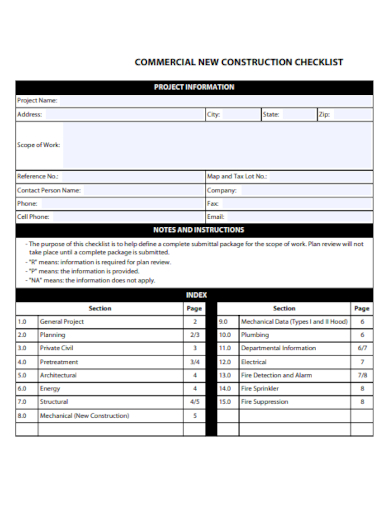

Commercial New Construction Checklist

download now -

New Construction Application Checklist

download now -

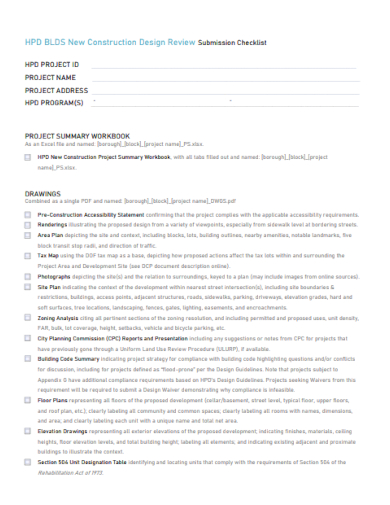

New Construction Design Checklist

download now -

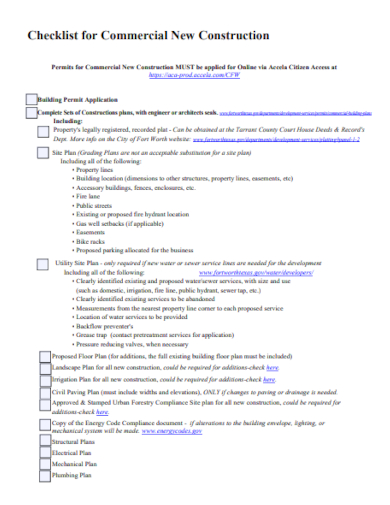

Checklist for Commercial New Construction

download now -

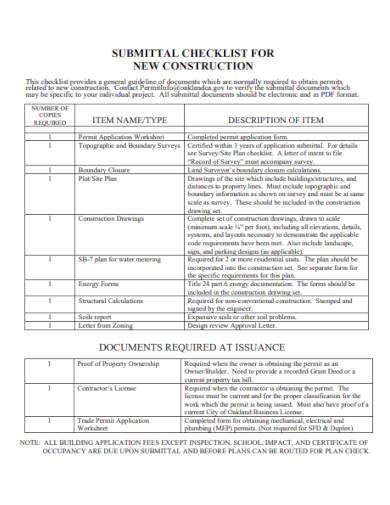

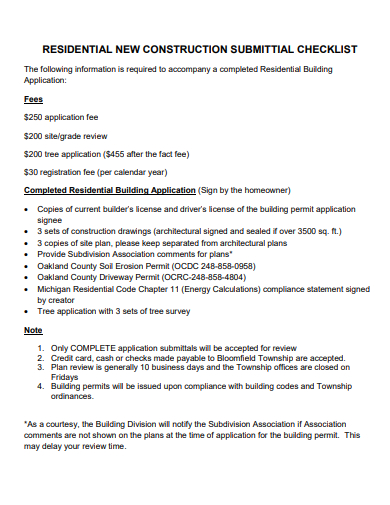

New Construction Submittal Checklist

download now -

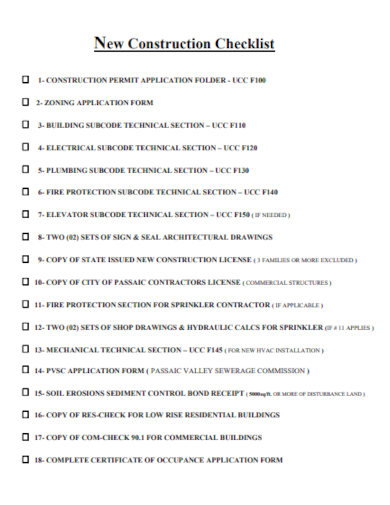

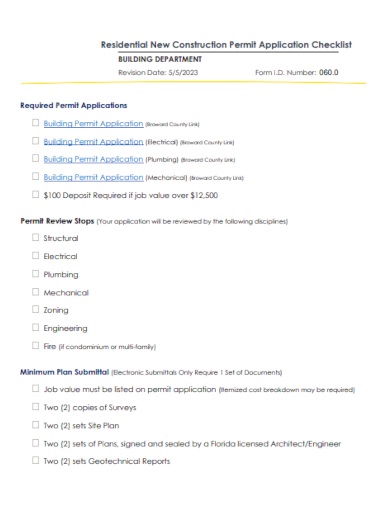

New Construction Permit Application Checklist

download now -

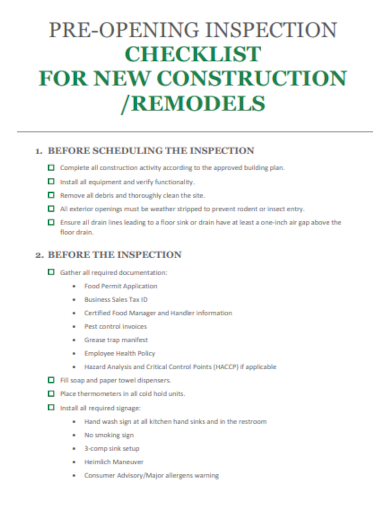

Pre-Opening New Construction Checklist

download now -

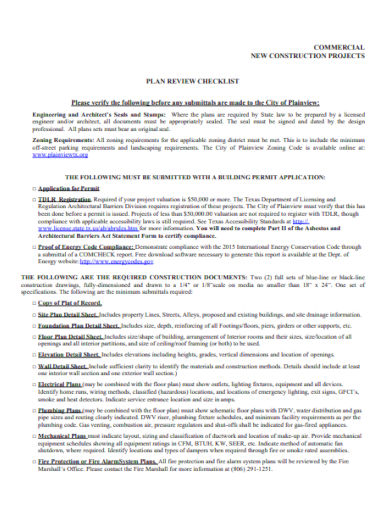

Commercial New Construction Project Checklist

download now -

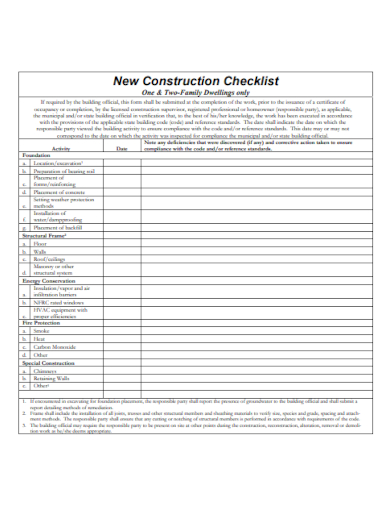

New Construction Checklist Form

download now -

New House Construction Checklist

download now -

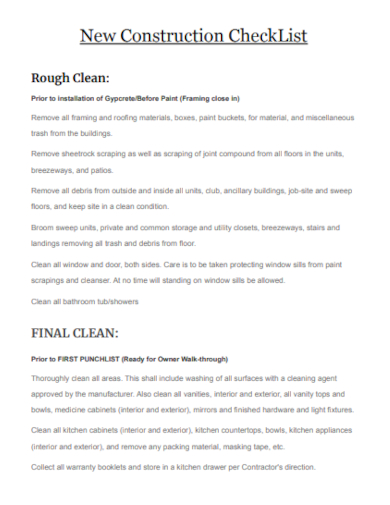

New Construction Cleaning Checklist

download now

FREE New Construction Checklist s to Download

25+ SAMPLE New Construction Checklist

Definition:

Site Assessment and Preparation:

Planning and Documentation:

Material Procurement:

Construction Phase:

Safety Measures:

What role does the new construction checklist play in managing project budgets?

Why is it crucial to involve all stakeholders in the checklist development process?

How can a new construction checklist aid in project closeout and handover?

When should the checklist include planning and design considerations?

Can this checklist assist in managing project timelines and milestones?

Definition:

A New Construction Checklist is a comprehensive document outlining essential tasks and considerations for a construction project’s lifecycle. It serves as a roadmap for builders, ensuring that each stage, from site preparation to final inspection, is executed correctly. This tool aids in maintaining quality, ensuring safety standards, and streamlining the construction process, reducing potential oversights or delays.

Site Assessment and Preparation:

Before laying a brick, understanding the site’s intricacies is paramount. Begin with:

1. Zoning and Land Use:

- Verify the property’s zoning designation.

- Ensure compliance with local land use regulations.

- Check if the intended use aligns with zoning requirements.

2. Property Boundaries and Ownership:

- Identify the property boundaries and corners.

- Confirm ownership and legal title.

- Check for any encumbrances or easements affecting the property.

3. Environmental Considerations:

- Conduct environmental assessments for potential contaminants.

- Identify any protected or sensitive habitats on the site.

- Assess the need for environmental permits.

4. Topography and Soil Conditions:

- Survey the topography and assess slope stability.

- Conduct soil testing to determine load-bearing capacity.

- Consider excavation and grading requirements.

5. Utilities and Infrastructure:

- Locate existing utility connections (water, sewage, gas, electricity).

- Evaluate capacity and suitability for the project.

- Plan for any necessary utility extensions or upgrades.

6. Accessibility and Transportation:

- Evaluate road access and transportation options.

- Ensure compliance with accessibility standards (ADA).

- Assess the impact of transportation on the site.

7. Natural Hazards and Climate:

- Identify potential natural hazards (flood zones, seismic activity).

- Consider climate-related factors (rainfall, temperature).

- Develop mitigation strategies for site-specific risks.

8. Demolition and Site Clearing:

- Determine if any existing structures need demolition.

- Plan for site clearing and removal of debris.

- Assess disposal and recycling options.

9. Regulatory Approvals and Permits:

- Identify required permits (building, environmental, etc.).

- Develop a timeline for permit applications and approvals.

- Ensure compliance with local building codes and regulations.

10. Site Security and Safety:

- Establish safety measures for construction workers.

- Secure the site to prevent unauthorized access.

- Address any potential safety hazards on the property.

11. Budget and Cost Estimations:

- Estimate construction costs based on site conditions.

- Include site preparation, utilities, and infrastructure costs.

- Develop a preliminary budget for the entire project.

12. Project Timeline and Schedule:

- Develop a construction schedule, considering site-related tasks.

- Identify critical path activities related to site work.

- Set milestones and deadlines for site-related activities.

13. Environmental Sustainability:

- Explore opportunities for sustainable design and construction.

- Consider energy-efficient practices and materials.

- Evaluate options for water conservation and green building.

14. Risk Assessment and Mitigation:

- Identify potential risks associated with site conditions.

- Develop risk mitigation strategies and contingency plans.

- Allocate resources for risk management during construction.

15. Stakeholder Communication:

- Establish communication channels with local authorities.

- Keep neighboring property owners informed about the project.

- Maintain open lines of communication with project stakeholders.

16. Health and Safety Compliance:

- Develop a health and safety plan for construction workers.

- Ensure compliance with Occupational Safety and Health Administration (OSHA) regulations.

- Conduct safety training for all personnel on site.

Planning and Documentation:

Every successful construction project leans heavily on meticulous planning.

1. Project Objectives and Scope:

- Clearly define the project’s objectives, scope, and goals.

- Document the expected outcomes and deliverables.

- Identify any constraints or limitations.

2. Budget and Cost Estimates:

- Establish a comprehensive budget that includes all project costs.

- Create detailed cost estimates for materials, labor, equipment, and overhead.

- Develop a contingency budget for unexpected expenses.

3. Project Schedule:

- Create a project schedule that outlines tasks, milestones, and deadlines.

- Sequence activities to ensure efficient workflow.

- Consider dependencies between tasks.

4. Risk Assessment and Mitigation:

- Identify potential risks and uncertainties that could impact the project.

- Develop a risk mitigation plan with strategies to address each risk.

- Allocate resources and assign responsibilities for risk management.

6. Resource Allocation:

- Determine the required resources, including labor, materials, and equipment.

- Allocate resources efficiently to prevent bottlenecks or shortages.

- Plan for resource availability throughout the project.

7. Safety Planning:

- Develop a comprehensive safety plan to protect workers and stakeholders.

- Implement safety protocols and guidelines.

- Conduct safety training for all personnel on the project.

8. Communication Plan:

- Create a communication plan that outlines how information will be shared.

- Identify key stakeholders and establish communication channels.

- Ensure regular updates and reporting.

9. Reporting and Monitoring:

- Implement a monitoring and reporting system to track project progress.

- Generate regular progress reports for stakeholders.

- Use Key Performance Indicators (KPIs) to measure project performance.

10. Contingency Planning:

- Develop contingency plans for potential disruptions or emergencies.

- Identify alternative solutions and response strategies.

- Ensure that all team members are aware of contingency procedures.

11. Legal and Contractual Considerations:

- Review and finalize all legal contracts and agreements.

- Ensure that contracts are clear, legally sound, and aligned with project objectives.

- Document any dispute resolution mechanisms.

12. Stakeholder Engagement:

- Engage with stakeholders, including clients, subcontractors, and the local community.

- Address concerns and maintain positive relationships.

- Communicate project milestones and updates.

Material Procurement:

Material procurement is a critical aspect of construction project planning and execution. Here are the key components to consider when managing material procurement:

1. Material Identification and Specification:

- Identify the specific materials required for the project based on design and technical specifications.

- Create detailed material specifications that outline quality standards, sizes, quantities, and any special requirements.

2. Vendor Selection and Evaluation:

- Research and identify potential suppliers, manufacturers, and distributors for the required materials.

- Evaluate vendors based on factors like reputation, reliability, cost, and past performance.

- Establish a vendor selection process and criteria.

3. Request for Quotations (RFQ) or Proposals (RFP):

- Issue RFQs or RFPs to selected vendors, outlining the project’s material requirements.

- Request price quotations, lead times, delivery schedules, and any applicable discounts or terms.

- Provide vendors with clear instructions for submitting bids.

4. Bid Evaluation and Negotiation:

- Evaluate received bids based on cost, quality, compliance with specifications, and other relevant criteria.

- Negotiate with vendors to secure favorable terms, such as pricing, delivery schedules, and payment terms.

- Consider factors like bulk purchasing to optimize costs.

5. Purchase Orders (POs):

- Issue purchase orders to selected vendors once terms are finalized.

- Ensure that POs include all relevant details, including material specifications, quantities, prices, delivery dates, and payment terms.

- Obtain written confirmation from vendors upon receipt of POs.

6. Quality Assurance and Inspection:

- Implement quality control measures to inspect materials upon delivery.

- Verify that materials conform to specifications and quality standards.

- Document any discrepancies or non-compliance issues.

7. Inventory Management:

- Establish an inventory management system to track material quantities, usage, and reorder points.

- Monitor inventory levels to prevent shortages or excess stock.

- Implement first-in-first-out (FIFO) or just-in-time (JIT) inventory practices when applicable.

8. Delivery and Logistics:

- Plan and coordinate material deliveries to the construction site.

- Ensure that deliveries align with the project’s schedule and sequencing.

- Address transportation and handling considerations to prevent damage or delays.

9. Material Handling and Storage:

- Develop safe and organized material handling and storage procedures.

- Provide appropriate storage facilities to protect materials from environmental factors and theft.

- Ensure compliance with safety regulations.

Construction Phase:

During the construction phase of a project, the plans and designs developed in earlier stages come to life. This critical phase involves the actual building or renovation of structures, and it includes several key components:

- Foundation Work: The foundation is laid, which can be a concrete slab, piers, or other types, depending on the project’s design and structural requirements.

- Structural Framing: Structural components such as beams, columns, walls, and roofs are erected. This phase creates the framework of the building.

- Interior Finishes: Interior elements such as drywall, insulation, flooring, ceilings, and fixtures are installed. This stage transforms the building’s interior spaces.

- Exterior Finishes: The building’s exterior is finished with materials like siding, stucco, brickwork, windows, doors, roofing, and exterior paint.

- Quality Control and Inspections: Quality assurance and inspections are conducted at various stages to ensure compliance with design specifications, safety standards, and building codes.

- Safety Measures: Safety protocols are strictly enforced throughout the construction phase to protect workers and minimize accidents.

- Project Management: Construction project managers oversee daily operations, coordinate subcontractors, monitor progress, and manage the project’s budget and schedule.

- Cost Control: Continuous cost monitoring helps prevent budget overruns. Change orders and cost adjustments are documented and approved as needed.

- Safety and Compliance: Ongoing safety measures and adherence to building codes and regulations are paramount. Safety inspections and compliance checks are conducted regularly.

- Risk Management: Construction risks, such as weather-related delays or unforeseen site conditions, are managed through proactive planning and mitigation strategies.

Safety Measures:

Ensuring the safety of all personnel involved in a construction project is a top priority. The construction phase comes with inherent risks, and it’s crucial to implement comprehensive safety measures to prevent accidents and injuries. Here are some key safety measures commonly employed during construction:

1. Safety Training:

All workers and personnel on the construction site must receive comprehensive safety training before beginning work. This includes training on equipment operation, hazard recognition, and emergency procedures.

2. Personal Protective Equipment (PPE):

Workers are required to wear appropriate PPE, such as hard hats, high-visibility vests, safety glasses, gloves, and steel-toed boots, to minimize the risk of injury.

3. Hazard Identification:

Regular hazard assessments are conducted to identify potential risks on the site. These assessments inform safety planning and mitigation measures.

4. Electrical Safety:

Strict electrical safety measures are enforced to prevent electrical accidents, including proper grounding, lockout/tagout procedures, and GFCI (Ground Fault Circuit Interrupter) use.

5. Traffic Control:

Construction sites near roadways implement traffic control measures to ensure the safety of workers and the public, including signage, barriers, and flaggers.

6. Reporting and Investigation:

Workers are encouraged to report safety concerns or incidents promptly. Incidents are thoroughly investigated to prevent similar occurrences.

7. Safety Leadership:

Safety leadership is promoted at all levels of the organization, emphasizing the importance of safety in every aspect of construction operations.

8. Compliance with Regulations:

Strict adherence to local, state, and federal safety regulations and building codes is maintained throughout the construction process.

What role does the new construction checklist play in managing project budgets?

The new construction checklist plays a critical role in managing project budgets by ensuring that all aspects of the project are accounted for from the outset, helping to prevent costly omissions and changes later in the construction process.

Why is it crucial to involve all stakeholders in the checklist development process?

Involving all stakeholders in the checklist development process is crucial because it ensures that the checklist is comprehensive and addresses the specific needs and requirements of all parties involved in the construction project, thereby promoting transparency, collaboration, and accountability.

How can a new construction checklist aid in project closeout and handover?

A new construction checklist aids in project closeout and handover by serving as a comprehensive record of completed tasks and quality checks. It helps ensure that all necessary inspections, documentation, and final touches are in place, facilitating a smooth transition to the project’s operational phase.

When should the checklist include planning and design considerations?

Planning and design considerations should be included in the checklist during the early stages of the project, ideally before construction begins. This ensures that important decisions and requirements are addressed from the outset, reducing the likelihood of costly changes later in the process.

Can this checklist assist in managing project timelines and milestones?

Yes, the checklist can assist in managing project timelines and milestones by ensuring that key tasks and milestones are clearly defined and tracked throughout the construction process, helping to maintain progress and meet project deadlines.

In conclusion, a new construction checklist is an indispensable tool for any construction project, ensuring every phase is executed flawlessly. By systematically following the checklist, project managers can significantly reduce errors, save time, and optimize resources. For those keen on maintaining industry standards and ensuring project success, embracing this checklist is a pivotal step, acting as the backbone of any well-managed construction venture.