A machine maintenance checklist is a document for ensuring equipment operates efficiently and avoids unexpected breakdowns. It provides a systematic approach to inspect, service, and maintain machines regularly. By…

continue reading

50+ SAMPLE Control Checklist

-

Internal Control Checklist

download now -

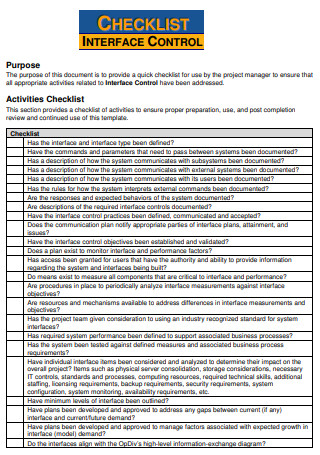

Interface Control Checklist

download now -

Strengthening Control Checklist

download now -

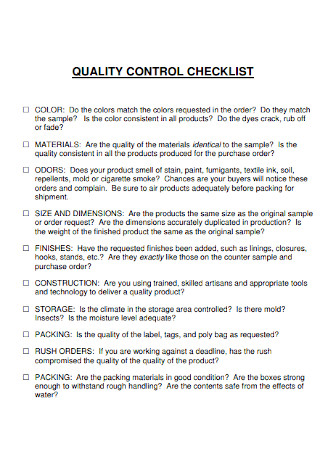

Quality Control Checklist

download now -

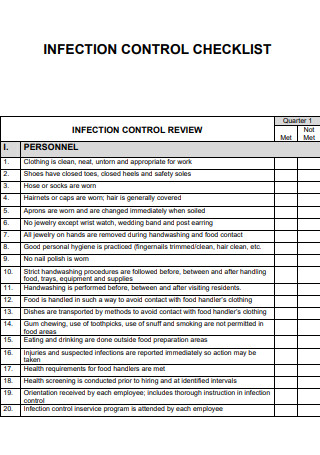

Infection Control Checklist

download now -

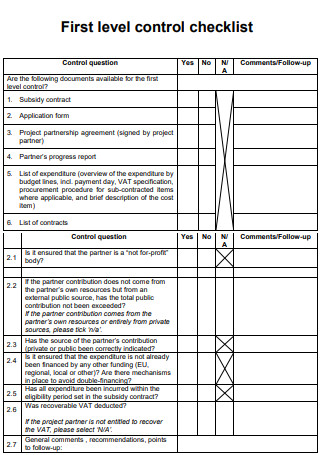

First Level Control Report Checklist

download now -

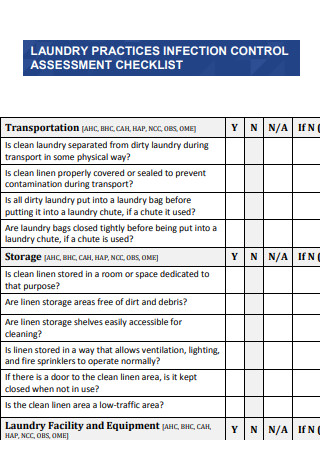

Infection Control Assessment Checklist

download now -

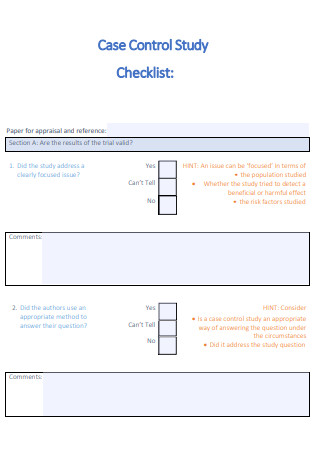

Case Control Study Checklist

download now -

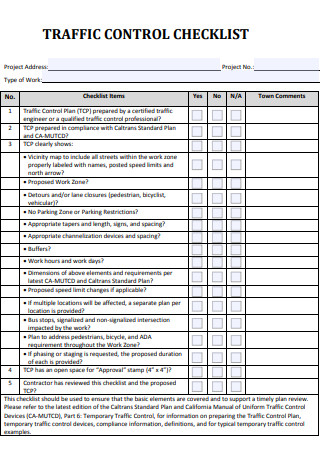

Traffic Control Checklist

download now -

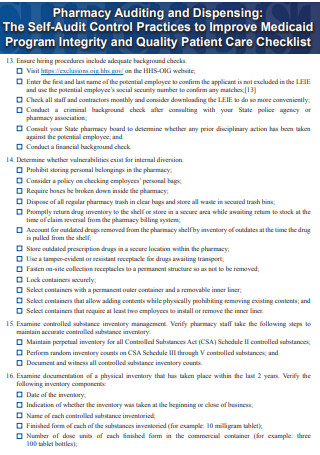

Self-Audit Control Checklist

download now -

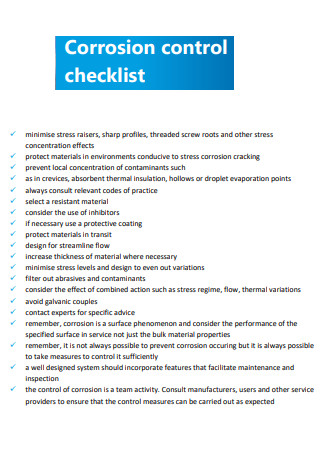

Corrosion Control Checklist

download now -

Infection Prevention Control Checklist

download now -

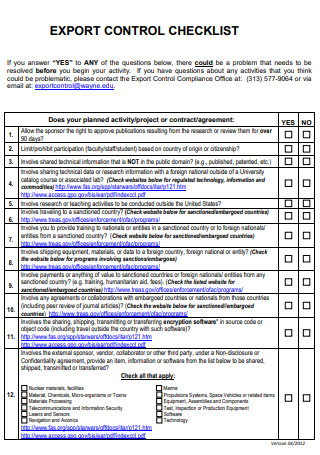

Export Control Checklist

download now -

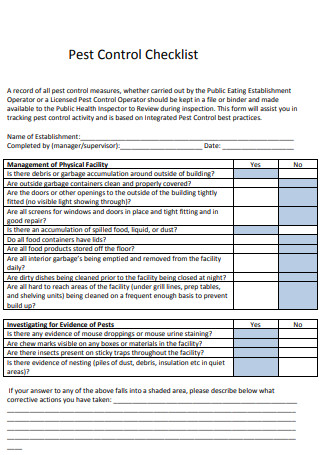

Pest Control Checklist

download now -

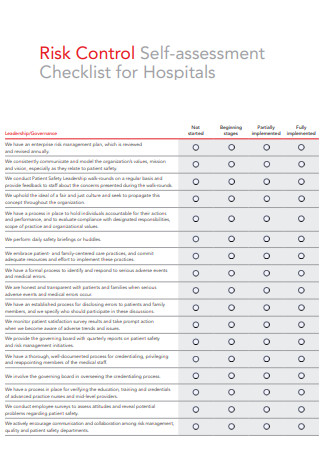

Risk Control Self-assessment Checklist

download now -

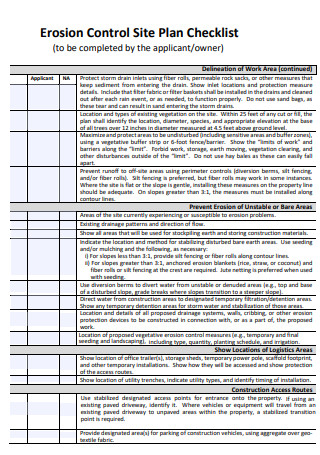

Erosion Control Site Plan Checklist

download now -

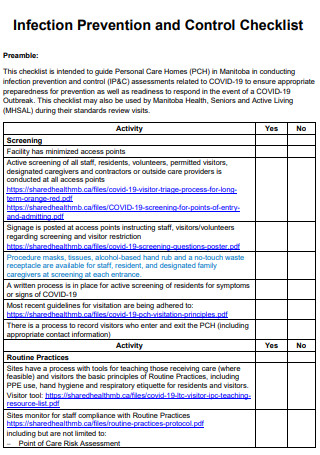

Infection Prevention and Control Checklist

download now -

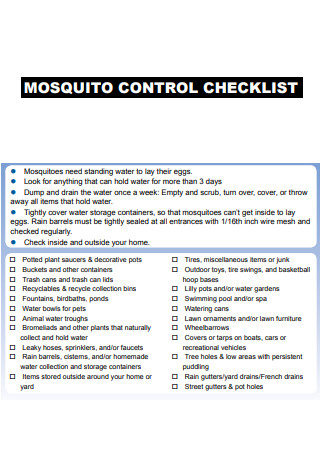

Mosquito Control Checklist

download now -

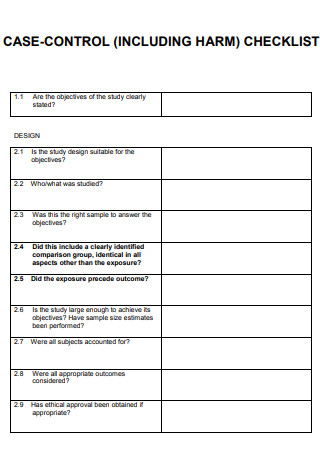

Case Control Checklist

download now -

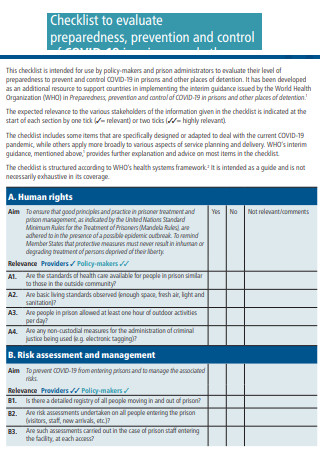

Prevention and Control Checklist

download now -

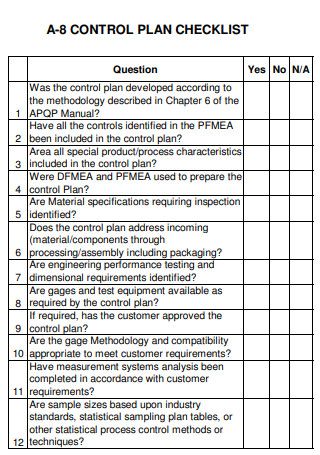

Control Plan Checklist

download now -

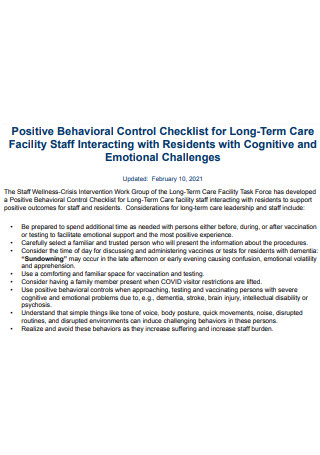

Positive Behavioral Control Checklist

download now -

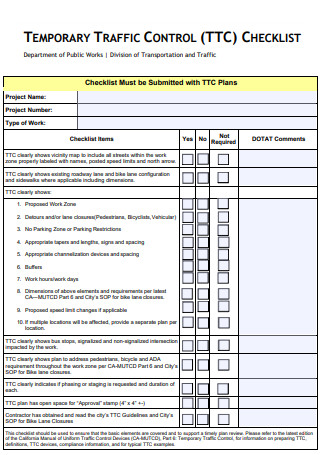

Temporary Traffic Control Checklist

download now -

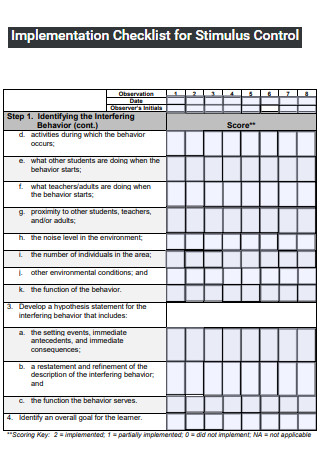

Stimulus Control Implementation Checklist

download now -

Source Control Checklist

download now -

Food Safety Preventive Control Plan Checklist

download now -

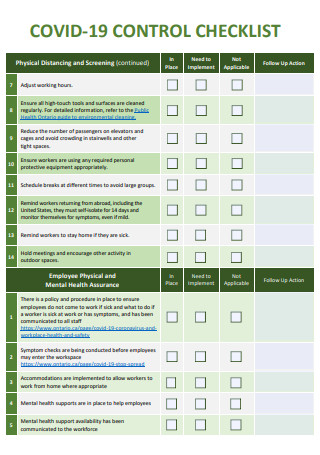

Covid 19 Control Checklist

download now -

Erosion Control Checklist

download now -

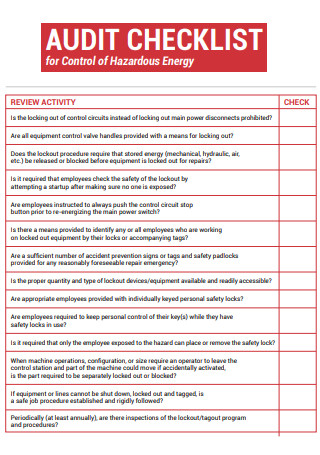

Control Audit Checklist

download now -

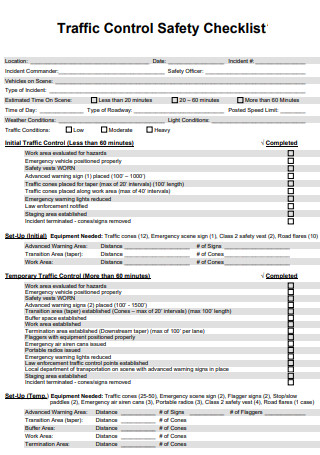

Traffic Control Safety Checklist

download now -

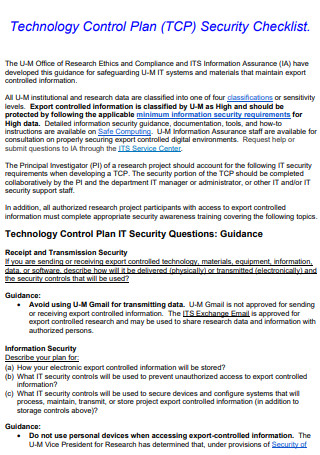

Technology Control Plan Security Checklist

download now -

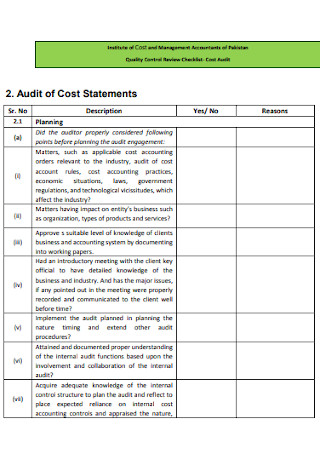

Quality Control Review Checklist

download now -

Quality Control Review Checklist

download now -

Allergen Control Checklist

download now -

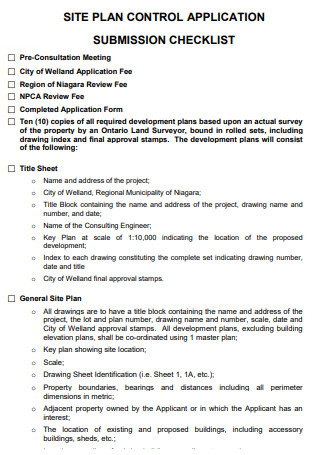

Site Plan Control Submission Checklist

download now -

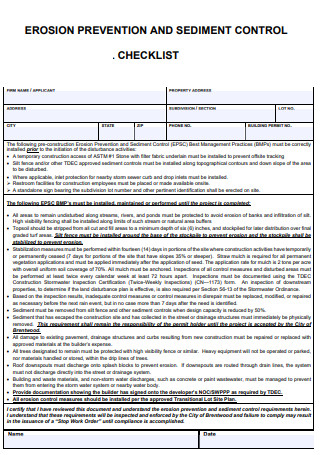

Erosion Prevention and Sediment Control Checklist

download now -

Internal Control Reference Checklist

download now -

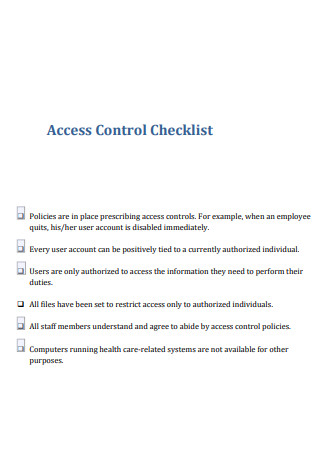

Access Control Checklist

download now -

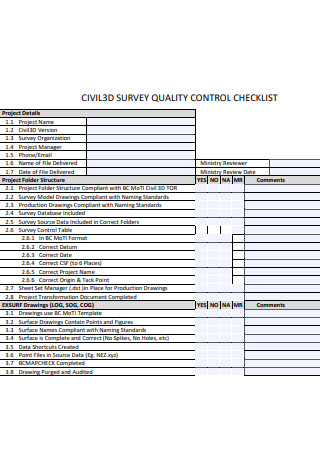

Survey Quality Control Checklist

download now -

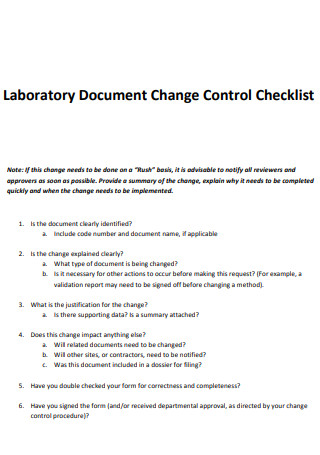

Laboratory Document Change Control Checklist

download now -

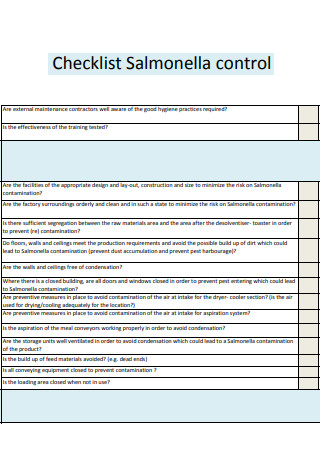

Salmonella Control Checklist

download now -

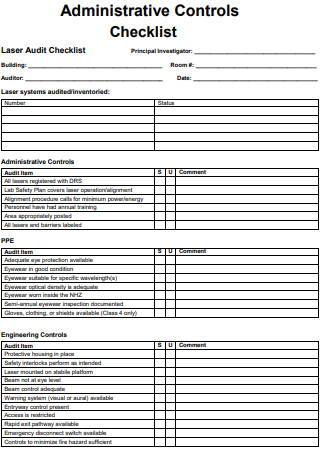

Administrative Control Checklist

download now -

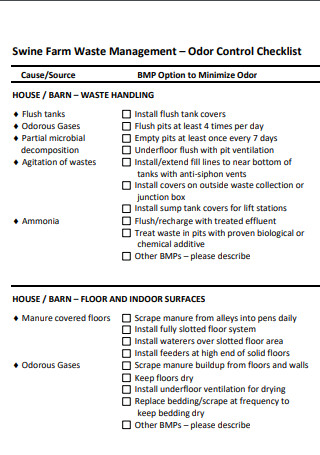

Odor Control Checklist

download now -

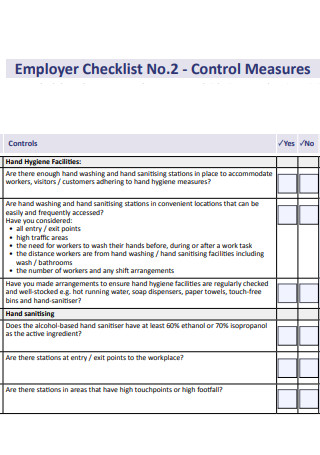

Employer Control Checklist

download now -

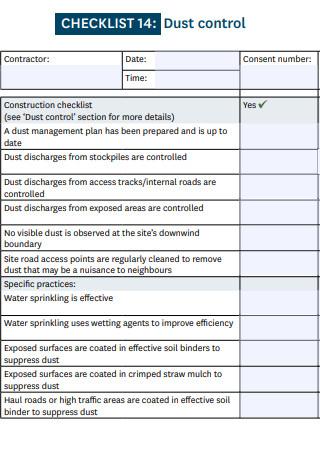

Dust Control Checklist

download now -

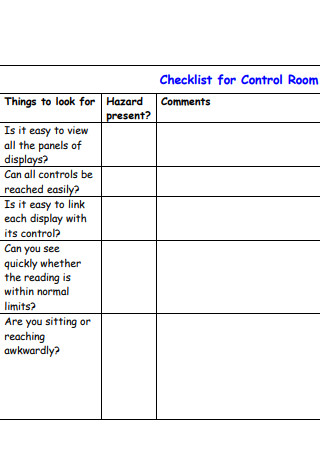

Control Room Checklist

download now -

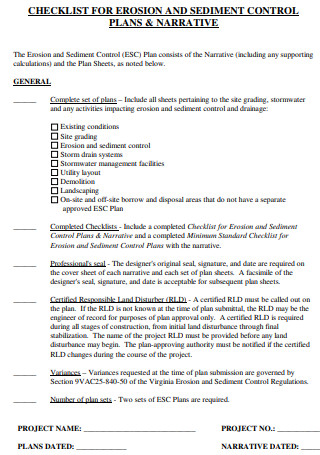

Sediment Control Checklist

download now -

Machining Control Checklist

download now -

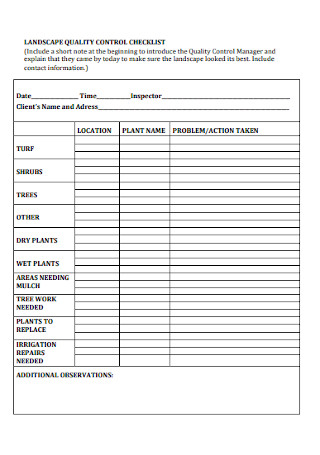

Landscape Control Checklist

download now -

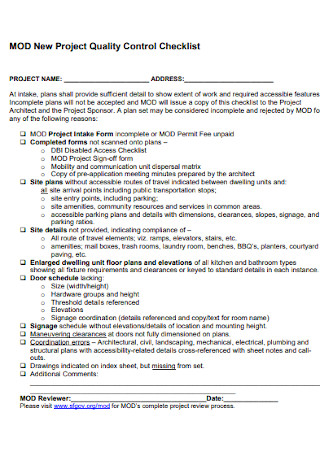

Project Quality Control Checklist

download now -

Traffic Control Measures Checklist

download now

What Is a Control Checklist?

A control checklist is a tool or document used to assess the state of something and its latest developments. It aids in the identification and isolation of issues. It’s mostly a routine measure that gets updated every now and then when new technology or processes are added. Its purpose is to use the checklist to check for faults and strengthen the system. It’s an effective and efficient means of checking and keeping everything under control. And it can even part of a quality agreement.

Control Measures

When it comes to health and safety, there are hierarchies in control measures. As a measure of regulation, risks and hazard assessment are always in place. Especially when it comes to manufacturing and supply operations, or any profession that involves a significant level of risk. As in a work where you are continually exposed to toxic substances. There are methods in place to control the vulnerabilities and hazards in place to limit the damage. Here are a few examples.

Benefits of Control Measures

Things that get out of hand tend to cause more damage. It is visible in any scenario. That is why people seek to implement control measures to assist mitigate its impact. Or, in the best-case situation, eradicate it. This is when the usage of a sample control checklist comes into play.

How To Make a Control Checklist

A control checklist serves as its own form of control measure. It aids in keeping the systems within acceptable limits. And keeps risks under control or, at the very least, up to date. As a result, if it has been detected, measures can be done. Alternatively, a strategy and a countermeasure could be devised. That’s because there’s a checklist that walks you through the process of monitoring something to ensure it’s under control. And here’s how to make your own.

-

Step 1. Identify Controls and Measures

Before you can create a checklist of what to look for, educate yourself with the existing control measures. It is then easier to create a checklist for the procedure itself. When reviewing the measures and controls, ensure that a qualified person on the topic is consulted. This will make it easier to recognize or know how to precisely handle it. It would be pointless if the control checklist did not do what it was designed to do. So, it is better to get advice from specialists or those who are well-versed in the system.

-

Step 2. Check the Available Resources

So, what are the accessible resources that may be employed to do reliable checks? Is it necessary to buy one? Perhaps it should be always available and stationary? As a response, before creating a checklist, this equipment and resources must be recognized and available. Skipping the process may result in a less reliable checklist. These resources also include the duration and time allotted to them. In addition, who can operate and use them. Or perhaps there are prerequisites, such as documentation, that must be met before it can be used.

-

Step 3. Risks and Costs

It is critical to identify hazards ahead of time to improve the accuracy of the control checklist. It can be as extensive or as common as you like. There are also additional expenditures in maintenance where control checklists are required. For labor, equipment, and time spent. As a result, it is critical to identify the resources, as well as their prices and dangers. All before completing the tasks on the checklist. Determine the acceptable level of fees and maintenance costs.

-

Step 4. Process

The most crucial aspect of the checklist is the process. This is the checklist’s real content. It would detail how to properly identify and quantify hazards. Or, more specifically, how to assess the level of safety and quality. All of this entails understanding the control measures and making use of the available resources.

FAQS

Why Is a Control Checklist Necessary?

A control checklist is a well-thought-out document that considers the resources available as well as the threats identified. And it’s a checklist created with the understanding of how all the control measures should function and operate properly. As a result, it is a crucial factor in developing more compact and robust control mechanisms.

Why are Control Measures Essential?

Control procedures prevent a risk from becoming a full-fledged hazard. It can, at best, eliminate it. The presence of dangers is a technological and potentially monetary issue. Putting operators or employees at danger and causing things to be delayed or damaged. As a result, control measures are in place to avoid going over and beyond what is permissible.

What Is the Best Control Measure?

The most effective control method is to eliminate the hazard. As a result, there is no need to use a substitute or pay additional money to add protective layers.

There are many levels of control measures in place to promote caution and awareness in different workplaces. This is where a quality control checklist or internal control checklist might help. It is used to manage and monitor the control mechanisms in place, as well as to detect hazards. And, as an illustration of control, you should download a control checklist template right now!