25+ SAMPLE Daily Construction Schedule

-

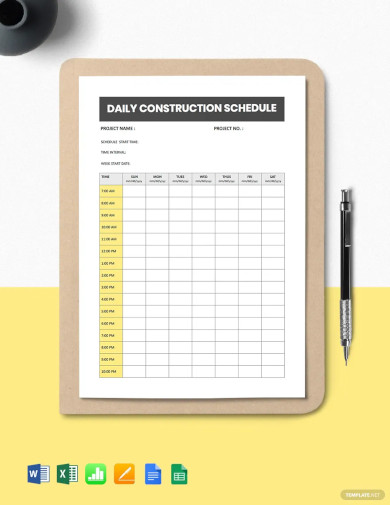

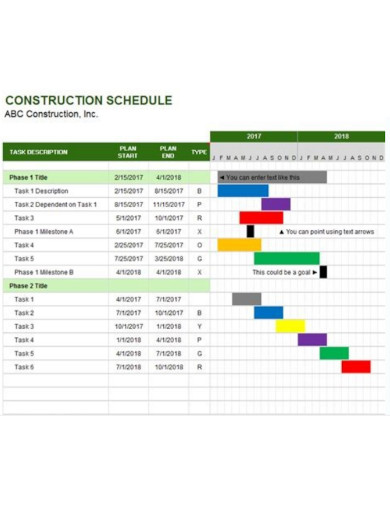

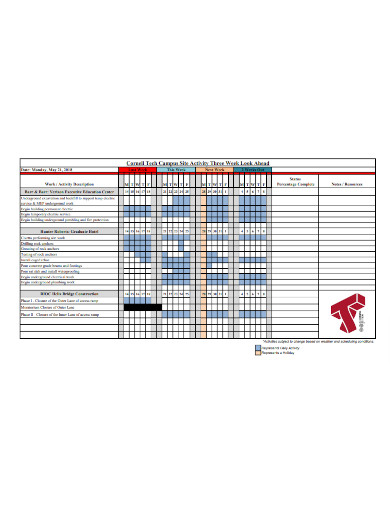

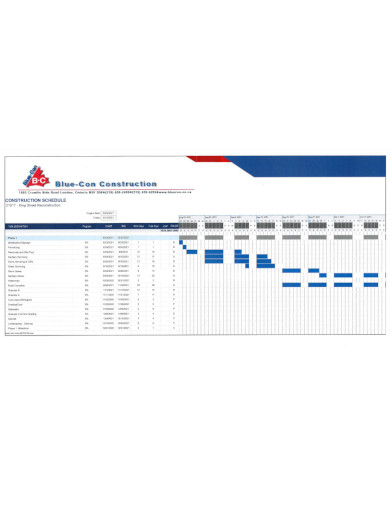

Daily Construction Schedule

download now -

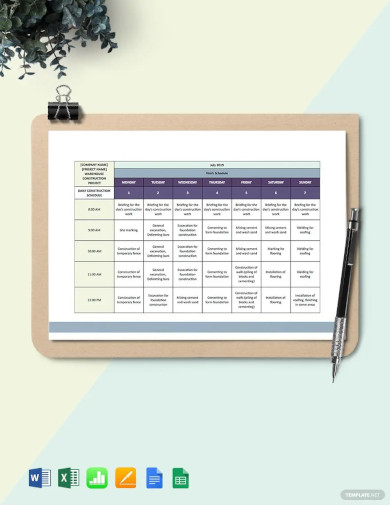

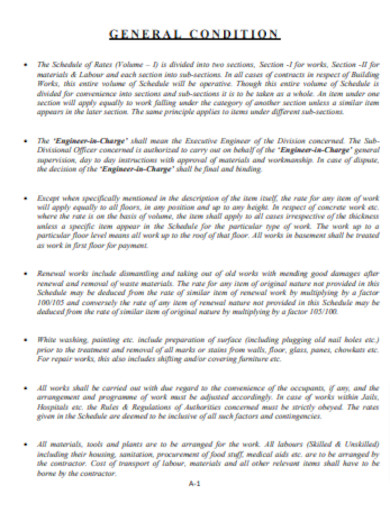

Commercial Daily Construction Schedule

download now -

Daily Construction Contractor Schedule

download now -

Daily Construction Project Management Schedule

download now -

Simple Daily Construction Schedule

download now -

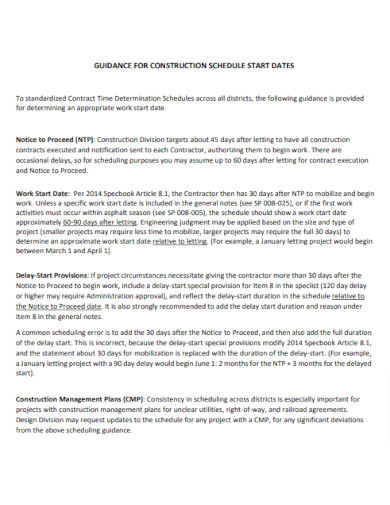

Daily Construction Start Date Schedule

download now -

Printable Daily Construction Schedule

download now -

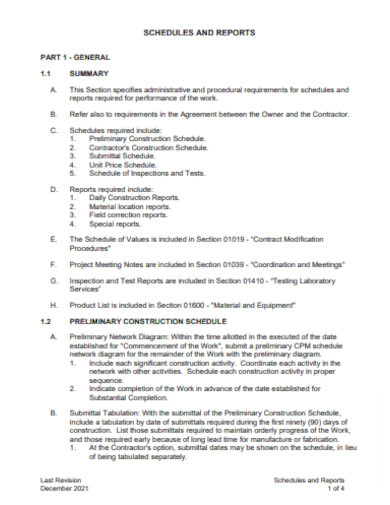

Daily Construction Schedule Report

download now -

Sample Daily Construction Schedule

download now -

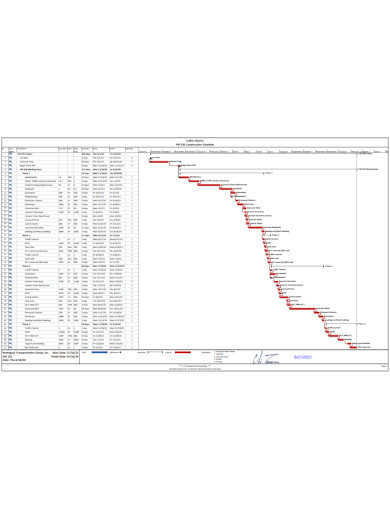

Daily Construction Project Schedule

download now -

General Daily Construction Schedule

download now -

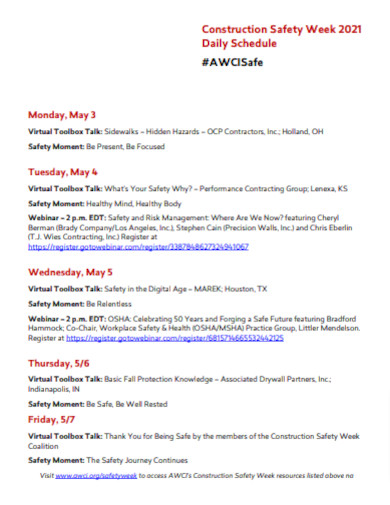

Daily Safety Construction Schedule

download now -

Daily Construction Schedule Outline

download now -

Editable Daily Construction Schedule

download now -

Daily Construction Programme Schedule

download now -

Daily Construction Schedule Layout

download now -

Daily Construction Common Schedule

download now -

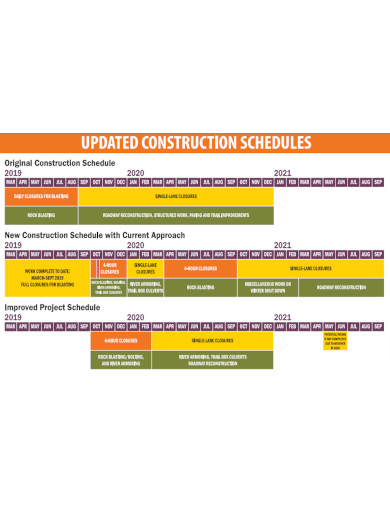

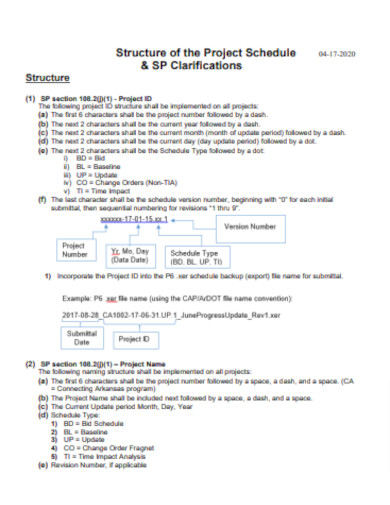

Daily Updated Construction Schedule

download now -

Basic Daily Construction Schedule

download now -

Daily Service Construction Schedule

download now -

Standard Daily Construction Schedule

download now -

Daily Construction Schedule Format

download now -

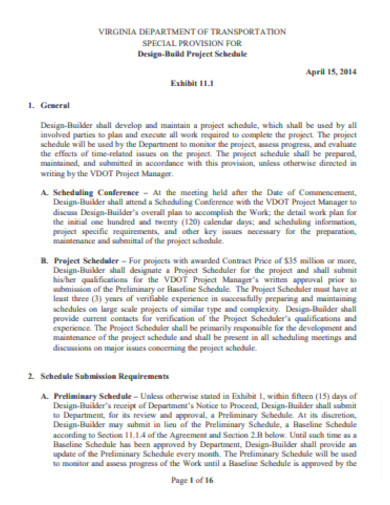

Daily Construction Schedule in PDF

download now -

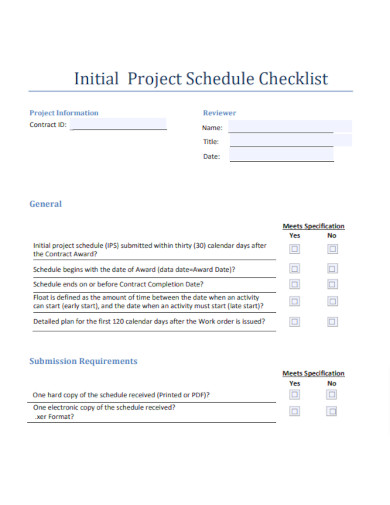

Daily Construction Schedule Checklist

download now -

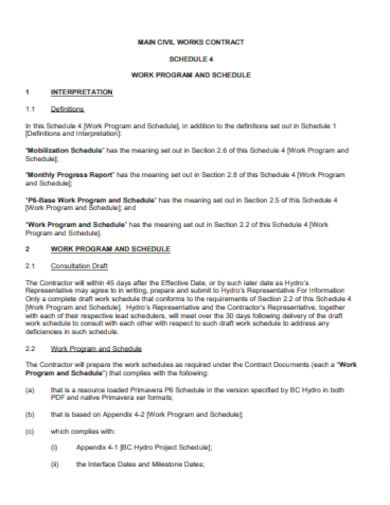

Daily Construction Work Schedule

download now -

Daily Construction Maintenance Schedule

download now

FREE Daily Construction Schedule s to Download

25+ SAMPLE Daily Construction Schedule

What is a Daily Construction Schedule?

Benefits of Daily Construction Schedule

Key Components of a Daily Construction Schedule:

Tips for an Effective Daily Construction Schedule:

FAQ’S

Why is a daily schedule vital in construction?

Who usually prepares the Daily Construction Schedule?

Is a daily schedule set in stone once it’s made?

How do unforeseen events impact the schedule?

What is a Daily Construction Schedule?

A Daily Construction Schedule is a detailed, time-specific breakdown of tasks, responsibilities, and resources allocated for a construction project on a day-to-day basis. This schedule provides a roadmap for the day’s activities, ensuring that workers, equipment, and materials are effectively coordinated to maximize productivity, adhere to safety standards, and achieve the set objectives within the stipulated time frame. The daily schedule also facilitates communication among all project stakeholders, from laborers to managers, ensuring everyone is aligned with the day’s goals and priorities.

Benefits of Daily Construction Schedule

A Daily Construction Schedule provides a systematic approach to manage and execute tasks on a construction site. The benefits of maintaining such a schedule are manifold:

- Enhanced Productivity: A clear daily outline ensures that every worker knows their tasks for the day, eliminating guesswork and optimizing time usage.

- Resource Optimization: Knowing the day’s tasks can help in efficiently allocating resources like machinery, manpower, and materials, reducing the risk of idleness or resource wastage.

- Improved Communication: A daily schedule serves as a communication tool, ensuring everyone, from laborers to supervisors and stakeholders, is on the same page about the day’s objectives.

- Safety Enhancement: Preplanning tasks allow for better anticipation of potential safety hazards, ensuring that adequate precautions are taken in advance.

- Financial Efficiency: With a structured daily plan, monitoring of labor hours and material consumption becomes easier, ensuring cost-effectiveness and budget adherence.

- Timely Completion: Daily scheduling and task tracking can help in identifying delays early on, allowing for quick course corrections and ensuring the project remains on track.

- Accountability: By assigning specific tasks to individuals or teams, everyone knows their responsibilities, leading to increased accountability.

- Client Satisfaction: Consistent progress as per the schedule provides transparency and reassures clients, enhancing their trust and satisfaction levels.

- Flexibility in Management: With a well-defined schedule, any unforeseen disruptions or changes can be managed more efficiently by adjusting subsequent tasks or resources.

- Reduced Stress: Knowing the day’s goals and having a clear roadmap helps reduce uncertainty and stress for both workers and supervisors.

- Enhanced Coordination: When multiple teams or subcontractors are involved, a daily schedule ensures that their tasks are coordinated, preventing overlaps or conflicts.

- Documentation and Record Keeping: Daily schedules, when archived, serve as a record of project progress, which can be useful for future reference or in case of disputes.

- Quality Control: Regular scheduling allows for checkpoints to review and ensure the quality of work being done, leading to better end results.

- Morale and Motivation: Achieving daily goals can boost the morale and motivation of the team, giving them a sense of accomplishment.

Incorporating a Daily Construction Schedule into the project management process is not just a logistical move but also a strategic one, as it sets the tone for the efficiency and success of the entire project.

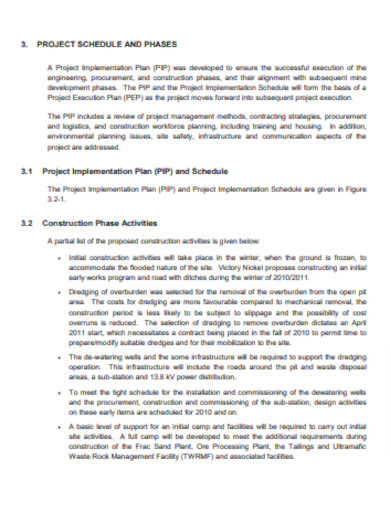

Key Components of a Daily Construction Schedule:

Absolutely! A Daily Construction Schedule plays a pivotal role in streamlining operations at the construction site. To understand its structure and value better, let’s break down the key components:

Start & End Times:

Definition: These represent the beginning and conclusion of a workday.

Importance: Establishing clear start and end times ensures that all tasks are carried out within designated working hours, aiding in effective time management and respecting contractual working hours.

Tasks List:

Definition: A comprehensive breakdown of all the tasks that need to be performed on that particular day.

Importance: Enumerating tasks ensures every activity is accounted for and helps in prioritizing and allocating resources appropriately.

Personnel Assignments:

Definition: Allocation of specific tasks to individual workers or teams.

Importance: This delineation establishes accountability and ensures that every task has a dedicated workforce, reducing ambiguities and potential overlaps.

Equipment Usage:

Definition: A schedule outlining when and where each piece of machinery or equipment will be used.

Importance: Efficient scheduling prevents equipment idleness, ensures maintenance breaks, and avoids situations where multiple teams vie for the same equipment.

Material Requirements:

Definition: A checklist or ledger of all the materials required for the day’s tasks.

Importance: Anticipating material needs ensures there are no work stoppages due to lack of materials and aids in inventory management.

Safety Protocols:

Definition: A set of guidelines and measures to ensure the safety of workers, especially concerning the day’s specific tasks.

Importance: Daily reminders of safety measures can prevent accidents, ensuring a safe working environment and regulatory compliance.

Progress Tracking:

Definition: A mechanism, often in the form of a log or digital tool, to document and assess the progress made against the set schedule.

Importance: Tracking progress provides insights into the efficiency of operations, allows for adjustments in future scheduling, and keeps stakeholders informed.

Breaks and Rest Periods:

Definition: Predetermined intervals for workers to rest and recuperate.

Importance: Regular breaks enhance productivity, ensure compliance with labor regulations, and prioritize worker well-being.

Contingencies:

Definition: Backup plans or alternate strategies for potential disruptions, like adverse weather conditions, equipment breakdowns, or unexpected delays.

Importance: Having contingency plans in place ensures that work can continue or be rescheduled efficiently without major disruptions.

Communication Channels:

Definition: Designated methods (e.g., morning briefings, digital apps, radios) for communicating schedule-related information.

Importance: Effective communication ensures that all parties are aligned, reducing misunderstandings and increasing overall site efficiency.

By thoroughly understanding each of these components, project managers and construction teams can maximize the utility of the Daily Construction Schedule, ensuring projects are completed on time, within budget, and to the required standards.

Tips for an Effective Daily Construction Schedule:

For a Daily Construction Schedule to truly serve its purpose, it should be more than just a to-do list. It should be a strategic tool that guides the entire construction process smoothly from start to end. Here are some tips to ensure your daily construction schedule is as effective as possible:

- Prioritize Tasks: Determine the most critical tasks for the day and allocate resources accordingly. This ensures that key activities don’t get delayed.

- Stay Realistic: Overloading the schedule can lead to incomplete tasks and demotivated teams. Ensure that tasks are achievable within the set time frame.

- Incorporate Flexibility: Construction is rife with unexpected disruptions. While the schedule should be adhered to as closely as possible, allow some wiggle room for unforeseen changes.

- Engage the Team: Input from the people on the ground can be invaluable. They might have insights into potential challenges or efficiencies that can be introduced.

- Use Digital Tools: Make use of construction management software. Digital tools can aid in creating, disseminating, and adjusting daily schedules seamlessly. They also provide a platform for real-time updates.

- Review Previous Schedules: Reflect on past schedules to determine what was accomplished and what wasn’t. This reflection can guide adjustments for future schedules.

- Allocate Resources Wisely: Ensure equipment and manpower are distributed in a way that maximizes their usage without leading to burnout or wear and tear.

- Set Clear Communication Channels: Everyone should know whom to report to and how. Whether it’s through daily briefings or digital communication tools, clarity in communication is crucial.

- Anticipate & Plan for Delays: Whether it’s due to weather, equipment malfunction, or other unforeseen circumstances, always have a backup plan.

- Highlight Safety Protocols: Every daily schedule should emphasize safety measures tailored to that day’s specific tasks. Ensure these are communicated clearly.

- Monitor & Adjust: At the end of the day, evaluate the day’s accomplishments. What went right? What challenges arose? Use this feedback to improve the next day’s schedule.

- Acknowledge Achievements: Recognizing and celebrating small daily victories can boost morale and motivation, making the team more inclined to respect and follow the schedule.

- Regular Training: Ensure that teams are regularly trained on the importance of the schedule and any tools/software used in its creation and implementation.

- Feedback Loop: Encourage team members to provide feedback on the schedule – what’s working and what isn’t. This can provide invaluable insights to enhance its effectiveness.

Remember, the essence of a daily construction schedule lies in its practical application. It’s a living document that should adapt to the realities of the site while keeping the project’s objectives in sharp focus.

While a Daily Construction Schedule can streamline operations and increase efficiency, its implementation is not without challenges. Here are some of the most common challenges faced:

- Unforeseen Delays: Unpredictable factors such as weather disruptions, equipment malfunction, or sudden unavailability of crucial materials can throw off a well-planned schedule.

- Resource Conflicts: Overlapping bookings for equipment or miscommunication about the availability of key personnel can disrupt the day’s planned activities.

- Scope Changes: Frequent changes in the project’s scope or last-minute client requests can make the daily schedule unstable and constantly shifting.

- Communication Gaps: Inadequate communication or misinterpretation of tasks can lead to delays, mistakes, or overlapping duties.

- Inaccurate Time Estimations: Overestimating or underestimating the time required for specific tasks can cause bottlenecks or idle times.

- Labor Issues: Unexpected absenteeism, labor disputes, or personnel health issues can throw the schedule off balance.

- Regulatory and Compliance Hurdles: Unexpected inspections or changes in local regulations can cause work stoppages or necessitate schedule changes.

- Supply Chain Disruptions: Delays in the delivery of essential materials or receiving sub-standard materials can halt scheduled activities.

- Lack of Flexibility: A rigid schedule that doesn’t account for potential disruptions can lead to frequent, unmanaged deviations.

- Complexity of Tasks: Some tasks might be more complex than initially thought, leading to overruns.

- Financial Constraints: Unexpected budgetary constraints can impede the progression of scheduled tasks, especially if they involve procurement or hiring external services.

- Technology Barriers: For sites using digital tools for scheduling, tech glitches, software crashes, or a lack of training among personnel can pose challenges.

- Stakeholder Interferences: Continuous interventions or unscheduled visits by stakeholders can interfere with the day’s planned activities.

- Safety Incidents: Accidents or safety incidents on site can halt operations, impacting the daily schedule.

- Cultural and Team Dynamics: Differing work cultures, especially when subcontractors are involved, or interpersonal conflicts can impact the smooth progression of tasks.

To mitigate these challenges, it’s crucial to maintain open lines of communication, utilize modern project management tools, and integrate feedback mechanisms to continuously improve the scheduling process. While it’s challenging to anticipate every potential disruption, being adaptable and proactive in response can help in maintaining project timelines and ensuring the effectiveness of the daily construction schedule.

FAQ’S

Why is a daily schedule vital in construction?

It offers clear direction for the day, ensuring workers know their tasks, resources are allocated efficiently, potential conflicts are identified and resolved, and progress is tracked against project milestones.

Who usually prepares the Daily Construction Schedule?

Typically, the responsibility lies with the project manager, site supervisor, or foreman. However, inputs often come from various team members, including subcontractors.

Is a daily schedule set in stone once it’s made?

No. While the daily schedule provides a roadmap, it’s crucial to be flexible and make adjustments as unforeseen events or challenges arise.

How do unforeseen events impact the schedule?

Unexpected events like bad weather, equipment breakdowns, or material shortages can delay tasks. When this happens, the schedule may need to be adjusted to accommodate these delays or to reprioritize tasks.

In conclusion, a daily construction schedule is more than just a list of tasks. It’s a dynamic tool that, when used effectively, can greatly influence the successful outcome of a construction project. By investing time in thoughtful planning and remaining adaptable to the inherent challenges of construction, teams can ensure that projects run smoothly from start to finish.