25+ SAMPLE Weekly Construction Schedule

-

Weekly Residential Construction Schedule

download now -

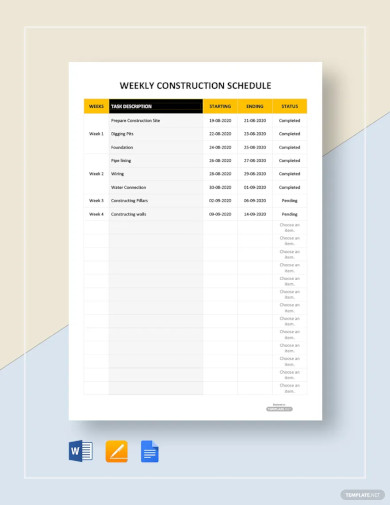

Weekly Construction Schedule

download now -

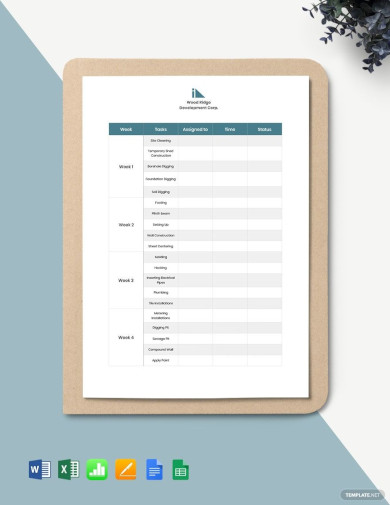

Weekly Commercial Construction Schedule

download now -

Weekly Construction Project Planning Schedule

download now -

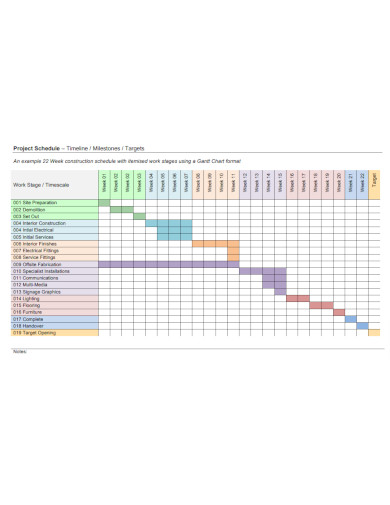

Weekly Construction Gantt Chart Schedule

download now -

Weekly Construction Checklist Schedule

download now -

Weekly Construction Proposal Schedule

download now -

Weekly Construction Project Management Schedule

download now -

Weekly Construction Implementation Plan Schedule

download now -

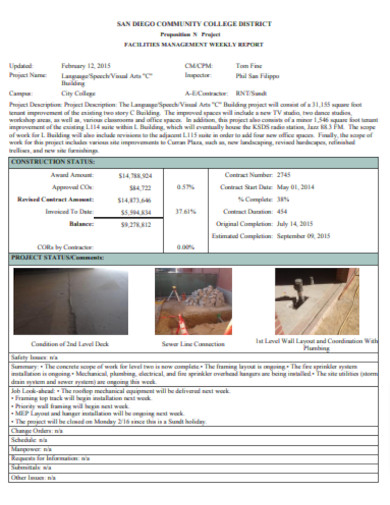

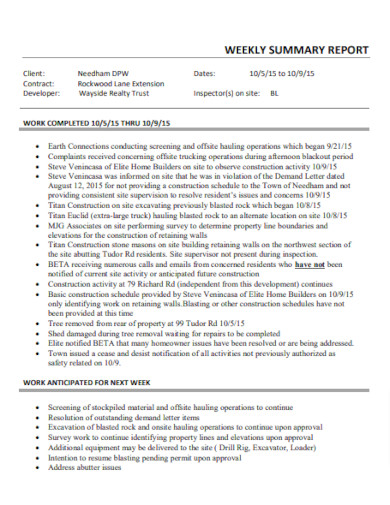

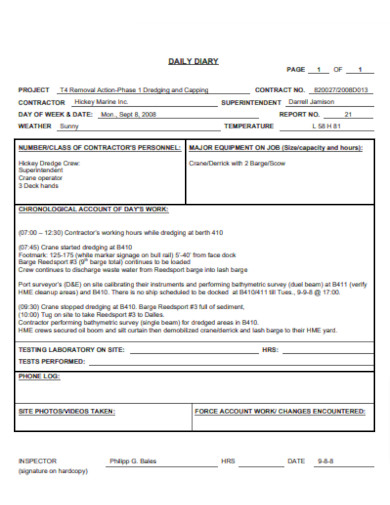

Weekly Construction Report Schedule

download now -

Simple Weekly Construction Schedule

download now -

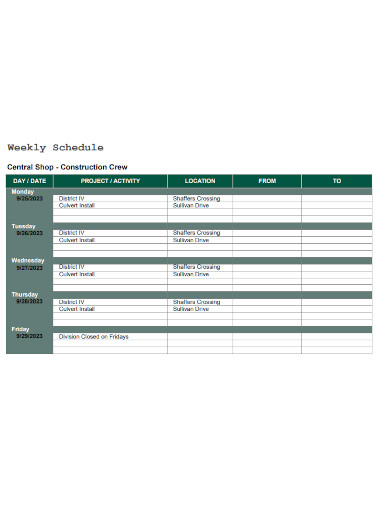

Weekly Construction Crew Schedule

download now -

Weekly Construction Summary Schedule

download now -

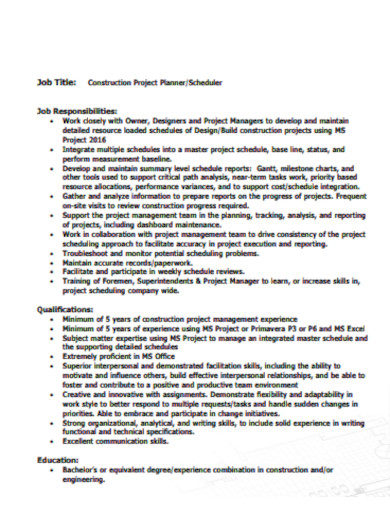

Weekly Construction Project Planner Schedule

download now -

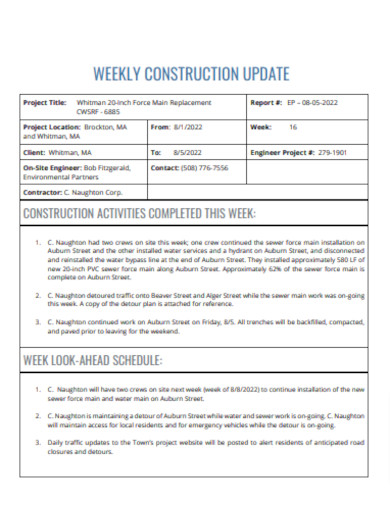

Weekly Construction Progress Schedule

download now -

Sample Weekly Construction Schedule

download now -

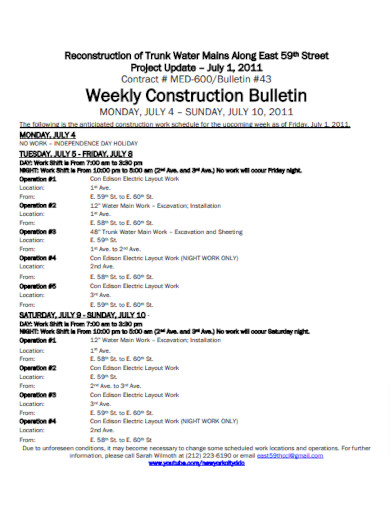

Weekly ReConstruction Schedule

download now -

Weekly Project Construction Schedule

download now -

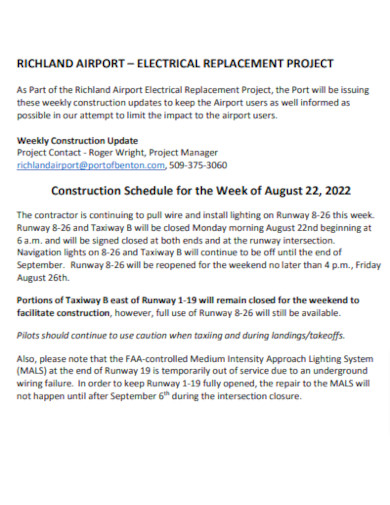

Weekly Electrical Construction Schedule

download now -

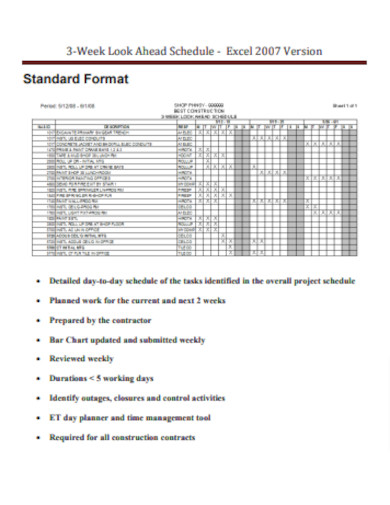

Weekly Construction Schedule Format

download now -

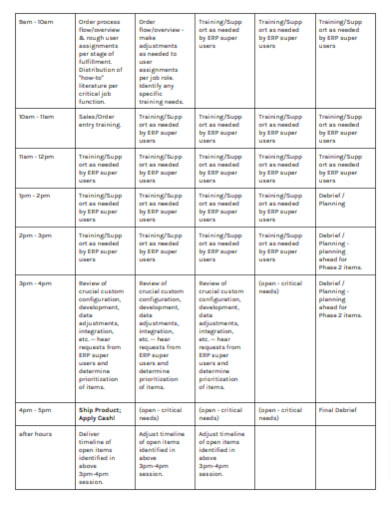

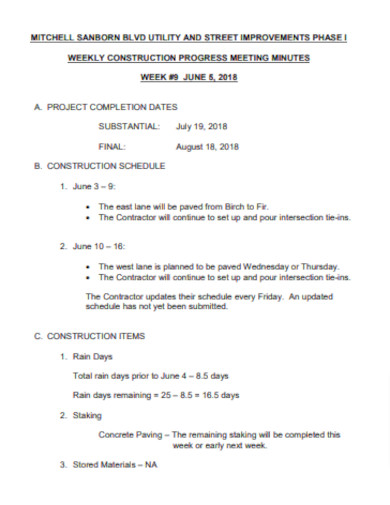

Weekly Construction Meeting Schedule

download now -

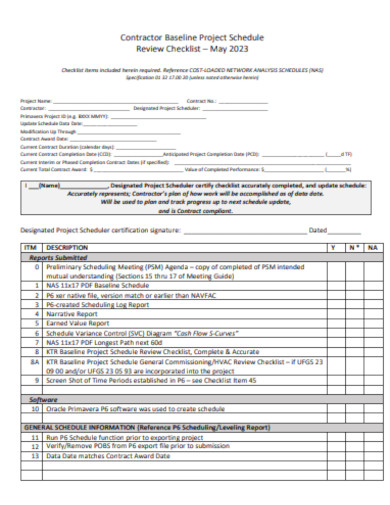

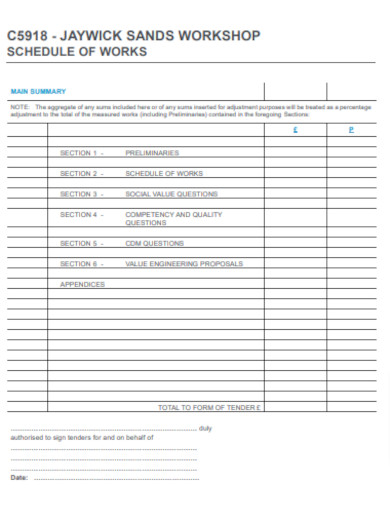

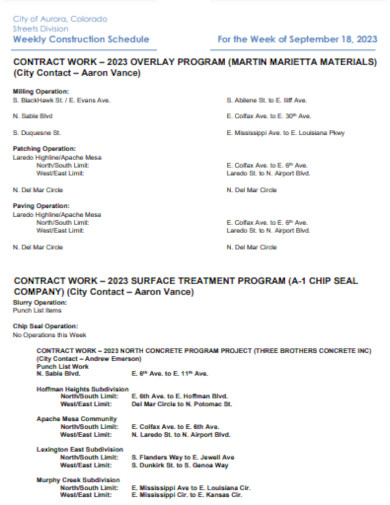

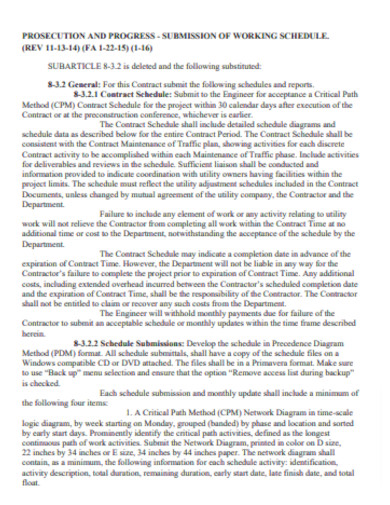

Weekly Contract Construction Schedule

download now -

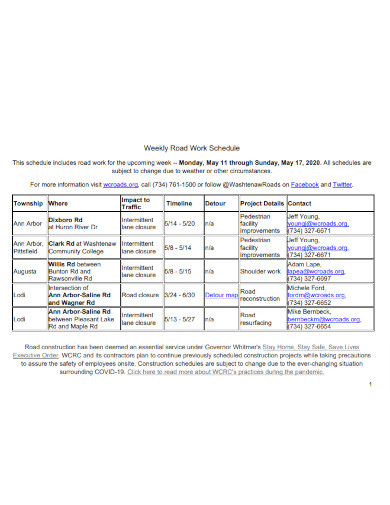

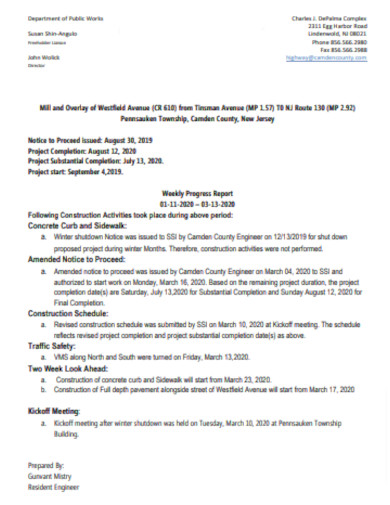

Weekly Road Work Construction Schedule

download now -

Editable Weekly Construction Schedule

download now -

Basic Weekly Construction Schedule

download now -

Weekly Construction Notice Schedule

download now -

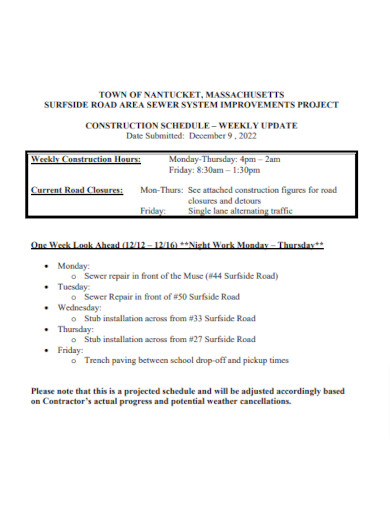

Weekly Improvement Project Construction Schedule

download now

FREE Weekly Construction Schedule s to Download

25+ SAMPLE Weekly Construction Schedule

The Significance of a Weekly Perspective in Construction Scheduling:

Tips for an Optimal Weekly Construction Schedule:

Challenges and Solutions

Why is a weekly perspective important in construction?

How does a weekly schedule differ from a daily or monthly schedule?

How do you handle unforeseen delays in a weekly schedule?

What tools can assist in creating a weekly construction schedule?

Is it necessary to communicate the weekly schedule to the entire team?

Certainly, understanding the importance of adopting a weekly perspective in construction scheduling is essential for efficient project management. Here’s a detailed exploration of why a weekly viewpoint is crucial:

The Significance of a Weekly Perspective in Construction Scheduling:

1. Holistic Overview:

A weekly schedule provides a more comprehensive view of the project’s progression. While daily tasks offer specificity, a weekly perspective lets managers and teams see how these tasks fit together, ensuring a cohesive approach to work.

2. Balanced Work Distribution:

Distributing tasks over a week ensures that resources – both human and material – are not overburdened on any particular day. This approach prevents burnout and optimizes productivity throughout the week.

3. Anticipation and Preparedness:

With a week-long lens, managers can anticipate challenges, be it a weather disturbance or a scheduled inspection, and make necessary adjustments in advance.

4. Enhanced Resource Allocation:

Knowing the tasks for the entire week allows for better coordination of resources. Managers can allocate equipment and labor where they are most needed, avoiding conflicts and downtime.

5. Mitigation of Delays:

In construction, delays are inevitable. A weekly view allows teams to adjust and reschedule tasks dynamically, ensuring that any lost time on one day can potentially be made up later in the week.

6. Improved Communication and Collaboration:

Sharing a weekly schedule ensures all stakeholders, from laborers to suppliers, are aligned with the project’s goals. This broader view encourages proactive communication, fostering a collaborative environment.

7. Strategic Decision Making:

A weekly schedule is a balance between the granular focus of daily tasks and the overarching monthly or project-wide plan. It offers a strategic depth, enabling managers to make decisions that are both immediate and forward-thinking.

8. Client and Stakeholder Engagement:

Updating clients and stakeholders on a weekly basis strikes the right balance. It keeps them informed and engaged without overwhelming them with day-to-day details.

9. Efficient Feedback Loop:

After the week concludes, teams can review achievements and challenges, turning insights into actionable changes for the upcoming week. This continuous loop of feedback ensures that the project adapts and evolves in real-time.

10. Cost Management:

A weekly perspective helps in tracking expenses closely. By monitoring weekly expenditures, managers can ensure the project stays within budget and identify potential financial issues before they escalate.

In essence, adopting a weekly perspective in construction scheduling brings together the immediacy of daily tasks and the broader vision of the project. It ensures efficiency, adaptability, and clarity, driving the project towards timely and successful completion.

Key Components of a Weekly Construction Schedule:

Certainly! A Weekly Construction Schedule is an intricate blend of tasks, resources, and timelines. It ensures that all activities are sequenced logically to promote efficient work progression. Let’s delve into the critical components that make up a comprehensive weekly construction schedule:

1. Task Breakdown:

List of Activities: Every activity that needs to be accomplished in the week, from significant milestones to the minutest tasks, should be enumerated.

Task Prioritization: Not all tasks are of equal importance. Tasks should be ranked based on their urgency and significance to the project’s overall timeline.

2. Resource Allocation:

Labor Distribution: Assign specific teams or individuals to particular tasks, ensuring clarity in roles and responsibilities.

Equipment Deployment: Determine which equipment is needed for the week and ensure its availability and functionality.

Material Requirements: Detail out the materials required for the week’s tasks and ensure they’re on-site or scheduled for delivery.

3. Time Estimation:

Start and End Times: Each task should have a defined start time and expected completion time.

Buffer Time: Incorporate some leeway between tasks to accommodate potential delays or unforeseen challenges.

4. Task Dependencies:

Identify which tasks can’t start until others are completed. This sequential mapping ensures a logical flow of activities and prevents potential roadblocks.

5. Safety Protocols:

Highlight any specific safety measures or briefings that need to be conducted based on the week’s tasks. Ensuring a safe working environment is paramount.

6. Stakeholder Communication:

Determine which tasks or milestones might require communication with stakeholders. This could be to update them, seek approvals, or inform them of potential disruptions.

7. Risk Assessment:

Identify potential risks for the week, whether they’re related to weather, equipment failure, or other unforeseen challenges. Having a contingency plan in place is crucial.

8. Feedback Mechanism:

Create a system for team members to provide daily updates on task progress. This allows for mid-week adjustments if certain tasks are running behind or ahead of schedule.

9. Budget Tracking:

Monitor the week’s expenditures in relation to the overall project budget. This helps in keeping the project financially on track and identifies areas where costs may be escalating.

10. Documentation & Records:

Maintain a record of all activities, completed tasks, and any deviations from the planned schedule. This documentation is essential for future reference, audits, or in case of disputes.

11. Review & Forward Planning:

Include a review segment at the end of the week to assess what went well and what didn’t. Also, based on the current week’s progression, start planning for the subsequent week.

By ensuring these components are well-defined and interlinked, a Weekly Construction Schedule can serve as a robust framework that drives project efficiency, team collaboration, and timely completion.

Tips for an Optimal Weekly Construction Schedule:

Creating an optimal Weekly Construction Schedule requires a blend of foresight, flexibility, and clear communication. Here are some tips to ensure your schedule is efficient and effective:

1. Review and Reflect:

Start by assessing the past week’s progress. Understand which tasks were completed on time, which were delayed, and why. Use these insights to improve the upcoming week’s schedule.

2. Involve the Team:

Engage with the on-ground team and subcontractors when planning. Their firsthand insights can shed light on practical challenges and help fine-tune the schedule.

3. Stay Realistic:

While it’s good to be ambitious, overloading the schedule can lead to mistakes, rushed jobs, and burnout. It’s crucial to ensure that the amount of work planned is achievable.

4. Prioritize Tasks:

Determine which tasks are critical for the week and which can be pushed if unforeseen delays occur. This clarity will help in making quick decisions if adjustments are needed.

5. Consider Dependencies:

Always keep in mind the sequence of tasks. Ensure that tasks which rely on the completion of others are scheduled logically to prevent bottlenecks.

6. Factor in Breaks:

Remember to allow time for breaks, especially in labor-intensive jobs. Breaks can improve productivity and reduce the risk of accidents.

7. Use Technology:

Utilize scheduling software or construction management platforms. These tools can automate scheduling, send reminders, and provide real-time updates.

8. Plan for Contingencies:

Unexpected issues will arise. Whether it’s inclement weather or equipment breakdowns, having a contingency plan will ensure the project remains on track.

9. Communicate Clearly:

Once the schedule is set, communicate it clearly to all relevant parties. Everyone should be on the same page about their roles and responsibilities for the week.

10. Stay Flexible:

While planning is essential, rigidity can be counterproductive. Be prepared to adjust the schedule as required. Flexibility can often be the key to maintaining efficiency in the face of challenges.

11. Monitor and Adjust:

Don’t wait for the week to end to make adjustments. If tasks are completed ahead of schedule or if delays are evident, tweak the plan accordingly.

12. Document Everything:

Maintain a clear record of all tasks, completed or pending, changes made to the schedule, and reasons for those changes. This documentation will be invaluable for future projects and any potential disputes.

13. Seek Feedback:

At the end of the week, seek feedback from the team. Understand what worked and what didn’t. This feedback loop is essential for continuous improvement.

Remember, the goal of an optimal Weekly Construction Schedule is not just to chart out tasks, but to ensure a fluid and efficient work process that maximizes productivity while safeguarding the well-being of the team and the quality of the construction.

Challenges and Solutions

When implementing a Weekly Construction Schedule, project managers often face a variety of challenges. However, with each challenge comes a potential solution. Let’s delve into some common challenges and ways to navigate them:

Unforeseen Delays:

Causes can range from unexpected weather conditions to equipment breakdowns.

Solution: Always have a contingency plan. Incorporate buffer periods in the schedule and be prepared to reallocate resources as necessary.

Resource Shortages:

Whether it’s a lack of skilled labor, equipment, or materials, shortages can throw the schedule off track.

Solution: Maintain a clear communication line with suppliers and have a backup list of subcontractors or rental agencies. Regularly train and upskill workers to handle diverse tasks.

Changing Client Requirements:

Client requests for changes can disrupt a well-laid plan.

Solution: Foster open communication with the client. Ensure changes are documented, evaluated for impact on the schedule, and appropriately incorporated.

Task Dependencies:

If one task gets delayed, it can create a domino effect on dependent tasks.

Solution: Clearly map out dependencies in advance. Have backup plans for critical tasks and ensure teams are ready to pivot when necessary.

Communication Breakdowns:

Misunderstandings or lack of clarity can hinder progress.

Solution: Implement regular briefings and utilize collaborative tools or platforms. Ensure all team members have access to the updated schedule and any changes made.

Budget Overruns:

Extended tasks or unforeseen issues can inflate costs.

Solution: Monitor expenses closely. Have a clear overview of the budget and initiate regular check-ins to ensure the project stays within financial parameters.

Quality Concerns:

Rushing tasks to stay on schedule can sometimes compromise quality.

Solution: Prioritize quality checks. Schedule regular inspections and always factor in time for rectifications if needed.

Health and Safety Incidents:

Construction sites can be hazardous, and accidents can cause both human and scheduling setbacks.

Solution: Never compromise on safety protocols. Ensure regular safety briefings, provide the necessary equipment, and encourage a culture of safety first.

Technology Hiccups:

Relying on construction management software or other tech tools can sometimes lead to glitches or data losses.

Solution: Regularly back up data and ensure there’s a manual backup system in place. Train teams on software usage and have IT support on standby.

Stakeholder Interferences:

External stakeholders, from governmental bodies to local communities, might disrupt the schedule.

Solution: Foster open communication and build relationships with key stakeholders. Ensure all necessary permissions are secured in advance and maintain a positive community relationship.

By proactively recognizing these challenges and preparing solutions, construction managers can mitigate risks and ensure that projects continue to progress smoothly, even in the face of unexpected hurdles.

Why is a weekly perspective important in construction?

A weekly perspective provides a balanced view, allowing managers to see how daily tasks fit together and ensuring tasks are distributed evenly. This approach helps in anticipating challenges, allocating resources efficiently, and keeping stakeholders informed.

How does a weekly schedule differ from a daily or monthly schedule?

While a daily schedule focuses on immediate tasks, and a monthly or project-wide schedule offers a broader view, a weekly schedule bridges the gap. It provides a more detailed overview than monthly plans while being more holistic than daily schedules.

How do you handle unforeseen delays in a weekly schedule?

Incorporate buffer times in the schedule, have contingency plans, and maintain open communication with the team to reallocate tasks and resources when necessary.

What tools can assist in creating a weekly construction schedule?

Many construction management software tools, such as Microsoft Project, Procore, or Primavera P6, are equipped to assist in creating detailed weekly construction schedules.

Is it necessary to communicate the weekly schedule to the entire team?

Absolutely. Clear communication ensures that everyone is aligned with the week’s objectives, understands their roles, and can anticipate potential challenges or changes.

The Weekly Construction Schedule stands as a linchpin in the vast machinery of construction project management. By offering a balanced vantage point between the micro details of daily activities and the macro overview of the entire project, it ensures that the myriad tasks, resources, and timelines harmoniously converge towards achieving set objectives. While crafting such a schedule requires precision, foresight, and adaptability, its rewards are manifold. It not only aids in efficiently allocating resources and anticipating bottlenecks but also ensures that every stakeholder, from the site worker to the project investor, remains informed and aligned. As construction projects grow increasingly complex and time-sensitive, the emphasis on a robust and flexible weekly scheduling system becomes paramount. In the dynamic world of construction, where myriad variables interact, the weekly schedule serves as both a compass and anchor, guiding teams towards timely and quality completions.