34+ SAMPLE Material Agreement in PDF

What Is a Material Agreement?

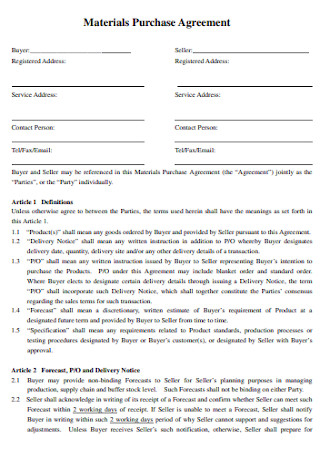

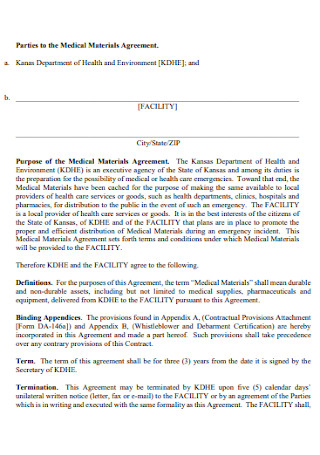

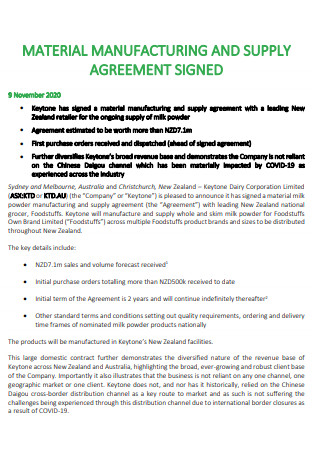

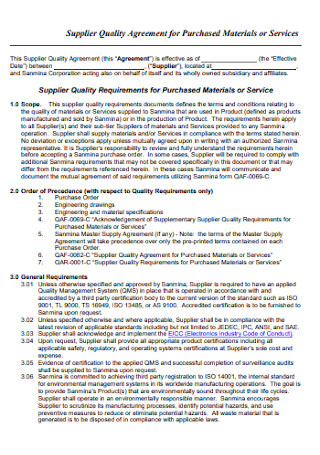

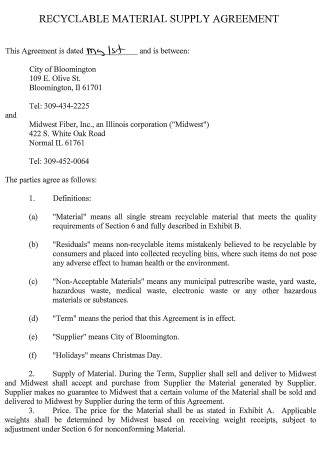

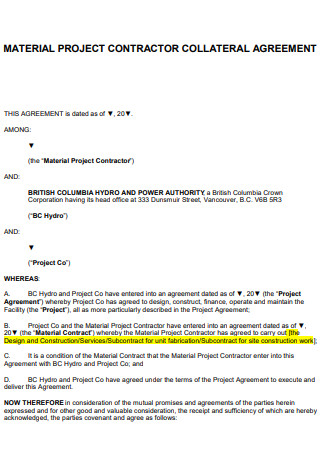

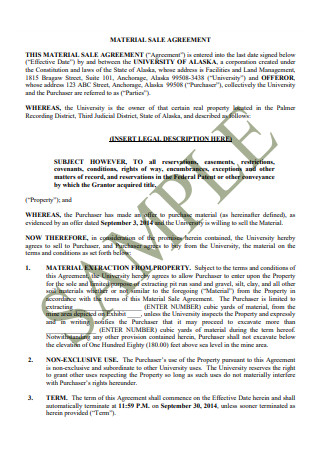

When two parties agree to make a purchase or transfer, a material agreement is required. It is primarily concerned with the amount, quality, and cost of these resources. As well as how they will be supplied, and the terms agreed upon by the two parties. The types and qualities of these materials, as well as their prices, are then enumerated. If there are any additional fees or an initial payment, these must be specified in the agreement. The agreement should also include a brief statement regarding who will use the materials, when they will be utilized, and for what purpose.

Types of Materials

Every day, various materials are used to build something new. Recognizing each type may assist you in determining which one ideally meets your needs. When negotiating an agreement, consider where and how you will obtain these resources. Especially in tech products, where material quality is important for sustainability and durability. Or in building projects when quality cannot be compromised for a lower price.

Metal: Metal is a natural resource that is frequently mined and purified before it can be sold. The most popular and expensive metals are those that are used to make jewelry. Silver, gold, and platinum are a few examples. They are rare and precious to most people. Because of its resistance to corrosion, gold is important in electronics. In space exploration, it can also act as a screen against solar heat waves. These forms of technology and inventions have propelled humanity out of its banal methods. Metals have proven to be a vital commodity in the development of stronger and more flexible technologies and materials. Metals are likely to be the most prominent raw materials proposed for use in manufacturing proposals. The product supply for these metals comes from mining companies and distributed all around the world. Metals can be reused multiple times without losing their qualities. However, aluminum can be recycled indefinitely without losing its quality. Plastics: Plastics are often man-made materials that are not good for the environment. It’s also inconvenient to deal with during waste management and disposal. However, plastic has also resulted in cheaper and more durable items. This is beneficial to both lower and middle-class members of society. It made goods easy to make and purchase. It can also protect its contents from getting wet. Plastic materials are ideal for packaging, textiles, machineries, electronics, and electrical appliances. It makes things more energy efficient, but it’s bad for the environment unless it’s recycled. Plastics make up most of the non-biodegradable waste. Tree-rubbers are one sort of natural plastic. Plastics in general are exceedingly soft and flexible. It is excellent for adhesives and serves as a protective coating layer. Glass: Brittle materials, such as glass, exist. It can be used in interior design to make mirrors, partitions, and tables. It can be applied in windows as well as packaging and jars. It might be clear or opaque. It can be used to collect solar energy for a more renewable energy source. It can also be used to guard against radiation or large collisions. Glass is created from sand and other materials that have been heated or melted to extremely high temperatures. Glass fiber can aid with sustainability by reducing weight. And its natural resource is plentiful on Earth. On this world, there is sand everywhere. It also has a long recycling life. It is a useful resource since it may be used to preserve food and store beverages. Wood: Wood is obtained by felling trees. Certain types of wood are ideal for use in house construction but not so much on large building construction. It can be used in art as a frame or as a foundation for sculpting. Most household objects, such as tables and chairs, were made of wood. Wood is already a source of charcoal and can be used to start a fire. However, deforestation is also a problem today. There is a risk in chopping more trees because of societal needs as well as how the environment is changing. We’ve been using it as a fuel source for thousands of years. As a result, the imbalance in nature existed and remains that way now. Trees contribute to the production of oxygen on our planet. Its roots absorb water, which helps to minimize flooding. It also reduces carbon emissions in the atmosphere. As a result, they are extremely vital to human existence. It can be used to make paper, flooring, and a variety of other recreational and engineering items. Fabrics: Fabrics are frequently used in apparel, carpeting, towels, cleaning curtains, and coverings. It is made by spinning cotton and weaving it into a thread. Then, weave the thread into something wearable or usable. It varies in quality in terms of texture, weight, and thickness. Some of these fabrics may even be made of animal fibers and fur. Those, along with silk, are pricey. Wool is an example of a product that is shorn from an alpaca or a sheep. It’s fantastic for warming up the body and keeping the cold at bay. Threads can be manufactured from a variety of plants. Cottons, flax for linen, and silk are examples. These products are made from both animal and plant fibers. It’s extremely effective for screening against weather and providing a layer of protection from direct heat or cold.

Properties to Consider in a Material

We’ve already discussed the many types of materials; now it’s time to talk about their properties. Not only is the type significant, but so are the properties it contains. That is because different materials have distinct properties that can be important if they’re used. And their qualities are most significant in terms of their function. So, let’s have a look at what these properties are down below.

Durability: The ability of a substance to withstand pressure or damage is referred to as its durability. Take, for example, plastics. These are highly long-lasting materials. Because of their longevity, they can be used for a longer period. It can withstand heavy pressure unless it is purposefully pulled apart. A clear example would be the difference between a paper bag and a plastic bag. When moist goods are placed inside, the resilience of a paper bag renders it unreliable. A plastic bag, on the other hand, can handle bigger objects and does not care whether they are wet. As a result, this level of quality is required for appliances and furniture. Plastic is desirable since it is also corrosion-free. There are other naturally durable materials, such as wood. It may be affected by the age of the tree as well as the chemical and physical modifications done to it. Supply agreements would commonly stipulate the guaranteed durability of the product. Corrosion Resistance: There are few metals that are resistant to corrosion. Copper is one example of a soft metal. It is also exceedingly pliable and has a high thermal conductivity. It indicates it can be formed without breaking. Because water is a key corrosion causer, focusing on corrosion resistance materials is particularly beneficial in water projects. As a result, the materials utilized must be either corrosion-free, such as aluminum, or corrosion-resistant, such as stainless steel. They could also be coated to provide further protection. Drinking water would be a concern if the materials utilized corroded. The higher the resistance, the longer it will last and the more durable it will be. The materials used in the construction of high-rise buildings often have a high corrosion resistance factor. This is due to the tremendous weight and pressure, which would lead it to break more quickly if there was already rusting. And in a building, that is a “no can do” situation. It would be more prone to collapsing, putting people at risk all the time. Strength: The strength of a material refers to how much stress or weight it can withstand before deforming or breaking. This is also how the load capacity is determined. Or because of the strain that develops and its severity. Or the force that caused it to break. When you compare that with durability, it can be confusing. Roughly put, strength focuses on “how much,” whereas durability focuses on “how long.” If you’re wondering how long this material can withstand this weight, the response would cater to its durability factor. But what if you put a scenario in which you wonder how much load it can withstand before irreversibly deforming or breaking? That, then, is strength. When it comes to materials, strength and durability frequently go hand in hand. They both have a significant impact on automobiles and transportation proposals. And the strength of a material can be modified by its size, thickness, and length. Of course, there’s also the force of how it’s loaded to see how strong it is. Malleability: A material’s malleability refers to its ability to be molded without breaking. The best example would be the process of forging swords. Different types of steel, such as Damascus steel, are commonly utilized to make weapons. The high temperature during forging makes steel more pliable to shape into a weapon. The inverse could also be true. Cold temperatures reduce the malleability of some metals. It is still a prevalent practice today, just as wielding is done to bend metal without breaking it. When compared to just joining materials, shaping them into form saves money, time, and increases durability. The best analogy would be with metals and wood materials. Wood has strength and durability, although it is not always malleable. And, when it comes to designing complex structures or items, malleability typically plays a significant part in making things easier. If a substance is malleable enough, it can be flattened into thin sheets. And when weight is a consideration, it’s a fantastic property. Elasticity: Elasticity refers to the ability of a material to return to its original shape after being stretched or getting the applied stress removed. As a result, when the influencing force is released, elastic materials will return to their original size and shape. Once a material is deformed, its elasticity will reach its limit. Especially if it is unable to return to its previous state. As a result, plastics, rubbers and some metals are the best examples of materials with high elasticity. Plasticity: The ability of a substance to keep its new form, as opposed to elasticity, is referred to as plasticity. Meaning that after it has been stretched or hammered, its plasticity is its ability to retain its permanent new shape. Unlike elasticity, which can return to its original form. Metals wielded and forged are perhaps two of the best examples. Heat also causes wood to plasticize and retain its shape.

Steps When Making a Material Agreement

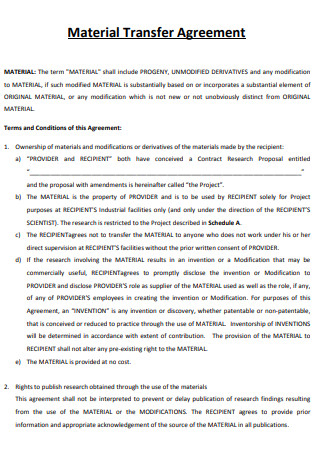

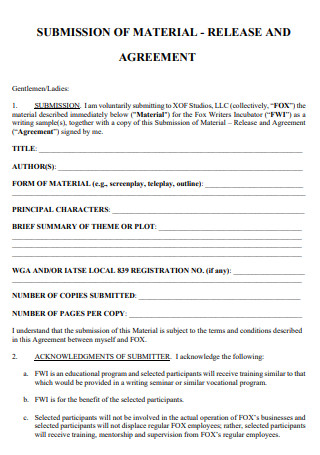

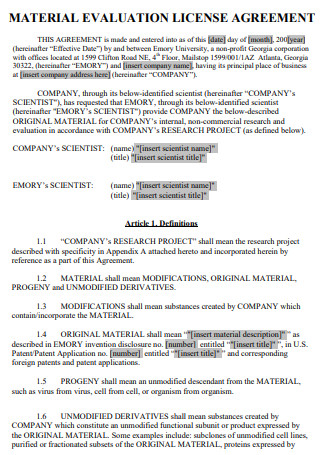

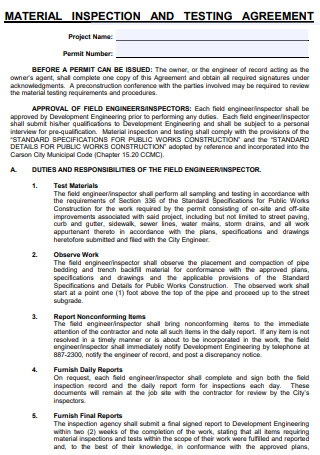

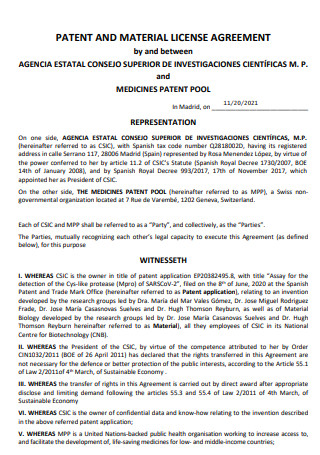

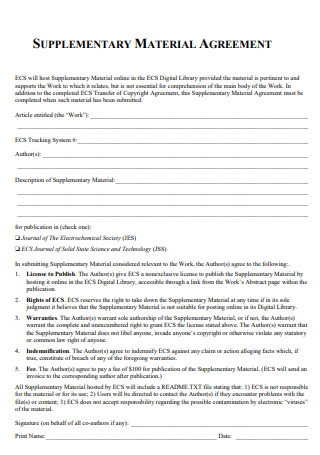

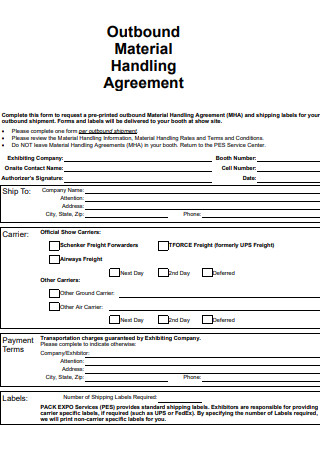

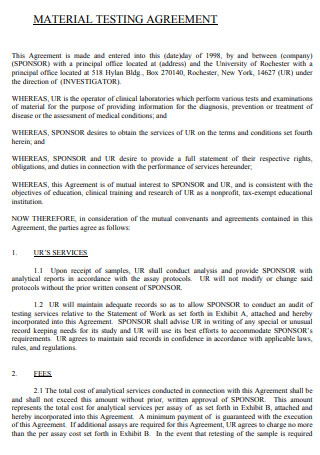

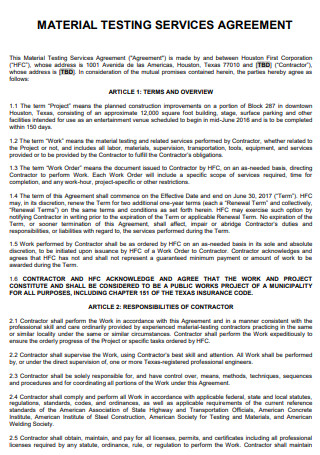

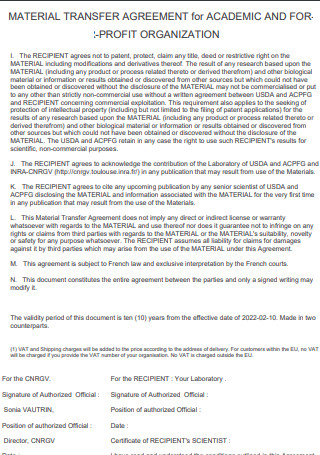

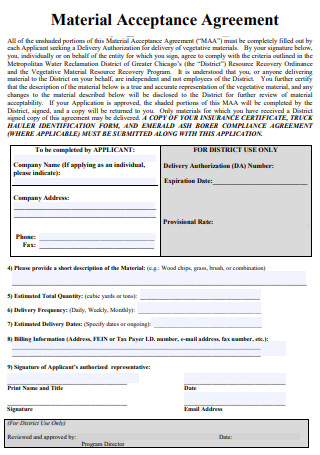

Now that we’ve covered all of the different types of materials and some of their features, it’s time to create a material agreement pdf. There are numerous sample material agreements above for you to use as a guide. Or we could learn how to make one or at least the contents of an mta agreement together. One of the most popular types of material contracts is the material transfer agreement. The methods below, however, are for a general material agreement.

-

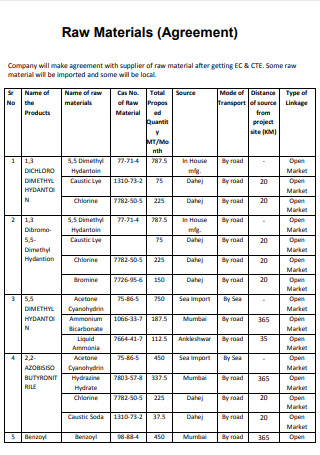

1. Identify the Materials

There is already an idea on what materials to purchase or transfer in a contract between two parties. Alternatively, what materials to select. However, it is critical to identify the exact materials, especially if they are specified. For example, if the material is already shaped or is still raw when it is delivered. Simply provide a brief description of what it is or if there are multiple items involved.

-

2. Quantity and Quality

The material’s quality is quite important. It could be because of their properties or the way they are created. And, of course, quantity is critical, especially for large-scale projects. So, specify how many are to be purchased or transferred, as well as their quality.

-

3. Price and Fees

Materials are frequently acquired in bulk. It is less expensive in terms of delivery fees, and there are also more discounts. As a result, agree on the price of each material or the total cost. Distinguish between the price and the expenses involved, such as delivery and even tariff. It’s also vital to consider how payment will be made and if an initial payment is needed.

-

4. Conditions

An agreement has clauses for termination or penalties. These specifications may address the issue of materials not arriving on schedule. Or low material quality, as well as failure to meet the agreed-upon amount. The two parties can reach an agreement on the fines or how the situation will be resolved.

FAQS

What Is the Distinction Between Material Strength and Durability?

The strength of a material is determined by how much load it can withstand. While a material’s durability refers to how “long” it can withstand a given weight. These two characteristics are inextricably linked.

What Exactly Are Natural Materials?

Most materials are extracted and refined naturally. Plant fibers are used to thread a fabric. Metals are refined after they have been extracted from the earth. Wood is obtained from trees. Plastic, such as rubber, can also be obtained naturally. Most of these natural resources are blended with chemicals that may improve their qualities.

Why Is a Material Agreement Necessary?

A material agreement is significant because it clarifies what the two parties agreed to. Particularly when it comes to pricing and services to be provided. It can also hold both parties accountable by establishing ground rules.

Materials are a highly valued resource in today’s world. A material supply agreement includes the qualities, quantities, and pricing of specific materials. And it’s always advisable to reach an agreement in order to safeguard and hold both parties accountable.