25+ Sample Manufacturing Contracts

-

International Manufacturing Contract

download now -

Contract Manufacturing Agreement

-

Manufacturing Agreement

-

Sample International Manufacturing Contract

-

Sample Manufacturing Agreement

-

Agreement Manufacturing Sourcing

-

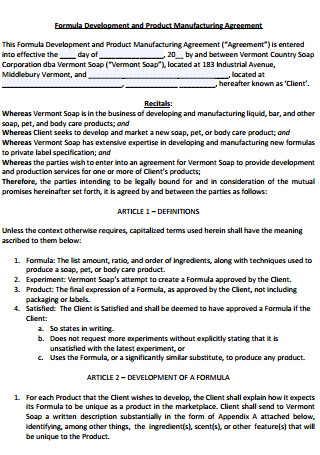

Formula Development and Product Manufacturing Agreement

-

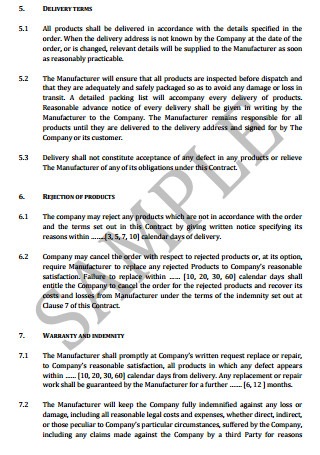

Key Contract Provisions For Supply Manufacturing Agreement

-

Agreement Manufacturing Format

-

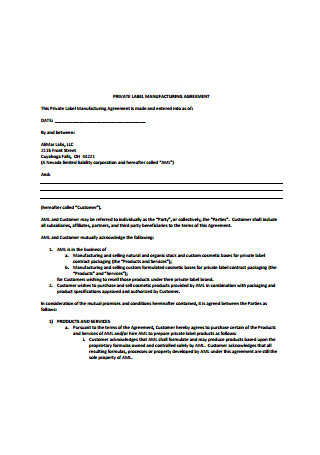

Private Label Manufacturing Agreement

-

Auto Manufacturing Contracts

-

Road to Contract Manufacturing Success

-

Sample Manufacturing Contracts

-

Overview on Contract Research Manufacturing Services

-

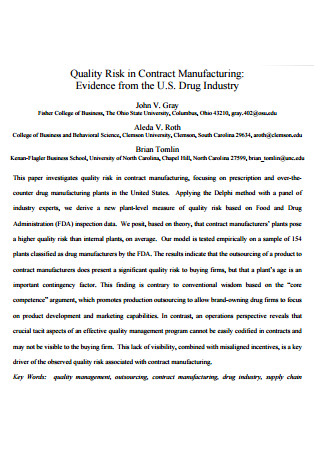

Quality Risk in Contract Manufacturing

-

Standard Contract Manufacturing

-

Printable Contract Manufacturing

-

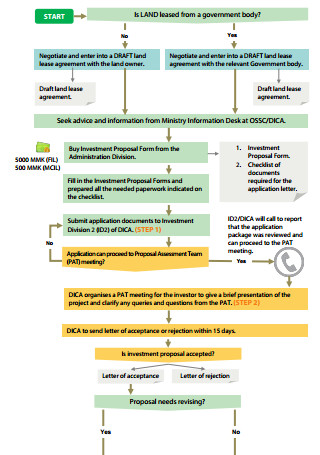

Permit in the Manufacturing Contract Sector

-

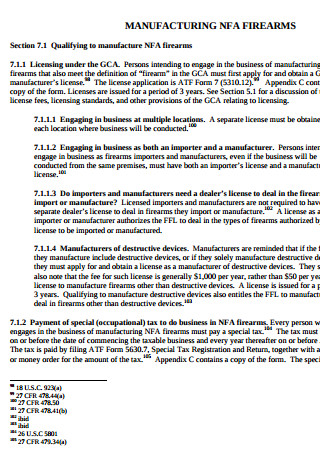

Manufacturing Contract Firearms

-

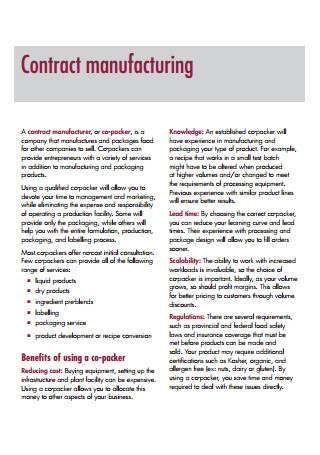

Using a Co Packer Contract manufacturing

-

Temporary Contracts of Spanish Manufacturing Firms

-

Sample International Manufacturing Contract

-

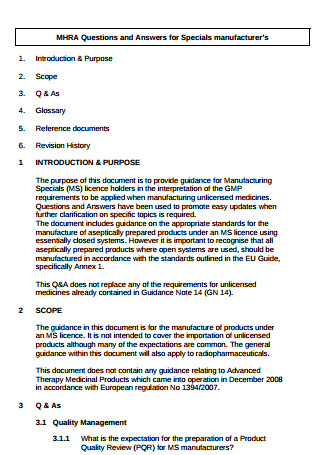

Manufacturing Specials Contract

-

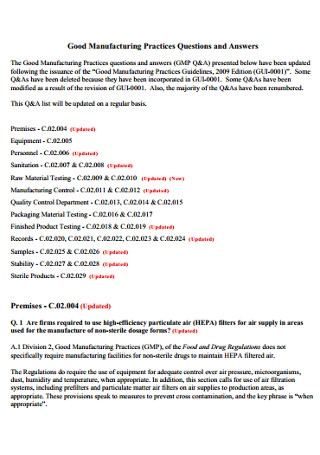

Good Manufacturing Practices

-

Global Contract Manufacturing Companies

-

Simple Manufacturing Agreement

-

Electronics Contract Manufacturing Template

download now

FREE Manufacturing Contract s to Download

25+ Sample Manufacturing Contracts

What Is a Manufacturing Contract?

Types of Manufacturing Contracts

Effective Service and Process Specification in a Manufacturing Contract

9 Steps for Developing a Detailed Manufacturing Contract

Benefits of Manufacturing Contracts to Clients

Advantages of Having an Excellent Manufacturing Contract for a Business

Do’s and Don’ts for Creating the Best Manufacturing Contract

Manufacturing Contract FAQs

What Is a Manufacturing Contract?

Business transactions and agreement must always be treated with professionalism and formality. If you want to enter an agreement or close a corporate deal, you have to know how you can reflect your organization in the best and most business-appropriate way possible so you can protect your brand and present your image accordingly. Are you a company who will provide manufacturing services to another business entity or organization? If you want to make sure that you can protect your business rights and credibility within the entirety of the transaction, it is only essential for you to create a comprehensive manufacturing contract. On the other hand, keep in mind that a manufacturing contract should be made not only for your own good but also for the good of the clients who will get your manufacturing services.

A manufacturing contract is a formal business document that is used to ensure that all parties involved in the transaction are well-aware of the right that they are entitled with as well as the responsibilities that they have to the other entity to whom they are having business with. It is important for a manufacturing contract to be developed as this can put all of the agreements that occurred between all parties into writing. Gone were the days when it is considered to be alright to enter a transaction without a signed contract. Even if you are transacting with long-time business partners, it is essential for you to consider the development of the specified document for purposes of agreement referencing, rights protection, and transaction documentation.

Most, if not all, manufacturing contracts are actually complex and crucial documents. Before you can finalize a manufacturing contract, there will be a lot of revisions, negotiations, and special requests that will take place. Since you have to ensure that you will have an excellent contract for a manufacturing agreement, it is important for you to develop in-depth presentations and descriptions of deliverable accountability. If the manufacturer and the client can be fully aware of what they need to bring to the table so that the manufacturing transaction can go smoothly, then it will be easier to fulfill the duties of one another in a timely manner.

Types of Manufacturing Contracts

Manufacturing contracts are commonly used by businesses who are in the food, technology, and pharmaceutical industries. However, the usage of manufacturing contracts are not limited to these. As long as manufacturing services are provided by a company or an establishment to another party, it is highly recommended for a manufacturing contract to created no matter what industry or field of business it is that you are in. Since there are variations with the manufacturing contract’s content and detail requirements, it is important for you to be knowledgeable of the type or kind of manufacturing contract that you need to develop. Some types of manufacturing contracts include the following:

Effective Service and Process Specification in a Manufacturing Contract

Do you want to know how you can have a successful manufacturing contract output? It is important for a manufacturing contract to be created with excellence and precision. You have to know the key terms and elements that you should highly consider when making a manufacturing contract so you can have a relevant contract document that can be beneficial to all parties. Your discussion flow as well as information presentation can help you a lot when it comes to clarifying all the areas of the agreement between a manufacturer and a client or a customer. Here are some ways on how you can effectively specify the agreed upon manufacturing services and processes in a standard manufacturing contract:

9 Steps for Developing a Detailed Manufacturing Contract

A basic manufacturing contract usually covers subject matters pertaining to the manufacturing requirements of clients. Aside from this, concerns about facility quality, manufacturing inventory management systems, transaction pricing, and other relevant and related issues are also covered in the manufacturing contract content specification and discussion. It is essential for a manufacturing contract to be as comprehensive as possible so all of the details that all parties should know about can be clearly and transparently presented. Below is a nine-step procedure that can enable you to develop a detailed manufacturing contract both for your organization and the other party that you are transacting with.

Benefits of Manufacturing Contracts to Clients

As we have mentioned in the early parts of this discussion, manufacturing contracts should be created in consideration not only of the business’ needs and rights, but also of the client’s responsibilities and relative advantage. There are many ways on how a client can benefit from having a manufacturing contract on-hand. To give you a wider perspective about this matter, here are the possible advantages and benefits that your clients can get if you will use a well-detailed, concise, and informative manufacturing contract:

Advantages of Having an Excellent Manufacturing Contract for a Business

Since most manufacturing contracts are expected to be developed by the manufacturer, you have to ensure that you will protect your rights without abusing the rights of your clients or customers. You have to be as honest, as objective, and as realistic as possible when making the manufacturing contract so you can provide a positive initial impression that can lead to a possible lasting business relationship. Having a well-developed manufacturing contract can be beneficial to your organization as it is of advantage to your clients. As a business, a few of the advantages of having an excellent manufacturing contract include the following:

Do’s and Don’ts for Creating the Best Manufacturing Contract

Manufacturing deals are unique transactions. You have to remember that no two manufacturing contracts are alike since there are different things, variables, and elements that are needed to be considered per manufacturing transaction. It is important for you to remember these items as you try to develop your own manufacturing contract. Being aware of the things that you should do and should not do within the entirety of the manufacturing contract development cycle can help you have a highly usable document output. Here are some guidelines and tips that can further help you to create the best manufacturing contract which can address all of the stakeholders’ needs, requirements, and specifications:

Manufacturing Contract FAQs

It is natural or normal for you to not know all the things that you have to be aware of with regards manufacturing contract development and implementation, especially if you are tasked to create and use the document for the very first time. Continuous learning with regards the subject matter can be achieved if you will ask relevant questions to professionals, experts, and other sources of information whenever you are given the chance to do so. Two of the questions that are frequently asked about manufacturing contracts include the following:

Why do you need a manufacturing contract?

A manufacturing contract is very important in every manufacturing transaction. You need a manufacturing contract as it is one of the documents which you can use as an evidence or a proof whenever disputes and misunderstanding arise in relation to a manufacturing agreement that you are involved in. It is necessary for a manufacturing contract to be created as this can help you assure the other party that you will deliver all your responsibilities and obligations. Aside from promoting accountability, a manufacturing contract can also specify all the rights and other entitlements that you have within a given manufacturing transaction. Through all of these, you can be at ease to begin the manufacturing agreement and actual transaction implementation since you have a legal document on-hand. Hence, a manufacturing contract is needed not only by the clients but also by the business. No matter what side of the transaction you are in, having a copy of a signed manufacturing contract can be very beneficial for you which is why it is highly-recommended for you to look for one whenever you plan to enter a manufacturing agreement.

How can you ensure the effectiveness of a manufacturing contract?

The content quality of your manufacturing contract matters a lot. If you want to ensure the effectiveness of a manufacturing contract, you first have to focus on all the information that you will put in the specified document. Excellent manufacturing contracts are those that can actually provide all the responsibilities of each party to one another. Aside from this, you need to have a complete and concise discussion of your manufacturing costs and pricing; product descriptions; manufacturing requirements and reasonable demands; agreement terms and clauses; provisions; dispute resolutions; and other relevant key points. If you can put all of these items in a well-structured layout, then you can easily present all the things that you would like the manufacturer and the client to be aware of. You can set metrics or measures that can help you further identify the effectiveness of the manufacturing contract document that you have developed.

Are you going to make a manufacturing contract now? We hope that you can allot some time to browse through and download the references that we have put together in the discussion above. Having reliable document formatting and content development guides can enable you to create excellent manufacturing contracts that your organization can utilize for its advantage.