20+ Sample Workplace Inspection Checklist

-

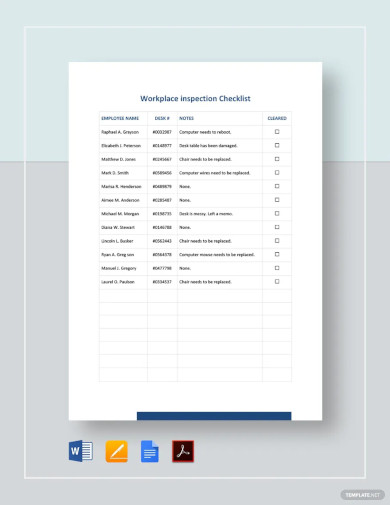

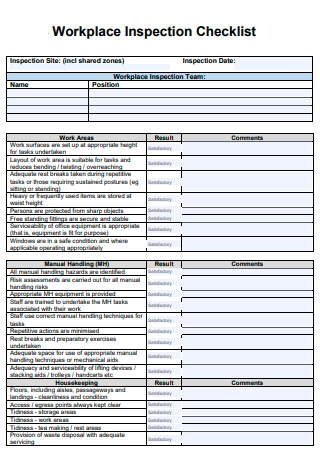

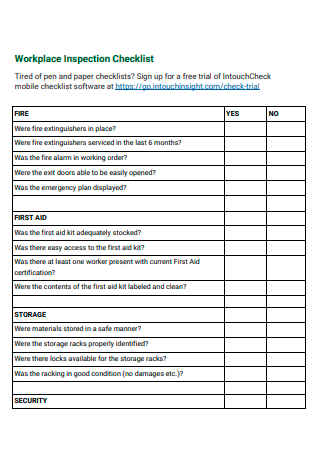

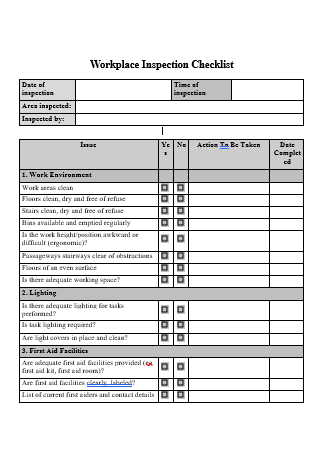

Workplace Inspection Checklist Template

download now -

Workplace Safety Inspection Checklist Template

download now -

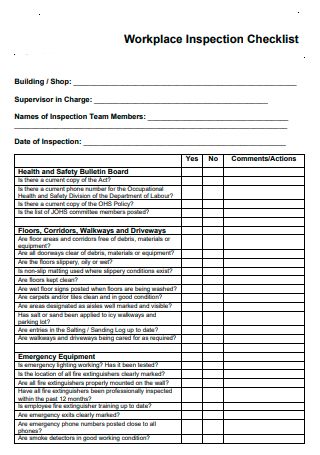

Workplace Inspection Checklist Template

download now -

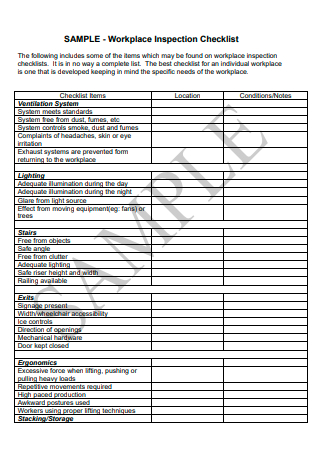

Sample Workplace Inspection Checklist

download now -

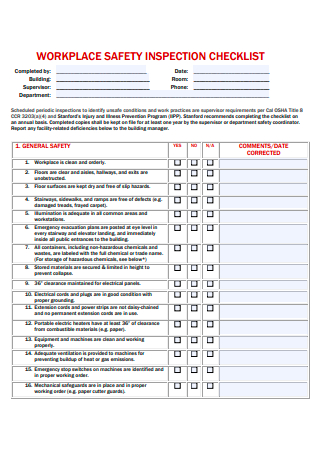

Workplace Safety Inspection Checklist

download now -

Basic Workplace Inspection Checklist

download now -

Workplace Inspection Checklist in PDF

download now -

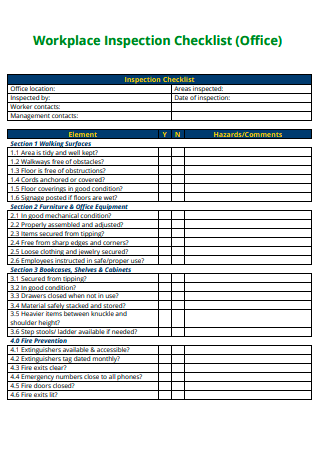

Office Workplace Inspection Checklist

download now -

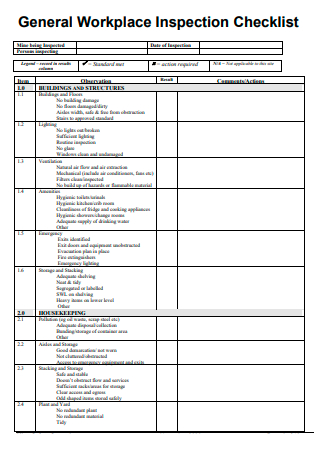

General Workplace Inspection Checklist

download now -

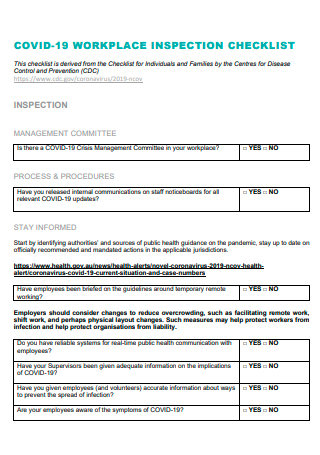

Covid-19 Workplace Inspection Checklist

download now -

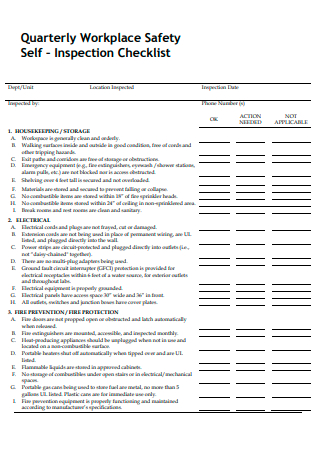

Quarterly Workplace Safety Self Inspection Checklist

download now -

Formal Workplace Inspection Checklist

download now -

Workplace Transport Site Inspection Checklist

download now -

General School Workplace Inspection Checklist

download now -

Workplace Inspection Checklist Example

download now -

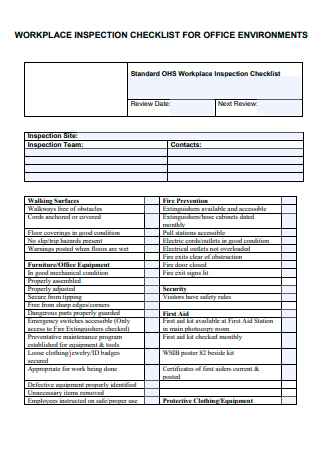

Office Environments Workplace Inspection Checklist

download now -

Workplace Inspection Health Issues Checklist

download now -

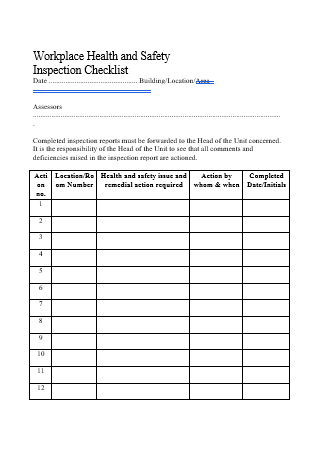

Workplace Health and Safety Inspection Checklist Template

download now -

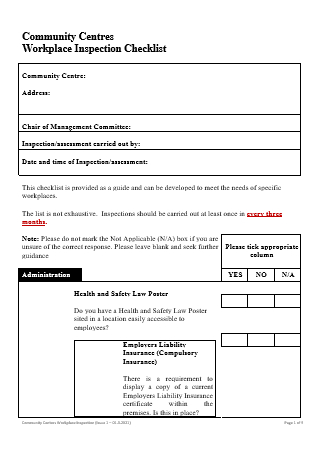

Community Centres Workplace Inspection Checklist

download now -

Secure Workplace Inspection Checklist

download now -

Workplace Inspection Checklist in DOC

download now

FREE Workplace Inspection Checklist s to Download

20+ Sample Workplace Inspection Checklist

a Workplace Inspection Checklist?

Benefits of a Safe Workplace

Types of Workplace Hazards

How To Conduct an Efficient Workplace Inspection

FAQs

How do I prepare for a checklist inspection?

What is the purpose of a daily safety checklist?

What is the purpose of sample inspection?

What Is a Workplace Inspection Checklist?

Employers and safety managers use workplace safety inspection checklists to conduct workplace safety checks. A checklist-based workplace safety inspection can assist in identifying hazards, escalating actions, and implementing controls to reduce the number or cause of harm and injury to employees, visitors, and contractors. Workplace safety inspections conducted by a standardized checklist assist in conducting regular and thorough work assessments of environments while proactively addressing hazards. By avoiding work-related incidents and injuries, you can potentially save money on your insurance premiums and avoid costly but avoidable work-related events. According to a national online study, most workers (94 percent) believe their office is a secure place to work. Along with feeling confident in general, most workers (85 percent) believe their workplace is adequately secured from fire, flood, or other disasters, and 83% consider their workplace is adequately protected against weather-related dangers.

Benefits of a Safe Workplace

Workplace safety is critical for every employee in the industry, as all employees desire to work in a safe and secure environment. The company has a legal and moral obligation to protect its employees. Every person who leaves their home in the morning for work should return home in good health in the evening. Nowadays, workplace wellness and safety procedures are essential for employees’ and employers’ well-being, as human loss is unquantifiable and intolerable. As such, losses or injuries can result in significant financial losses for families. While all industries involve some level of risk, management should devote time to considering and strategizing about the safety precautions that should be implemented in their organization to ensure that their employees remain safe at all times. Also, management should communicate with all employees regarding their daily work schedule and comfort. Thus, management can take the same step by the desired characteristics of employees. This assists them in increasing productivity and product quality, among other things.

Types of Workplace Hazards

It is critical to be as complete as possible while doing a safety hazard and risk assessment, as you cannot protect your workers from threats that you are ignorant of or unprepared for. By considering these six types of workplace dangers, you may avoid creating blind spots in your workplace safety practices.

Safety Hazard

Safety hazards are ranked first on a list of six different categories of workplace dangers. These dangers immediately affect employees who operate with machines or on construction sites. Safety risks are hazardous to work environments that can result in injury, disease, or death. The most common type of workplace risk is a safety hazard. They include the following:

- Anything that could result in spills or trips, such as cords crossing the floor or ice

- Unguarded and moving mechanical components that a worker may come into contact with.

- Frayed cords, missing ground pins, and faulty wiring are all electrical risks.

- Restricted spaces.

Physical Hazard

Physical dangers may be the least visible of all the hazards in your workplace. Despite their name, physical risks are not usually visual or tactile. Physical threats can occur when workers are exposed to hazardous weather conditions or work in dangerous locations. Workers exposed to the sun for an extended amount of time may face physical threats that might hurt their health in the long run. Physical risks can be defined as any factor in the environment that can injure the body without physically contacting it.

Biological Hazard

Biological hazards sometimes referred to as biohazards, are any biological substance that poses a risk to people. Biological hazards include the risk of injury or disease due to working with animals, humans, or infectious plant materials. Workplaces with these types of safety concerns have but are not limited to schools, daycare centers, colleges and universities, hospitals, laboratories, emergency response, and nursing homes.

Ergonomic Hazard

Ergonomic safety hazards occur when the nature of your work, body positions, and working surroundings place undue pressure on your body. They are the hardest to detect since you may not instantly realize the strain on your body or the danger these hazards bring. While brief exposure may result in “sore muscles” the following day or in the days after the strain, prolonged exposure might result in significant long-term problems.

Chemical Hazard

Chemical dangers exist whenever an employee is exposed to any chemical preparation in any form on the job (solid, liquid, or gas). While some are safer than others, even ordinary solutions might cause illness, skin irritation, or breathing difficulties for chemically sensitive workers. Not only does establish and adhere to a sound chemical safety policy save lives and protect the environment, but it also helps avoid fines and penalties. Before implementing any chemical safety measures, it is necessary to consider chemicals’ physical and biological effects.

Work Organization Hazard

Hazards to safety or pressures result in stress and strain. These are workplace risks such as excessive workload, a lack of control and respect, and so forth. Work organization risks are pressures that lead workers to experience tension, worry, or strain. These can be short-term or long-term and are related to workplace concerns such as workload, lack of control and respect, and so forth.

How To Conduct an Efficient Workplace Inspection

Regular workplace inspections are critical for avoiding mishaps, injuries, infections, property damage, and revenue loss. Certain businesses, primarily for financial reasons, choose to forego these inspections to save money. Unfortunately, this can only be regarded as a temporary solution or a recipe for disaster at worst. Business owners can save money, avoid accidents, and avoid potential liability by thoroughly reviewing the workplace. When conducted professionally and consistently, these inspections will detect potential Risks Analysis, recommend corrective action, obtain a better understanding of the duties and tasks performed, and listen to employee complaints. The following are five strategies for increasing the effectiveness of your workplace Inspection Report.

-

Step 1: Recognize Potentially Dangerous Situations

Each inspection should take a close check at all of the workplace’s components. It contains information about who, what, where, when, and how. You should, however, pay special attention to noise, lighting, temperature, vibration, and ventilation – all of which can evolve into harmful or unhealthy circumstances over time. Inspections should also extend beyond the areas where work is usually performed and include a parking lot, locker rooms, and rest areas. There are numerous workplace risks to be aware of, including biological, chemical, ergonomic, physical, psychological, and safety hazards. Multiple factors contribute to this, including insufficient machine guards or unsafe workplace conditions, viruses, bacteria, fungi, and parasites, repetitive and forceful movements, as well as prolonged awkward postures, inadequate or faulty equipment, noise, temperature, overwork, stress, or even violence.

-

Step 2: Pay Attention to Employee Concerns

Employees who are most exposed to day-to-day operations are best equipped to handle problems. Their opinion will be critical in deciding which areas require additional attention and modifications to streamline processes and boost productivity. Remote work has increased 44 percent in the last five years, according to research. And 80% of employees in the United States say they would decline a job that did not offer flexible work options.

-

Step 3: Identify Substantial Issues

When identifying health or safety hazards in your workplace, you should not stop there. Once such a hazard is placed, you should investigate any underlying conditions contributing to its occurrence. Depending on the conditions, if these concerns are not addressed, they can recur.

-

Step 4: Everything should be communicated to management.

Nothing should be overlooked or swept under the rug, not during an inspection or regularly. The sooner an issue is recognized and reported, the simpler and less expensive it is to resolve. Whatever appears out of the norm, possibly harmful, or stifles productivity or wellbeing should be addressed immediately for the benefit of everyone.

-

Step 5: Follow Up

This is the inspection’s most critical component. Once the Assessment Checklist is complete and possible dangers are discovered, the employer must take quick corrective action. As a result, there must be a record of the inspecting team advising the employer about potential risks and maybe making recommendations on resolving the concerns and ensuring a hazard-free workplace. Employers, safety professionals, department heads, and anyone responsible for the workforce’s safety should obtain a copy of the inspection report to assist them in identifying and resolving any issues.

FAQs

How do I prepare for a checklist inspection?

Make a list of potential defects and categorize them as major, minor, or critical. Bring a simple safety checklist to every meeting. You can use one you’ve previously used or one from a library of inspection checklist templates. Also, please make a list of potential flaws and categorize them as major, minor, or critical. Bring a simple checklist to every meeting. You can use one you’ve previously used or one from a library of inspection checklist templates.

What is the purpose of a daily safety checklist?

A daily safety inspection checklist assesses critical workplace health and safety hazards that may arise daily. This checklist assists you in maintaining constant vigilance over everyday work conditions, incidents, and compliance with safety standards for people, processes, and machinery.

What is the purpose of sample inspection?

Sampling inspection is a technique for determining whether a lot or population should be rejected or accepted based on the number of defective components discovered in a randomly selected sample from the lot. The lot is left if the number of faulty parts exceeds a preset threshold. Also, it is more accurate because errors are introduced during 100% inspection due to inspector tiredness and boredom caused by vast amounts of repetitive inspection work.

Safety is a significant concern, and it is entirely up to managers and business owners to ensure that their staff is working in a safe atmosphere. The management should ensure that they continue to motivate and boost personnel to keep them engaged in the job process. Regularly, suitable discussions regarding work and office culture should occur to be aware of how they simplify things for employee comfort. Additionally, to motivate employees, management should present prizes as a token of appreciation for their efforts. Thus, by taking these simple procedures, you can ensure that your workplace is highly secure and safe for employees to work.