26+ Sample Delivery Orders

-

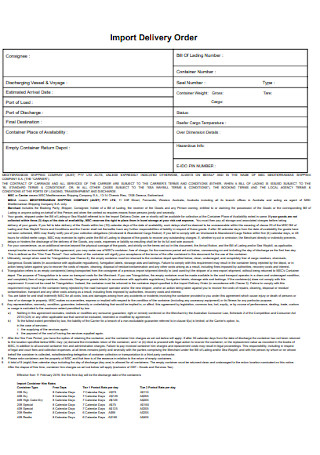

Import Delivery Order

download now -

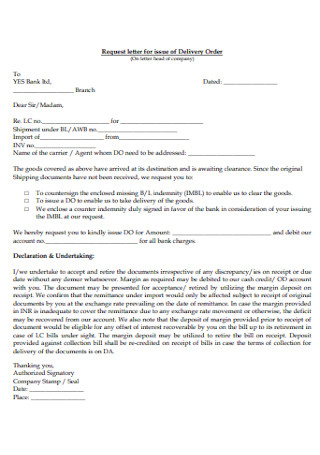

Delivery Order Letter

download now -

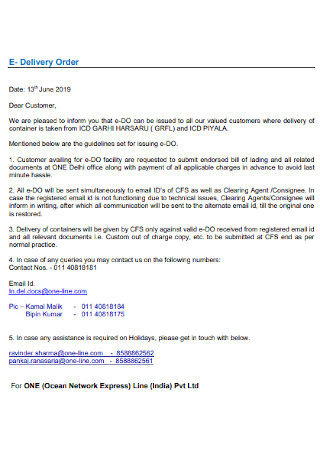

Sample E- Delivery Order

download now -

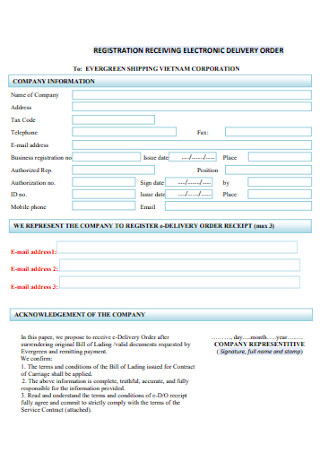

Electronic Delivery Order

download now -

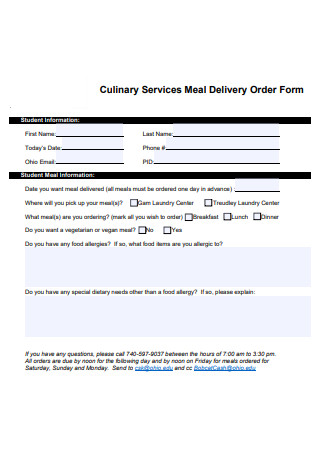

Meal Delivery Order Form

download now -

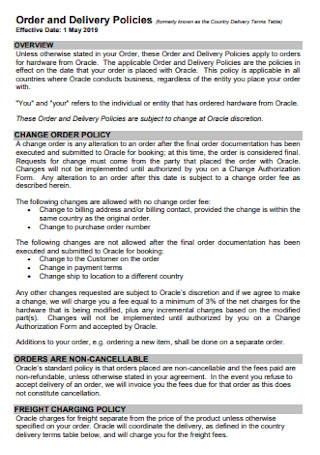

Delivery Order Policy Template

download now -

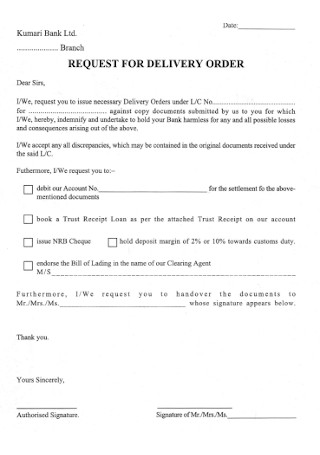

Request for Delivery Order

download now -

Online Delivery Order

download now -

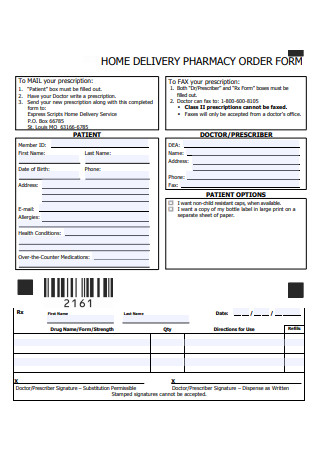

Home Delivery Order Form

download now -

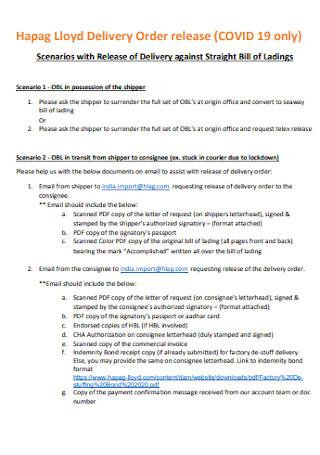

Delivery Order Release Template

download now -

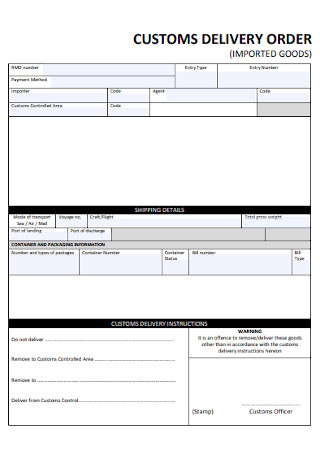

Custom Delivery Order

download now -

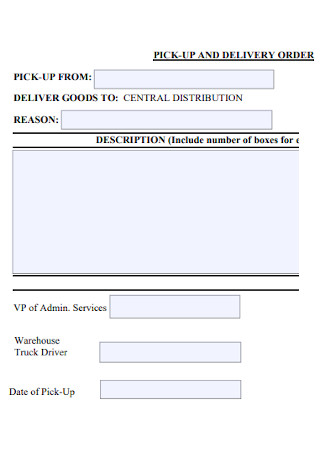

Pick-Up and Delivery Order

download now -

Delayed Delivery Orders

download now -

Home Delivery Order

download now -

Basic Delivery Order

download now -

Simple Delivery Order Form

download now -

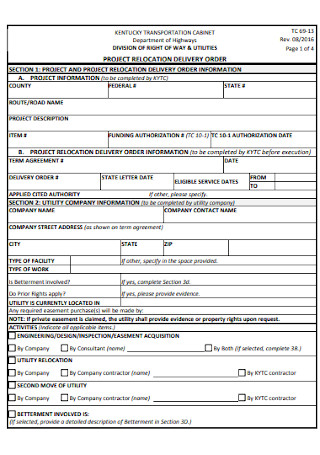

Project Relocation Delivery Order

download now -

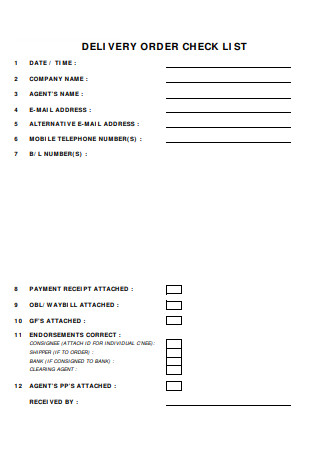

Delivery Order Checklist

download now -

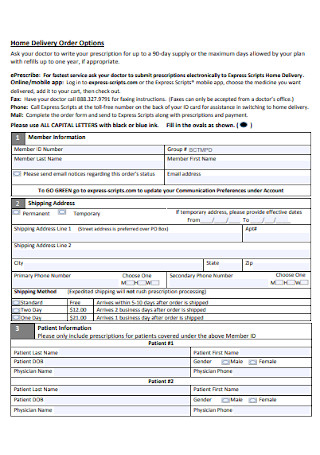

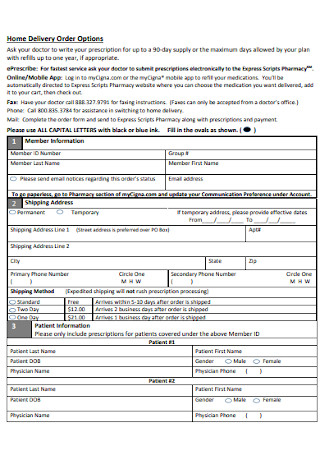

Home Delivery Order Options

download now -

Small Order Delivery

download now -

Delivery Order Application Template

download now -

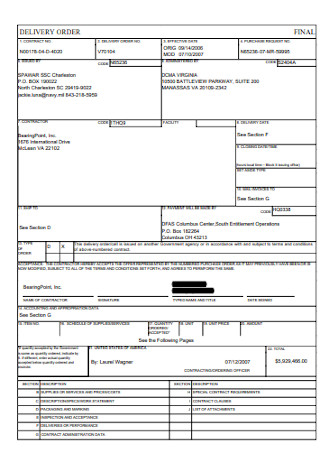

Task Delivery Order

download now -

Ships Delivery Order

download now -

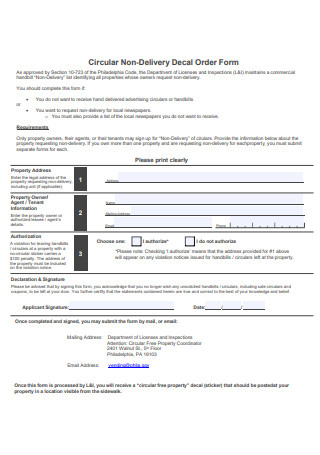

Non-Delivery Order Form

download now -

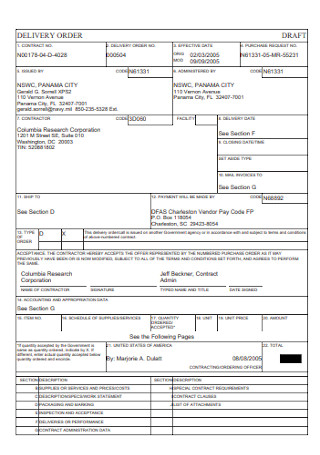

Formal Delivery Order

download now -

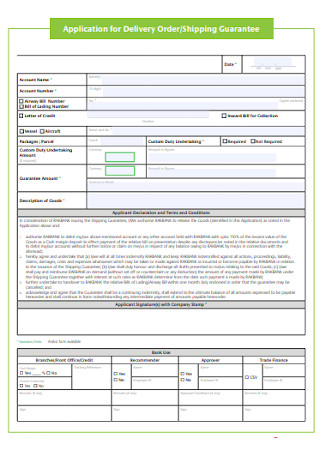

r Delivery for Application

download now -

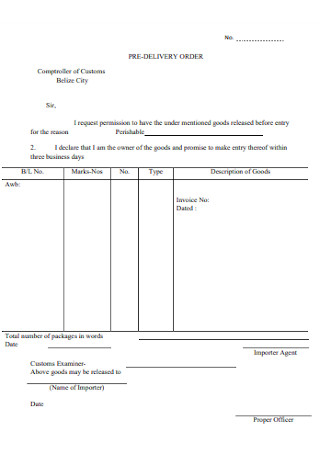

Simple Pre-Delivery Order

download now

FREE Delivery Orders s to Download

26+ Sample Delivery Orders

What Is a Delivery Order?

Benefits of On-Time Delivery Orders

Tips to Improve Your Delivery Order Workflow

How to Obtain On-Time Delivery Success

FAQs

Is the delivery order the same as the invoice?

What is a delivery document?

What is a delivery notice?

What Is a Delivery Order?

A delivery order is a type of document that is given by a specific carrier, a carrier’s agent, or someone who is authorized to release cargo to a named party or another carrier on behalf of the called party. These orders are only given right after a consignee gives back a bill of lading that has been signed. But a delivery order and a statement of lading should each have their definition because they are so different. The carrier is giving this out to show the cargo shipment route. It will be used as a contract for the movement of the freight. Also, a delivery order is not a document that can be changed, so it shouldn’t be used as proof or as a receipt. In a study by Gloria Food, 86% of Americans said that they ordered food delivery at least once a month. 68% say they will order takeout more often in 2021 than before the pandemic.

Benefits of On-Time Delivery Orders

As the pace of business persists and your end customers expect continuous improvement, ensuring that your supply chain enables you to meet your product delivery commitments is a key performance indicator that distinguishes successful companies from those that fall behind. Outstanding quality, cost, and delivery are market expectations that must be met in today’s business environment. While we know that on-time delivery from suppliers has value, it is essential to consider how it can impact a company’s resources and, consequently, its bottom line.

Tips to Improve Your Delivery Order Workflow

Customers desire a seamless transaction when they place an order, necessitating a robust order processing system. With such a system, businesses can guarantee that their customers receive what they require when they need it without any complications. The foundation of e-commerce is a quick, convenient, and automated shopping experience designed to make the customer’s life easier. However, order processing has a dark side when things go wrong. A single incorrect order is sufficient to permanently lose many customers, especially those unfamiliar with your service. A survey found that 32% of customers would not order from a business again if they had a negative shopping experience, even if they liked the brand. This is why many companies prioritize their order processing workflow to make the process as efficient as possible. And more than a single sale is at stake. The precision and speed with which your company processes orders can affect customer loyalty and, in turn, the likelihood of future business. Typically, a workflow for order processing consists of the following five steps:

1. Placing an order

When a client places an order, the workflow begins. In this step, your company collects all the information necessary to collect payment and complete the delivery, including payment card information, the delivery address, and the customer’s pertinent personal information. At this stage, a business needs to be transparent about its inventory and when customers can anticipate shipment and delivery.

2. Picking the product

In this step, the company assigns a worker or automated system to select the product requested by the customer and prepare it for shipment. This procedure must be exhaustive and efficient to ensure the company delivers the correct item within the customer’s preferred time frame.

3. Sorting and packing products

Typically, a product is included in a larger order. Then, workers must determine which items belong to which orders and where each order will be shipped. This step is crucial for order accuracy, so it must be structured to ensure that customers receive the items they purchase. Additionally, proper packaging is essential for a positive customer experience. Even if you get everything right before packing, you may lose business if your products are not adequately protected or packaged. It is essential to match each product with the correct shipping information to ensure that the valid customer receives the right product.

4. Shipping the product

Lastly, the business must ship the product via a reliable carrier to deliver it to its final destination. Customers must have an easy pass to their shipment tracking information to complete the order processing workflow in its entirety.

How to Obtain On-Time Delivery Success

Excellent customer service for delivery operations is not an accident. While errors and miscommunications are an inevitable part of running a retail operation, well-thought-out policies and procedures aid in resolving problems when they arise and preventing their occurrence. This necessitates examining and refining processes throughout the entire shop, from receiving new inventory items to handing off the finished product to the customer. The following guidelines will assist you in ensuring that your shop has the necessary personnel, policies, and procedures to provide superior customer service with every bottle.

1. Stock the Items Your Customers Desire

Assuring you never run out of your best-selling products is the first step toward a satisfied customer base. Establish a procedure to identify and track your core items and to calculate points that account for each distributor’s required lead time. It is advised to utilize trend data to provide insight into what your customers may want before they ask for it. Ensure that your distributor’s sales representatives know essential items for your business. So that you can adequately prepare, request that they notify you of potential out-of-stock situations, changes to vintages, or price adjustments. Nevertheless, regardless of how efficient your ordering process is, you will occasionally run out of a critical item. When this occurs, have a system for recommending potential short-term substitutes and informing customers when their preferred item will return to stock.

2. Maintain Competitive Pricing

Knowing what your customers desire is only the beginning. It would help if you also sold it at the price they wanted. Many of the most popular brands are frequently sold with substantial volume discounts, so buy as profoundly as you can while maintaining as much margin. Smaller stores should inquire with their distributors whether a bill and hold option is available, and if so, ensure that the payment and delivery terms are clearly understood. Check-in regularly with your distributor representatives about potential price increases or special offers so that you can budget for large purchases. A store with a stellar reputation for customer service may be able to charge an additional dollar or two per bottle, but this may not be possible for large, well-known brands. Customers willing to take a chance on something new may be better served by a selection of inexpensive, high-margin discoveries.

3. Make Sure Your Inventory Is Accurate

Whether online or in-store, incorrect inventory is one of the most common causes of customer complaints. A good POS system that integrates seamlessly with your e-commerce platform will eliminate numerous potential problems. Developing a process to check in new items accurately is of equal importance; without it, your data will be incorrect from the start. Continuous inventory counts and reconciliation, either monthly or on a rolling basis, must identify and correct inaccuracies before they become a problem.

4. Make It Easy to Accept Substitutions

Regardless of how solid your process is, inventory problems are inevitable. Incorporating a “substitutions allowed” checkbox into your e-commerce platform will allow customers to choose between receiving their order quickly or receiving the exact items they were seeking. If a customer approves a substitution, ensure that it is well-considered. Notifying the customer that they will receive a substitution — and indicating that it is an upgrade — will typically prevent post-delivery complaints.

5. Manage Time-of-Delivery Expectations

Delivery delays are a common reason for online customer service complaints. Managing customer expectations can be one of the most challenging aspects of running a business because timely delivery depends on many factors beyond a shop’s immediate control, such as weather, traffic, and delivery location. If you anticipate longer delivery times than expected, promptly and truthfully inform your customer. Losing a single sale today is preferable to losing a customer permanently. If you charge delivery fees, waiving them is a gesture of goodwill that is greatly appreciated. For your best customers, offering to include an additional bottle or applying a discount can relieve the tension of late delivery.

6. Check the Order and Impress

Ensure that the item being shipped corresponds precisely to what the customer ordered. Giving a refund and replacing a misdelivered item requires time and effort, so getting things right the first time is worth the extra effort. There are numerous ways to structure this procedure to function optimally for your store, employees, and order flow. In addition, it is crucial that your delivery staff is well-versed in the store’s policies and prepared to handle and resolve any problems that may arise at the delivery location. Frequently, the delivery person is the only shop representative with whom a customer will interact. The delivery staff should be cordial and make customers feel comfortable. If they know about the product being delivered, encourage them to share it with the customer during the delivery handoff by telling them something interesting or valuable. Ensure that your delivery staff knows their significance in maintaining high customer satisfaction.

FAQs

Is the delivery order the same as the invoice?

An invoice is a sale record showing how much the buyer needs to pay. A delivery note is a note that tells the buyer that the seller has sent and delivered the goods.

What is a delivery document?

Typically, delivery documents provide instructions for an order or trip and detail the products and quantities to be delivered. They serve to transfer product ownership to the customer. Some forms may also include the product price and any additional fees.

What is a delivery notice?

In commodity futures markets, delivery notices are documents furnished by the futures contract seller. The document confirms that the seller intends to fulfill their obligations under the contract by physically providing the underlying commodity to the futures holder.

Utilizing a delivery order would give the business an overview of inputs and outputs while allowing customers to verify that they are receiving the correct products for which they have paid. If something is reported missing from one of the items in the package, the buyer can directly contact the sender with details about the problem.