3+ Sample Heavy Vehicle Inspection Checklist

FREE Heavy Vehicle Inspection Checklist s to Download

3+ Sample Heavy Vehicle Inspection Checklist

What IS a Heavy Vehicle Inspection Checklist?

Benefits of Vehicle Inspection

Making the Heavy Vehicle Inspection Checklist

FAQs

What are the usual systems or parts being inspected in a vehicle?

What are some of the different types of heavy trucks?

What makes a checklist significant?

What IS a Heavy Vehicle Inspection Checklist?

Safety is the primary reason why vehicles are being inspected, especially heavy-type vehicles. This safety procedure does not only benefit the driver of the vehicle, the goods or products stored in the vehicle, the vehicle itself, but as well as the other drivers and passengers driving along the road. But let’s define what a heavy vehicle is first. FleetNetAmerica has defined heavy vehicles as “any vehicle exceeding 26,001 pounds is considered heavy-duty. Examples include city transit buses, mobile cranes, cement mixers, refuse trucks, and tractors designed to pull refrigerated trailers, dry vans, and other equipment.” This categorizing the vehicles according to their weight is important to address vehicle safety concerns, especially when it comes to the load that the vehicles are carrying.

If a vehicle carries more than it is allowed to load, a lot of danger comes with it such as possible failure in brakes, strain in the tires, suspension problems, and so on. Hence, aside from the weight or load factor, a lot of these components are also included in a heavy vehicle inspection checklist. A heavy vehicle inspection checklist, or vehicle checklist, is created to ensure that, first of all, the weight of the load of the vehicle does not exceed the quantity which is allowed for heavy vehicles. And second, the checklist also serves as a guide by a technician to ensure that the vehicle is thoroughly checked to avoid possible mechanical issues that will occur, especially when the vehicle is out on the road. If a heavy vehicle is being used for commercial purposes, then the vehicle needs to undergo a yearly DOT (Department of Transportation) truck inspection. The heavy vehicle inspection checklist will then serve its purpose as the main tool to ensure that the vehicle is in good condition, accessories and parts are safe to use, and everything else is working properly, before the big day of the DOT inspection.

Benefits of Vehicle Inspection

Vehicle inspections are not only limited to heavy vehicles. It is a safety procedure that should be followed by all types of vehicles and should be taken seriously by car manufacturers or by private individual vehicle owners. Inspections should not be done just for the sake of regulation compliance. Although it is required of car manufacturers to have their vehicles properly inspected and audited for quality purposes, what the general public is not that much aware of is that there really are some benefits out of having your vehicles inspected on a regular basis. Not just to inspect that you have enough fuel or air in your tires for your road trip, but there are actually more payoffs for a vehicle that gets a proper rundown of inspection. What are these benefits? Read on to find out more.

Making the Heavy Vehicle Inspection Checklist

A heavy vehicle inspection is often a standard procedure and might seem a bit like a repetitive task at some point. Despite being repetitive, surprisingly, there are still some procedures or parts during the inspection process that are left out or that are left undone due to so many different factors. This is where a heavy vehicle inspection checklist comes into play. Believe it or not, technicians, especially the certified ones, do use a checklist when they’re conducting their rounds of inspection. A checklist ensures that whatever criteria or quality standards are required from a heavy vehicle are met by the car manufacturer before its release to the public, or even before any government inspection is being made, such as the one coming from the Department of Transportation. Checklists, whatever style or format, over the years have proven time and time again its usefulness when it comes to organizing or managing tasks. It helps improve consistency, productivity, and efficiency. On top of it all, it is the tool that’s used to ensure that all tasks are completed. There is no strict format when it comes to creating a heavy vehicle inspection checklist, although care has to be taken when listing the items or the things to do because, after all, heavy vehicles are subjected to DOT inspections as well. Read on to find out how to create that effective heavy vehicle inspection checklist.

-

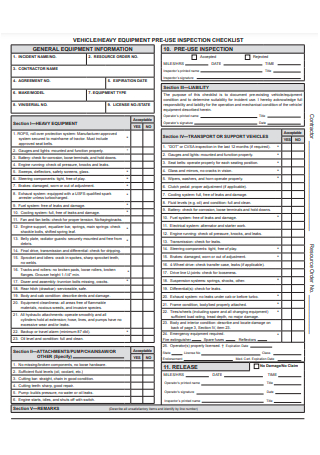

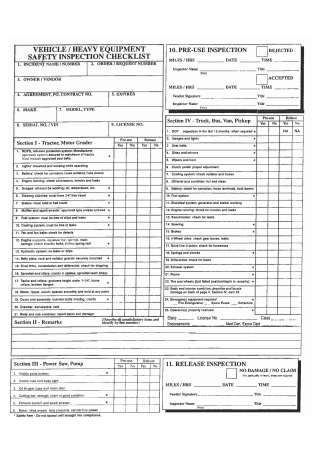

1. Name and Date of the Checklist

At the top, the middle part of your document is the name of your checklist. The name could be as simple as “Heavy Vehicle Inspection Checklist”, or it could be more specific such as “B-double Freight Trucks Inspection Checklist” or “DOT Inspection Checklist for Mobile Cranes.” Right below the name or the title is the date of the checklist. The date signifies when the inspection was made. It could even be in a date range that is inclusive of how long the inspection was conducted, from the start date to the date of completion.

-

2. Name of the Participants and Heavy Vehicle Identification

Right below the date or the date range are the names of the participants of the inspection. The participants are the name of the person who is assigned to do the inspection, and the other participant is the name of the heavy vehicle owner, or the name of the business or company who owns the heavy vehicle(s). Or, the inspection is being personally done by the owner of the heavy vehicle, so then the only name that’s reflected is the owner of the vehicle. Just right below the names are the details of the heavy vehicle(s). Details would include the type of heavy vehicle (kind of truck, bus, tractor, and so on); the make, brand, model, color, and year; license plate; VIN; and/or the current mileage of the vehicle.

-

3. Creating Columns

A typical checklist column consists of two to three columns. The first column is for the tasks to be done. The second column is either divided into a yes or no column or else into tick boxes that stand for yes or no. A third column is made for the feedback, suggestions, or comments for every task that was performed found in the first column. This is what a checklist commonly looks like. This can be utilized for heavy vehicles inspections, too. There is another checklist format that is much more closely designed for heavy vehicles. This format still has three columns to it. The first column is listed as items. Items are the parts of the heavy vehicle that needs to be checked. Items can also be broken down into the specific functionality of a heavy vehicle. We will go more into this in the next number. The second column is titled Response. The response could be answered as “OK” if the item in the task is performing fine, or something more specific such as “needs repair” or “not working”. The third column could be titled as comments or details. These are the findings, results, or conclusions from each item that were inspected.

-

4. Items and Other Details

A vehicle inspection checklist, especially for heavy vehicles, tends to be more detailed compared to any other kind of checklist. For instance, each item listed can also have some subcategories under it. These are the usual items to be checked for heavy vehicles, including their subcategories: Item #1 Engine Operation. Right below it is different items such as compressor belts/fan, radiator, oil pressure, battery; Item #2 Fuel System. Underneath are leaks, fuel tank filler cap, fuel tank attached securely; Item #3 Safety Equipment. Seatbelts working, flags, flares, decals, fuses, spare bulbs; Item #4 Lighting Devices. Headlights, brake lights, tail lights, dash lights, clearance lights, turn lights, or indicators; Item #5 Tires. Condition, chains, air pressure, and so on. You can add more later on according to the requirement of your heavy vehicle. In the response column, indicate “OK” if the item or the parts are working properly or in good condition. For example, for lighting devices, if the headlights are working, write “OK” on the column next to it. If it’s not working, indicate “not working” or “needs repair/replacement.” In the third column, you write down more details, comments, or suggestions if the item is not working. You could indicate “bulb needs replacement” or “not connected to battery” and so on.

-

5. Remarks or Recommendations

At the bottom part of your checklist is a space for your remarks or recommendations. This is for your overall evaluation or assessment of the heavy vehicle inspected. You could indicate “check oil levels”, “recommended for repair”, “be mindful of steering”, “check tire pressures further”, and so on. Some checklists would even give a scoring system if the heavy vehicle has passed the inspection or failed the inspection.

FAQs

What are the usual systems or parts being inspected in a vehicle?

Vehicle inspection depends on the type of vehicle and state or local mandated laws or regulations. The common systems or parts being inspected are the steering system, brake system, engine operation, fuel system, exhaust system, coupling devices, lighting devices or system, safety equipment, safe loading, suspension, windshield, tires and wheels, and so on.

What are some of the different types of heavy trucks?

Heavy trucks weigh somewhere between 26,000 to 33,000 pounds. These are dump trucks, mobile cranes, concrete transport trucks, tractor units, tank trucks, garbage trucks, haul trucks, heavy haulers, ballast tractors, and so on.

What makes a checklist significant?

A checklist serves as a task management tool. It helps you keep track of the important tasks that you need to do, and it helps you organize your tasks according to their priorities. A checklist also improves your productivity and efficiency since you’re able to keep track of what you need to do. Last but not least, it helps reduce human errors by reducing mistakes because of tasks left undone or incomplete.

Every time you’re on the road and you see a dump truck either in front of you or right behind you, you tend to slow down and be careful, or else make sure that there is enough room space between your vehicle and the heavy vehicle. You’re just being cautious, right? Or else just follow standard driving procedures that dictate how to maneuver in case you come in contact with a heavy vehicle. There’s always that anxiety when we encounter heavy vehicles on the road, which is pretty natural, of course. Needless to say, the vehicle manufacturers are pretty much aware of the safety concerns of their vehicles, that’s why heavy trucks and the likes have to go through rigid inspections and audits before they would make it on the road. And the tool to assist in inspecting and auditing is what is known as the Heavy Vehicle Inspection Checklist.

If you’re planning on creating a heavy vehicle inspection checklist, check out our website and download one of our many available inspection checklists templates!