50+ Sample Safety Inspection Checklists

-

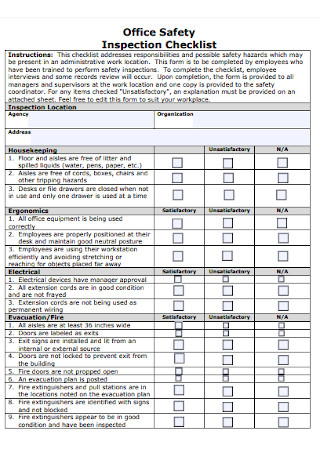

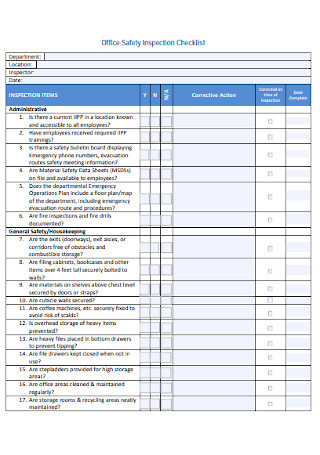

Office Safety Inspection Checklist

download now -

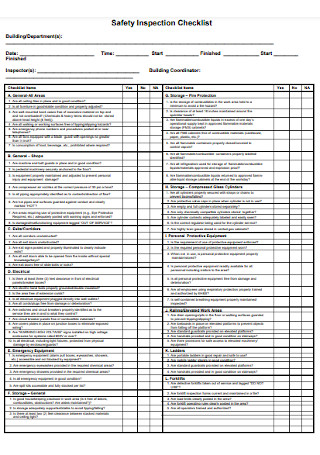

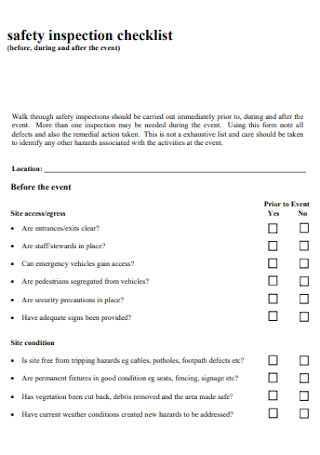

Sample Safety Inspection Checklists

download now -

Facility Inspection Checklist Template

download now -

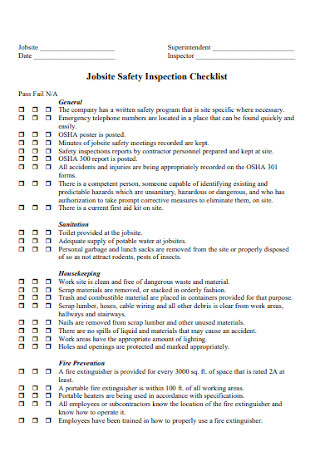

Jobsite safety Inspection Checklist

download now -

Construction Safety Inspection Checklist

download now -

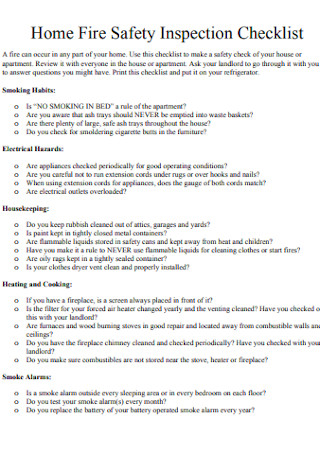

Home Fire Safety Inspection Checklist

download now -

Fire Safety Inspection Checklist

download now -

Office Safety Inspection Checklist

download now -

Sample Safety Inspection Checklist

download now -

Office Safety Inspection Checklist

download now -

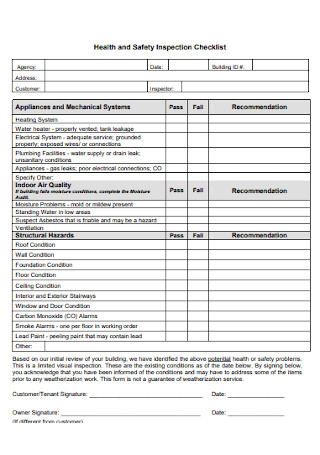

Health and safety Inspection Checklist

download now -

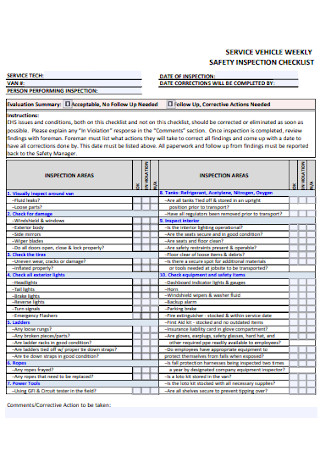

Vehicle Safety Inspection Checklist

download now -

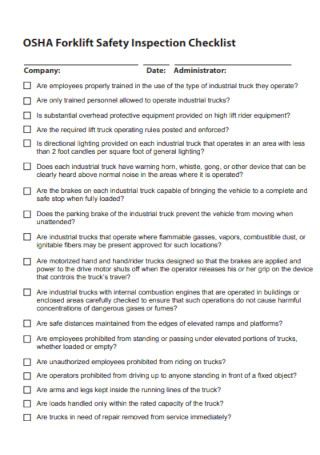

Forklift Safety Inspection Checklist

download now -

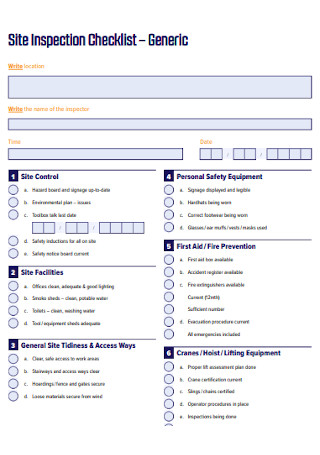

Site Generic Inspection Checklist

download now -

Basic Safety Inspection Checklist

download now -

Construction Site Safety Inspection Checklist

download now -

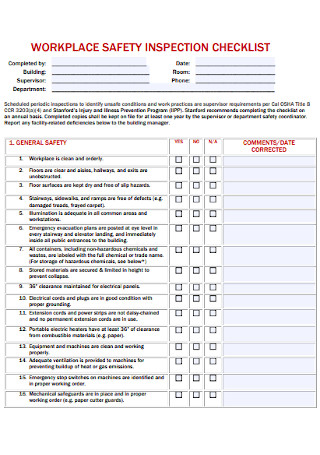

Workplace Safety Inspection Checklist

download now -

Safety Inspection Checklist Format

download now -

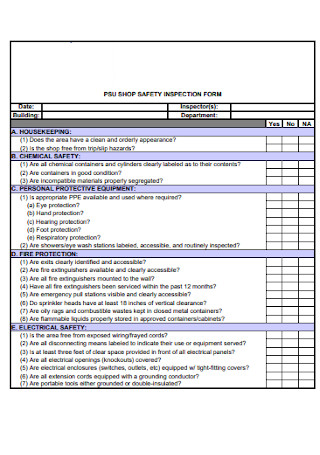

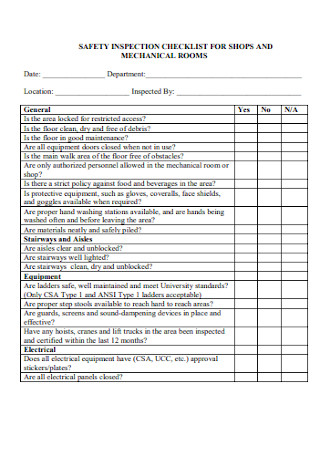

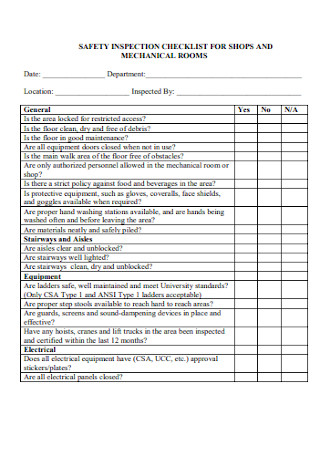

Shop safety Inspection Checklist

download now -

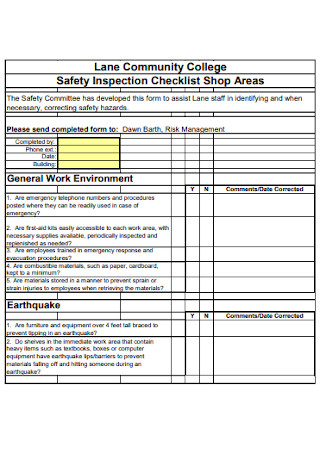

Shop Areas Safety Inspection Checklist

download now -

General Fire Safety Checklist

download now -

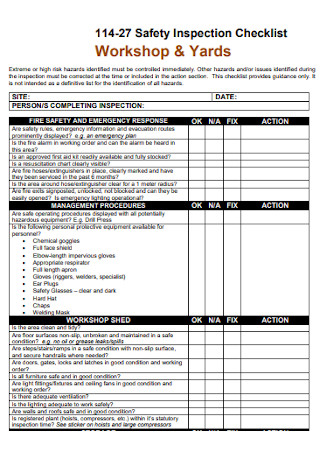

Workshop Safety Inspection Checklist

download now -

School Safety Inspection Checklists

download now -

Safety Inspection Checklist for Offices

download now -

Construction Safety Inspection Checklist Example

download now -

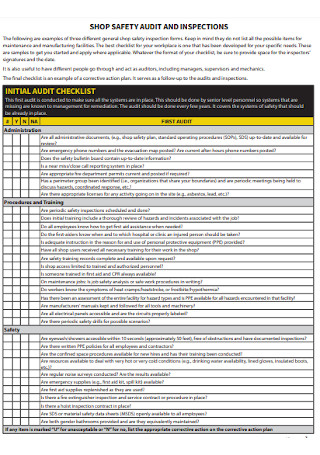

Shop Safety Audit Inspection Checklist

download now -

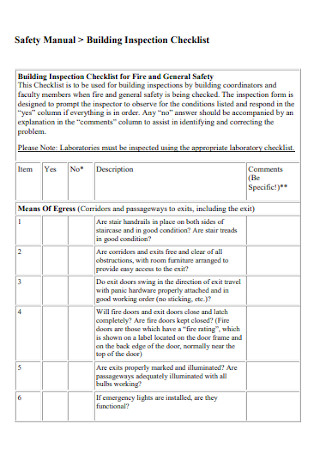

Building Safety Inspection Checklist

download now -

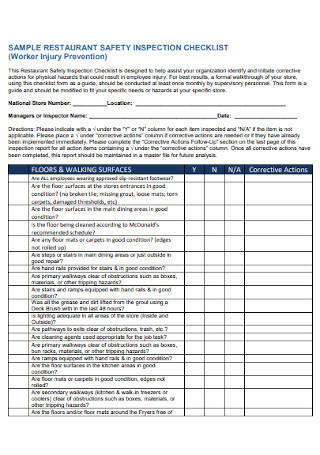

Restaurant Safety Inspection Checklist

download now -

Departmental Safety Inspection Checklist

download now -

Rooms Safety Inspection Checlist

download now -

Machine Shop Safety Inspection Checklist

download now -

Sample Shop Safety Inspection Checklist

download now -

Kitchen Safety Inspection Checklist

download now -

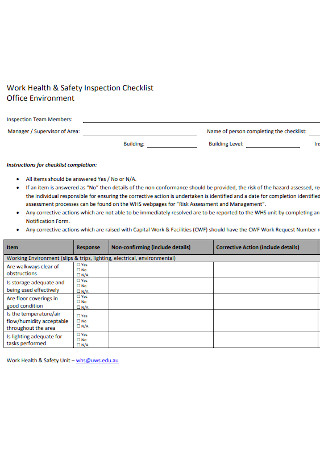

Office Environment Safety Inspection Checklist

download now -

Yards Safety Inspection Checklist

download now -

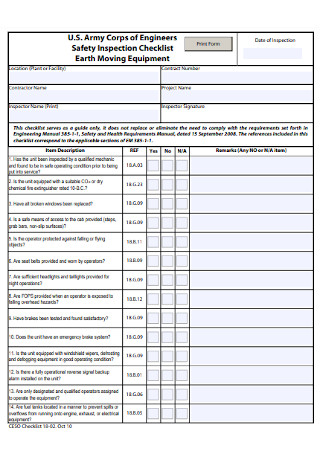

Engineers Safety Inspection Checklist

download now -

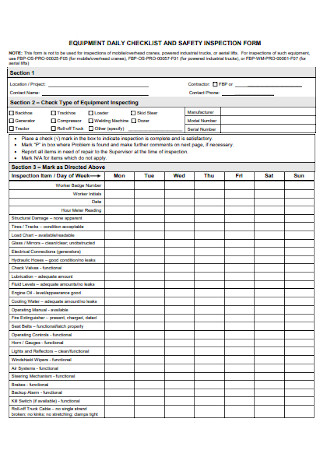

Safety Inspection Checklist Form

download now -

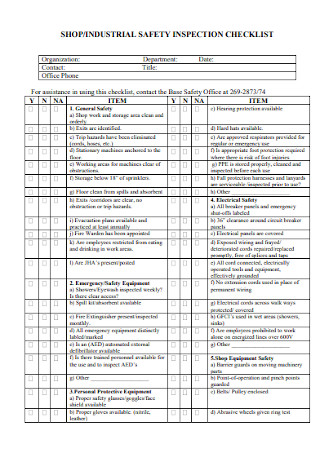

Industrial Safety Inspection Checklist

download now -

Work Safety Inspection Checklist

download now -

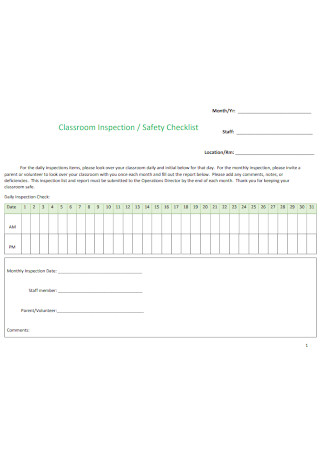

Classroom Safety Inspection Checklist

download now -

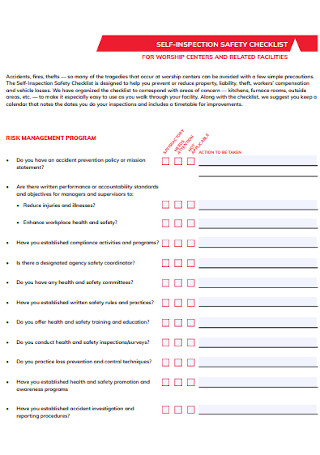

Self-Safety Inspection Checklist

download now -

Standard Safety Inspection Checklist

download now -

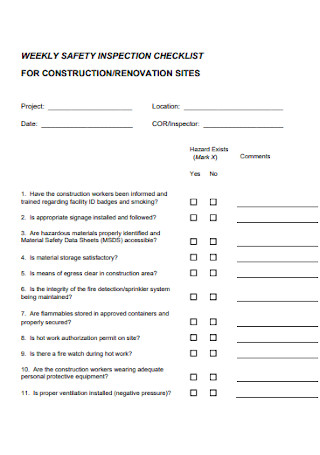

Weekly Safety Inspection Checklist

download now -

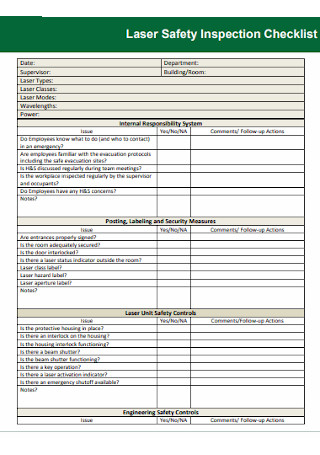

Laser Safety Inspection Checklist

download now -

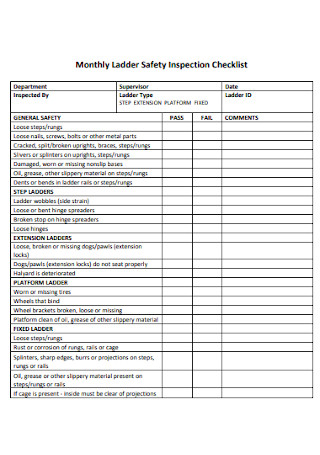

Monthly Ladder Safety Inspection Checklist

download now -

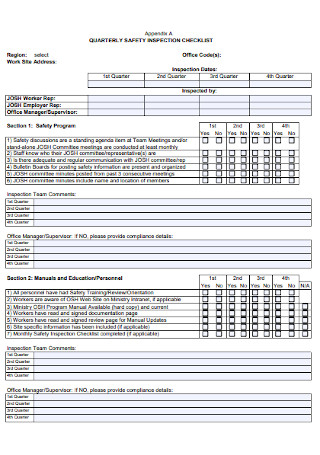

Quaterly Safety Inspection Checklist

download now -

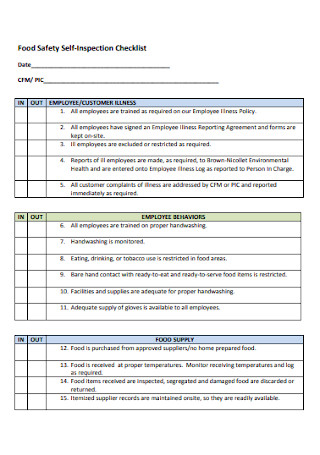

Food Safety Self-Inspection Checklist

download now -

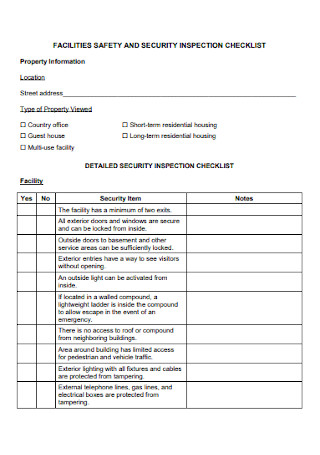

Safety Security Inspection Checklist

download now -

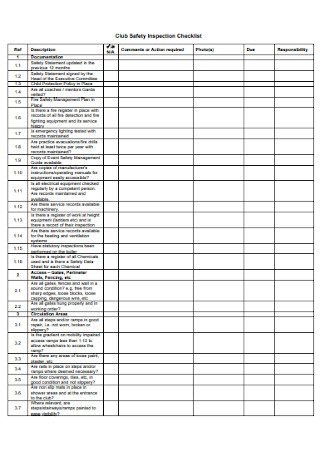

Club Safety Inspection Checklist

download now -

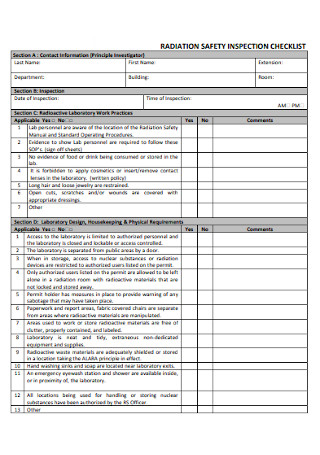

Radiation Safety Inspection Checklist

download now -

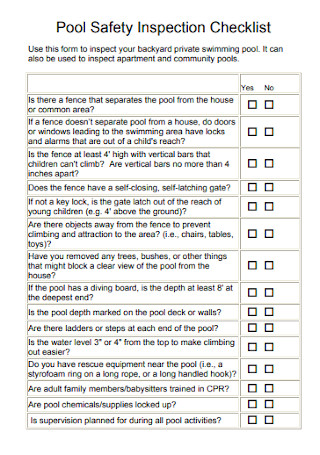

Pool Safety Inspection Checklist

download now

FREE Safety Inspection Checklist s to Download

50+ Sample Safety Inspection Checklists

Safety Inspection Checklist: What Is It?

Why Are Safety Inspection Checklists Important?

The Basic Parts of a Safety Inspection Checklist

How to Create a Top-Notch Safety Inspection Checklist

FAQs

What are the common concerns for safety inspections in the workplace?

How common are workplace fatalities?

What are the main types of inspections?

Safety Inspection Checklist: What Is It?

A safety inspection checklist is what every professional safety officer uses to perform appropriate safety examinations in a building, car, equipment, or any subject. Like an office inspection checklist, it contains the criteria of what to inspect. However, safety inspection checklists are more focused on the criteria and instructions related to safety or health matters. Thus, safety inspection checklists help you determine potential hazards that could harm or cause injuries onsite.

According to Statista’s research survey, the US continued its movement focusing on workplace safety for the last two decades. In fact, the number of fatal workplace injuries in every 100,000 American employees fell from 4.2 in 2006 down to 3.5 in 2018.

Also, did you know that around 5,333 employees died on the job in 2019? That is according to the Occupational Safety and Health Administration (OSHA).

Why Are Safety Inspection Checklists Important?

You already know what a safety inspection checklist is. But you should also know that it is essential for many possible reasons. And here are some significant examples:

Easy Reference for Safety Inspectors

Safety inspectors won’t have a hard time operating when they just refer to the safety inspection checklist on what to do first until last. The same goes for what criteria they follow the entire time. That is because the checklist involves a set of instructions and detailed criteria. Hence, inspectors prevent forgetting possible areas that need safety inspection because the checklist serves as a project roadmap, meaning it can guide them with the complete steps on how to inspect efficiently.

Flexible for Different Inspection Concerns

Safety inspection applies to different subjects or areas of concern. That explains why there is an electrical safety inspection, occupational health and safety inspection, auto safety inspection, and many other examples. Although safety inspection checklists are commonly used for workplace situations, don’t simply limit their function there. On another note, you can’t just use the same criteria for one concern of safety inspection to all subjects, especially since each subject or area of concern has its own set of intricacies.

Required by Workplace Ordinances Including OSHA

Bear in mind that maintaining safety for different industries is required by many workplace ordinances. And OSHA is one example that really commits to ensuring all occupations have regular safety inspections. In fact, America continued to focus on workplace safety for the last two decades. With that said, fatal workplace injuries from every 100,000 US employees decreased from 4.12 in 2006 down to 3.5 in 2018.

Not Only Identifies but Also Fixes Hazards

Indeed, safety inspections can determine the possible hazards from areas of concern. But it does more than just identify what and where the hazards are. It also aims to provide an improvement plan wherein such hazards would decrease and eventually be gone. At least you can depend on a safety inspection checklist for providing solutions to the problems rather than just knowing if problems exist or not.

The Basic Parts of a Safety Inspection Checklist

Safety inspectors have control over what data to add inside safety inspection checklists. Although there will be differences from one example to another, you can still see some common denominators per checklist. And here are the parts that you often see among standard safety inspection checklists:

How to Create a Top-Notch Safety Inspection Checklist

Building a safety inspection checklist is not that hard, especially when you look at common examples for reference and talk with actual safety inspectors for guidance. In fact, you won’t have a hard time when you observe these five effective steps to make the best safety inspection checklist:

-

Step 1: Get to Know Your Subject and Objectives

Indeed, you are planning to make a safety inspection checklist. But you need to confirm first what it is for until you can determine your objectives and align them to your checklist’s needs. If it is for work, for example, then you would surely follow OSHA’s training program towards workplace safety. Then, you will determine if you need to follow the checklist on a daily, weekly, monthly, or yearly basis. A tip is to observe a full analysis report of your safety inspection’s concern or subject and you will be sure of what to add to the checklist later on.

-

Step 2: Optimize a Sample Safety Inspection Checklist

See those 50+ safety inspection checklist templates enlisted above this article? Choose your preferred sample template to optimize so you need not make a checklist from the very beginning. Just work on a template to customize and fill its content according to your preferences. Also, you can opt for many sample templates such as a free workplace safety inspection checklist template, simple workplace inspection checklist template, vehicle safety inspection checklist template, and many more business checklists to select from.

-

Step 3: Lay Out the Standard Safety Inspection Checklist’s Elements

Remember the title, purpose, down to the remarks? Be sure that your safety inspection checklist is complete with its standard elements as they slowly complete your checklist. However, there is enough room to add more elements that you think would benefit the checklist. Also, you can get rid of unnecessary elements from the standard examples. You can even follow the format of a workplace inspection report, daily inspection report, audit report, daily safety checklist, and internal audit checklist. Go for the format and content that works according to your subject and objectives.

-

Step 4: Keep It Easy to Follow

Every safety inspection checklist must be easy to follow. Inspecting is challenging already as it is crucial for safety and health reasons. So don’t make the checklist even more difficult. You can keep it simple by using the appropriate graphic organizers as not every checklist should be in table form. You can also go for graphs. And inserting simple instructions as a reminder on how to work on the checklist will help make it easier. Most importantly, use words that are brief and specific.

-

Step 5: Conduct and Edit the Checklist Regularly

Lastly, commit to the instructions given by the safety inspection checklist every time safety inspections are conducted. And safety examinations and audits better be ongoing since it has to be a regular thing. You won’t be updated about new safety problems and possible changes affecting safety without regular checkups. There is even room to change the data of a checklist from time to time, especially if required. So watch out for alterations on the checklist as well. Thus, make safety assessments and inspections on a daily, weekly, monthly, or annual basis.

FAQs

What are the common concerns for safety inspections in the workplace?

Safety inspections for work are generally concerned about the health and safety of employees, emergency equipment, cleanliness of environment, lighting, pathways, and required workplace safety ordinances.

How common are workplace fatalities?

According to OSHA’s 2019 survey, around 5,333 employees died on the job. And that goes to show how much safety inspections should be valued at work and even in other industries.

What are the main types of inspections?

It is known that there are four main types of inspections. These are the pre-approval inspection, routine inspection, compliance follow-up inspection, and the “for cause” inspection.

By working in an office, driving a car, or residing in a building, it is easy to become focused on so many things that safety measures end up forgotten. So no matter what your industry is, you can never go wrong with a safety plan, specifically by using a dependable safety inspection checklist to make sure you won’t overlook potential hazards. In fact, you need not go through the arduous process of making it from scratch because you can simply choose and optimize a sample safety inspection checklist template. Download now!