4+ SAMPLE Manufacturing Audit Checklist

What Is a Manufacturing Audit Checklist?

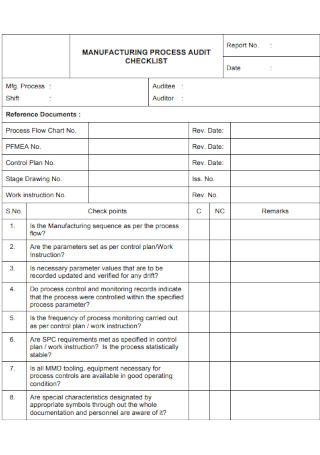

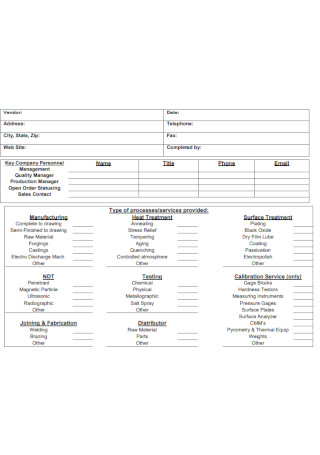

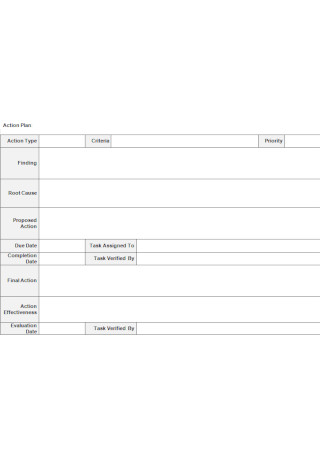

A manufacturing audit checklist is essential for comparing the business practices or production of a supplier’s products and services to the requirements and criteria established by the company or ISO standards. A manufacturing audit checklist includes every item required to conduct an audit or inspection precisely and efficiently. It systematically examines a company’s or a supplier’s manufacturing processes to determine if they conform to a predetermined set of standards. Typically, the inspection is conducted by a designated auditor. Passing a manufacturing audit assures you and your company that whatever you receive from your manufacturer meets the initial specifications. The document is an invaluable resource for manufacturers who must conduct quality checks to ensure that every production component is of the highest standard. It improves the company’s products and services, leading to higher production quality. According to UN statistics, China is the world’s manufacturing powerhouse. Additionally, it accounts for nearly 30% of the nation’s economic output.

Benefits of Audits

If your organization must undergo an audit due to industry regulations or because potential investors or other stakeholders require one, it need not be a stressful or negative experience. Here, we see how an audit is advantageous, as it allows you to enhance your organization. Here, we will emphasize a few of the audit’s most important benefits.

Types of Audit

An audit is a thorough examination or inspection of a business or individual’s financial records and accounting documents. Although most audits are performed on a company’s finances to determine its financial health and success, there are several other types of audits. Understanding what they are and their purposes can assist businesses and professionals in deciding whether to conduct an audit and how it might be advantageous. Different organizations work on different types of audits. A construction company, for instance, may conduct an audit to examine project expenses or contractor costs. The following are various types of audits:

1. Internal Audits

An employee of the company conducts an internal audit and then reports their findings to a committee composed of board members. Internal audits can help a company identify areas for improvement and provide the information necessary to achieve its objectives. While an external audit typically focuses on financial matters, an internal audit’s scope is much broader and can encompass anything that may impact the achievement of company objectives.

2. External Audit

A third party can conduct an external audit without connection to a business, such as the Internal Revenue Service or an independent accountant. Generally accepted auditing standards govern external audits, and determining the accuracy of accounting records is their primary objective. Companies of a specific size are mandated by company law in most jurisdictions to undergo an annual external audit. The need for an external audit is necessitated by the separation of control and ownership in a large organization, in which company leaders appoint directors to manage the business on their behalf. These leaders, including external financial contributors, require assurance that the company’s financial reports are accurate. An external audit assures shareholders that the financial statements are not material misstatements.

3. Forensic Audit

Forensic audits are used if there is a legal concern about how a business handles its money. For example, it is used when embezzlement or fraud is suspected, to figure out tax liability, to look into a spouse during a divorce, or to look into bribery claims, among other things. People do forensic audits with criminology and accounting skills. These people are experts at following the money, keeping track of both natural and fake balance sheets, and looking for mistakes in comprehensive and detailed income or expense reports. If they find differences, it might be the auditor’s job to find out why, or it might be the job of a different financial investigator.

4. Tax Audit

An “audit” is a check, review, verification, or inspection of a document, transaction, account, etc. A tax audit verifies and inspects a taxpayer’s accounts to ensure compliance with the provisions of the Income Tax law. The IRS conducts tax audits to evaluate the accuracy of tax returns and the amounts paid or refunded. Certain businesses must undergo periodic tax audits in some jurisdictions, whereas balloting systems randomly select enterprises for a tax audit in others. There are three primary tax audits conducted by the IRS: mail, office, and field audits.

5. Public Sector Audit

In some jurisdictions, the law mandates that a public sector auditor audit state-owned businesses and organizations. Public sector audits are supervised by the auditor general, an institution that strengthens public sector accountability. During an audit of the public sector, operations and standard procedures of state-owned enterprises are evaluated for compliance with good governance. This audit is more comprehensive than the financial audit of a private organization, which focuses on the accuracy of a company’s financial statements.

6. Information System Audit

Auditing information systems is a part of the auditing process, which is vital to good corporate governance. Even though there isn’t a single, it’s described as “the process of collecting and evaluating evidence to determine if a computer system protects assets, keeps data accurate, helps the organization reach its goals, and uses resources efficiently.” Large businesses can’t run without information systems. As in the past, computer systems don’t just keep track of business transactions; they also run essential business processes. Senior management and business managers worry about information systems in this situation. An IS audit aims to review and give feedback, assurances, and ideas.

7. Social and Environmental Audit

This audit evaluates the social and environmental impact of an organization’s economic activities. Increasing numbers of businesses include environmental and sustainability reports in their annual report, describing the effects of their business activities on the environment and their efforts to reduce their carbon footprint. Environmental audits are conducted to verify the integrity of business environment reports and claims. For instance, an ecological audit confirms a company’s CO2 emissions report.

How to Manufacture a Product

Creating a brand-new, one-of-a-kind product is exciting for retailers and an excellent opportunity for expansion. However, manufacturing can be daunting, especially if you do not know where to begin. This article examines how to manufacture new products for your business, from ideation to mass production for your retail store.

Step 1: Create a Product Idea

You first need to develop a product concept to initiate the manufacturing process. This involves conceiving a new product concept that is novel and appealing to your target market. Lesser standards will result in products that consumers can obtain elsewhere or do not desire. Need and target market are the two most important factors to consider at this stage of product development. If your product satisfies an unmet need and there is a market to sell it to, these are positive indicators of its market success. Consultation with a professional with expertise in product development and manufacturing is one of the best ways to gain insight into the manufacturing process. Before delving deeper, reach out to friends or community pages, or hire a consultant for the invaluable information you can use to evaluate your preparedness.

Step 2: Develop a Prototype

When selecting a manufacturer, you should consider whether you want to work with domestic or international suppliers. Because labor costs are lower in Asian countries like China, India, and Taiwan, it is often cheaper to source labor from abroad. It would be best to have a local resource as a more dependable backup, even with an international supplier. Domestic manufacturers generally have fewer options, and their labor and material costs will be higher. With domestic production, however, there is no language barrier to overcome, and shipping is typically faster and less expensive. Once you have developed a financially viable and market-need-satisfying product concept, it is time to create a prototype. A prototype is a preliminary model of a product from which you and your manufacturers will develop the final version. Your prototype may be physical or digital, but in either case, it must represent your vision for your manufacturers to use as the basis for the products they produce for you.

Step 3: Obtain Estimates from Numerous Sources

It is time to begin requesting bids once you have identified some reputable vendors, evaluated their dependability, and confirmed that they could meet your logistical, pricing, and quantity needs. Before committing to a purchase, manufacturers will provide you with price estimates based on your requirements. To obtain a quotation, you must contact suppliers, typically via email. When establishing a working relationship with a manufacturer, the last thing you want to do is bombard them with emails, so provide all pertinent information upfront.

Step 4: Order Samples

It would be best to limit your top manufacturers based on your quotes, typically based on the price at this stage. I would suggest selecting at least two viable options so that you can compare their final products and make a choice based on quality. After identifying the leading candidates, you can order samples. Samples are test products produced in single or tiny quantities for retailers to evaluate before mass production. A sample is essential for ensuring that your final product is what you want, and it can serve as a point of development between you and your manufacturer as you create the final product. Typically, ordering samples is straightforward. You need only email your manufacturer requesting a sample and include your prototype and instructions; the manufacturer will use this information to create a sample product.

Step 5: Set Your Terms

After deciding on a manufacturer and testing and finalizing your final product, you should anticipate negotiating with your supplier. At this stage, you must discuss and possibly negotiate your payment terms, order quantities, and logistics, among other topics. Some manufacturers require full payment before production when working with new businesses. Consider this when creating a budget for your products. This arrangement, however, should not continue, and you should switch to a more equitable payment split. If a manufacturer refuses to negotiate future payment terms with you, this should raise red flags. A 50/50 split, in which you pay half up front and half when you receive the goods, is a good starting point for negotiations. This divides responsibility equally between you and the supplier.

Step 6: Construct Your Product

Now that everything is in place, you need to wait. There isn’t much to do besides talking to your supplier and waiting for your products to appear. You can now apply for a patent for your product, though it is no longer necessary. By US law, you must file for a patent one year from your product’s sale date. A patent allows the owner to produce and market their invention or design by prohibiting others from doing so. However, since foreign manufacturers are not subject to US laws, patents will not stop them from stealing your designs.

FAQs

What is a QA auditor?

An auditor of quality assurance oversees a company’s production process to ensure compliance with government regulations. In addition, they provide that the appropriate decisions regarding the quality characteristics of products, materials, and equipment are made.

What is meant by dock audit?

A dock audit is a quick, final review of completed goods before they are sealed, boxed, and approved for shipment. It is a visual inspection typically conducted by quality control inspectors on the loading dock of a warehouse just before the product is loaded onto a delivery truck.

What are audit questions?

The primary objective of preliminary audit questions is to understand the organization’s structure, clients, suppliers, and core business operations. During this phase, the executive is typically asked about areas of concern, fraudulent or suspicious activity, and the audit’s primary objective.

Several components, including requirements and product criteria, differ between manufacturers. These specific components are based on the product or service they offer and the items you may wish to manufacture. Therefore, you may need to consider these factors when searching for a potential business partner. Working with external manufacturers presents its unique risks. A reliable manufacturing audit checklist enables you and your organization to evaluate these risks early on to determine whether the venture is worthwhile.