Preventive Maintenance Checklist Samples

-

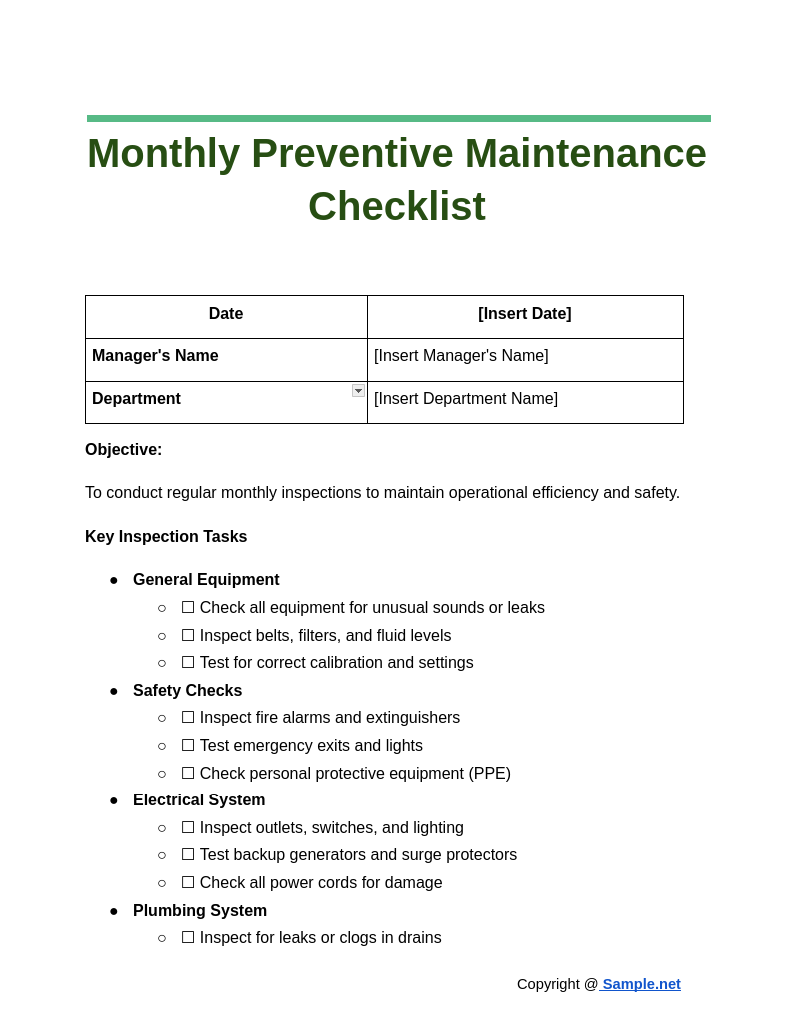

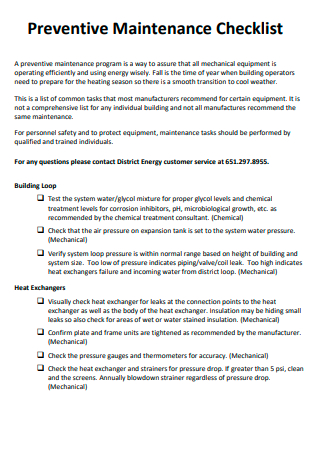

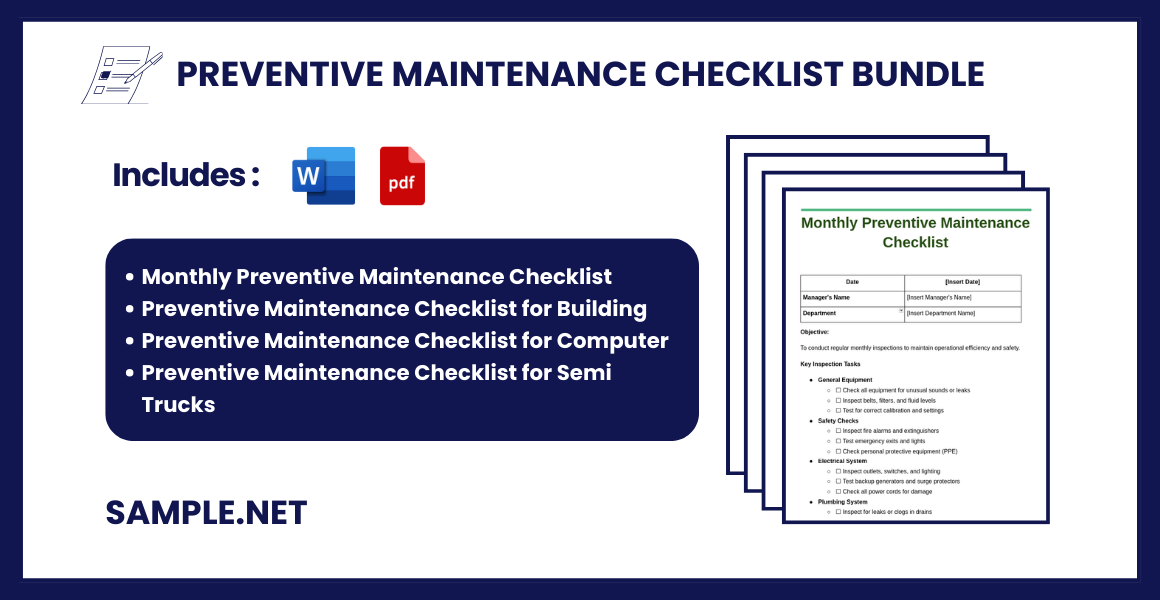

Monthly Preventive Maintenance Checklist

download now -

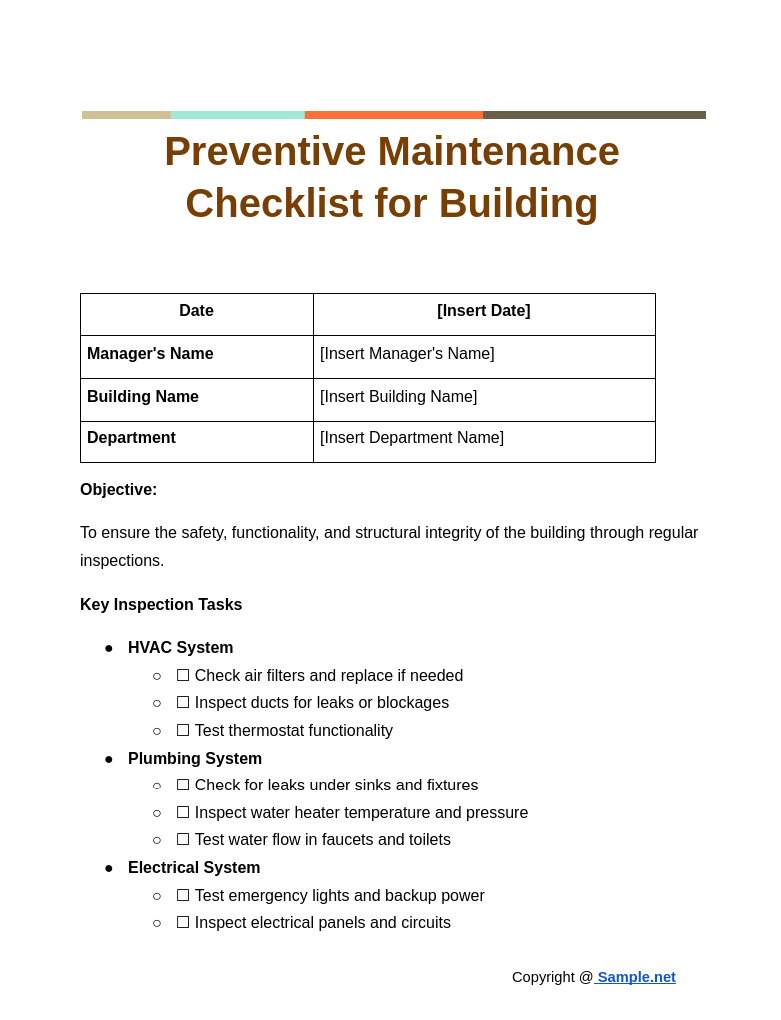

Preventive Maintenance Checklist for Building

download now -

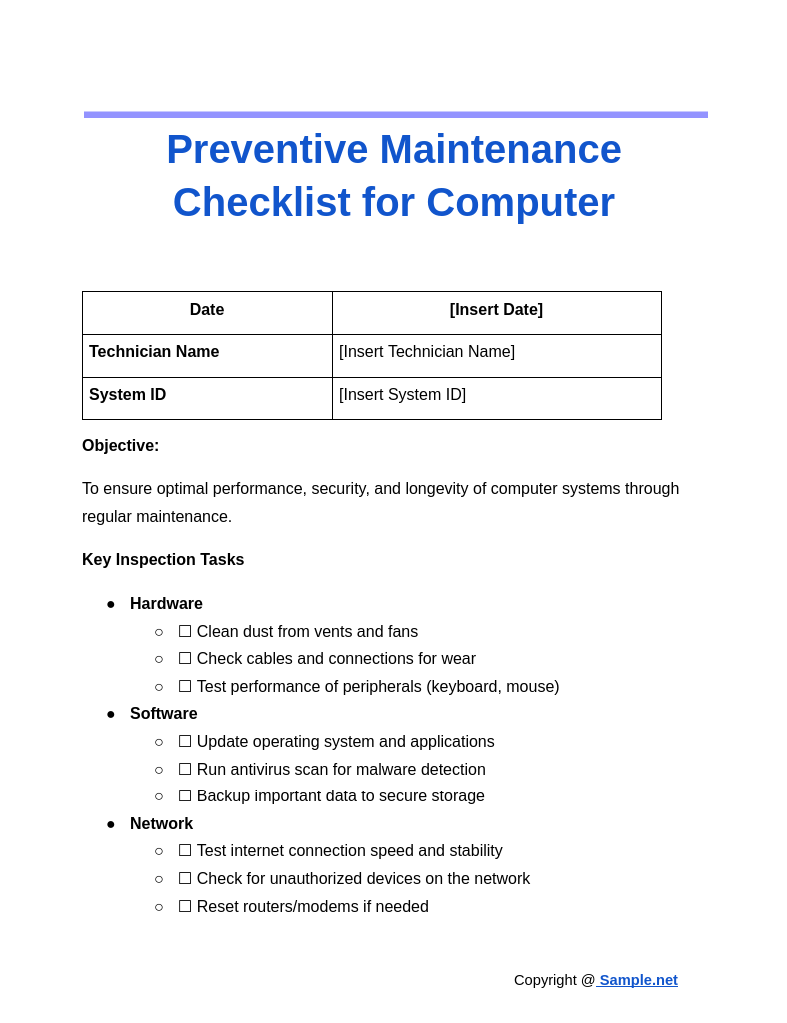

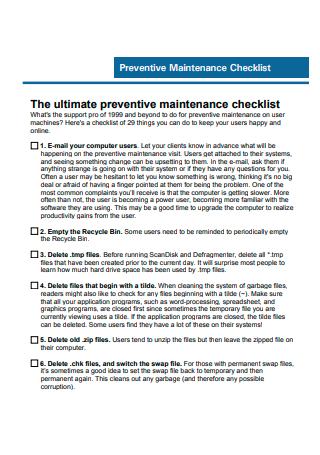

Preventive Maintenance Checklist for Computer

download now -

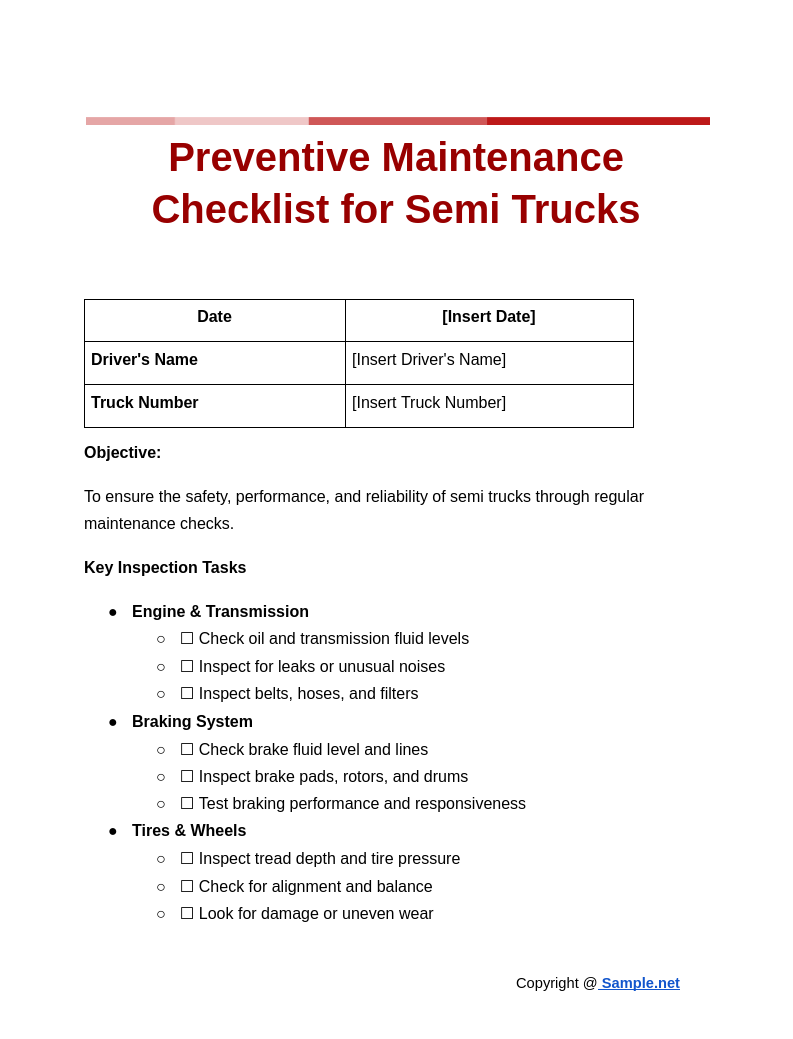

Preventive Maintenance Checklist for Semi Trucks

download now -

Preventive Maintenance Checklist Template

download now -

Basic Preventive Maintenance Checklist

download now -

Owner Preventive Maintenance Checklist

download now -

Preventive Maintenance Checklist Example

download now -

Standard Preventive Maintenance Checklist

download now -

Preventive Maintenance Cleaning Checklist

download now -

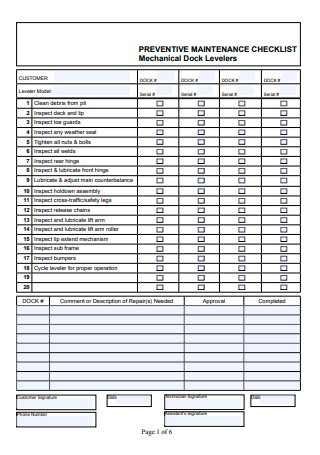

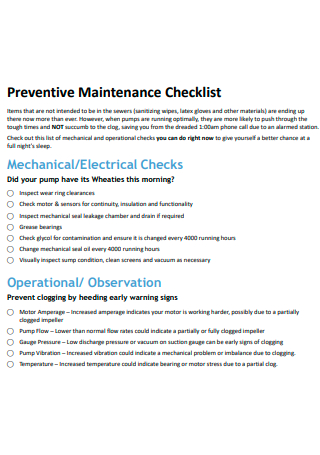

Mechanical Preventive Maintenance Checklist

download now -

Preventive Maintenance Checklist in PDF

download now -

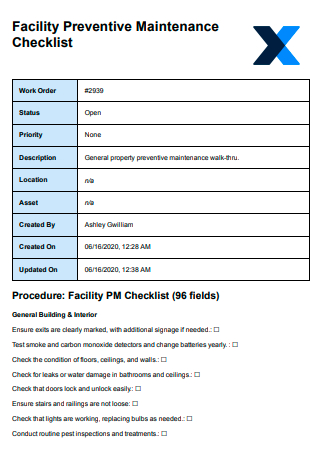

Facility Preventive Maintenance Checklist

download now -

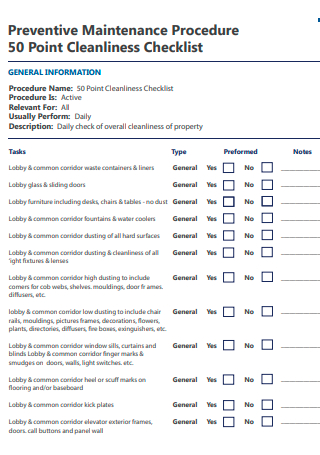

Preventive Maintenance Procedure Cleanliness Checklist

download now -

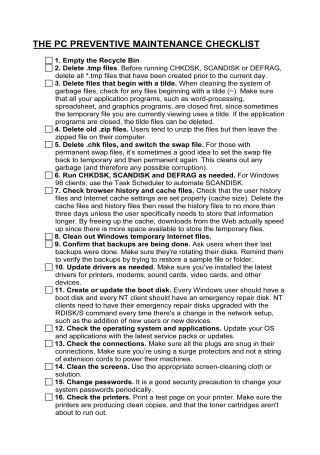

Printable Preventive Maintenance Checklist

download now -

Sample Preventive Maintenance Checklist

download now -

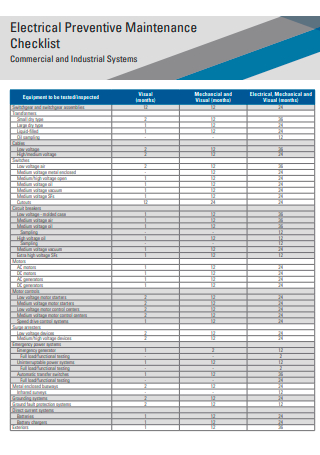

Electrical Preventive Maintenance Checklist

download now -

Preventive Maintenance Checklist Format

download now -

Draft Preventive Maintenance Checklist

download now -

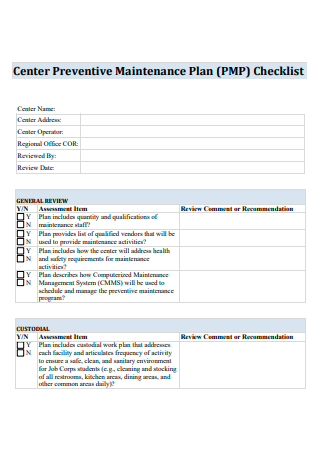

Center Preventive Maintenance Plan Checklist

download now -

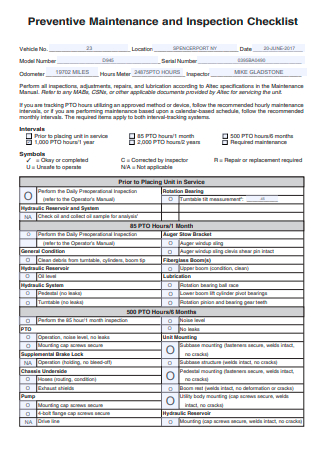

Preventive Maintenance and Inspection Checklist

download now -

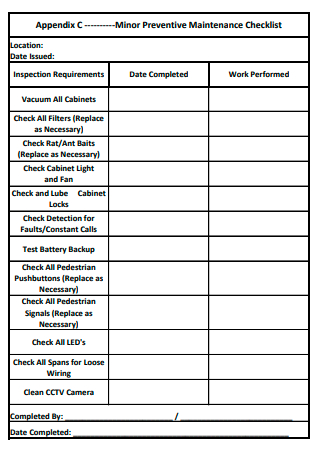

Minor Preventive Maintenance Checklist

download now -

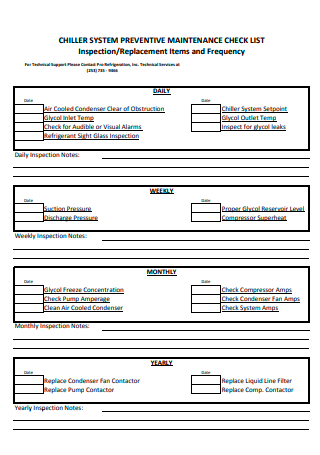

System Preventive Maintenance Checklist

download now -

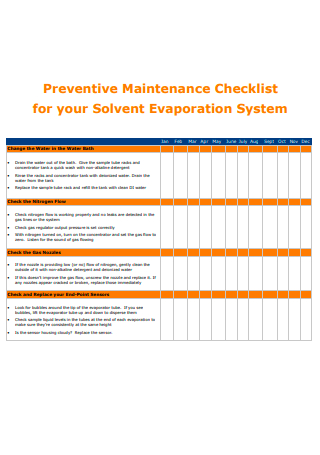

Solvent Evaporation System Preventive Maintenance Checklist

download now -

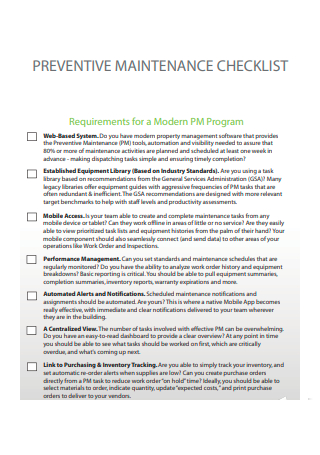

Modern Program Preventive Maintenance Checklist

download now -

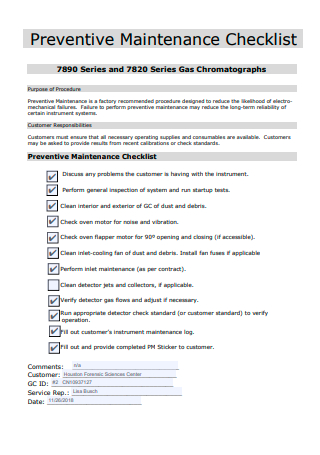

Simple Preventive Maintenance Checklist

download now -

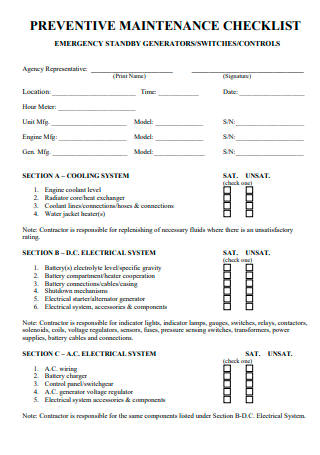

Emergency Preventive Maintenance Checklist

download now -

Preventive Maintenance Checklist in DOC

download now

FREE Preventive Maintenance Checklist s to Download

Preventive Maintenance Checklist Format

Preventive Maintenance Checklist Samples

What is a preventive maintenance checklist?

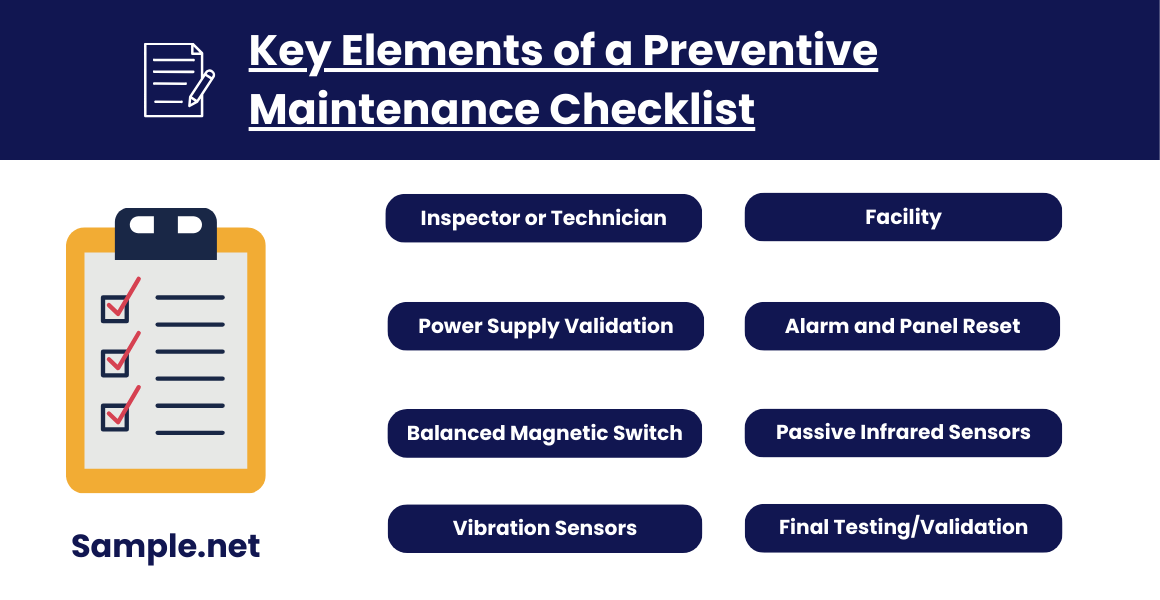

Key Elements of a Preventive Maintenance Checklist

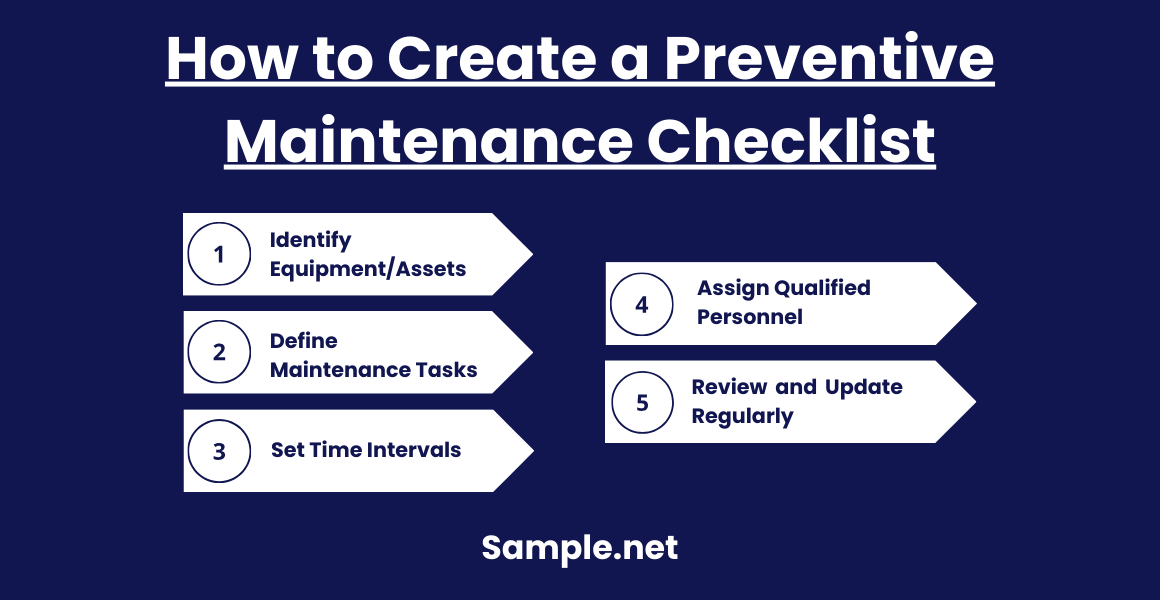

How to Create a Preventive Maintenance Checklist

How important is a preventive maintenance checklist?

What should be recorded in a maintenance report?

What are the five types of maintenance?

What challenges can occur without a preventive maintenance checklist?

How can a preventive maintenance checklist save costs?

Download Preventive Maintenance Checklist Bundle

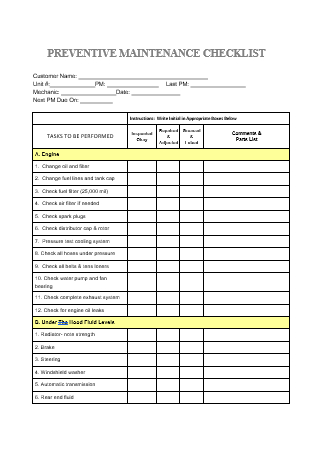

Preventive Maintenance Checklist Format

| Date | [Insert Date] |

|---|---|

| Manager’s Name | [Insert Manager’s Name] |

| Company | [Insert Company Name] |

| Department | [Insert Department Name] |

Objective:

A checklist designed to ensure regular maintenance, identify potential issues, and prevent costly repairs or safety hazards.

[Equipment/System Name] Section

Key Inspection Tasks

1. [Task 1: Task Description]

[Subtask 1.1]: [Detail]

[Subtask 1.2]: [Detail]

2. [Task 2: Task Description]

[Subtask 2.1]: [Detail]

[Subtask 2.2]: [Detail]

3. [Task 3: Task Description]

[Subtask 3.1]: [Detail]

[Subtask 3.2]: [Detail]

General Maintenance Tasks

- Engine & Transmission

- Check oil and fluid levels

- Inspect for leaks or unusual noises

- Cooling System

- Check coolant level

- Inspect hoses and connections

- Braking System

- Check fluid levels and brake pads

- Test braking responsiveness

- Electrical System

- Test battery voltage

- Inspect lights and signals

- Tires & Wheels

- Check tread depth and pressure

- Inspect for alignment issues

- Chassis & Undercarriage

- Check for rust or corrosion

- Inspect for loose or damaged parts

What is a preventive maintenance checklist?

A Preventive Maintenance Checklist is a structured list of tasks and procedures to regularly inspect and maintain equipment, ensuring its proper functioning and reducing the likelihood of unexpected breakdowns. You can also see more on Equipment Maintenance Checklist.

Key Elements of a Preventive Maintenance Checklist

A preventive maintenance checklist has to be holistic and complete in a sense that all important information are being embodied. With that being said, this checklist has key elements that are really needed for inspectors to be able to do their job well, and comply with the goal of not overlooking any bullet point containing vital equipment or devices that ultimately need to be checked up on. There are also parts of the preventive maintenance checklist that are needed in order for it to become a legitimate and credible document, which is why the following pieces of information are integral in making one, or in modifying a sample checklist in order to truly tailor-fit it into the format that is required by your company. These are the key elements of a preventive maintenance checklist.

How to Create a Preventive Maintenance Checklist

1. Identify Equipment/Assets

- Start by listing all equipment and assets requiring maintenance.

- Include machinery, tools, safety equipment, and facility systems.

- Assess maintenance needs and frequency based on manufacturer guidelines.

2. Define Maintenance Tasks

- Specify tasks for each asset, such as inspection, cleaning, lubrication, or part replacement.

- Use manufacturer manuals for accurate task descriptions.

- Organize tasks in sequence, from basic checks to detailed procedures.

3. Set Time Intervals

- Establish maintenance schedules like daily, weekly, monthly, or annually.

- Adjust intervals based on equipment usage, age, and criticality.

- Align scheduling with staff availability for consistent maintenance.

4. Assign Qualified Personnel

- Ensure tasks are assigned to personnel with the right expertise or certification.

- Provide training for staff to execute tasks accurately.

- Review performance to identify any skill gaps or training requirements.

5. Review and Update Regularly

- Periodically evaluate the checklist’s relevance and effectiveness.

- Update tasks as per new safety standards, regulations, or equipment changes.

- Gather feedback from staff to refine and enhance the checklist.

A well-implemented Preventive Maintenance Checklist is essential for maximizing asset performance and reducing unexpected failures. By following a scheduled maintenance routine, businesses can improve safety, efficiency, and equipment lifespan, resulting in fewer costly repairs and increased productivity. You can also see more on Maintenance Schedule Checklist.

How important is a preventive maintenance checklist?

Preventive maintenance checklists guides inspectors into the important things that they should be assessing when conducting an inspection. Having an automatic guideline is strategic for companies to have since checklists help avoid the human error of forgetting. This optimizes the inspection process by making sure that the important things to check are ultimately being assessed by the inspector.

What should be recorded in a maintenance report?

In the report, the inspection should be clear about the problems that he or she has spotted within the workplace regarding specific equipment or devices. The type of equipment should then be specified, its respective department, and an overview of the problem. This prompts supervisors or department heads to hire more advanced technicians to fix a few things about the device itself, if it is still redeemable. You can also see more on Maintenance Checklists.

What are the five types of maintenance?

The five types of maintenance are condition-based, predictive, predetermined, corrective, and preventive. The condition-based maintenance pertains to the inherent need of certain device to constantly be checked on due to sensitivity, while predictive maintenance pertains to the inspection of a device with the underlying assumption of it having a broken part. Predetermined maintenance, on the other hand, pertains to inspection that is required through a calendar of schedules, meaning that it is something that has already been formulated a long time ago, while corrective maintenance refers to the fixing of devices in the aftermath of being broken. Preventive maintenance talks about the preemptive inspection of devices to make sure that there is nothing wrong with them.

What challenges can occur without a preventive maintenance checklist?

Increased downtime, frequent repairs, higher costs, and potential safety hazards.

How can a preventive maintenance checklist save costs?

A preventive maintenance checklist reduces the need for major repairs by addressing issues early. This minimizes costly downtime and prevents complete equipment replacement. Proactive maintenance leads to more predictable budgeting and lower expenses. You can also see more on Apartment Maintenance Checklist.