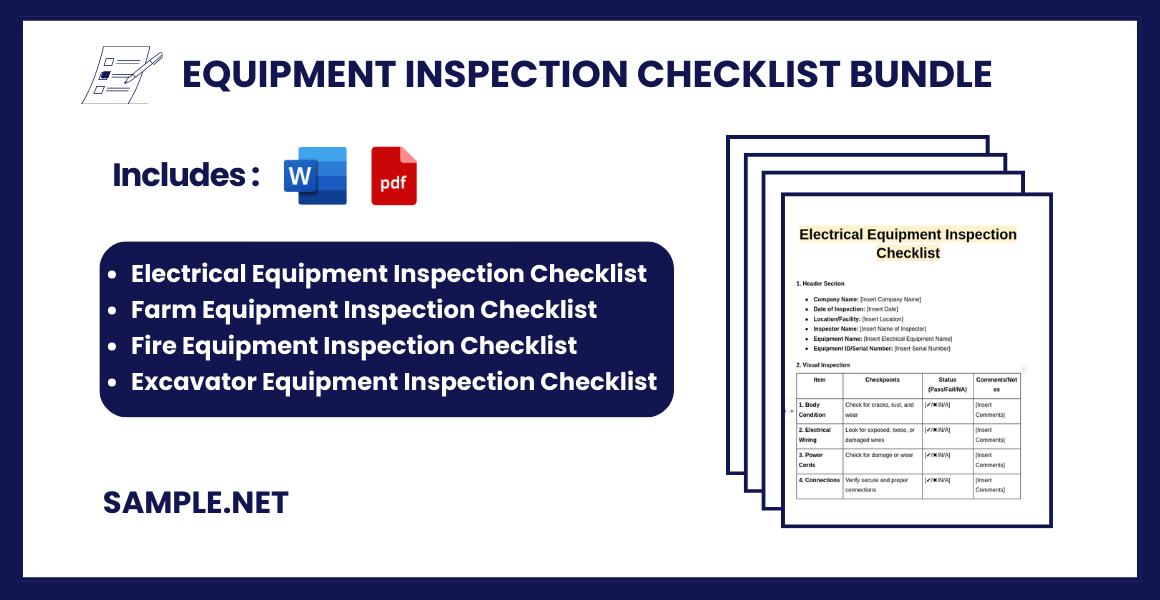

Equipment Inspection Checklist Samples

-

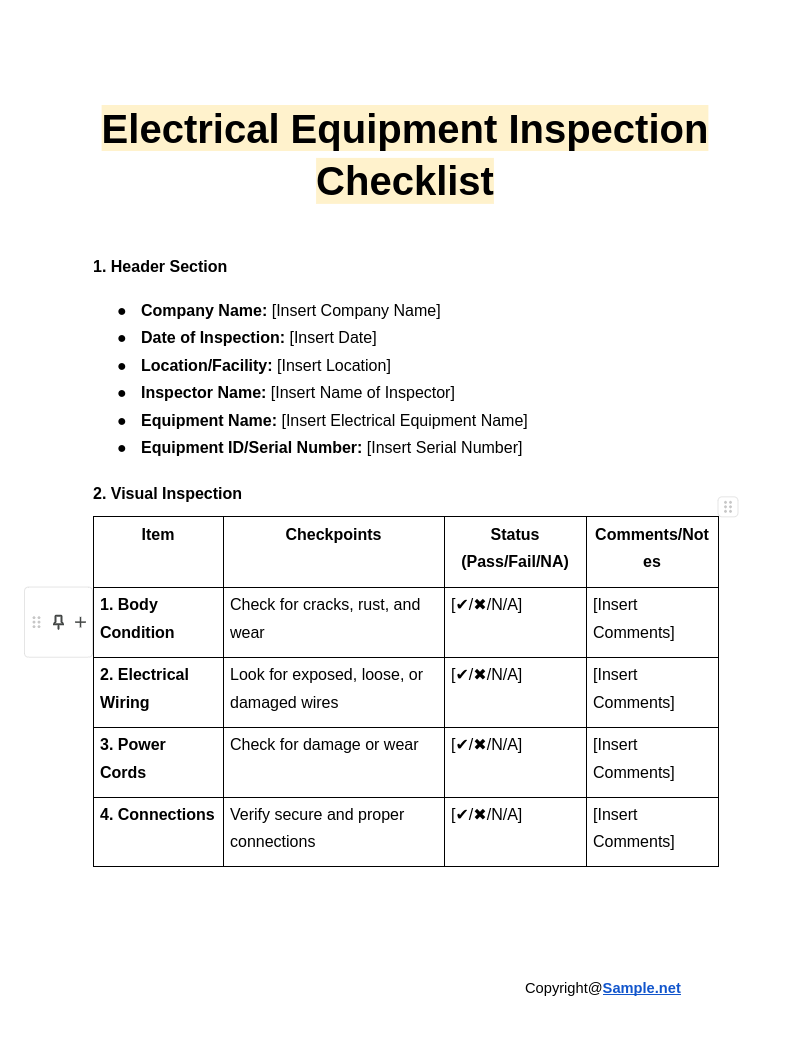

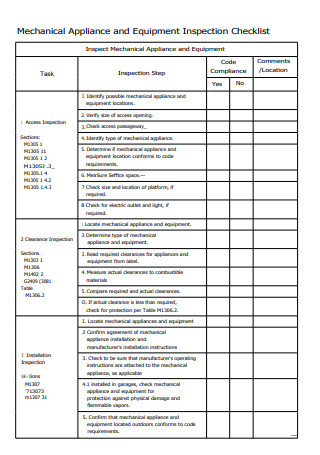

Electrical Equipment Inspection Checklist

download now -

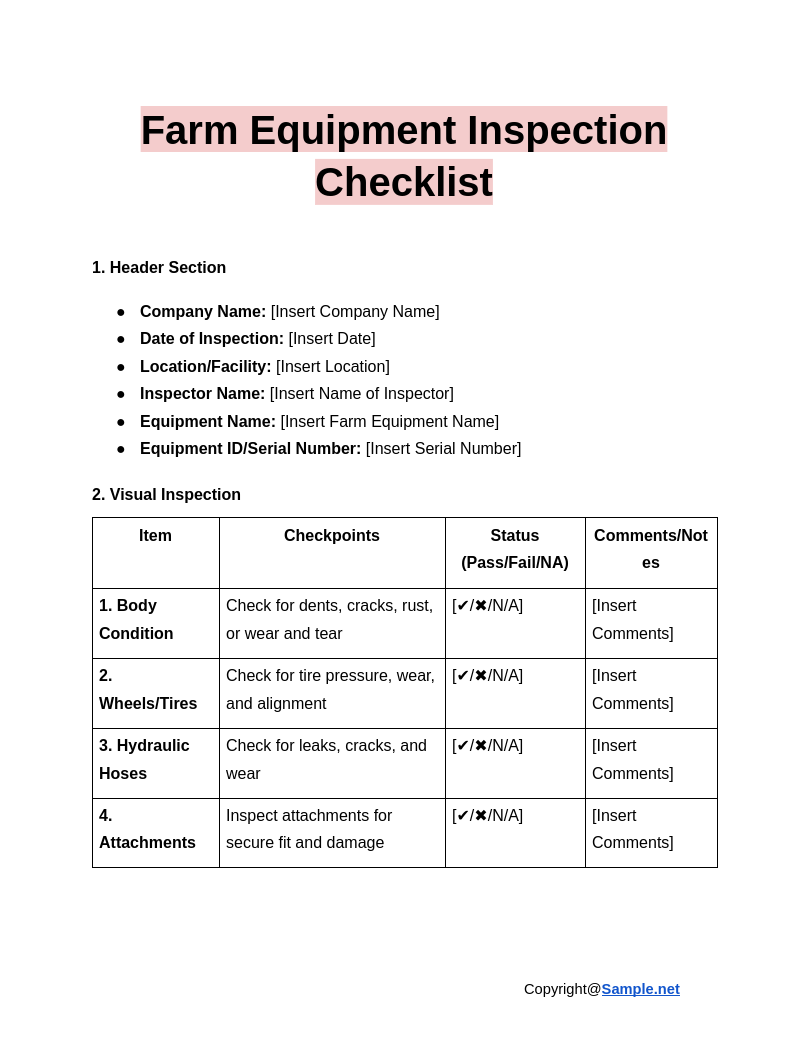

Farm Equipment Inspection Checklist

download now -

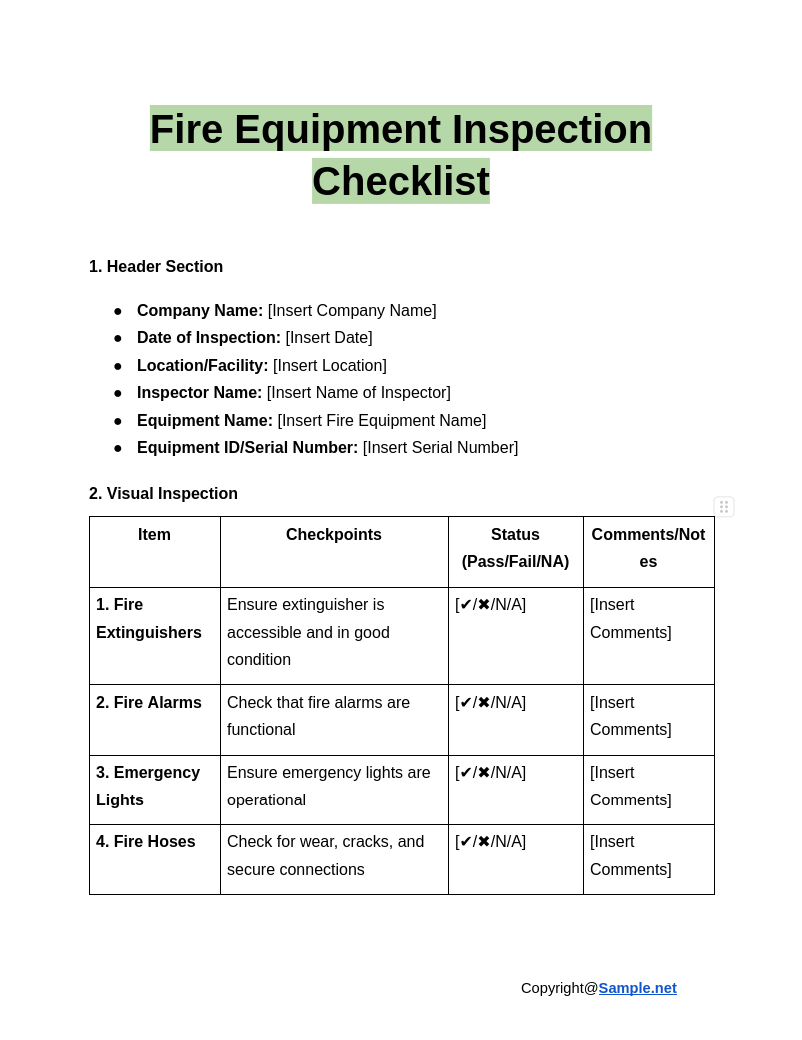

Fire Equipment Inspection Checklist

download now -

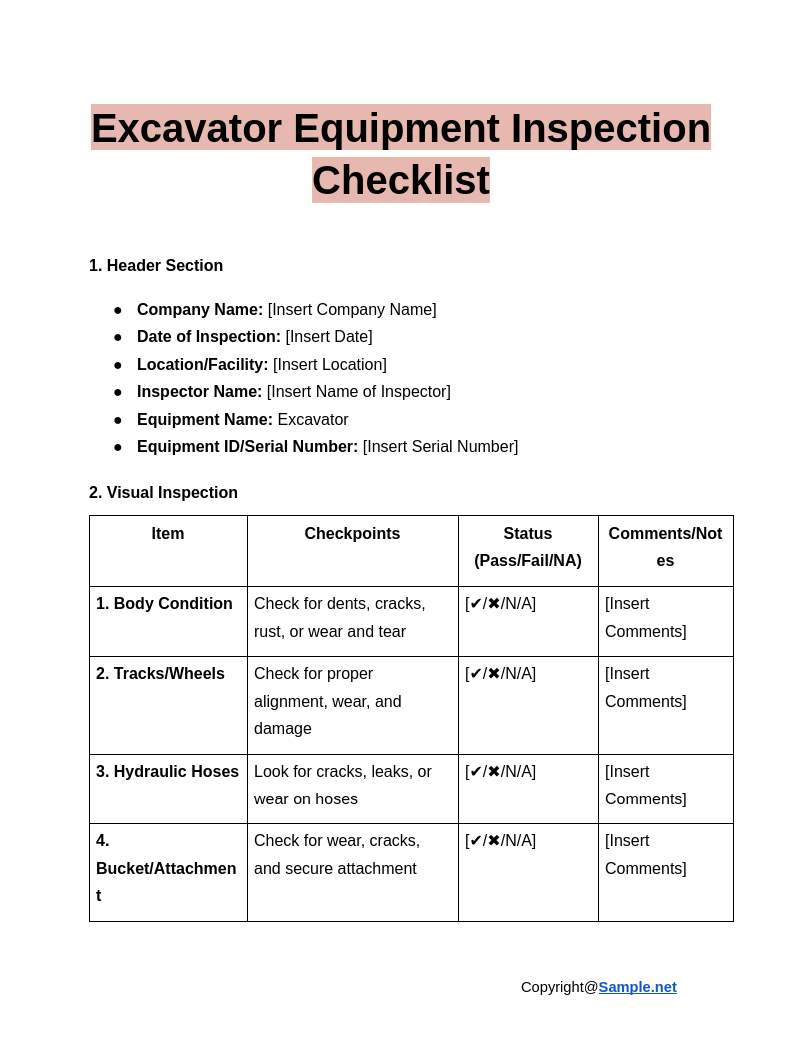

Excavator Equipment Inspection Checklist

download now -

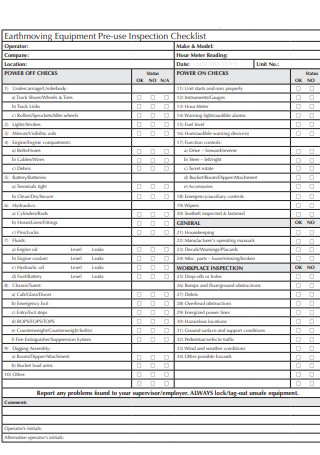

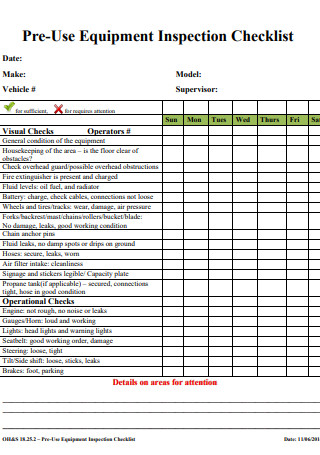

Earthmoving Equipment Pre-use Inspection Checklist

download now -

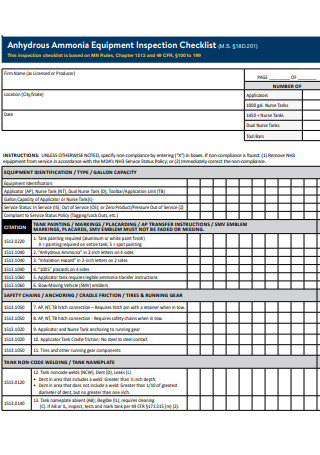

Printable Anhydrous Ammonia Equipment Inspection Checklist

download now -

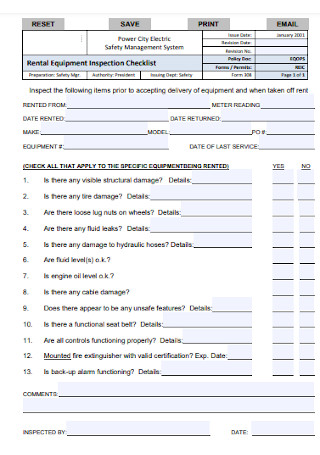

Rental Preventive Maintenance Equipment Inspection Checklist

download now -

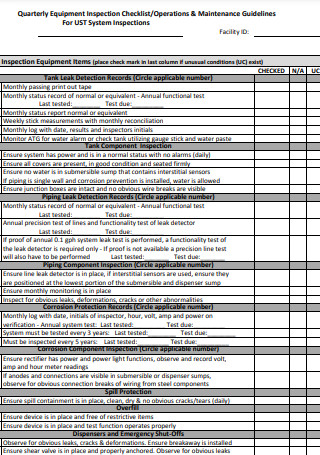

Quarterly Equipment Inspection Checklist

download now -

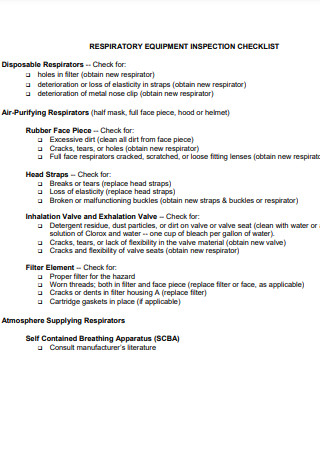

Respiratory Weekly Equipment Inspection Checklist

download now -

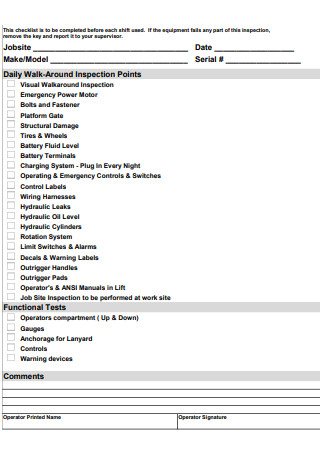

Mobile Equipment Vehicle Inspection Checklist

download now -

Construction Equipment Inspection Checklist

download now -

Sample Equipment Cleaning Inspection Checklist

download now -

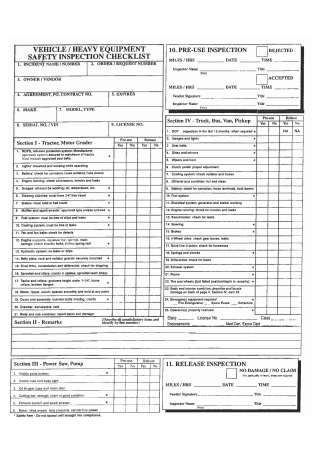

Heavy Equipment Work Inspection Checklist

download now -

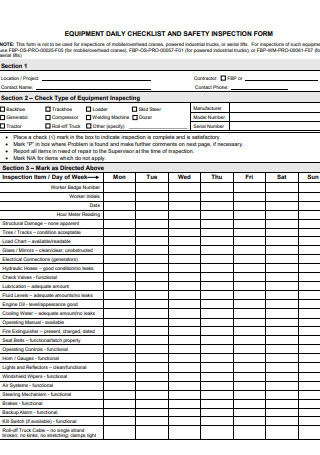

Restaurant Equipment Daily Checklist And Safety Inspection Form

download now -

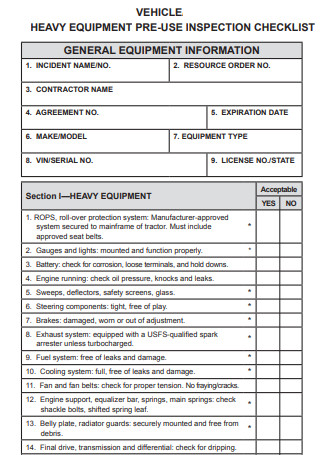

Tractor Vehicle Equipment Pre-Use Inspection Checklist

download now -

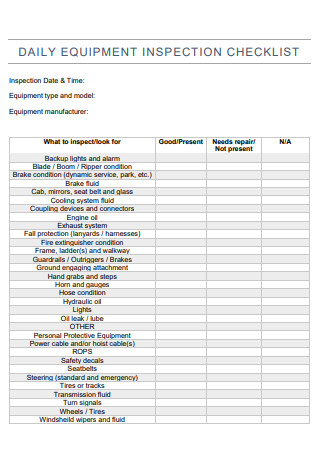

Daily Generic Equipment Inspection Checklist

download now -

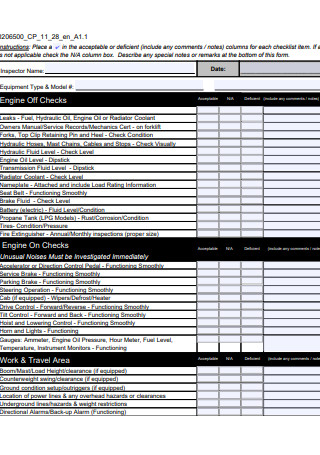

Equipment Condition Inspection Checklist

download now -

Personal Protective Equipment Inspection Checklist

download now -

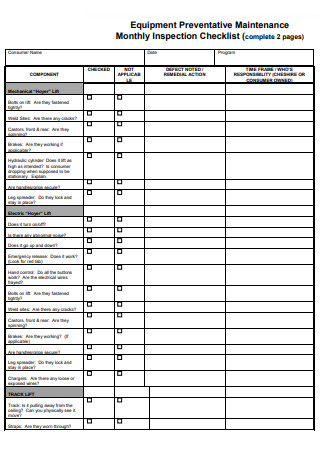

Equipment Preventative Maintenance Monthly Inspection Checklist

download now -

Project Equipment Inspection Checklist

download now -

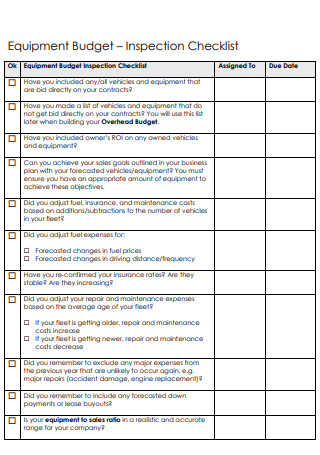

Equipment Budget Inspection Checklist

download now -

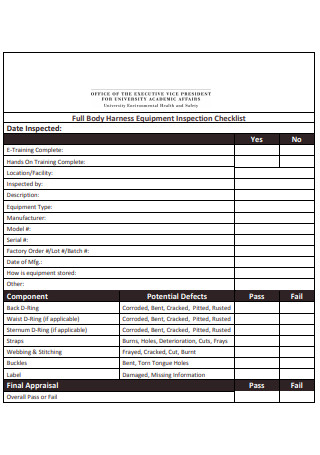

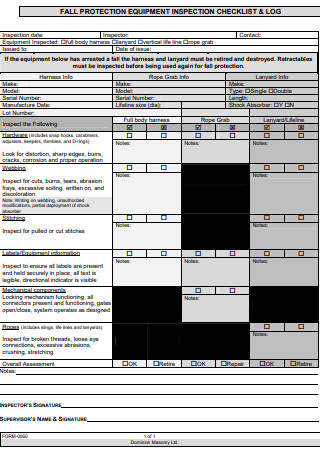

Fall Protection Equipment Inspection Checklist

download now -

Patient Handling Equipment Pre-Use Inspection Checklist

download now -

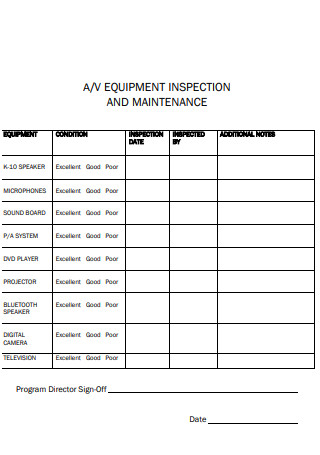

Equipment Inspection and Maintenance Checklist

download now -

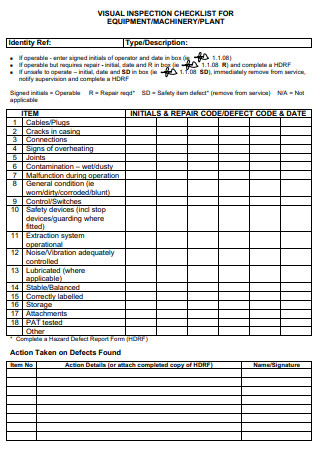

Visual Inspection Checklist for Equipment

download now -

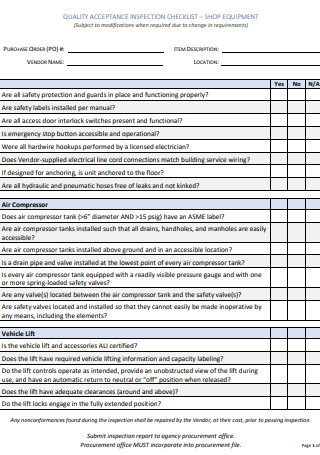

Quality Acceptance Inspection Checklist for Shop Equipment

download now

FREE Equipment Inspection Checklist s to Download

Equipment Inspection Checklist Format

Equipment Inspection Checklist Samples

What is an equipment inspection checklist?

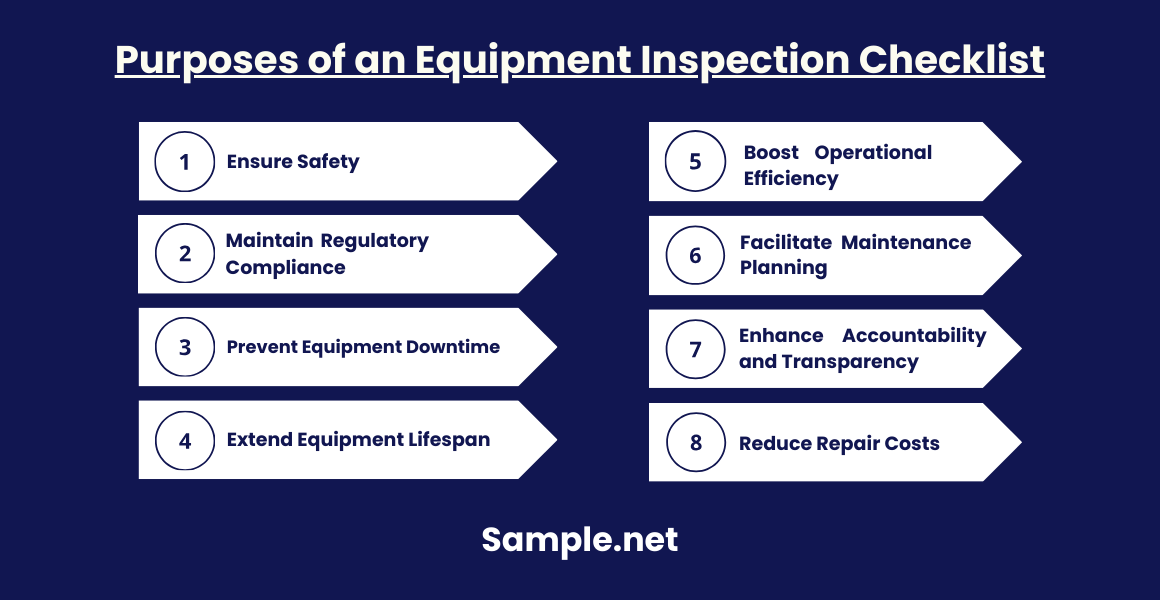

Purposes of an Equipment Inspection Checklist

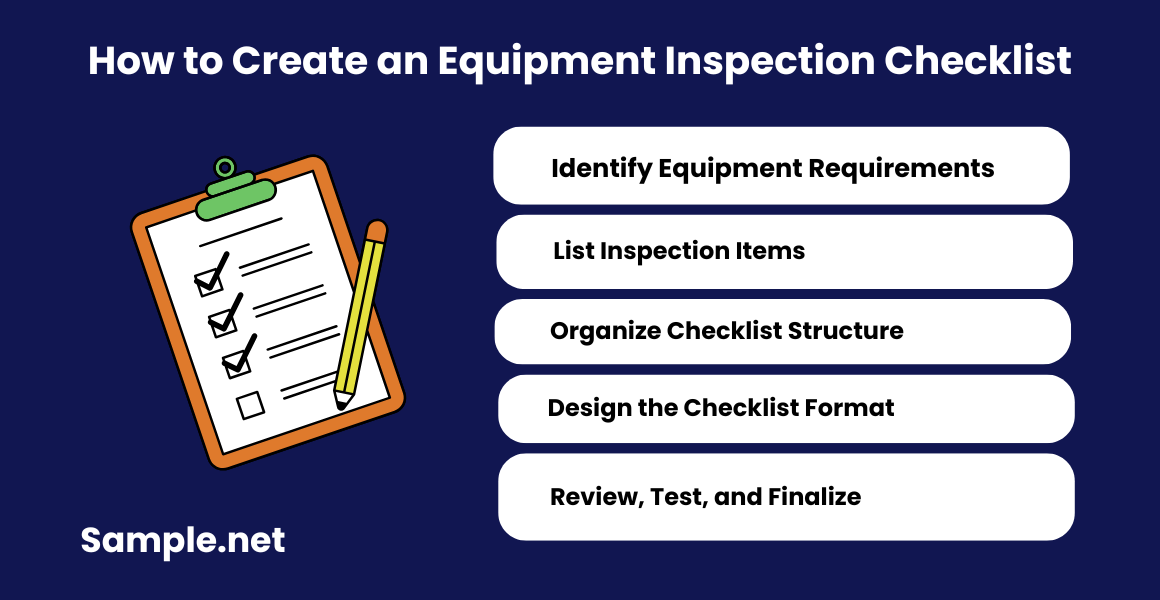

How to Create an Equipment Inspection Checklist

FAQS

How often should equipment be inspected?

Do I need to have an equipment inspection checklist?

What is a full inspection?

How often should inspections be done?

Which industries use Equipment Inspection Checklists?

What should be included in an Equipment Inspection Checklist?

How do I track and document inspection results?

Download Equipment Inspection Checklist Bundle

Equipment Inspection Checklist Format

1. Header Section

- Company Name: [Insert Company Name]

- Date of Inspection: [Insert Date]

- Location/Facility: [Insert Location]

- Inspector Name: [Insert Name of Inspector]

- Equipment Name: [Insert Equipment Name]

- Equipment ID/Serial Number: [Insert Serial Number]

2. General Information

- Equipment Type: [Type of Equipment]

- Manufacturer: [Manufacturer Name]

- Date of Last Inspection: [Insert Last Inspection Date]

- Inspection Frequency: [Daily, Weekly, Monthly, etc.]

3. Visual Inspection

| Item | Checkpoints | Status (Pass/Fail/NA) | Comments/Notes |

|---|---|---|---|

| 1. Cleanliness | Check for dirt, grease, and debris | [✔/✖/N/A] | [Insert Comments] |

| 2. Physical Damage | Look for cracks, rust, or wear and tear | [✔/✖/N/A] | [Insert Comments] |

| 3. Labels & Signage | Ensure safety labels are intact and legible | [✔/✖/N/A] | [Insert Comments] |

| 4. Fluid Leaks | Check for oil, fuel, or other fluid leaks | [✔/✖/N/A] | [Insert Comments] |

| 5. Structural Integrity | Check for loose bolts, joints, and welds | [✔/✖/N/A] | [Insert Comments] |

4. Mechanical and Functional Checks

| Item | Checkpoints | Status (Pass/Fail/NA) | Comments/Notes |

|---|---|---|---|

| 1. Moving Parts | Check for smooth movement and lubrication | [✔/✖/N/A] | [Insert Comments] |

| 2. Controls & Switches | Ensure all controls function properly | [✔/✖/N/A] | [Insert Comments] |

| 3. Emergency Stops | Verify emergency stop functions as intended | [✔/✖/N/A] | [Insert Comments] |

| 4. Safety Guards | Ensure all safety guards are secure and intact | [✔/✖/N/A] | [Insert Comments] |

| 5. Alarms & Indicators | Check if warning alarms and indicator lights work | [✔/✖/N/A] | [Insert Comments] |

5. Electrical Checks

| Item | Checkpoints | Status (Pass/Fail/NA) | Comments/Notes |

|---|---|---|---|

| 1. Electrical Connections | Check for exposed, loose, or damaged wires | [✔/✖/N/A] | [Insert Comments] |

| 2. Power Supply | Ensure power source is stable and operational | [✔/✖/N/A] | [Insert Comments] |

| 3. Battery Condition | Check battery charge and signs of leakage | [✔/✖/N/A] | [Insert Comments] |

| 4. Circuit Breakers | Verify breakers are functioning properly | [✔/✖/N/A] | [Insert Comments] |

| 5. Grounding | Ensure proper grounding of the equipment | [✔/✖/N/A] | [Insert Comments] |

6. Safety Equipment and PPE Check

| Item | Checkpoints | Status (Pass/Fail/NA) | Comments/Notes |

|---|---|---|---|

| 1. Fire Extinguisher | Ensure fire extinguisher is nearby and functional | [✔/✖/N/A] | [Insert Comments] |

| 2. First Aid Kit | Check first aid kit is stocked and accessible | [✔/✖/N/A] | [Insert Comments] |

| 3. PPE Availability | Ensure PPE (gloves, helmets, goggles) is available | [✔/✖/N/A] | [Insert Comments] |

| 4. Emergency Procedures | Ensure emergency procedures are posted and visible | [✔/✖/N/A] | [Insert Comments] |

7. Operational Test

| Task | Checkpoints | Status (Pass/Fail/NA) | Comments/Notes |

|---|---|---|---|

| 1. Power On/Off | Check if equipment powers on and off properly | [✔/✖/N/A] | [Insert Comments] |

| 2. Load Test | Test equipment under load to ensure functionality | [✔/✖/N/A] | [Insert Comments] |

| 3. Performance Test | Check speed, efficiency, and output of equipment | [✔/✖/N/A] | [Insert Comments] |

| 4. Noise & Vibration | Check for unusual noises or excessive vibration | [✔/✖/N/A] | [Insert Comments] |

8. Safety Compliance Check

| Item | Checkpoints | Status (Pass/Fail/NA) | Comments/Notes |

|---|---|---|---|

| 1. Safety Devices | Ensure emergency stops, guards, and sensors are functional | [✔/✖/N/A] | [Insert Comments] |

| 2. Lockout/Tagout | Verify proper Lockout/Tagout procedure is followed | [✔/✖/N/A] | [Insert Comments] |

| 3. Operator Safety | Ensure operator is trained on safety protocols | [✔/✖/N/A] | [Insert Comments] |

9. Documentation and Record Keeping

| Document Type | Description | Status (Attached/Not Attached) | Comments/Notes |

|---|---|---|---|

| 1. Inspection Checklist | Attach a completed checklist for record-keeping | [✔/✖] | [Insert Comments] |

| 2. Equipment Logbook | Update logbook with inspection details | [✔/✖] | [Insert Comments] |

| 3. Photos and Images | Attach images of any issues found during inspection | [✔/✖] | [Insert Comments] |

10. Summary of Findings

- Overall Status of Equipment: [Operational / Requires Repair / Out of Service]

- Critical Issues Identified: [List critical issues]

- Recommended Actions:

- [Action 1: Describe required action]

- [Action 2: Describe required action]

- [Action 3: Describe required action]

11. Inspector’s Declaration

I hereby certify that I have conducted a complete inspection of the equipment listed above and have documented my findings truthfully and accurately.

Inspector’s Name: [Insert Name]

Signature: [Insert Signature]

Date: [Insert Date]

What is an equipment inspection checklist?

An Equipment Inspection Checklist is a structured document used to assess the condition, functionality, and safety of equipment. It provides a step-by-step process for evaluating essential components, ensuring compliance with industry standards and operational efficiency. These checklists are used across various industries, such as manufacturing, construction, healthcare, and logistics, to minimize risks, prevent breakdowns, and maintain peak performance. By documenting inspection results, companies can track maintenance needs, schedule timely repairs, and improve the lifespan of their equipment. You can also see more on Equipment Maintenance Checklist.

Purposes of an Equipment Inspection Checklist

1. Ensure Safety

The primary purpose of an Equipment Inspection Checklist is to maintain the safety of workers and equipment operators. By identifying potential hazards, defects, or malfunctions, it helps prevent accidents, injuries, and damage to equipment. Ensuring safety is essential for reducing liability, maintaining a safe work environment, and complying with workplace safety regulations.

2. Maintain Regulatory Compliance

Many industries have specific safety and operational standards that equipment must meet. An inspection checklist helps businesses adhere to these regulatory requirements. Compliance with OSHA (Occupational Safety and Health Administration) standards and industry-specific guidelines ensures organizations avoid fines, penalties, and legal liabilities. You can also see more on Field Inspection Checklist.

3. Prevent Equipment Downtime

Unexpected equipment breakdowns lead to costly downtime and production delays. Inspection checklists help detect small issues before they turn into major problems. Early identification of wear and tear, loose parts, or failing components allows for timely repairs, minimizing operational disruptions.

4. Extend Equipment Lifespan

Regular inspections keep equipment in good working condition, reducing wear and tear over time. By catching maintenance issues early, businesses can extend the useful life of equipment. This reduces the need for frequent replacements, lowering operational costs and capital expenditures.

5. Boost Operational Efficiency

Well-maintained equipment operates more efficiently, resulting in smoother workflows and higher productivity. An inspection checklist ensures that equipment is always in optimal condition, supporting maximum operational performance. Equipment failures are reduced, leading to more consistent production schedules. You can also see more on Inspection Checklists.

6. Facilitate Maintenance Planning

By recording inspection results, businesses can schedule maintenance activities proactively. Historical data from checklists help track trends, anticipate potential issues, and develop a preventive maintenance schedule. This ensures that maintenance is timely and targeted, rather than reactive.

7. Enhance Accountability and Transparency

Equipment Inspection Checklists create a formal record of inspections, ensuring that all inspections are completed and documented properly. This promotes accountability among employees, supervisors, and safety officers. It also provides evidence of due diligence during audits or legal investigations.

8. Reduce Repair Costs

Detecting issues early during inspections prevents the need for costly emergency repairs. Early intervention allows for smaller, less expensive repairs rather than complete overhauls or part replacements. This proactive approach reduces overall repair and maintenance costs. You can also see more on Safety Inspection Checklists.

How to Create an Equipment Inspection Checklist

Step 1: Identify Equipment Requirements

Start by determining which equipment needs inspection and the specific requirements for each. Review equipment manuals, industry regulations, and safety standards. This helps to outline key areas that require attention during inspections, such as safety features, operational controls, and essential components.

Step 2: List Inspection Items

Create a detailed list of all items and components to be inspected. This can include safety controls, mechanical parts, electronic systems, and cleanliness. Ensure each point is specific and clear to avoid confusion. For example, instead of “check brakes,” specify “check brake responsiveness and wear.” You can also see more on Maintenance Checklists.

Step 3: Organize Checklist Structure

Group similar inspection tasks together for better clarity. Divide the checklist into categories like “Safety Features,” “Mechanical Systems,” “Electrical Systems,” and “General Maintenance.” Use a logical sequence so inspectors can work systematically from start to finish.

Step 4: Design the Checklist Format

Decide on the format for the checklist. It can be paper-based, digital, or part of an inspection app. Include checkboxes, rating scales, and comment sections where inspectors can note observations or defects. Clarity and usability are essential for an effective checklist.

Step 5: Review, Test, and Finalize

Before finalizing, review the checklist with supervisors, inspectors, and operators. Conduct test inspections to identify any missing points or areas that require clarification. Make necessary adjustments, and ensure the checklist aligns with compliance standards. Once complete, distribute it for use. You can also see more on Kitchen Inspection Checklist.

An Equipment Inspection Checklist is a document for maintaining safety, efficiency, and regulatory compliance. It allows organizations to identify potential issues before they become costly repairs, ensuring uninterrupted operations. By following a step-by-step creation process, companies can customize checklists that meet industry standards and suit specific equipment needs. Regular use of these checklists improves equipment lifespan, enhances operational efficiency, and reduces workplace risks. Ultimately, it ensures smooth and secure day-to-day operations.

FAQS

How often should equipment be inspected?

Equipment have different required frequency for inspection. Some of those mentioned above need to be assessed on a daily basis since they are constantly being used by workers like lifting equipment, and are basically tools that hold their life further from danger. Some equipment, however, only require inspection every once, three, or six months. You can also see more on Facility Inspection Checklist.

Do I need to have an equipment inspection checklist?

It is certainly advisable. Not only does it make your job easier, but it also makes sure that the important tools and equipment are regularly checked and remained unforgotten for the workers to feel the comfort and confidence of wearing. Equipment inspection checklists are a form of preventive measure, which is why they are very important.

What is a full inspection?

Full inspection pertains to the assessment of deformities of equipment. This additionally helps in accomplishing safety, consistency, and assurance of quality level of the items by contrasting them and setting up guidelines and determinations. You can also see more on Workplace Inspection Checklist.

How often should inspections be done?

The frequency of inspections depends on the type of equipment. Some may require daily inspections, while others might need weekly, monthly, or pre-operational checks.

Which industries use Equipment Inspection Checklists?

They are widely used in construction, manufacturing, logistics, healthcare, and transportation, where equipment maintenance and safety are essential for daily operations.

What should be included in an Equipment Inspection Checklist?

The checklist should include safety features, operational controls, wear and tear, emergency features, electrical components, and general maintenance. Each point should be specific and actionable.

How do I track and document inspection results?

Tracking can be done using inspection apps or digital forms, allowing easy storage, analysis, and retrieval of inspection records. Documentation helps with audits, compliance, and future maintenance planning. You can also see more on Machine Maintenance Checklist.