3+ SAMPLE Predictive Maintenance Checklist

FREE Predictive Maintenance Checklist s to Download

3+ SAMPLE Predictive Maintenance Checklist

Predictive Maintenance Checklist: What Is It?

Why Are Predictive Maintenance Checklists Important?

The Main Elements of a Standard Predictive Maintenance Checklist

Predictive Maintenance vs Preventive Maintenance

How to Form a Solid Predictive Maintenance Checklist

FAQs

What are the main types of maintenance?

What is a good example of a predictive maintenance checklist?

What is the flow of a predictive maintenance process?

Predictive Maintenance Checklist: What Is It?

A predictive maintenance checklist is simply an organization’s official to-do list or checklist that outlines predictive maintenance tasks and procedures. Remember that in predictive maintenance, you are to monitor and evaluate your company’s assets, from their performance to their overall condition, until the chances of issues and failures at work would be reduced. And the details enlisted in a predictive maintenance checklist will guide whoever conducts maintenance on how to accomplish the said maintenance on an easy-to-follow and step-by-step basis.

Why Are Predictive Maintenance Checklists Important?

Anyone working in any type of business knows the importance of maintenance in general. But why should you specifically opt for a predictive maintenance checklist in the first place? In this section, you will learn the importance of using predictive maintenance checklists.

Detailed Reference of Instructions

Predictive maintenance checklists guide you in terms of the who, what, when, where, why, and how of the whole predictive maintenance process. It not only works as a task checklist that teaches you how to achieve predictive maintenance in a series of steps but it also answers who conducts the maintenance, where to do it, and other sets of details. Nonetheless, you can always refer to the checklist to remind you of the complete details, which is especially helpful for those who easily forget certain instructions.

Caters to Different Assets and Business Types

Predictive maintenance can be applied to different types of assets and businesses. For example, are you maintaining a bus, air conditioner, or perhaps a washing machine? Maintenance may concern a facility maintenance, vehicle maintenance, and even house maintenance. So be sure to know your main purpose of needing a predictive maintenance checklist so that you can align the checklist’s data according to your purpose. Although predictive maintenance covers a vast range of assets, you can’t use the same checklist for every asset; hence, personalize it.

Personalized Instructions and Schedules

Speaking of personalizing, one of the great things about using predictive maintenance checklists is how you can alter the set of instructions and maintenance schedules in the document. For example, you can get rid of expensive maintenance procedures and go for less expensive options instead. Another important decision is whether you want to conduct predictive maintenance as daily maintenance, weekly maintenance, monthly maintenance, or yearly maintenance. Go for options you prefer.

Prepares You for What Could Happen

Predictive maintenance checklists heighten your sense of preparedness when it comes to knowing the possible limits of your assets. Take a brand new manufacturing machine, for example. As you use that daily, you can predict how long it lasts or how long it stays in great condition. With predictive maintenance as part of your maintenance planner, you can assure that the machine won’t reach its worst circumstances early. And it is better to maintain assets so you need not go through expensive repairs or new replacements right away.

Leads to the Benefits of Predictive Maintenance

A predictive maintenance checklist can lead you to the advantages of conducting predictive maintenance. As you follow the steps in the checklist, you are guaranteed for a better machinery performance, more improved asset condition, lesser work downtime, and even higher maintenance efficiency. So regard the checklist as the main strategic plan behind making predictive maintenance happen in your company. Otherwise, failing to maintain your assets means you will constantly be dealing with arduous repairs and high costs in fixing damaged assets.

The Main Elements of a Standard Predictive Maintenance Checklist

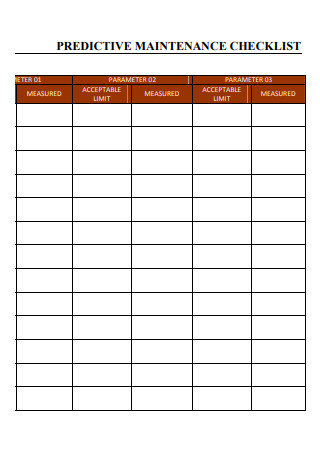

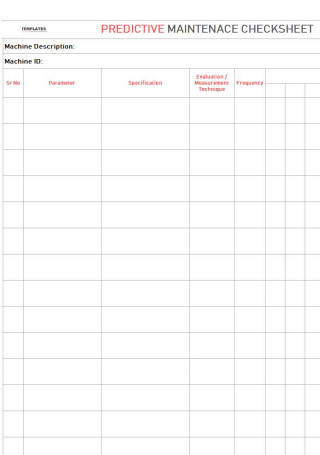

A predictive maintenance checklist looks different per use. However, you can expect a common format towards how most predictive maintenance checklists are made. Generally, predictive maintenance checklists contain the following basic elements:

Predictive Maintenance vs Preventive Maintenance

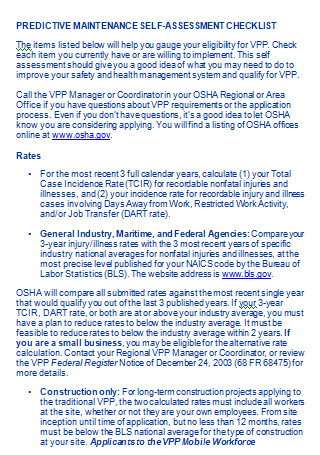

Predictive maintenance is often confused with preventive maintenance. Although they are nearly the same in terms of function and spelling, there is a slight difference between the two. First of all, predictive maintenance happens when you perform maintenance tasks and processes while machines and systems run in the usual operation or production. Meanwhile, preventive maintenance occurs when those systems and machines are not running in operations. So if you are maintaining a machine that is currently shut down, it already involves preventive maintenance.

With predictive maintenance, you can evaluate the performance or condition of an asset directly, even as operations are running. And it helps you predict the possible chances of failures, how to keep production high but with low costs, and more. Oftentimes, artificial intelligence can help you trace upcoming machine breakdowns and prepare for issues that need to be fixed in the long run. Meanwhile, preventive maintenance is often on a monthly schedule of inspection. You basically maintain an asset regularly to ensure it won’t fail you.

How to Form a Solid Predictive Maintenance Checklist

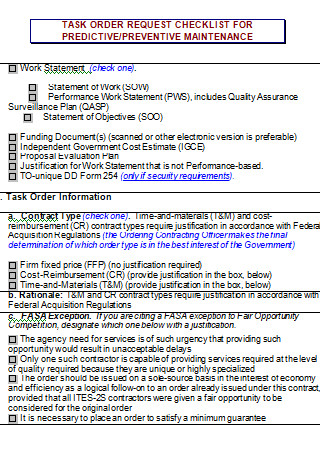

With everything you learned about the meaning, importance, and elements of a predictive maintenance checklist, it is time to apply your knowledge to the test. Make your own predictive maintenance checklist. And you can surely accomplish that successfully when you observe these six essential steps:

-

Step 1: Determine Your Reasons for Maintenance

Why are you planning to make a predictive maintenance checklist? It helps to define your reasons for the need to conduct maintenance practices whether it is for maintaining an office, apartment, vehicle, warehouse, or any asset. With the help of business impact analysis, you can align your reasons to maintain in the appropriate purpose. For example, you might need predictive maintenance to remain a competitive business, to enhance the effectiveness of your equipment, or perhaps, to lessen work downtime. Rest assured, the results you cover in your analysis will be helpful as your reference on how to build the best predictive maintenance checklist later on.

-

Step 2: Use a Sample Predictive Maintenance Checklist Template

You need not work from scratch in terms of making the checklist since predictive maintenance checklist samples are up for grabs, as seen above in this article. You can even customize your preferred template so it will look original. An example is to transform a general predictive maintenance checklist into a building maintenance checklist, equipment maintenance checklist, and so much more. Optimize a sample predictive maintenance checklist template now!

-

Step 3: Add the Checklist’s Standard Elements

You were already introduced to the predictive maintenance checklists elements from the title to the notes. So check if you have every standard element covered already to slowly complete your checklist. Also, you are allowed to add more inclusions that you think are useful for the checklist or purpose of your predictive maintenance. And as much as possible, do not just add one detail to another in a disorganized manner. Keep the presentation of your details smooth so its flow will be readable or understandable.

-

Step 4: Use the Appropriate Parameters or Metrics

Review how you evaluate or monitor your assets using the predictive maintenance checklist. Besides the list of tasks to accomplish, you would likely use certain parameters or metric systems to gauge if an asset is in good condition or not well-maintained. And the appropriate metrics must be used. An example is you use the Likert scale method if you like to investigate the condition of an asset whether it is of excellent quality, good quality, neutral, fair, or needs improvement. Others depend on parameters that let them show the status of the before and after of an asset. So whatever system you want to use, it should be the right system to prevent making a flawed report afterward.

-

Step 5: Apply Simple and Easy-to-Read Instructions

Never forget to judge your checklist’s readability, accuracy, and completeness. For example, are the instructions properly explained, or do they still need to be simplified? Improve the presentation as well wherein anyone who follows the checklist will find the document to be user-friendly. Also, check how precise the details are. Incorrect data may lead to poor maintenance and you would not want that to happen. Hence, constant evaluation of your work should be a standard while making the predictive maintenance checklist.

-

Step 6: Set a Regular Maintenance Schedule

The only way to make sure your assets are regularly maintained is to make the predictive maintenance process a routine. Set the recommended maintenance schedule of your asset from the time and date since maintenance is not just on a one-time basis. It should run continuously and aim for improvements no matter what.

FAQs

What are the main types of maintenance?

There are around five main types of maintenance so predictive maintenance is just one type. The five types of maintenance are predictive, preventive, corrective, predetermined, and condition-based maintenance.

What is a good example of a predictive maintenance checklist?

Here is an acceptable example of a predictive maintenance checklist according to purpose:

General Safety

- Inspect the personal protection equipment (PPE) for any possible damage.

- Store enough items in the first aid kits.

- Restock the wash station items and necessities.

Equipment and Machinery

- Wipe any machine with a cleaning solution.

- Ensure that the machine’s fluid levels are replaced and filtered properly.

- Check the power sources for possible short circuits.

Facilities

- Ensure that there is a gap between equipment to prevent blockage.

- Inspect if safety signs are visible enough.

- Clear any debris from pathways.

- Repair anything that needs repair in the electrical, plumbing, fire, and network system.

- Inspect the building’s structural condition.

- Maintain a solid roof.

- Look for other external hazards.

Vehicles

- Inspect the fuel levels regularly.

- Use the vehicle safety mechanisms if they still work.

- Change any damaged car part.

- Update your car insurance for possible accidents.

What is the flow of a predictive maintenance process?

The predictive maintenance process goes like this: determine the asset to be monitored, figure out the frequency, track the condition, issue a report, set a work order, plan the work date, ensure the availability of the needed labor and parts, conduct a report, and set a closing statement.

Any kind of workplace has its own set of equipment, machines, products, tools, and systems that require regular maintenance to guarantee continuous and productive operations. These assets must be in stellar condition no matter what or the damages and breakdowns caused would lead to heavy repairs, expensive costs, and operation downtime. Thankfully, a strategy map in the form of a predictive maintenance checklist can mitigate these problems and ensure effective maintenance in the workplace. Download a sample predictive maintenance checklist now!