4+ Sample Supplier Audit Checklist

FREE Supplier Audit Checklist s to Download

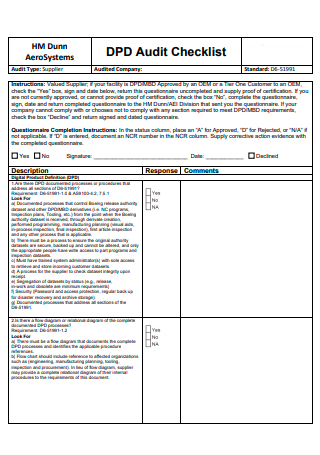

4+ Sample Supplier Audit Checklist

What Is a Supplier Audit Checklist?

What Does an Audit Team Do?

What Are the Benefits of Being Audited?

What Are the Risks of Being Not Audited?

What Are the Benefits of Supplier Audit Checklist?

Why Is it Necessary to Conduct a Process of Supplier Auditing?

Who Conducts the Supplier Audit Annually?

How Often Should Suppliers be Audited?

What Are Types of Supplier Audit?

Tips to Help When Conducting a Supply Audit

Steps in Writing a Supplier Audit Checklist

FAQs

Why are supplier audits done?

Can a customer audit a supplier?

When should supplier audits be used?

What Is a Supplier Audit Checklist?

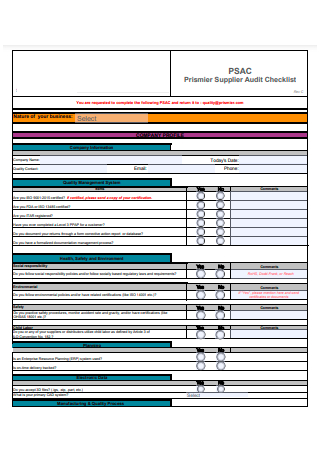

Numerous firms utilize supplier audit checklists to ascertain their vendors’ performance. When you audit your suppliers, you are able to identify areas for improvement. Additionally, you may determine the impact of your vendor’s performance on your business. Supplier audit checklists are a very useful tool in a variety of sectors. You can personalize your list to your industry’s exact requirements and requirements. As a result, different supplier audit checklists will differ in terms of the types of questions included. However, the majority of supplier audit checklists will include questions on a similar subject. This post will offer you with a useful supplier audit checklist for auditing your suppliers and vendors. Additionally, we’ll discuss why doing audits is a prudent company strategy.

Other templates are available on our website, and you can use them whenever you need them. They are as follows: financial audit checklist, buyout agreement, laboratory audit checklist, Labor Contract, position agreement, staffing agreement, business lease proposal, work agreement, payroll audit checklist, tenancy contract, facility inspection checklist, and other similar templates are available.

What Does an Audit Team Do?

From constantly evolving quality control requirements, where quality control is viewed as a need rather than as a luxury, a close and wise examination of the attributes and practices of a supplier has developed. The auditor serves as a neutral third party. In order to complete the assignment, they must discover and verify that the supplier fits all of the specifications and requirements put forth by their supervisor. They will subsequently be asked to give a full report on their findings, as well as specific recommendations and action plans for the organization. The majority of audits are carried out on-site by a team of people, each of whom has a specific area of expertise. On-site activities are arranged so that the relevant supplier resources are present to guarantee that the overall process is speedy and adheres to all applicable regulations and guidelines.

What Are the Benefits of Being Audited?

For a supplier, it allows them to increase efficiencies and their internal processes and standards. It allows the to show other suppliers that they can work within stringent criteria and adhere to them. As well, the supplier will benefit from all past audits done with other vendors- as those learning will be conveyed to them by the auditors.

What Are the Risks of Being Not Audited?

Unless an audit is performed, a supplier runs the danger of having their business opportunities restricted. They also expose themselves to legal actions should their standards or practices not be up to standard. Having to endure multiple independent audits by each of their suppliers will occupy a lot of the vendor’s time and resources. To ensure that the product’s quality is not compromised throughout production, this is a must.

What Are the Benefits of Supplier Audit Checklist?

Carrying out supplier audits can assist organizations in determining whether or not their present supplier’s performance fulfills their company’s operating criteria. The following are four advantages of auditing your suppliers:

1. Maintain Control Over Production Downtime

Improve the efficiency with which resources are reallocated, and track how vendors perform in relation to service level agreements.

2. Profitability Should be Increased

Supplier risks and quality-related expenditures are now managed through this advantage.

3. Ensure the Highest Level of Quality and Compliance

Determine whether or not your supplier’s performance fulfills your requirements by auditing their performance on a regular basis. Identify and document recurrent errors and potential dangers in the process, as well as contingency strategies for dealing with these issues.

4. Improve the Quality of Your Work on a Continuous Basis

Evaluating and monitoring the overall quality of the service and products provided by your suppliers is essential. Learn about your supplier’s performance over time by getting a thorough picture.

Why Is it Necessary to Conduct a Process of Supplier Auditing?

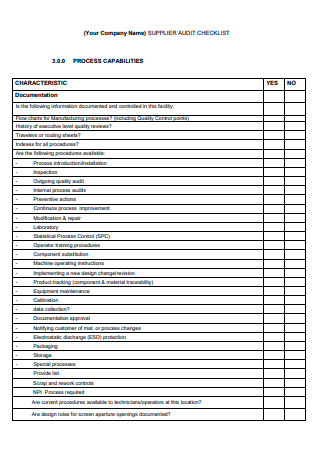

All types of industries and organizations, it is clear that supplier evaluation and vendor audit are regarded vital parts of the evaluation process, regardless of the business or organization. The fact that the entire industry is dependent on the many sorts of materials given for the purpose statement of manufacturing is readily apparent. Furthermore, these raw materials can be transformed into the finished or final product. Furthermore, it becomes vital to ensure that the raw material supplied to the industry is of good and product standard quality and that the materials supplied correspond with industry requirements.

Who Conducts the Supplier Audit Annually?

High-quality products are essential in setting the bar and providing trustworthy final products that will suit the needs of the clients. And with supplier auditing, the company and other large corporations can inspect, assess, and compare a vendor’s and supplier’s quality management process, as well as its practices, goods, and documentation, among other things. The necessity of conducting a supplier audit stems from the greater demand for quality control in the company, which should be regulated more stringently than any other industry on the planet. The primary purpose statement for an organization to conduct audits is to minimize expenses while simultaneously improving quality control. Rather than building identical skills in-house, the auditor and analyst choose to take advantage of the experience of the product and service supplier as a backup option. Every year, experts such as quality engineers and analysts conduct audits within the firm to ensure that all policies and procedures are followed.

How Often Should Suppliers be Audited?

A supplier audit is frequently cited as one of the most effective first stages toward improved supply chain management, since it can help to improve quality and efficiency directly at the point of origin. Supplier audits should be undertaken at least once a year, and as frequently as necessary, depending on the risks associated with a given vendor, or supplier risk profiles, as determined by the organization. Maintaining the quality of a specific ingredient, for example, is critical to the safe creation of your finished product. If the raw material from your supplier has been compromised, resulting in severe consequences for consumers, product quality, and the manufacturing process, you should conduct more frequent audits of that vendor.

What Are Types of Supplier Audit?

When it comes to the manner in which they are carried out, supplier audits may be divided into three broad categories. This will allow for a more thorough plan to ensuring that vendors meet the required standards. The following are examples of these types:

1. Audits that Have Been Announced

This audit entails notifying suppliers ahead of time that an audit would be done. This is agreed upon by both parties prior to the inspection taking place, giving for enough preparation time. Despite the fact that this technique is effective, it can be perceived as lacking authenticity because any faults can be concealed prior to the appointed date.

2. Unannounced Audits Are Conducted

Unannounced audits occur when the date of the inspection is not communicated to the auditors in advance. As a result, this type of inspection is becoming increasingly popular because it provides an insight into the everyday operations and techniques that are used on the job site. Making certain that nothing has been planned in advance (which can occur in announced visits).

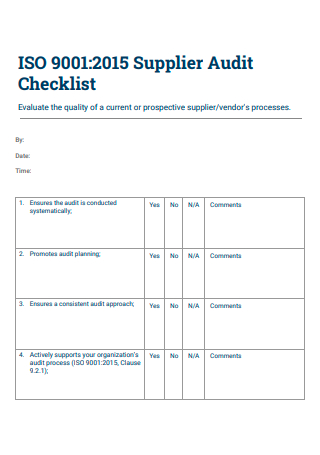

3. Audits Performed on a Computer Desktop

Desktop audits do not necessitate the physical presence of an inspector on the job site. This, on the other hand, is primarily concerned with ensuring that the supplier’s documentation and certifications are up to date. Things like the ISO 9001 certification, which certifies their quality management system to ensure they are up to the required and agreed-upon level set out by the organization partnering with the supplier and governing organizations that oversee the industry, are examples of what they may offer.

Tips to Help When Conducting a Supply Audit

When it comes to organizing a supplier audit. Certain considerations should be made that will aid in the production of a more thorough audit. Among these are the following:

Steps in Writing a Supplier Audit Checklist

A supplier audit is tailored to the organization’s specific requirements; as a result, it may vary across inspections. However, there is a general guideline that is followed. The following sections will walk you through a typical “announced audit” and the processes that ensue:

-

1. Prepare a Questionnaire and Pre-Inspection Meeting Prior to the Audit

This entails the gathering of information about the supplier, as well as the processes and procedures in place. Allowing for the development of a defined purpose and a list of objectives.

-

2. Selection of Teams

From here, a team will be formed that is most appropriate for the audit type. These personnel will be picked based on their knowledge in conducting this type of audit in order to conduct the inspection properly.

-

3. Notification to Supplier of Audit

After a team is picked, the supplier is notified in writing (with several months’ notice) to allow time for preparation. Additionally, written notices include the following information: the audit’s objective, the inspection’s schedule, the auditors’ names and contact information

-

4. Pre-Inspection Consultation

This includes a brief introduction to the auditors and finalizing any scheduling modifications.

-

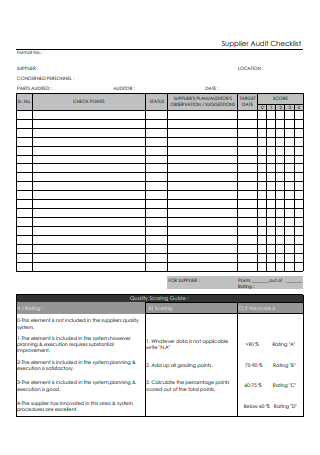

5. Conducting an Audit of Suppliers

Following the adjournment of the meeting, the inspection will begin, during which the auditors will scrutinize every part of the brief using a checklist based on the original aims and objectives. This checklist is in the form of an observation sheet (OS), on which the inspector enters his or her findings.

-

6. Reporting on Audit Findings and Concluding the Audit

Following the completion of the audit, the auditors convene to compare and discuss the findings. Once this is completed, a report is generated based on the inspection with recommendations for improvement or confirmation that they meet the specified requirements. After this is received, the audit can be closed.

As a consequence of the analysis of this information, the overall supplier rating can be determined. Using these evaluations, an organization can identify the best suppliers based on their needs, such as cost or schedule or quality, and then select them.

FAQs

Why are supplier audits done?

When performed correctly, a supplier audit identifies, addresses, and prevents problems with a supplier’s product quality or procedures prior to them spreading, ensuring the provider regularly meets quality expectations.

Can a customer audit a supplier?

The customer (business) frequently contracts for supplier audits (second-party audits), which include delivery expectations, costs, quality criteria, and any other agreed-upon specifications.

When should supplier audits be used?

An organization suggests six-monthly audits and frequent communication if a critical supplier has concerns with product quality or delivery. It is advocated annual audits for critical suppliers who perform effectively.

In today’s globalized market, organizations have a plethora of partners to pick from. This is particularly true with suppliers. As a result, manufacturers and merchants must exercise caution and thoughtfulness when selecting suppliers with whom to partner. Numerous processes can aid in this decision-making process. Supplier audits are one of these. These audits are meticulously planned to ensure suppliers adhere to best practices and perform at the required level, allowing an organization to determine whether a supplier is a good fit for collaboration. Permitting an organization to monitor and audit these vendors on a continuous basis to verify that quality and best practices are adhered to. The purpose of this essay is to educate the reader on what a supplier audit is and how it is conducted. Finally, its significance.