33+ SAMPLE Facility Inspection Checklist

-

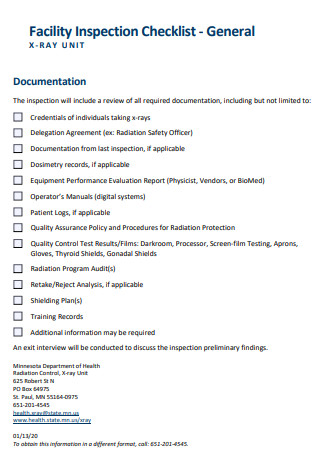

General Facility Inspection Checklist

download now -

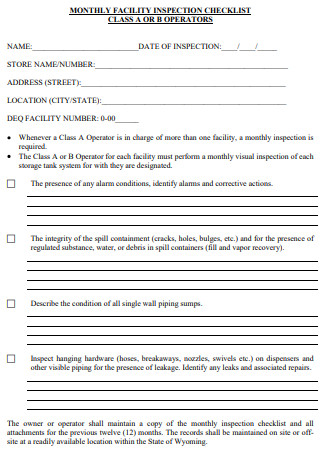

Monthly Facility Inspection Checklist

download now -

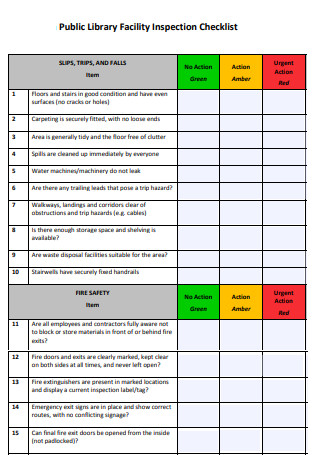

Public Library Facility Inspection Checklist

download now -

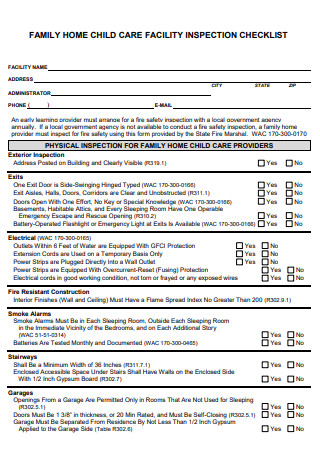

Family Home Child Care Facility Inspection Checklist

download now -

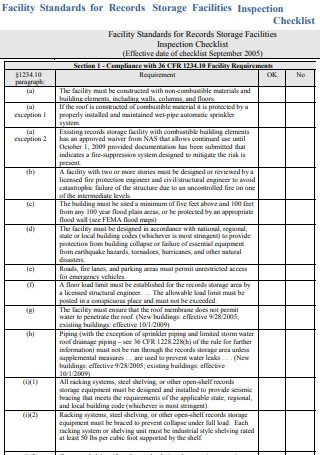

Facility Standards for Records Storage Facility Inspection Checklist

download now -

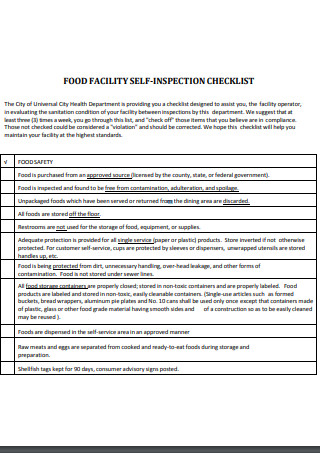

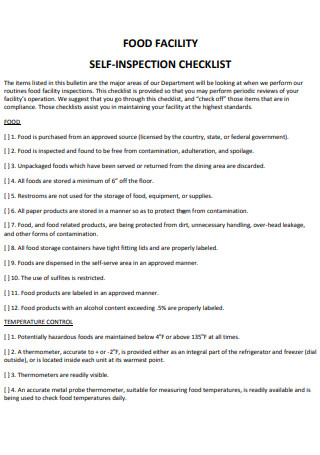

Food Facility Self Inspection Checklist

download now -

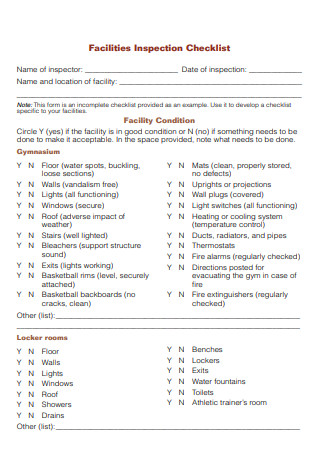

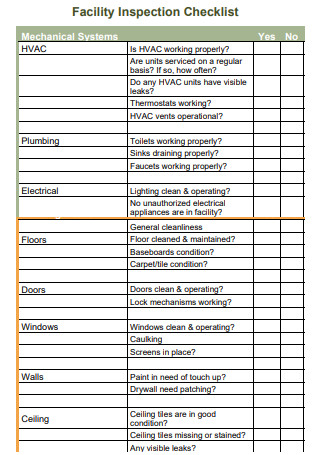

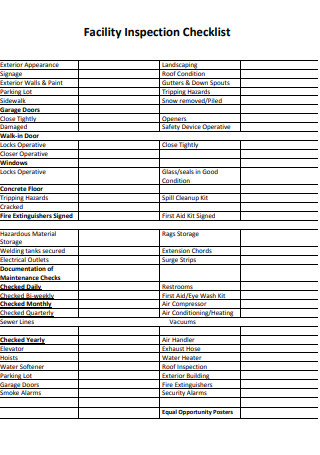

Facility Inspection Checklist

download now -

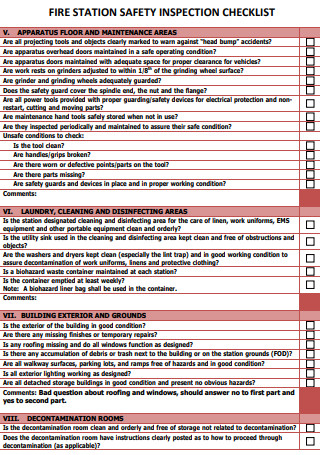

Fire Station Facility Inspection Checklist

download now -

Sample Facility Inspection Checklist

download now -

Sample Food Facility Self Inspection Checklist

download now -

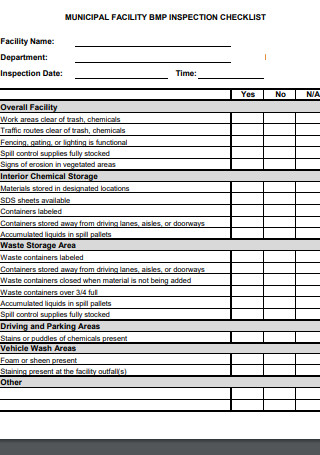

Municipal Facility Inspection Checklist

download now -

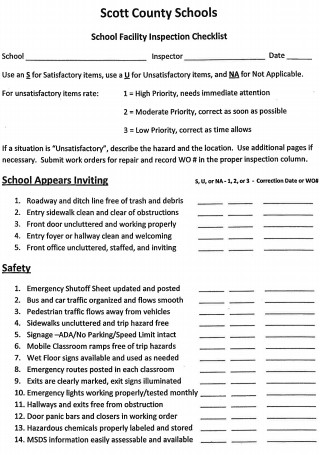

School Facility Inspection Checklist

download now -

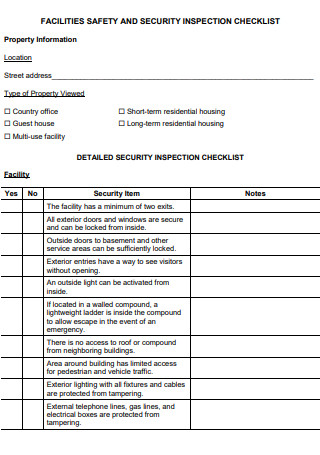

Facility Safety And Security Inspection Checklist

download now -

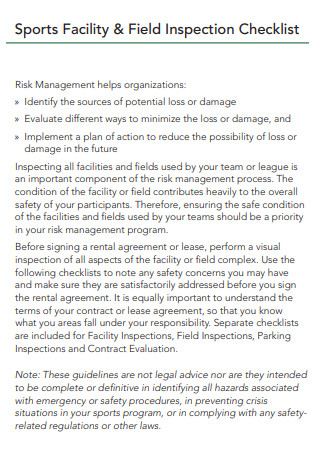

Sports Facility And Field Inspection Checklist

download now -

College Facility Inspection Checklist

download now -

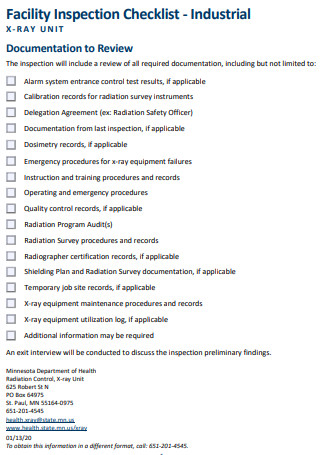

Industrial Facility Inspection Checklist

download now -

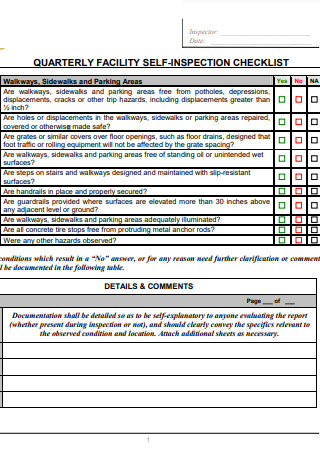

Quaterly Facility Self Inspection Checklist

download now -

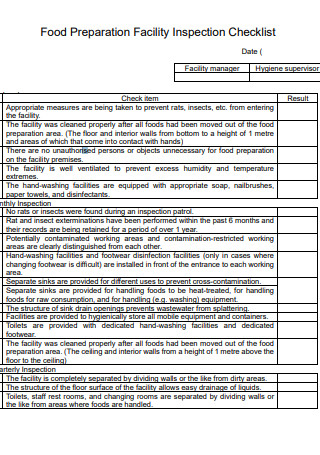

Food Preparation Facility Inspection Checklist

download now -

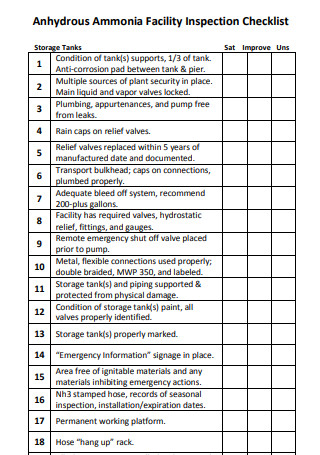

Anhydrous Ammonia Facility Inspection Checklist

download now -

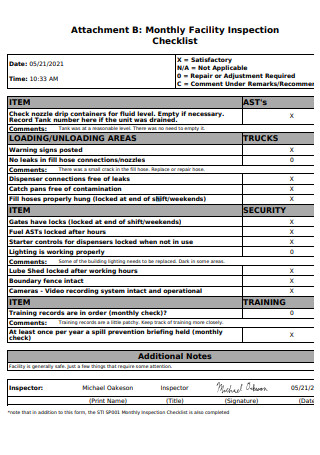

Sample Monthly Facility Inspection Checklist

download now -

Formal Facility Inspection Checklist

download now -

Slip Inspection Checklist of Facility

download now -

Private Stormwater Facility Self Inspection Checklist

download now -

Facility Maintenance Inspection Checklist

download now -

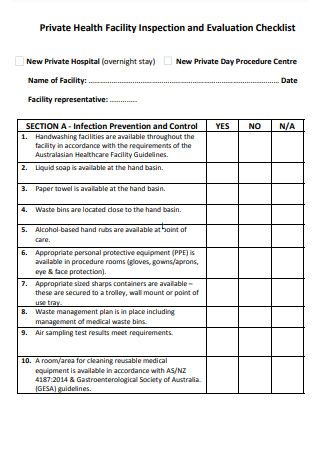

Private Health Facility And Evaluation Inspection Checklist

download now -

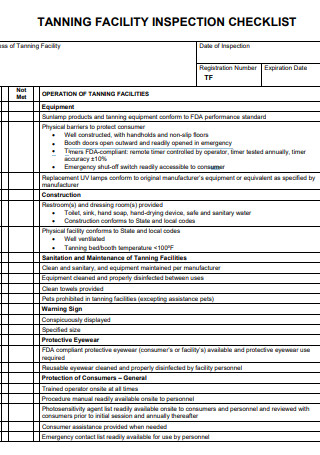

Tanning Facility Inspection Checklist

download now -

Facility Annual Inspection Checklist

download now -

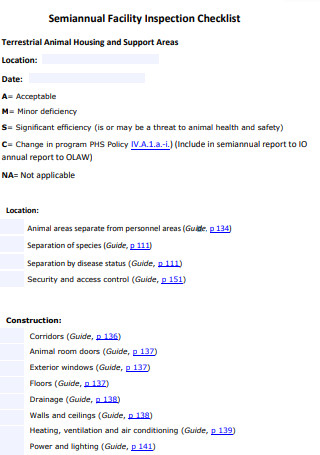

Semi Annual Facility Inspection Checklist

download now -

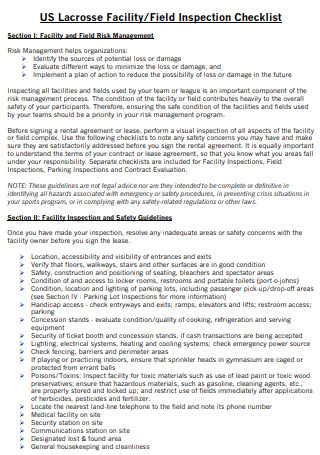

Lacrose Facility Field Inspection Checklist

download now -

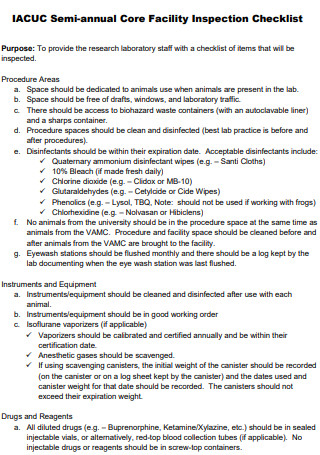

Semi Annual Core Facility Inspection Checklist

download now -

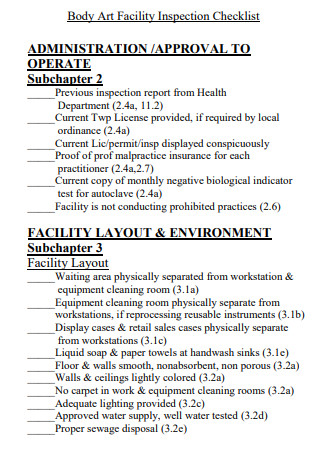

Body Art Facility Inspection Checklist

download now -

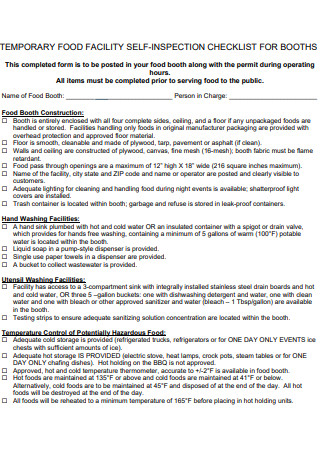

Temporary Food Facility Inspection Checklist

download now -

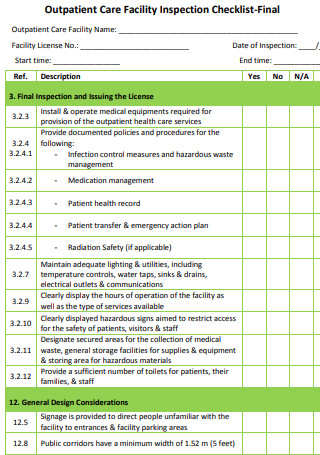

Outpatient Care Facility Inspection Checklist

download now -

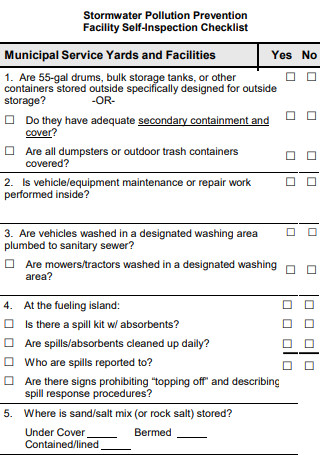

Stormwater Pollution Prevention Facility Self Inspection Checklist

download now

FREE Facility Inspection Checklist s to Download

33+ SAMPLE Facility Inspection Checklist

What Is a Facility Inspection Checklist?

Tips for Inspecting a Facility

Elements of Facility Inspection Checklist

How to Use Facility Inspection Checklist

FAQs

What to Look for in a Warehouse Inspection?

What to Look for in a Facility Inspection?

How Often Should You do a Preventive Maintenance Checklist?

Inspections of workplace facilities aid in the identification and documentation of dangers. Accidents and incidents can be avoided if corrective action is taken to address these risks. When conducting building and property safety audits, it is beneficial to use a Facility Inspection Checklist to keep track of the dangers in the building or property. Every workplace must adhere to local safety rules in order to ensure the well-being of both employees and customers. The use of an inspection checklist or audit checklist to capture dangers at your facility is a proactive step toward achieving the ultimate goal of zero accidents, which is the ultimate safety goal for every organization.

What Is a Facility Inspection Checklist?

For enterprises, the Facility Inspection Checklist (FIC) is a safety audit form that they can use to assess the safety of their facilities. The frequency of inspections will vary depending on your industry, however, it is advised that you execute the inspections at least once a month. Furthermore, a facility maintenance checklist is a priceless defense tool for keeping a building dependable and safe through periodic planning, checkups, and preservation initiatives, all of which are included in the cost of ownership. It is also referred to as a preventative maintenance checklist in some circles. Consider the building maintenance checklist templates supplied in the section and select the one that best suits your needs and requirements.

The facility inspection checklist provides detailed information about your facility and also provides information about the need for repairs as well as the state of the facility you currently have. Maintenance should be observed on a weekly, biweekly, monthly, and annual basis, and all damages and degradation should be noted at the time of inspection. The proper management should then be implemented to overcome the degradation, as well as measures to prevent the occurrence of similar failures and degradation in the future should be implemented. After storms, earthquakes, and other natural disturbances in the environment or other geological changes, a facility maintenance schedule checklist is frequently kept so that the damage caused by these can be repaired in a relatively short period of time. Other than that, if you are seeking checklist samples to assist you with the inspection process, look no further since you have arrived at the appropriate location. It will be easier to stay organized if you use inspection checklists while working with objects or activities where you will need to examine critical features of a specific object or activity. Before buying a home, make sure you receive your money’s worth by having it inspected to avoid dealing with flaws and wasting money. Use this home inspection checklist form to keep track of everything in the house before you buy it, ensuring a good investment. Inspecting the house from an architectural and safety standpoint is useful whether you hire a professional or do it yourself. We also have other checklists such as building and grounds maintenance checklist, building maintenance checklist- exterior, industrial building maintenance, kitchen inspection checklist, sustainable building checklist, room inspection checklist, property maintenance checklist, monitoring, and maintenance checklist, and exterior doors inspection.

Tips for Inspecting a Facility

The purpose of Facility Inspection Checklists is not to identify and correct problems on the spot. As a preventative step, the objective is to document issues, neutralize any immediate threats, and advise corrective action as a result of the documentation. With so many different types and descriptions of facilities, there is virtually an infinite number of possible scenarios in which certain safety audits and results are found to be necessary. Several things, however, are universally suggested, regardless of the type of facility. Here are a few of our best practices recommendations to help you conduct a successful facility inspection.

1. Tailor Your Inspection to Your Specific Facility

A general facility inspection checklist, such as the one we are giving you here, is a good idea to have on hand. Even better is the ability to customize a facility safety audit checklist. Staff inspectors who use the same checklist every day may overlook certain issues if the list does not specifically identify them; nonetheless, the inspector is expected to add additional items to the checklist after each inspection. The ability to personalize your facility inspection checklist helps to ensure that all of your facility’s inspection standards are completed and that nothing is left to chance.

2. Identify and Evaluate All Risks Using Systematic Inspection Methods

Certain companies aim to block objects within their inspection based on a form of hazard method, which is something that some companies do. The smartest thing to do is to split down your inspection into important criteria that make sense for you. An inspector can ensure that nothing is missed from the checklist by inspecting a facility by area and ensuring that each section is thoroughly inspected before moving on to the next section. This will ensure that no risks go unnoticed and that all risks are documented for future reference.

3. Immediate Threats Should be Neutralized and Documented

When conducting a facility inspection with an FIC, it is important to remember that your personnel may uncover hazards that pose a direct danger or threat to the facility’s operation. Your institution’s staff inspectors should be trained in the prompt neutralization of threats that arise within the facility. They should be aware of the locations of various items, such as caution tape, safety cones, and power shut-offs before they arrive (and lock-outs). The inspector should have received training in the use of such safety equipment as well as the knowledge of how to neutralize the hazards that may exist in your business in order to avert imminent harm.

4. Update the Information on Your Inspection Form With the New Information

The danger of using the same or a generic template for all of your safety audits and facility inspections stems from the issue of familiarity with the template. When inspectors use the same sheet over and over again, they may become “comfortable” with the checklist and skim over critical elements since they are familiar with the form and assume that they have already checked something because they “just checked that last week.” We are convinced that it occurs far more frequently than anyone would want to admit. It is advisable to keep your facility inspection form up to date with the most recent facts to avoid the occurrence of “form familiarity.” In the case of a new piece of equipment entering your facility, you should immediately update your facility inspection checklist to reflect the equipment changes and train inspectors on the new equipment.

5. Rotate Inspectors, Not Inspections, as a Final Point

The scheduling of facility inspections and safety audits is an important part of developing your health and safety procedures. When it comes to organizing your facility inspections, it’s a good idea to have more than one inspector on hand among the employees of your firm. The argument for having numerous inspectors is similar, if not the same, as the reason for preventing form familiarity in the first place. When an inspector does the same inspection twice in a row, he or she is significantly more likely to gloss over faults that were discovered during the first inspection. There is a high possibility that an inspector may skip over an item because he or she just checked that item during the previous inspection. The use of a rotating schedule of inspectors ensures that no inspector skips items because they were aware that they had already inspected the item on the previous round of inspection. Maintaining regular strategic planning for your facility inspections is critical, so make sure you have one in place. However, using a rolling inspector schedule will ensure that the highest levels of audits are maintained.

Elements of Facility Inspection Checklist

The facility inspection checklist is a generic facility safety audit form that may be used for any type of working facility, including offices, warehouses, and other types of workplace facilities. Consider the following items on the checklist in further detail.

How to Use Facility Inspection Checklist

Comprehensive and systematic inspection practices are the most effective way for facility inspection. The following are some additional suggestions to assist you in following the best practices when using the FIC:

1. Make a Habit of Performing Your FIC on a Regular Basis

Businesses that are required to conduct daily or shift inspections as a result of municipal or federal legislation must adhere to the regulations governing the consistency and frequency of inspections performed. This technique of systematic and pre-scheduled inspections enables firms to identify and eliminate dangers in the workplace before they become a serious problem.

2. Carry Out a Random Inspection of Your Property

Pre-planning facility inspections is a fantastic idea and one that should be implemented. Random inspections, on the other hand, are likely to be as effective as or even more effective in identifying and documenting dangers. Employees cannot plan ahead of time to pass a random safety audit because the exams are conducted at random. It gives you the ability to “catch” people who are not adhering to the company’s safety rules.

3. Review Inspection Results on a Regular Basis in Order to Develop a Remedial Action Plan.

It is one thing to make a note of a potential hazard in the workplace. It’s quite another to put a stop to it. Planning and managing corrective actions to neutralize hazards in your place of business is made easier with a planned, regular review of facility inspection checklists. This ensures the effectiveness of your safety audit program by allowing for the planning and management of corrective actions to neutralize hazards in your place of business.

4. Make Sure to Include Your Employees

The likelihood of employees participating incorporate safety increases significantly when they are included in the inspection or safety decision-making processes.

Inspections may be obligatory and scheduled on a regular basis in some industries, depending on local laws. Food manufacturing, pharmaceutical manufacturing, and medical manufacturing are just a few examples of such businesses.

FAQs

What to Look for in a Warehouse Inspection?

Moving on to the safety inspections that must be performed in certain regions of the warehouse, you must ensure that all lanes are clearly marked with some type of identification before proceeding. Fill out the form blanks below to keep track of what you discover. In general, keep an eye out for the coding system that is specific to your company’s needs.

What to Look for in a Facility Inspection?

It’s now time to double-check that any vending machines in the reception area are completely stocked, just as it was with the cooler before. If they are not, you will need to make arrangements to have them refilled, just like you would with the cooler. Vending machines that sell food and beverages should be included in these inspections (from coke to hot coffee). Again, make a note of your findings in the form boxes provided below.

How Often Should You do a Preventive Maintenance Checklist?

This preventive maintenance template guarantees that the inside of your building remains in excellent functioning condition. It is a good habit to keep an eye out for the things on the following checklist while you go about your daily business in the facility, but this checklist should be reviewed at least once a month for completeness and accuracy.

As facilities and maintenance executives’ to-do lists grow in size, it is becoming more and more difficult to keep track of everything that needs to be done and when it needs to be done. Team members can remain on top of their to-do lists with the help of facility maintenance checklists, which outline how frequently each aspect of your facility’s management has to be examined and maintained. When a leader adheres to checklists, the assets, and equipment under his or her control will live longer.