8+ Sample Supplier Quality Analysis

-

Supplier Quality Potential Analysis

download now -

Supplier Quality Audit Analysis

download now -

Supplier Quality Assurance Analysis

download now -

Supplier Quality Analysis in PDF

download now -

Supplier Quality Codes Analysis

download now -

Supplier Quality Manual Analysis

download now -

Standard Supplier Quality Analysis

download now -

Basic Supplier Quality Analysis

download now -

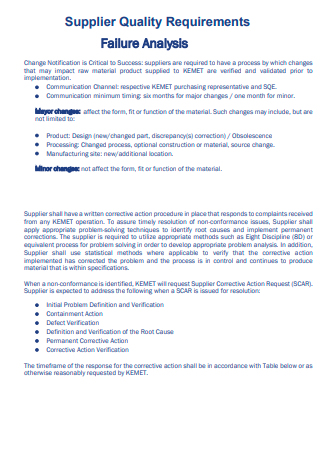

Supplier Quality Requirements Failure Analysis

download now

FREE Supplier Quality Analysis s to Download

8+ Sample Supplier Quality Analysis

What Is a Supplier Quality Analysis?

Benefits of Supplier Quality

Tips For Dealing Shipping Delays

How To Increase Supplier Performance in a Long-Term Manner

FAQs

What are supplier evaluation criteria?

What is supplier KPI?

What is a supplier rating system?

How do you conduct a supplier quality audit?

What Is a Supplier Quality Analysis?

Quality control is frequently the final stage before a corporation exposes a product to a distribution channel. During this production stage, producers execute various procedures, including quality checks and corrections, to guarantee that the final product meets quality standards. This phase is crucial since it determines whether or not the product is ready for shipment to the consumer. Failure to provide high-quality items can result in a damaged reputation, decreased customer retention, and increased return rates. In addition, quality control examines a product’s manufacturing, storage, and distribution processes. A “defective” product does not meet quality standards or has been damaged. Therefore, firms must build effective procedures to ensure the integrity of their products along the supply chain. Statistics indicate that “on-time delivery” is a critical and possibly the most significant supplier performance criterion to measure. This measure influences the supply chain’s efficiency directly. Supply chains whose on-time delivery rate typically exceeds 90 percent maintain their machines are operating, their inventory is low, and their customers are satisfied.

Benefits of Supplier Quality

It is simple to assume that supplier quality management influences the final product’s quality. That is not the situation. Yes, supplier quality management may make or break the quality of your goods, but it also influences your brand’s perception, value, profitability, and overall success. Here are the benefits of executing a strategy for supplier quality management:

Tips For Dealing Shipping Delays

Despite your best efforts to simplify your business procedures and shipping operations, shipment delays are inevitable. Your consumer will always perceive it as an issue, regardless of the source, and you risk losing them to the competition if you do not act promptly to alleviate their dissatisfaction. The answer lies in appropriately responding to such delays to safeguard your brand’s reputation. Here are some suggestions for dealing with shipping delays.

1. Engage in dialogue with your customers

The first step in dealing with delays is to call your clients and explain why their orders are not being delivered on time. While emails and dedicated response channels such as Facebook Messenger are viable solutions, contacting your customers is preferable. You’ll be able to provide a customized solution, and your clients will appreciate the extra effort you’ve taken to call them. Discuss every aspect of the order delay and give an estimated delivery date.

2. Offer free delivery

Free shipping can reduce your clients’ expectations for speedy delivery. If you provide free shipping, your customers will not anticipate same-day or next-day delivery. Having lowered their expectations, you can then make every effort to enhance your shipping timings and avoid any delays to capitalize on the competitive advantage that faster shipping provides. According to research, only 17.5% of the most renowned eCommerce retailers offer free shipping on all orders. Only 175 of the top 1,000 online retailers offer free shipping on all orders.

3. Shipment tracking

A shipment option that provides you and your clients with real-time tracking information helps alleviate the stress and aggravation caused by delays. By providing the tracking number to your clients, they will be able to check the delivery status and locate their package. Easyship enables you to offer branded tracking pages that provide your customers with a 360-degree branded experience and simple order tracking. According to research, the most popular type of discount is a percentage-based discount. Online businesses provide small discounts (5-10% off) and more significant discounts (15-25% off) as purchasing incentives. Brands also usually offer at least 50 percent discounts to clear old and surplus inventory.

4. Invest in domestic suppliers

Working with suppliers who have held in your target nations might reduce delivery delays because suppliers can fulfill orders from the closest facilities. This will help you prevent delivery delays and minimize your products’ shipment timeframes. Easyship collaborates with warehouses worldwide, so we can assist you in ensuring that your items are in the optimal location to reach clients.

5. Offer promotions and discounts

Providing clients with promo codes or small gifts can help alleviate their frustrations. This will cost you a small amount of money, but it is considerably less expensive than having your consumers post unfavorable reviews that could deter hundreds of potential buyers. According to research, the most popular type of discount is a percentage-based discount. Brands also usually offer discounts to clear out old and surplus inventory.

6. Package stalled in transit

If a truck is suffering mechanical difficulties, web-based tracking can help locate the issue and assign the nearest driver to complete the delivery. In addition, contacting your clients to advise them of the potential delay before they become aware of it would help you manage the problem. Some shipping firms can assist you in mitigating the issue by providing your consumers with accurate, branded order tracking emails and websites. They can also simplify the shipping process by providing access to more than 250 dependable couriers and automating labor-intensive steps such as label creation and customs form completion.

How To Increase Supplier Performance in a Long-Term Manner

In conversations about how to increase operational performance or product quality, Supplier Management is sometimes overlooked. Buyers identify reliable suppliers on the market, considering price, service, and quality, and then sign supply contracts. Now, the difficulty is in the manufacturing/production sector. Supplier management should extend beyond the purchasing phase. The “buying” team can and should be more engaged throughout the production process. Active management of suppliers can bring unexpected outcomes. Here are the techniques to assist you in accomplishing this.

1. Include executive leadership in the process.

Involving higher management is the process’s initial (and one of the most crucial) step. This necessitates connecting supplier performance objectives with company objectives in your business plan. Regardless of the focus of your goals, such as cutting expenses, developing new technologies, expanding into new markets, or optimizing efficiency, you must first approach management and provide an effective initial plan. If higher management is involved, resource allocation is more likely to be supported, ensuring that goals are met.

2. Create a measuring system

The most advantageous chances come when expected and actual results are effectively communicated. Based on this concept, suppliers respond faster when they realize you watch them daily. Long-term supplier performance improvement is facilitated by a clear, simple-to-understand daily dashboard containing only a handful of essential performance data (KPIs). Instead of assessing twenty items daily, choose a few fundamental areas, such as delivery or quality, and make them visible to all providers. Suppliers typically have many clients to satisfy, so the one who expresses their criteria and monitors them daily will receive their undivided attention. With this system operational, you are well positioned to enhance long-term supplier performance.

3. Define your supplier’s expectations and report them.

Permanent measurement systems with annual evaluations are a suitable alternative. This scorecard of performance indicators should cover all significant critical areas, such as supplier response capacity, service evaluation, product management, and sales support. The idea is to inform the supplier precisely what makes you happy and what you want. Developing a list of individual requirements for each vendor instead of generic scorecards can also be helpful. It can entail a little more labor, but its effectiveness can be more than double in the long term. Suppliers have a stricter time dodging you when targets are tailored. This scorecard acts as the daily dashboard, complementing the previous item, giving the provider and the client clearly defined standards and duties.

4. Analyze purchasing and supply chain management

A proper analysis will focus on recognizing strengths and weaknesses and identifying the organizational changes necessary to close the identified gaps. For an internal evaluation to be effective, it must be complete, sincere, honest, and realistic. Look for areas of complacency and improvement chances inside your organization by comparing them to other businesses or operations that are similar. And if you truly desire an impartial evaluation, you should seek outside assistance.

5. Implement a collaborative strategy for supplier management

By utilizing a team-based strategy, all functional groups accountable for various facets of supplier performance are brought together under a centralized organizational framework. In these groups, buyers typically serve as team leaders. Relying on the size and complexness of the supply chain, quality, logistics, planning, and engineering are added to the team structure. For these teams to be helpful, they must be permanent. These should not be transient tasks with short-term objectives to achieve. Instead, team members should discuss supplier management objectives and plans. In other words, members share knowledge and collaborate to enhance providers. The complexity of contemporary supply chains necessitates more resources than most purchasing firms, but the benefits of employing this team-based strategy are considerable.

6. Offer continual training to your staff

Most businesses are irresponsible regarding fundamental training on internal systems, processes, long-term supplier improvement goals, or even basic industry norms. Compared to the productivity of adequately trained teams, this results in a loss of up to 30 percent effectiveness. Improving supplier performance necessitates knowing how to approach suppliers, displaying an awareness of their operations, processes, and procedures, and assisting them in achieving higher levels of success. Training should emphasize a supplier’s requirement and how to obtain it.

7. Know your primary suppliers

When I suggest you know your significant suppliers well, I do not mean that you should audit them every two years and file a report. Your teams should frequently visit suppliers. The more they understand the supplier and involvement in the supply process, the more likely they will uncover opportunities in terms of costs, quality, delivery, new product development, and sustainable supply chain performance. Some customers do not leave their desks except to walk to the reception area to greet a meeting-attending provider. For increased efficiency, purchasing should be encouraged to travel and engage in hands-on supplier management.

FAQs

What are supplier evaluation criteria?

In procurement, supplier evaluation refers to a formal review of suppliers to measure their performance against various criteria and determine if they fit the organization’s needs. The purpose is to develop a portfolio of available suppliers that is best-in-class and low-risk.

What is supplier KPI?

Organizations use key performance indicators (KPIs) to survey progress. Supplier management KPIs ensure that suppliers and vendors provide value for the money invested while keeping an eye on cost savings.

What is a supplier rating system?

The solution shows the strengths and weaknesses of each supplier across various categories and assesses the supplier’s suitability for each specific request, helping your workers to become more strategic buyers. Supplier Rating System allows you to analyze supplier performance using predefined KPIs.

How do you conduct a supplier quality audit?

Ask to see the supplier’s audit results on its vendors. If the supplier doesn’t let you do that, ask to see the supplier’s incoming inspection of subcontracted materials and any other paperwork that shows the supplier is holding its vendors to quality standards and getting quality items.

A properly-written action plan guarantees that the goals of your company or organization and your own goals are fulfilled and exceeded. Alternately, it gives life to your vision. It can help you keep on track with your project and prevent potential obstacles. The approach for producing a high-quality action plan is essentially comparable. It allows you to maintain a particular level of quality while providing an opportunity for progress.