23+ SAMPLE Project Quality Control Plan

-

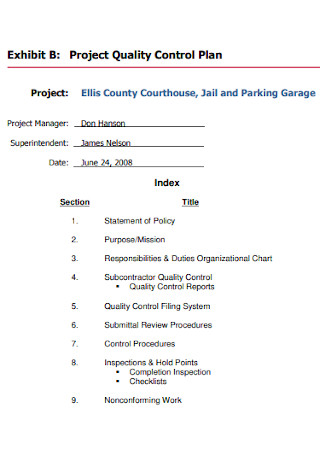

Project Quality Control Plan

download now -

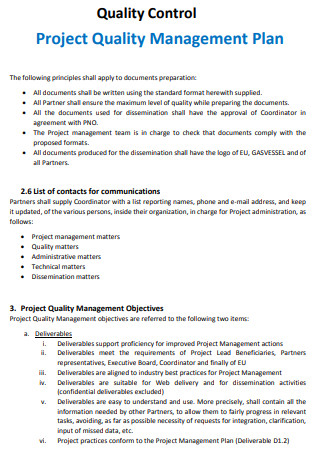

Project Quality Control Management Plan

download now -

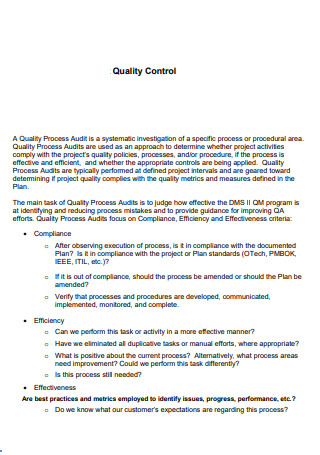

Sample Project Quality Control Plan

download now -

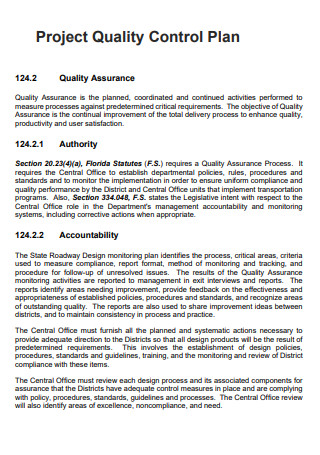

Pharma Project Quality Control Plan

download now -

Project Design Quality Control Plan

download now -

Electrical Project Quality Control Plan

download now -

Simple Project Quality Control Plan

download now -

Project Center Quality Control Plan

download now -

Project Audit Quality Control Plan

download now -

Highway Projects Quality Control Plan

download now -

Components of Projects Quality Control Plan

download now -

Project Manager Quality Control Plan

download now -

Contractor Project Quality Control Plan

download now -

Basic Project Quality Control Plan

download now -

Cancer Center Project Quality Control Plan

download now -

Design Project Quality Control Plan

download now -

Project Organization Quality Control Plan

download now -

Highway Safety Project Quality Control Plan

download now -

Project Quality Control Monitoring Plan

download now -

Project Quality Control Plan Example

download now -

Design-Build Projects Quality Control Plan

download now -

Quality Control Plan for Water Project

download now -

Implementation of Project Quality Control Plan

download now -

Standard Project Quality Control Plan

download now

FREE Project Quality Control Plan s to Download

23+ SAMPLE Project Quality Control Plan

What is a Project Quality Control Plan?

Different Types of Project Quality Control Plan

Basic Components of a Project Quality Control Plan

How to Write a Project Quality Control Plan

FAQs

What are the fundamental elements of a project quality control plan?

What are the multiple uses of documenting quality planning?

What are some examples of project quality control plans?

How to ensure project quality control?

What is a Project Quality Control Plan?

Also known as a quality assurance plan, quality management plan or project quality management plan, a project quality control plan is a comprehensive, and well-integrated written document which is commonly used for a specific project’s successful quality development and execution. It is a clear roadmap that outlines the goals, activities, high quality standards, tools, and processes which are fundamental to assist project consultants and project managers in how they should manage and maintain the optimal quality on a specific project. They also need to consider that the quality of a project is also defined by the customer. That’s why businesses and organizations should create a product or provide a service that fulfills the expectations of their target customers. Aside from achieving the quality requirements and standards, it is fundamental to assure the customers that their expectations of the given product or service will be met.

A statistical report has shown that 83% of organizations believe a quality management system (QMS) solution at least somewhat helped them recover from a product recall. It can be stressful when recovering from a product recall because of the need to audit internal quality operations, evaluate supply chain quality and consider corrective actions in order to mitigate damages and prevent possible incidents in the future. Using an automated QMS makes it easier for project consultants and managers to increase the efficiency of each of the integral processes, to recover faster from a product recall and to minimize the costs. Thus, all kinds of construction project consultants, project quality control supervisors, and other project quality inspectors should effectively create a compelling and well-detailed project quality control plan.

Different Types of Project Quality Control Plan

Due to the COVID-19 pandemic, many businesses and organizations start maintaining hybrid work models. Project leaders and quality consultants need to overcome the challenges to quality management processes that remote work has. For example, a data report stated that 87% currently experience difficulty ensuring quality assurance and 77% struggle with maintaining compliance in a remote setting. As a project consultant, another thing you need to do is have a clear insight and understanding about the different types of project quality control plans that you will use for your quality management matters. Here we will explain to you about the different types of project quality control plans:

1. Pharma Project Quality Control Plan

Pharmaceutical companies and firms need to ensure that all of their pharmaceutical products provide better end results in terms of health. If they compromise on the quality of their products, they would also compromise the overall health of the patients and other customers. That’s why one of the most important aspects of the overall drug manufacturing process is pharmaceutical quality assurance in order to ensure that the medication being manufactured will bring the desired effect to the patient. Every firm and organization involved in pharmaceutical manufacturing must absolutely ensure that they are producing safe and effective health products. Preparing a pharma project quality control plan is essential for pharmaceutical product quality managers and consultants so that they know and understand who are the key individuals in charge of maintaining quality assurance in their products. While writing this plan, indicate the roles and responsibilities of the scientific and technical manager, the impact manager, the ethics manager, and the members of the steering committee. For example, define the main tasks of the scientific and technical manager such as the coordination of the overall scientific and technical operational activities of the project, reporting and monitoring of the progress of work packages covering scientific and technical issues to the committee and the coordinator, and ensuring the translation of scientific, technical, practical requirements into technical solutions.

2. Project Design Quality Control Plan

A good design quality is a crucial element to improve project outcomes. Project team leaders should consider to maintain a balance between complexity and simplicity of a specific project. To effectively strengthen the project design, project managers need to avoid these things: overambitious scope and timeframe, use of the wrong modality, inappropriate or unclear implementation arrangements, and over-the-top incentives for capacity building. They should consider certain aspects beyond the technical nature when designing and formulating projects which include the broader implications on related sector policies and possible resistance from key stakeholders. If you need to create a project design quality control plan, determine your goals, purpose and primary tasks in facilitating quality assurance, authority, and accountability. Include in your plan an explanation how it will identify the process, crucial areas, criteria used to measure compliance, report format, method of monitoring and tracking, and procedure for follow-up of unresolved issues. Emphasize the quality assurance monitoring activities that will be performed in order to detect areas requiring improvement, provide feedback on the effectiveness and appropriateness of established policies, procedures, and standards, and recognize areas of outstanding quality.

3. Electrical Project Quality Control Plan

Quality and safety occupies a significant position in electrical engineering as electrical engineering quality greatly affects the overall safety of the building equipment. Through the periodic maintenance and services of installed/existing electrical systems, quality assurance in electrical equipment and wiring systems is very important to make sure that there are no further faults on these electrical systems. To prevent accidents and casualties, electrical project managers should ensure the safe operation of the electrical equipment and systems in power transmission construction projects. Creating an electrical project quality control plan is important to strengthen the management of electrical engineering project quality and efficient transfer of production standards. Include a brief overview of the construction and electrical engineering plan, description of the project startup and quality control coordination meeting, and informative details regarding the work task requirements during the preparatory project quality assurance or quality control planning.

4. Design-Build Projects Quality Control Plan

The contractors, designers, subcontractors, and project manager of a design-build project need to work together in monitoring and managing the quality of their project. If you are one of the key members of a design-build construction project, develop a design quality control plan as you write the general information concerning the responsibility of the developer in managing the project quality. Define the quality requirements of the developer as you define the processes, methods, procedures, and documentation to deliver quality control on the design-build project. Tell the roles and responsibilities of the staffing and describe the remaining requirements.

Basic Components of a Project Quality Control Plan

In this section, you will learn how to construct a well-written and systematic project quality control plan. But you need to learn about the different kinds of components of a project quality control plan. Include the following elements for you to create a professional piece of writing:

How to Write a Project Quality Control Plan

Reeves & Bednar stated that quality is a multifaceted concept, whose definition is complex and fundamentally context-dependent. Based on a figure illustration, product quality involves the quality of the idea (prototype or design) and quality of the technical realization (conformance), as well as process quality or the effectiveness or quality of the result, and efficiency when it comes to time/cost minimization. Most importantly, the quality of the product represents the company’s and its products’ impact. What are the most important aspects that project quality managers need to focus on? Below are some easy-to-follow tips that indicate how to write a clear and structured project quality control plan:

Step 1: Create an Overview or Introduction

The first thing that you need to accomplish is creating a brief overview or introduction of the quality assurance project by defining the goals, objectives and principles of your business firm or organization in project quality. It is essential that you understand how your organization views quality. Then, detail the background, need, scope, activities, and important dates or deadlines of the project quality control plan.

Step 2: Describe the Quality Management Team

Next, include the organizational structure or organization chart which details the key quality assurance or quality management team members, as well as the external vendors. Specify the roles and responsibilities of each team member. Indicate their qualifications and expertise when it comes to fulfilling their stated duties. So, determine who is particularly responsible for carrying out a task, and who is responsible for checking and inspecting the work.

Step 3: Explain the Project Quality Control Needs and Requirements

List down the names of the qualified suppliers for the quality management work. Describe the testing parameters, performance standards and how performance will be documented, acceptance criteria, deliverables, internal and/or external customer feedback, quality control procedures, and many other tools, methods and strategies needed when conducting a quality assurance monitoring and evaluation work.

Step 4: Develop a Summary

After that, develop the summary of the project quality control work. Record and point out the key points while monitoring and evaluating the quality of a project. Indicate the corrective action and preventive actions, including the person or people responsible for the quality management work. Explain why you suggested the corrective action in the plan.

Step 5: Proofread and Prepare the Overall Project Quality Control Plan

Review your overall project quality control plan and make sure that you fully indicate all the fundamental points in your plan. Emphasize the connection between the specific project quality management goals, objectives, resources, strategies and methods used for reaching the objectives, and the evaluation of the project managers and inspectors involved in the project quality control plan. If you realize that you forget some sections that need more important details, we highly suggest that you edit and revise the document as soon as possible.

FAQs

What are the fundamental elements of a project quality control plan?

The fundamental elements of a project quality control plan are project quality specifications, project quality management personnel, quality communications tools and methods, quality assurance surveillance, subcontractors and suppliers, quality assurance inspections and tests, control of nonconformances, and project completion inspections.

What are the multiple uses of documenting quality planning?

Some of the multiple uses of documenting quality planning are ensuring conformance to customer requirements and preferences, ensuring conformance to external and internal standards and procedures, facilitating traceability, furnishing a basis for training, providing objective evidence, and offering a basis for effective evaluation of the effectiveness and efficiency of the quality management system.

What are some examples of project quality control plans?

Some examples of project quality control plans are project quality control management plan, production control plan, pharma project quality control plan, project design quality control plan, electrical project quality control plan, simple project quality control plan, project center quality control plan, project audit quality control plan, highway projects quality control plan, cancer center project quality control plan, project organization quality control plan, project quality control monitoring plan, design-build projects quality control plan, quality control plan for water project, and more.

How to ensure project quality control?

In order to ensure project quality control, you need to establish your quality standards and requirements, select which quality standards to focus on, make operational processes to deliver quality management, review your results, get feedback from others, and make improvements.

William A. Foster said: “Quality is never an accident; it is always the result of high intention, sincere effort, intelligent direction and skillful execution; it represents the wise choice of many alternatives.” Writing a clear and well-integrated project quality control plan is an integral method to carefully determine the quality of the creation, development, process, and impact of the project, product, program, or service. To guide you in writing your project quality control plan, you can learn and apply the tips aforementioned in this article. Plus, we have included several project quality control plan templates, project quality control management plan templates, pharma project quality control plan templates, project center quality control plan templates, highway projects quality control plan templates, project quality control monitoring plan templates, and other project quality control plan templates that you can download.