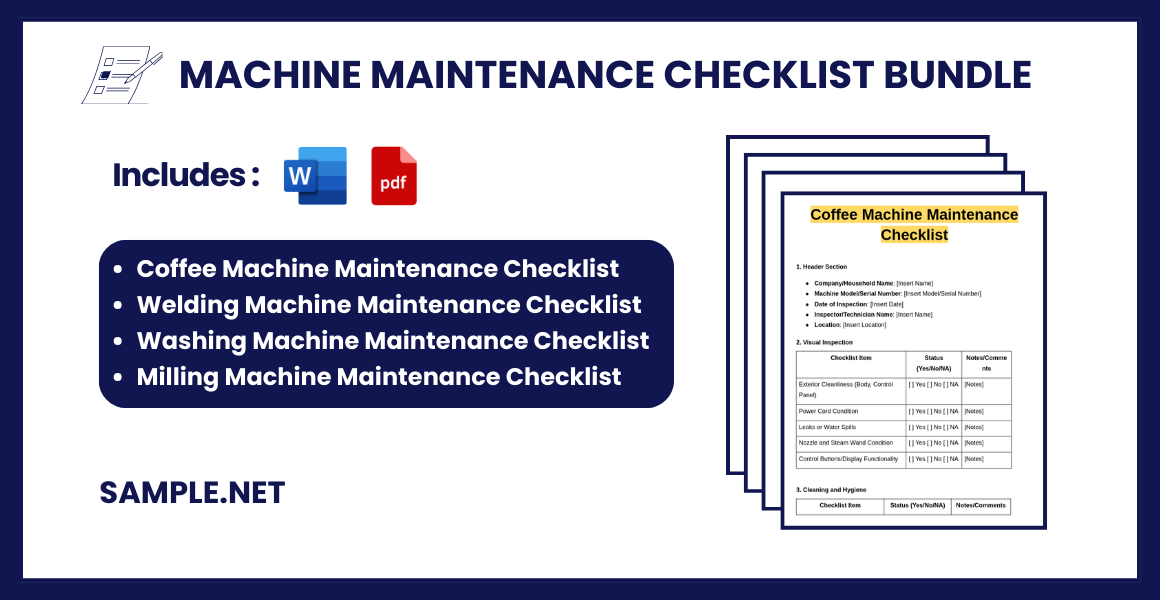

Machine Maintenance Checklist Samples

-

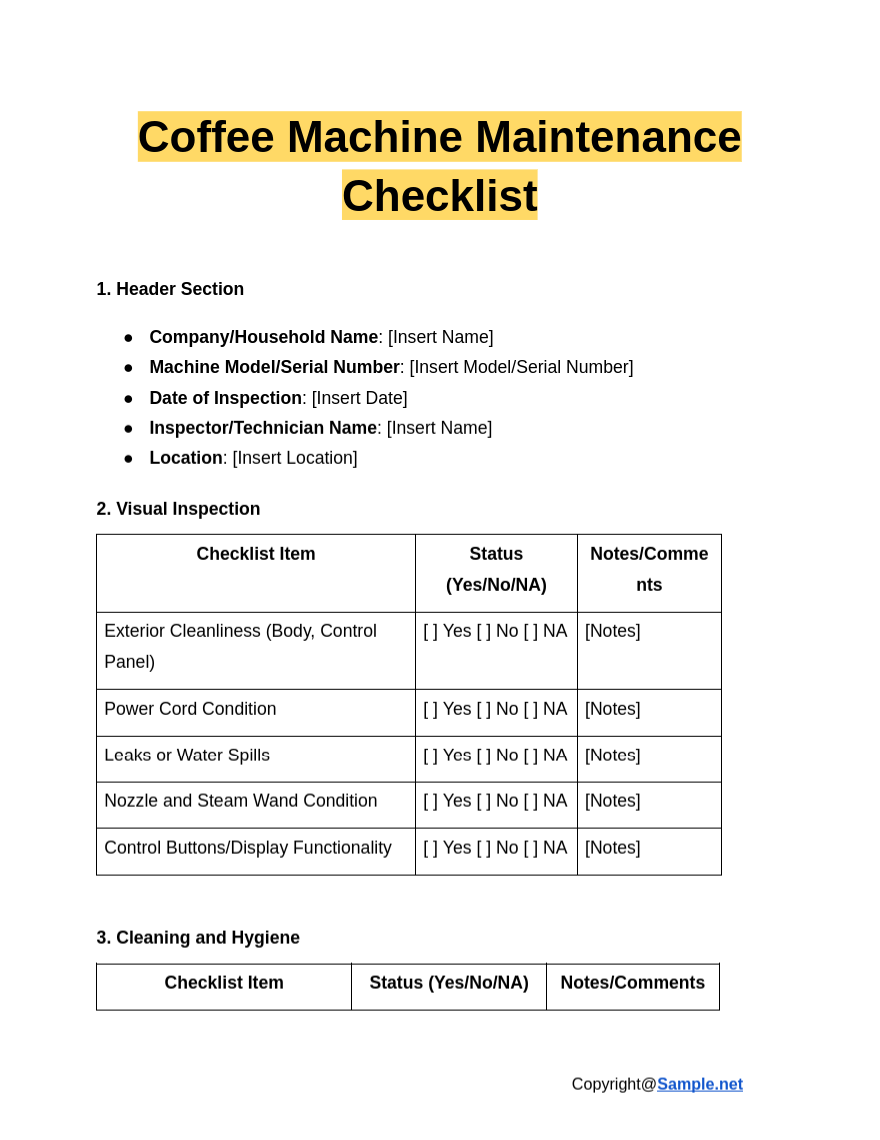

Coffee Machine Maintenance Checklist

download now -

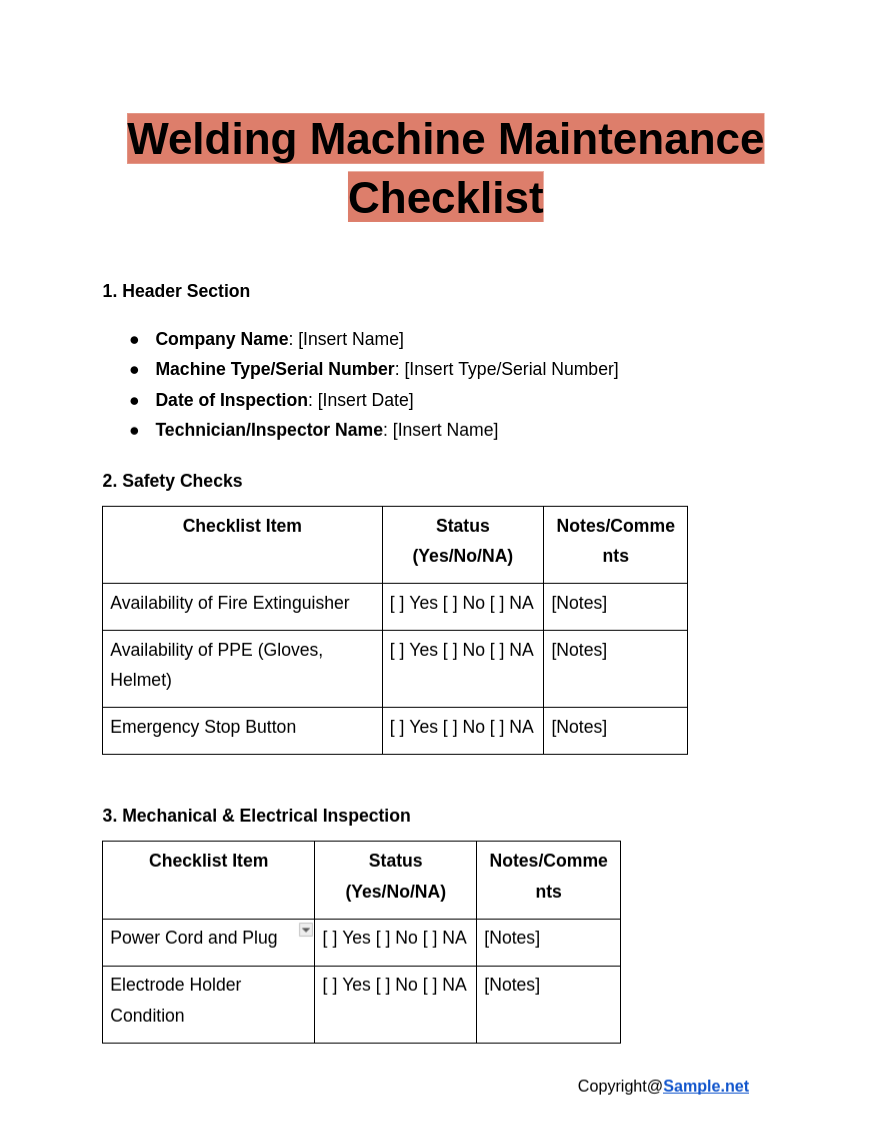

Welding Machine Maintenance Checklist

download now -

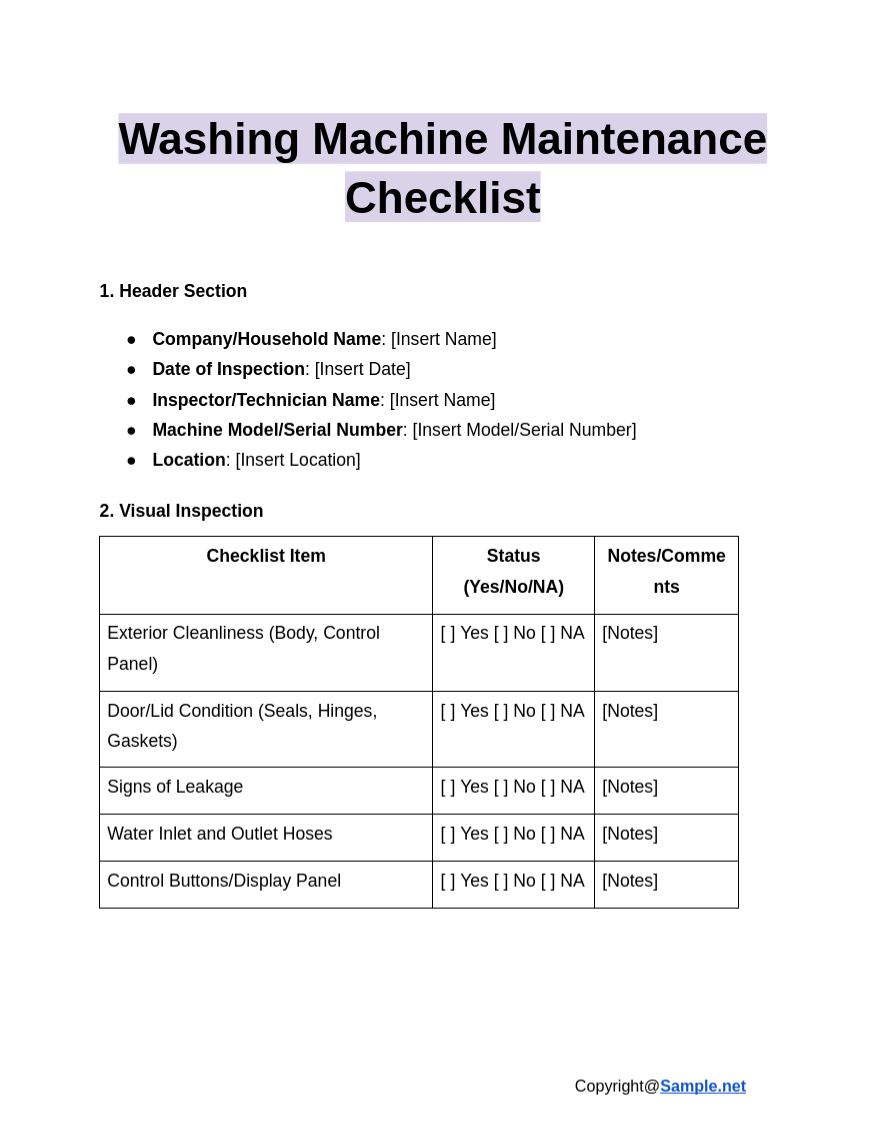

Washing Machine Maintenance Checklist

download now -

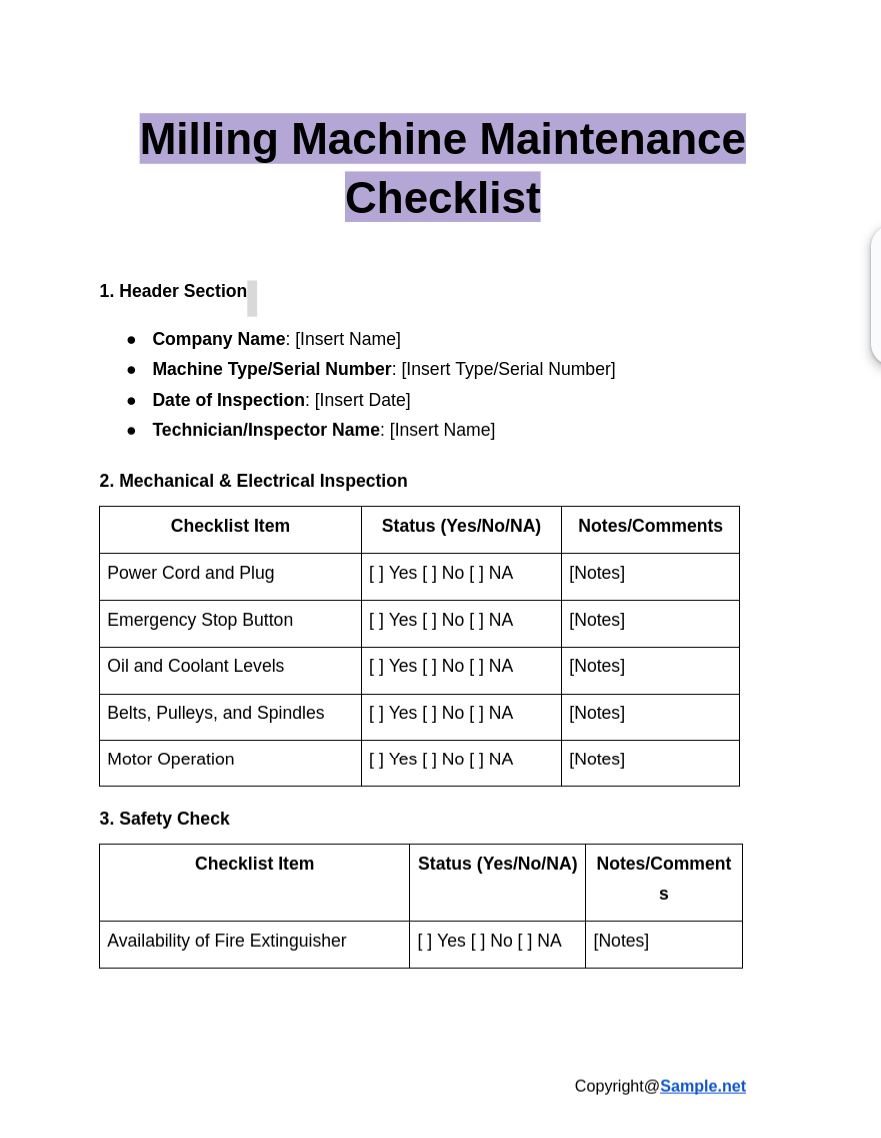

Milling Machine Maintenance Checklist

download now -

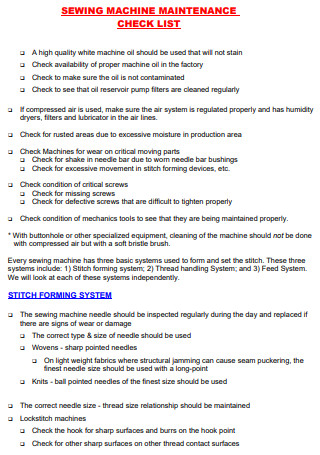

Sewing Machine Maintenance Checklist

download now -

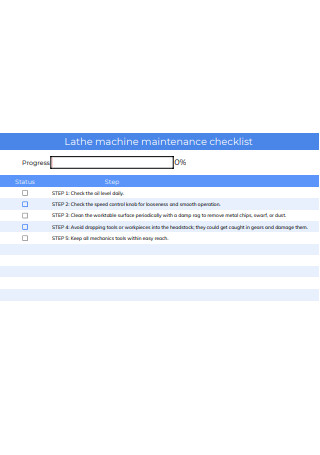

Machine Maintenance Checklist

download now -

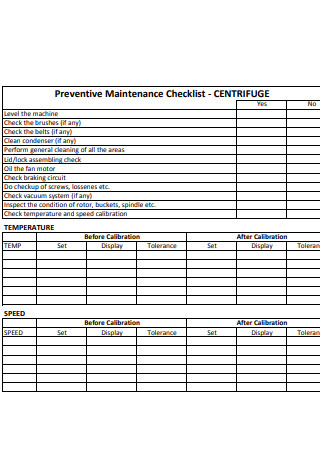

Centrifuge Machine Maintenance Checklist

download now -

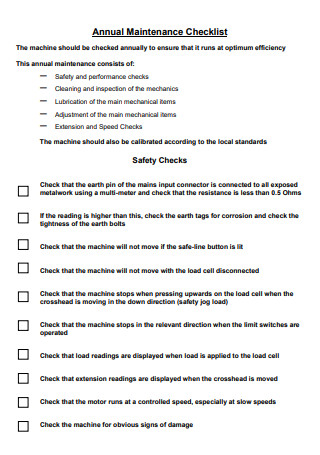

Annual Machine Maintenance Checklist

download now -

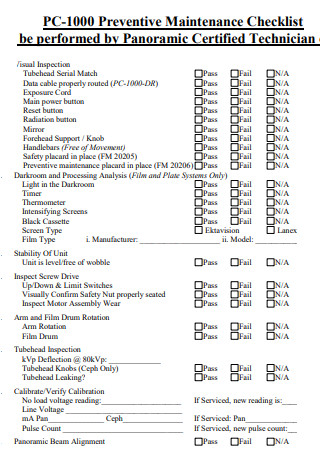

Machine Preventive Maintenance Checklist

download now -

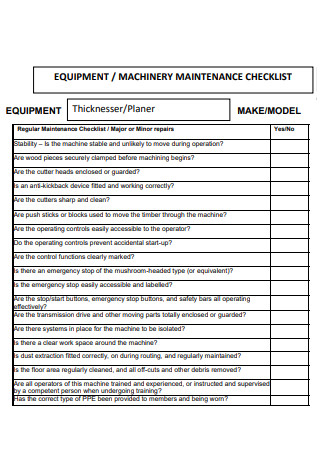

Equipment Machinery Maintenance Checklist

download now -

Machine Inspection Maintenance Checklist

download now -

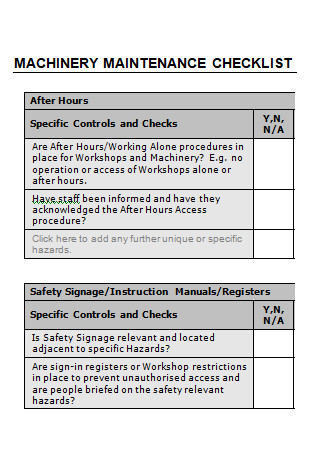

Work Equipment Machinery Maintenance Checklist

download now -

Workshop Plant Machinery Maintenance Checklist

download now -

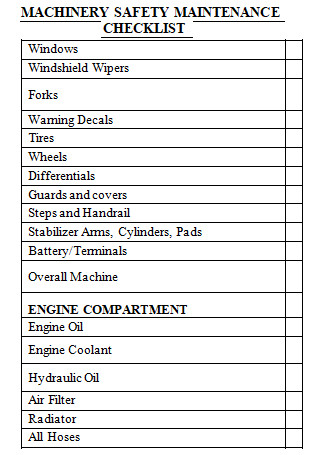

Machine Safety Maintenance Checklist

download now

FREE Machine Maintenance Checklist s to Download

Machine Maintenance Checklist Format

Machine Maintenance Checklist Samples

What is a Machine Maintenance Checklist?

Purposes of a Machine Maintenance Checklist

How to Make a Machine Maintenance Checklist

FAQs

Why is machine maintenance important?

What is equipment maintenance?

Who is responsible for machine maintenance?

How often should I use a Machine Maintenance Checklist?

What happens if the Machine Maintenance Checklist is not followed?

Download Machine Maintenance Checklist Bundle

Machine Maintenance Checklist Format

1. Header Section

- Company Name: [Insert Company Name]

- Machine Name/ID: [Insert Machine Name or Unique Identifier]

- Date of Inspection: [Insert Date]

- Inspector Name: [Insert Name of Inspector]

- Department: [Insert Department]

2. General Information

- Location of Machine: [Insert Location]

- Machine Type/Model: [Insert Type/Model of the Machine]

- Serial Number: [Insert Serial Number]

- Last Maintenance Date: [Insert Date of Last Maintenance]

- Next Scheduled Maintenance Date: [Insert Next Date]

3. Visual Inspection

| Checklist Item | Status (Yes/No/NA) | Notes/Comments |

|---|---|---|

| Physical Damage (Cracks, Dents, etc.) | [ ] Yes [ ] No [ ] NA | [Notes] |

| Cleanliness (Dust, Grease, etc.) | [ ] Yes [ ] No [ ] NA | [Notes] |

| Loose Bolts or Fasteners | [ ] Yes [ ] No [ ] NA | [Notes] |

| Safety Guards in Place | [ ] Yes [ ] No [ ] NA | [Notes] |

| Electrical Wiring/Connections | [ ] Yes [ ] No [ ] NA | [Notes] |

4. Mechanical Components Inspection

| Checklist Item | Status (Yes/No/NA) | Notes/Comments |

|---|---|---|

| Bearings and Bushings | [ ] Yes [ ] No [ ] NA | [Notes] |

| Belts and Pulleys | [ ] Yes [ ] No [ ] NA | [Notes] |

| Chains and Sprockets | [ ] Yes [ ] No [ ] NA | [Notes] |

| Gears and Gear Teeth | [ ] Yes [ ] No [ ] NA | [Notes] |

| Moving Parts Lubrication | [ ] Yes [ ] No [ ] NA | [Notes] |

5. Electrical Components Inspection

| Checklist Item | Status (Yes/No/NA) | Notes/Comments |

|---|---|---|

| Control Panel Condition | [ ] Yes [ ] No [ ] NA | [Notes] |

| Emergency Stop Button | [ ] Yes [ ] No [ ] NA | [Notes] |

| Power Supply Cables | [ ] Yes [ ] No [ ] NA | [Notes] |

| Circuit Breakers & Fuses | [ ] Yes [ ] No [ ] NA | [Notes] |

| Indicators & Warning Lights | [ ] Yes [ ] No [ ] NA | [Notes] |

6. Lubrication & Fluid Check

| Checklist Item | Status (Yes/No/NA) | Notes/Comments |

|---|---|---|

| Oil Level Check | [ ] Yes [ ] No [ ] NA | [Notes] |

| Hydraulic Fluid Check | [ ] Yes [ ] No [ ] NA | [Notes] |

| Coolant Level Check | [ ] Yes [ ] No [ ] NA | [Notes] |

| Water Leakage | [ ] Yes [ ] No [ ] NA | [Notes] |

| Lubrication System | [ ] Yes [ ] No [ ] NA | [Notes] |

7. Operational Checks

| Checklist Item | Status (Yes/No/NA) | Notes/Comments |

|---|---|---|

| Noise Levels (Unusual Sounds) | [ ] Yes [ ] No [ ] NA | [Notes] |

| Vibration Check | [ ] Yes [ ] No [ ] NA | [Notes] |

| Machine Speed/Output | [ ] Yes [ ] No [ ] NA | [Notes] |

| Temperature of Key Components | [ ] Yes [ ] No [ ] NA | [Notes] |

| Startup/Shutdown Process | [ ] Yes [ ] No [ ] NA | [Notes] |

8. Safety Check

| Checklist Item | Status (Yes/No/NA) | Notes/Comments |

|---|---|---|

| Operator Safety Equipment (Gloves, Glasses, etc.) | [ ] Yes [ ] No [ ] NA | [Notes] |

| Emergency Alarms and Signals | [ ] Yes [ ] No [ ] NA | [Notes] |

| Fire Extinguishers Nearby | [ ] Yes [ ] No [ ] NA | [Notes] |

| Risk of Exposure to Hazards | [ ] Yes [ ] No [ ] NA | [Notes] |

| Accessibility of Safety Controls | [ ] Yes [ ] No [ ] NA | [Notes] |

9. Final Assessment

- Overall Condition of the Machine: [ ] Excellent [ ] Good [ ] Needs Repair [ ] Critical

- Immediate Action Required: [ ] Yes [ ] No

- Action Taken: [Insert Description of Actions Taken]

- Parts Replaced (if any): [Insert Parts Replaced]

10. Recommendations & Next Steps

- [Provide details on recommended actions, spare parts required, etc.]

- [Indicate if the machine is safe to operate or needs to be shut down for repairs.]

11. Inspector’s Signature

- Name of Inspector: [Insert Name]

- Signature: [Insert Signature]

- Date: [Insert Date]

What is a Machine Maintenance Checklist?

A machine maintenance Checklist for machines is the process of keeping mechanical assets functioning with the least amount of downtime. Manufacturers of the asset and other subject matter experts, such as consultants, have created an itemized list of discrete maintenance activities. Regularly planned servicing, routine checkups, and both scheduled and emergency repairs are examples. It also entails the repair or adjustment of worn, broken, or misaligned elements. Machine maintenance can be performed either before or after a failure occurs. A maintenance program’s foundation is built on checklists. It assists businesses in meeting production deadlines, reducing costly downtime, and reducing the risk of worker accidents and injuries. You may see Accident reports.

Purposes of a Machine Maintenance Checklist

1. Prevent Equipment Failure and Downtime: Identifies and resolves potential issues early to avoid unexpected breakdowns and production delays.

2. Increase Equipment Lifespan: Regular maintenance extends the lifespan of machinery, reducing the need for frequent replacements. You can also see more on Maintenance Checklists.

3. Enhance Workplace Safety: Ensures that machinery is safe to operate, reducing the risk of accidents and workplace injuries.

4. Improve Operational Efficiency: Keeps machines running at peak performance, leading to higher production rates and consistent output.

5. Reduce Maintenance and Repair Costs: Lowers expenses by addressing minor issues before they escalate into costly repairs or replacements. You can also see more on Predictive Maintenance Checklist.

How to Make a Machine Maintenance Checklist

Step 1: Identify the Machines and Equipment

Start by listing all the machinery and equipment that need maintenance. Focus on critical assets that directly impact production. Analyze which machines are high-priority based on their usage and importance. Gather manufacturer recommendations and industry standards to determine the type of maintenance each machine requires. This step ensures that no essential equipment is overlooked.

Step 2: Break Down Tasks by Frequency

Categorize maintenance tasks into daily, weekly, monthly, and annual intervals. Daily tasks might include cleaning and lubrication, while monthly tasks could involve part replacements and calibration. This classification allows technicians to manage their schedules efficiently and ensures timely completion of crucial tasks. You can also see more on Equipment Checklist.

Step 3: Specify Each Task in Detail

For each maintenance task, clearly define the steps, tools, and techniques required. Include details like inspection points, cleaning procedures, lubrication instructions, and calibration standards. By providing specific instructions, you reduce the risk of errors, ensure consistency, and promote effective maintenance practices.

Step 4: Assign Responsibility and Accountability

Assign responsibility for each task to specific personnel. Specify the technician, maintenance team, or machine operator responsible for each inspection, cleaning, or repair. This ensures accountability and helps track task completion. It also prevents confusion regarding task ownership, leading to smoother operations. You can also see more on Room Maintenance Checklist.

Step 5: Use a Checklist Template or Software

To make maintenance tracking easier, use ready-made templates or maintenance management software. These tools allow you to create and customize checklists, set reminders, and track task completion. Using templates helps maintain a consistent format and ensures nothing is overlooked. Automated software can also provide maintenance history, performance data, and reminders.

A Machine Maintenance Checklist is essential for maintaining equipment performance, ensuring workplace safety, and reducing repair costs. It provides a structured approach to inspections, cleaning, lubrication, and part replacements. By following the checklist, companies can prevent unexpected breakdowns, increase machine lifespan, and maintain productivity. It also ensures compliance with safety and industry standards. A well-crafted maintenance checklist helps businesses track maintenance progress, reduce operating costs, and promote a safer, more efficient working environment. You can also see more on Field Inspection Checklist.

FAQs

Why is machine maintenance important?

When a machine fails due to a lack of Maintenance forms, it is unable to create the product that the firm sells, resulting in lost sales. You can reduce the effect of machinery and equipment failure and preserve your bottom line by ensuring that regular machine cleaning and maintenance are carried out. Without machine maintenance, the overall performance of the said machine may not be up to par and could heavily affect the productivity of the company. This is a bad thing since companies will suffer a loss of profit or time to repair a machine that could easily have been cleaned up during a scheduled maintenance.

What is equipment maintenance?

Any technique for keeping a company’s equipment in excellent working order is referred to as Equipment maintenance. It might encompass both normal maintenance and remedial repairs. Depending on the kind, different resources will be necessary to keep everything in perfect functioning order. After each shift, the business inspects its power tools. Their pneumatic jackhammers, for example, are inspected daily for hose fractures, bit wear, and loose screws. This not only extends the life of their products, but it also improves safety by eliminating severe equipment failures. Their tools are also more efficient, allowing them to stay productive. You can also see more on Daily Checklist.

Who is responsible for machine maintenance?

The maintenance crew can’t be everywhere at once waiting for anything to go wrong. This begs the question: who is truly in charge of detecting the tiny tweaks and enhancements that help your facility function more smoothly? Everyone is the short answer. Total productive maintenance is the concept that everyone should help in maintenance. Total productive maintenance is based on the belief that including the whole workforce in machine maintenance and prioritizing proactive and preventive maintenance would result in fewer breakdowns, a safer workplace, and improved overall performance.

How often should I use a Machine Maintenance Checklist?

The frequency of use depends on the equipment type and workload. Some tasks require daily checks, while others might be weekly or monthly. Daily inspections typically include cleaning and lubrication. More complex tasks like calibration or part replacement are done monthly or quarterly. Consult the manufacturer’s guidelines to set the correct frequency. You can also see more on Safety Inspection Checklists.

What happens if the Machine Maintenance Checklist is not followed?

If the checklist is not followed, machines may experience unexpected breakdowns, costly repairs, and safety risks. Delayed maintenance can cause wear and tear, leading to reduced equipment lifespan. Production may be disrupted due to unplanned downtime, affecting productivity and profits. Companies may face compliance issues, fines, or regulatory penalties for not maintaining equipment properly. Proper checklist usage prevents these risks, keeping equipment running efficiently.