3+ Sample Building Safety Inspection Checklist

FREE Building Safety Inspection Checklist s to Download

3+ Sample Building Safety Inspection Checklist

What Is a Building Safety Inspection Checklist?

What Is The Purpose of a Building Inspection?

How Is Building Safety Inspection Done?

What Is Included in The Building Safety Inspection Checklist?

Steps for the Building Inspection Checklist:

FAQs

What do building inspectors inspect?

What qualities should a building inspector possess?

What kinds of inspections are performed?

How can an organization benefit from conducting inspections?

What are the strategies for passing a building inspection?

What Is a Building Safety Inspection Checklist?

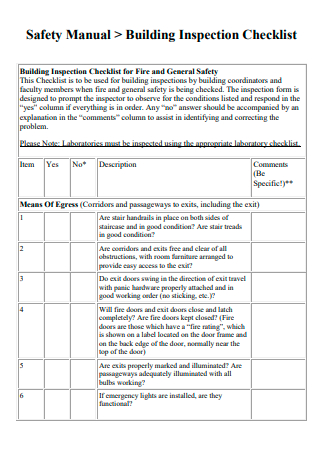

A building safety inspection checklist is a list of tasks on an on-site walk through to identify potential hazards to occupants and personnel and options for remedial action. Safety inspections are also important for property insurance issues. A review of safety equipment (emergency eyewash, shower, fire extinguishers, first aid kits, etc.) is also completed to verify proper working order.

After completion of a safety inspection, the responsible area supervisor, building coordinator, campus facilities maintenance and appropriate personnel is contacted for remedial action. These actions prevent future incidents, injury/illness, or property/equipment damage.

A building inspection is a process that determines whether or not an organization is in compliance with specific laws and regulations. Equipment, machinery, physical infrastructure and maintenance processes are all examples of things within a building that require regular checkups to ensure safety and compliance.

What Is The Purpose of a Building Inspection?

As stated above, the objective of an inspection boils down to two things: safety and compliance. Safety is the driver of compliance (either to a regulation or a company policy). When a company is in compliance, employees are better able to do their jobs because they are operating in a safe working environment that doesn’t put their health and wellbeing at risk. Compliance benefits everyone – it’s just good business!

How Is Building Safety Inspection Done?

Inspections are used to detect and eliminate any actual or potential hazards that could lead to accidents or incidents. There are companies or businesses who has the responsibility to provide a healthy and safe workplace. They may include an annual physical walk-through and an overall general preventive maintenance review. Safety inspections are intended to raise awareness of safety; detect unsafe conditions, deficiencies, and practices; and to make recommendations for corrective or appropriate remedial action(s).

What Is Included in The Building Safety Inspection Checklist?

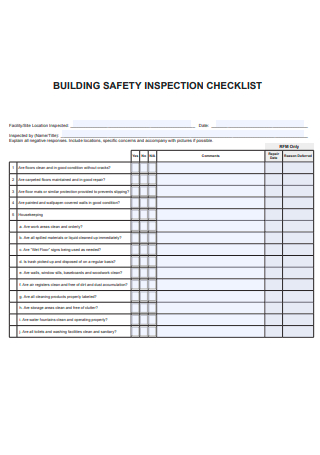

Housekeeping/Storage

- Workspace is generally clean and orderly.

- Walking surfaces inside and outside in good condition, free of cords and other tripping hazards.

- Exit paths and corridors are free of storage or obstructions.

- Emergency equipment (e.g., fire extinguishers, eyewash /shower stations, alarm pulls, etc.) are not blocked nor is access obstructed.

- Shelving over 4 feet tall is secured and not overloaded.

- Materials are stored and secured to prevent falling or collapse.

- No combustible items are stored within 18” of fire sprinkler heads.

- No combustible items stored within 24” of ceiling in non-sprinklered area.

- Break rooms and rest rooms are clean and sanitary.

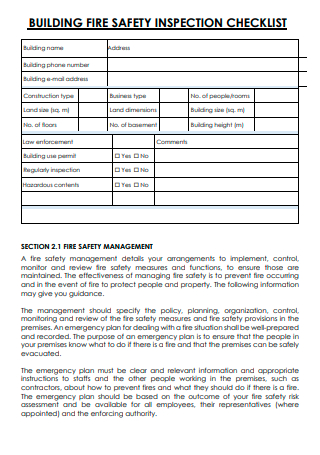

Fire Prevention/Fire Protection

- Fire doors are not propped open or obstructed and latch automatically when released.

- Fire extinguishers are mounted, accessible, and inspected monthly.

- Heat-producing appliances should be unplugged when not in use and located on a non-combustible surface.

- Portable heaters shut off automatically when tipped over and are UL listed.

- Flammable liquids are stored in approved cabinets.

- No storage of combustibles under open stairs or in electrical/mechanical spaces.

- Portable gas cans being used to store fuel are metal, no more than 5 gallons UL listed. Plastic cans are for immediate use only.

- Fire prevention equipment is properly functioning and maintained according to manufacturer’s specifications.

Electrical

- Electrical cords and plugs are not frayed, cut or damaged.

- Extension cords are not being used in place of permanent wiring, are UL listed, and plugged directly into the wall.

- Power strips are circuit-protected and plugged directly into outlets (i.e., not “daisy-chained” together).

- There are no multi-plug adapters being used.

- Ground fault circuit interrupter (GFCI) protection is provided for electrical receptacles within 6 feet of a water source, for exterior outlets and throughout labs.

- Electrical equipment is properly grounded.

- Electrical panels have access space 30” wide and 36” in front.

- All outlets, switches and junction boxes have cover plates.

Chemicals

- Chemical inventories are complete and Safety Data Sheets (SDSs) are available/accessible to all workers.

- Chemical containers are properly labeled and stored on shelves with lips, below eye level.

- Fume hoods are not used for storage of chemicals.

- Chemicals are stored by compatibility, not alphabetically.

- Expiration dates on chemical containers have not been exceeded.

- No food or beverages are being stored or consumed in areas where chemicals are used or dispensed.

- If required, spill kits are on-hand and adequately maintained.

- Compressed gas cylinders are properly secured at all times, away from exits.

- Doors are signed indicating chemical and/or physical hazards and PPE requirements.

First Aid/Life Safety

- First aid kits are available and properly maintained.

- An adequate number of employees are certified in first aid, CPR and AED.

- Exits and emergency routes are properly marked and illuminated.

- Exterior walkways are in good condition and adequately illuminated.

- Handicapped entrances and exits are identified and unobstructed.

Equipment

- Machine guards are in place.

- Personal Protective Equipment (PPE), where required, is accessible, stored correctly and properly maintained.

- Equipment is being properly arranged, used, maintained and inspected.

- Only Type 1A, 1, or 2 ladders are available as needed (Type 3 not allowed).

- Flashback protection is installed on oxyfuel hoses.

Steps for the Building Inspection Checklist:

A constant and effective approach to inspecting facilities, equipment, materials, processes, procedures, and buildings is necessary to prevent illnesses, injuries, and Potential Hazards.

-

Step 1: Preparation.

The first step of conducting an inspection is to ensure you have the answer to three questions?

What will I inspect? It sounds like common sense, but you need to know ahead of time what you are actually inspecting. The requirements to inspect a construction site are much different than a wheel loader, for example.

How will I inspect? Will you be using a paper checklist form or software? Do you have a floor plan? Do you have any special instructions that must be followed to complete your inspection? When will I inspect? Make sure you have set aside enough time to complete the inspection.

-

Step 2: Training.

Workplace inspections aren’t necessarily complex, but they can be. It’s essential to train any personnel who will conduct inspection. They need to know the area, assets, potential hazards, controls, and how to use information from previous inspections. They should also be familiar with the data from previous accident and maintenance reports.

-

Step 3: Inspection.

Inspecting requires attention to detail. Inspectors need to be fully alert and keep their eyes and ears open for all potential hazards. Checklists guide inspectors, but a safety mindset is also important.

-

Step 4: Documentation.

If an inspection checklist book or inspection software is used when conducting the inspection, any defects or hazards will be documented in the results of the inspection. By maintaining a detailed record of the inspection, where it was conducted, when it was conducted and what risks were identified, it is easy to prove due diligence should you ever need to do so.

-

Step 5: Closing the Loop.

Once an inspection is complete and any potential hazards identified, it’s crucial to close the loop by ensuring actions are taken to address any issues. Ideally, there will be a record of the inspector informing Management or maintenance about defects and problems.

FAQs

What do building inspectors inspect?

Commercial building inspectors review many documents during the inspection process. They may review appraisals, building plans, citations, certificates of occupancy, construction permits, evacuation plans, environmental studies, fire safety system records, floor plans, maintenance records and surveys.

What qualities should a building inspector possess?

Construction and building inspectors need to:

Communicate

- Speak clearly so listeners can understand.

- Understand spoken information.

- Read and understand work-related materials.

- Listen to others and ask questions.

- Understand written information.

- Write clearly so other people can understand.

Reason and Problem Solve

- Notice when something is wrong or is likely to go wrong.

- Combine several pieces of information and draw conclusions.

- Use reasoning to discover answers to problems.

- Analyze ideas and use logic to determine their strengths and weaknesses.

- Recognize the nature of a problem.

- Judge the costs and benefits of a possible action.

- Develop rules that group items in various ways.

- Follow guidelines to arrange objects or actions in a certain order.

- Understand new information or materials by studying and working with them.

- Identify what must be changed to reach goals.

- Concentrate and not be distracted while performing a task.

- Recognize when important changes happen or are likely to happen in a system.

Use Math and Science

- Use math skills to solve problems.

- Manage Oneself, People, Time, and Things

- Manage the time of self and others.

- Check how well one is learning or doing something.

Work with People

- Teach others how to do something.

- Persuade others to approach things differently.

- Use several methods to learn or teach new things.

- Change behavior in relation to others’ actions.

- Solve problems by bringing others together to discuss differences.

- Be aware of others’ reactions and understand the possible causes.

Work with Things

- Inspect and evaluate the quality of products.

- Perceive and Visualize.

- Identify a pattern (a figure, object, word, or sound) that is hidden in distracting material.

- Quickly and accurately compare letters, numbers, objects, pictures, or patterns.

- Imagine how something will look if it is moved around or its parts are rearranged.

What kinds of inspections are performed?

Different companies inspect several areas for different reasons:

- Hazardous Materials Management inspects areas using and storing hazardous materials.

- Radiation Safety inspects areas using and storing radioactive materials.

- There are also property insurance inspections, food safety inspections, and general safety inspections. While each inspector has a specific list of items to look for, they all work together to spot problems areas.

How can an organization benefit from conducting inspections?

Inspections ensure safety and compliance with codes, but they also illuminate potential risks and hazards in your building. Moreover, inspections inform which repairs and replacements should be prioritized when it comes to capital planning. Here are four ways that your organization will benefit from conducting regular in-house inspections:

- Inspections help identify existing (and potential) hazards in the building. A physical safety audit, conducted by your maintenance team, will reveal anything within your building that poses risks to visitors, staff members and occupants of your building. Regularly scheduled visual inspections will help your facilities team determine how well (or not so well) current measures are working.

- Inspections will help you monitor your progress toward risk control and abatement. Inspection reports will prove the progress you’ve made as an organization and demonstrate that actions have been taken to remedy any red flags revealed during an inspection. Consistent evaluation will lead to increased progress toward safety and compliance.

- Inspections will help your safety team determine the underlying causes of safety risks. Facility directors and their teams take safety and security within their buildings very seriously. Maintenance teams can utilize frequent inspections to identify risks and take steps to mitigate them before an inspector even arrives.

- Inspections reveal corrective actions required to remedy compliance issues. Corrective action may involve adjusting company policies, reviewing safety procedures, wearing additional personal protective equipment or speaking with employees to understand their safety concerns. Inspections will help your organization gain insight into everyday operations and how they can be adjusted to promote safety.

What are the strategies for passing a building inspection?

1. Improve efficiency of inspection routines with the PDCA Cycle. The “Deming Cycle” (also known as the PDCA Cycle) is a quality improvement model that promotes continuous improvement in the workplace. This four-step model can be applied to a variety of situations, including facility inspection routines. Let’s take a closer look at how leadership teams can utilize the cycle to improve the ease of inspections. The Deming Cycle is a model that aims to solve problems and implement solutions in a rigorous, methodical way. Use this framework to help your maintenance team explore a range of solutions to problems and pilot them in a controlled way before selecting one for implementation. Continuous improvements will benefit your safety program and help your organization reach its company-wide initiatives.

2. Utilize this safety inspection checklist to reduce risks and hazards. Performed by a safety officer, a safety inspection (or audit) assesses risks and hazards in the workplace. It also evaluates the reliability of health and safety systems. Your executive leadership team can utilize the results of this process to prevent work-related incidents, injuries and fatalities, and ensure that your organization complies with safety requirements.

3. Get a reliable building inspection checklist. Having a proper building inspection process in place is integral to a safe, functional and code-compliant work environment. Inspections not only reveal regular wear-and-tear on equipment, but also alert your team to dangerous equipment malfunctions that could result in injury or even death.

Here’s a list of best practices to follow when putting an inspection process in place at your organization.

- Utilize a building inspection checklist to know what to look for when conducting an inspection.

- Elect a different employee to check that the action has been taken care of by the agreed time.

- Elect an employee to complete an inspection by a specific date and time.

- Record all inspection results in a facility inspections software to produce an audit trail.

- If an inspection fails, elect an employee to remedy the issue and provide a hard deadline of when the task should be completed.

- Provide consistent training sessions during the year for all members of your inspections team.

4. Aggregate critical information for inspectors in a specialized software. In today’s technology-driven world, it is not uncommon for inspectors to accept (or even prefer) using an organization’s inspection software to prove compliance. An inspection software can eliminate bulky binders of asset maintenance history, and is much faster and more convenient for inspectors to use than traditional organization methods. Your building inspector will enjoy the convenience of having this information right at their fingertips.

Maintenance team will be empowered to instantly create inspection-related work orders and close them out once procedures have been concluded. If your organization has been on the fence about purchasing an inspection software to help track your compliance, make this year the year that you commit.

The top priority of any inspection is to assist in eliminating or significantly reducing the chance of injury and incidents. The steps are a great place to begin ensuring that you are getting the most out of your inspections.