50+ Sample Material Lists

-

List of Approved Material

download now -

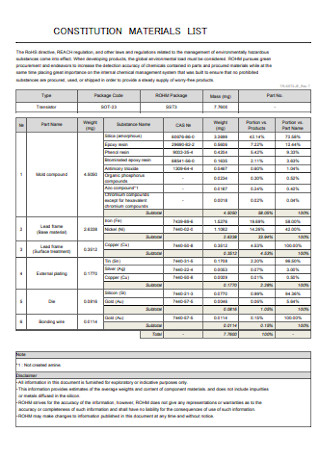

Constitution Material List Template

download now -

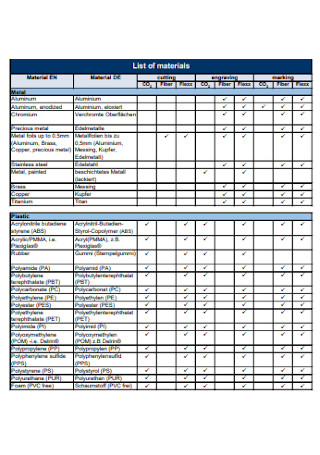

Sample List of Materials Template

download now -

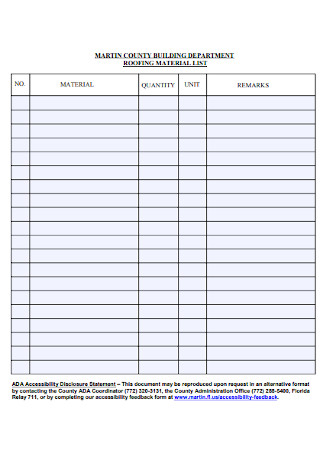

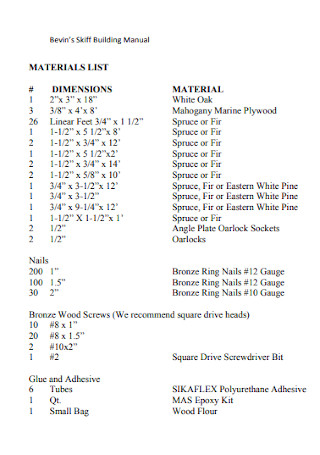

Building Material List Template

download now -

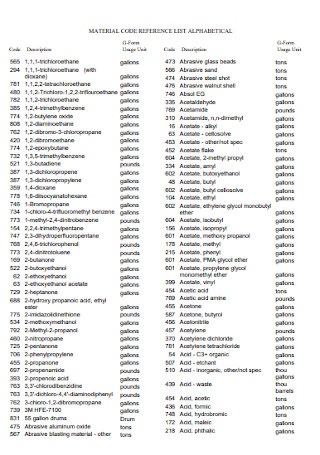

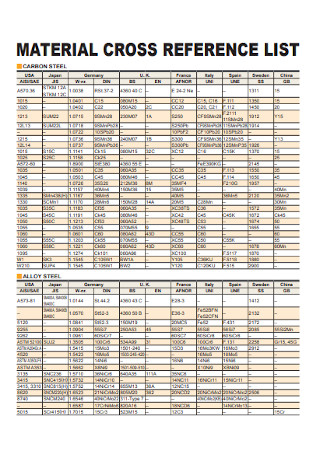

Material Code Reference List

download now -

Simple Material List Template

download now -

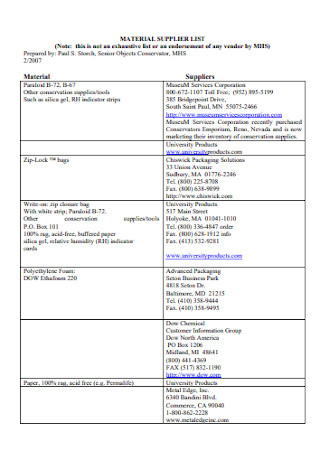

Material Supplier List Template

download now -

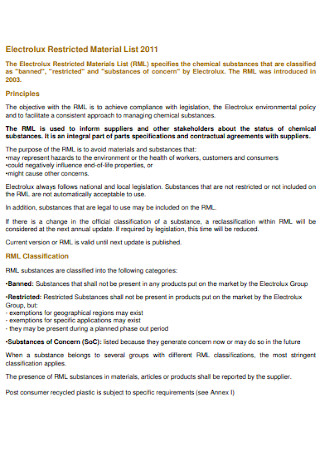

Sample Restricted Material List

download now -

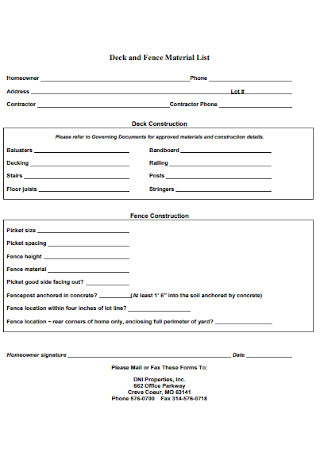

Deck and Fence Material List

download now -

Organic Input Material List

download now -

Material Price List Template

download now -

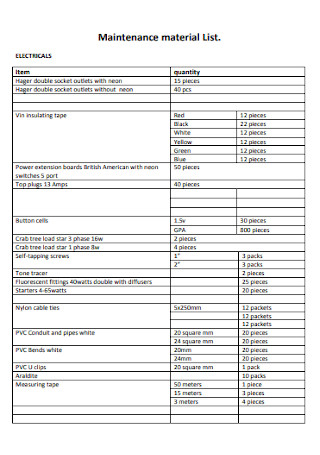

Maintenance Material List Template

download now -

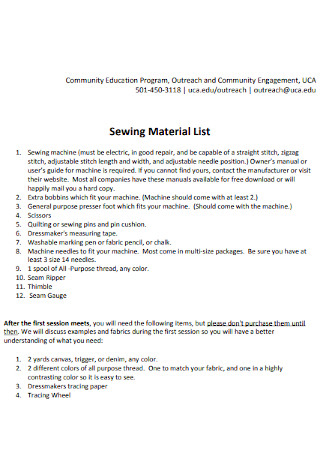

Sewing Material List

download now -

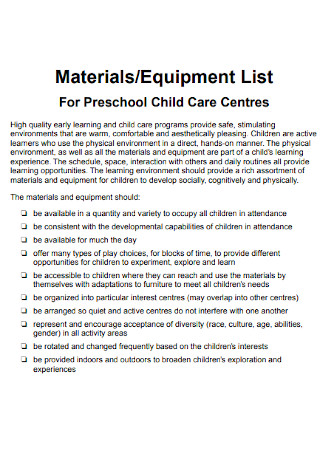

Material and Equipment List

download now -

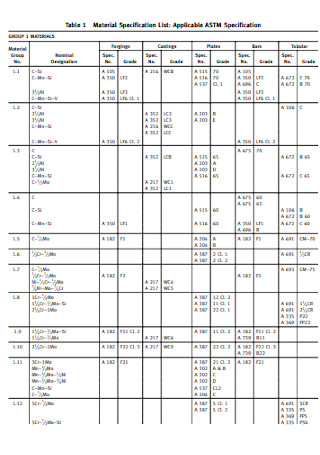

Material Specification List

download now -

Additional Exam Materials List

download now -

School Materials List Template

download now -

List of Material third Countries

download now -

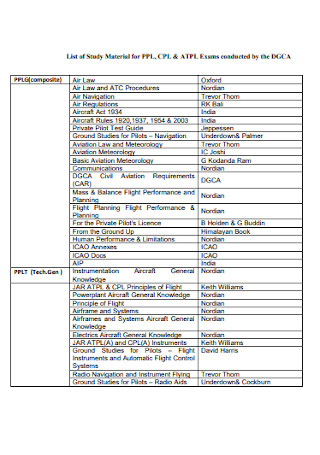

List of Study Material Template

download now -

Student Material List Template

download now -

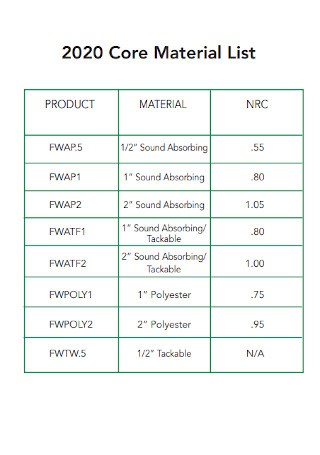

Core Material List Template

download now -

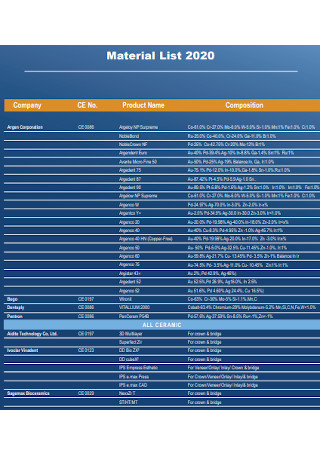

Material List Format

download now -

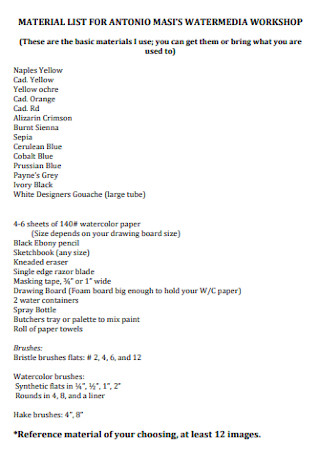

Workshop Material List

download now -

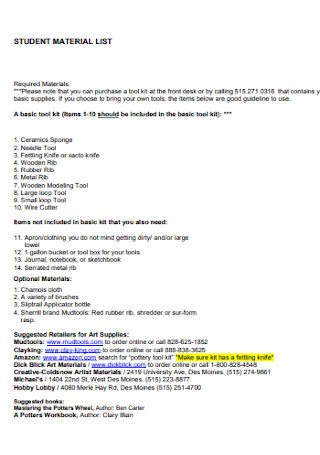

Student Material List Example

download now -

Basic Material List Template

download now -

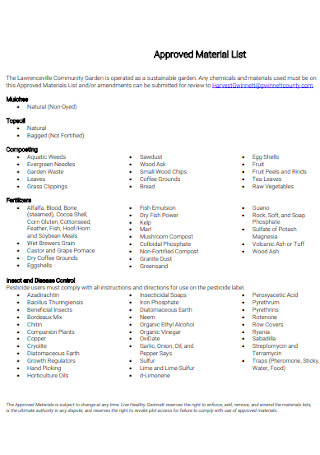

Garden Approved Material List

download now -

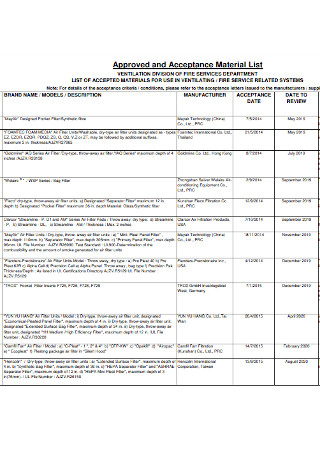

Approved and Acceptance Material List

download now -

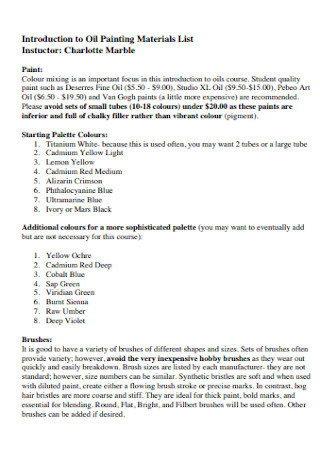

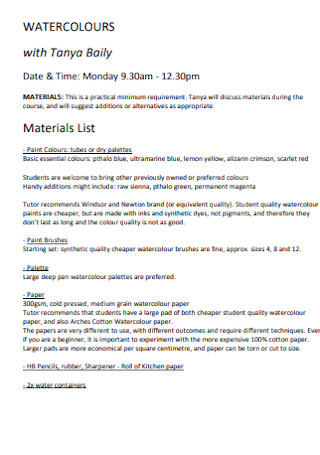

Oil Painting Materials List

download now -

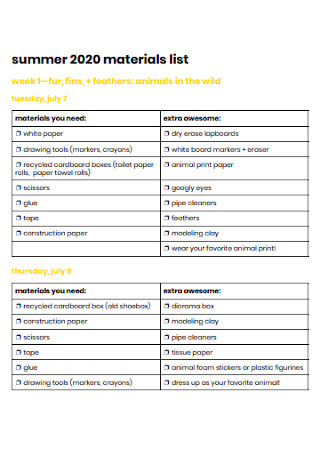

Summer Material List

download now -

Straight Line Style Material List

download now -

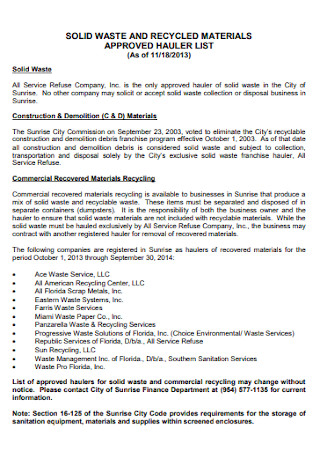

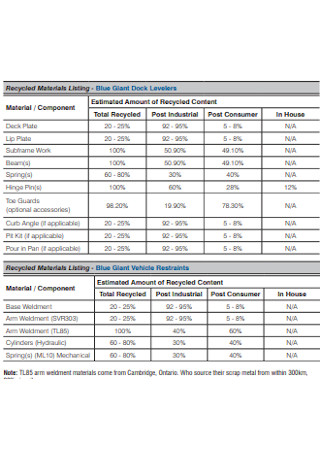

Recycle Material List

download now -

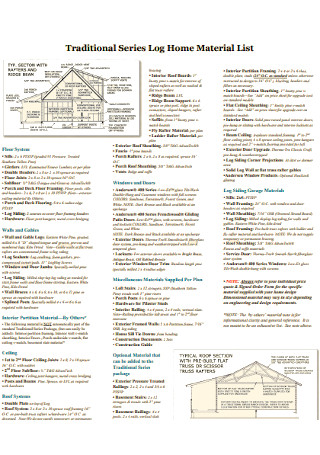

Home Material List

download now -

Recycled Materials List Template

download now -

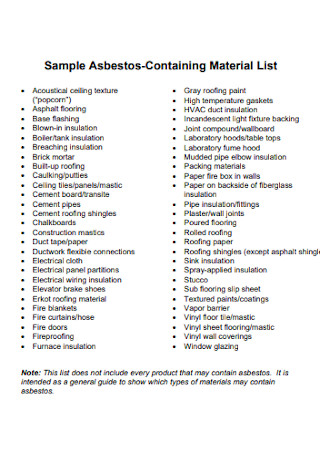

Sample Asbestos-Containing Material List

download now -

Material Cross Reference List

download now -

Landscaping Material List

download now -

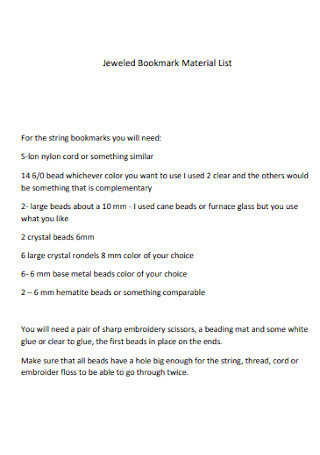

Bookmark Material List

download now -

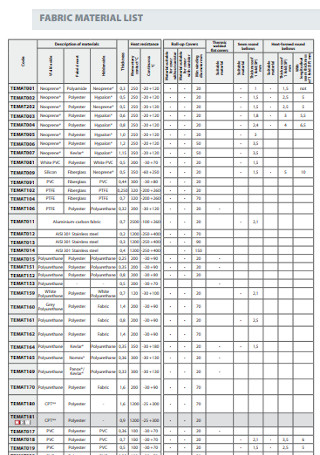

Fabric Material List Template

download now -

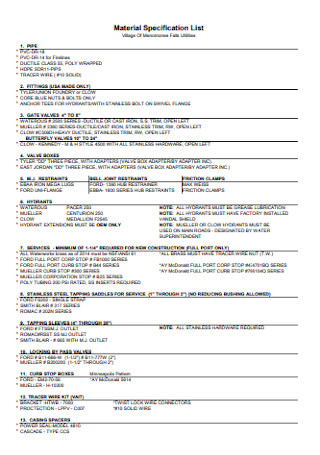

Material Specification List

download now -

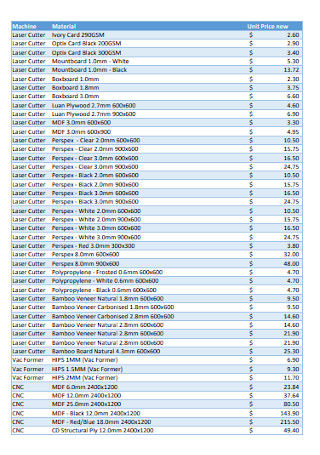

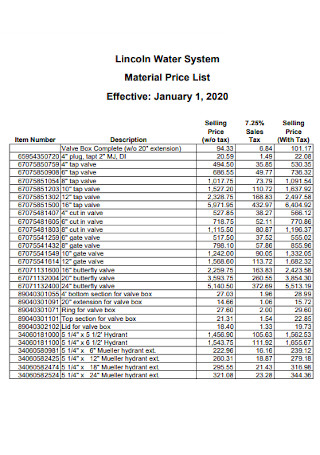

Material Price List

download now -

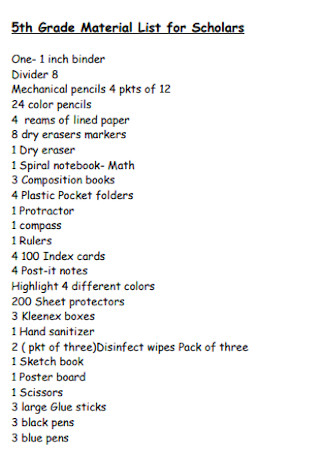

Material List for Scholars

download now -

Materials List Format

download now -

Non-conductive Materials List

download now -

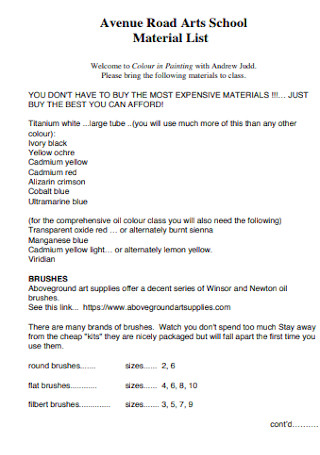

Arts School Material List

download now -

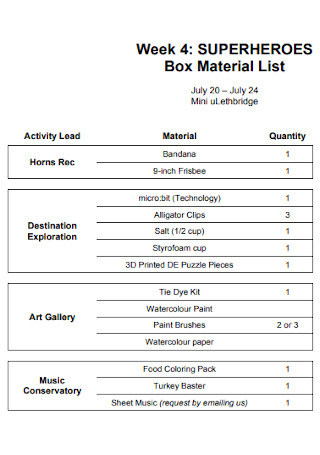

Box Material List Template

download now -

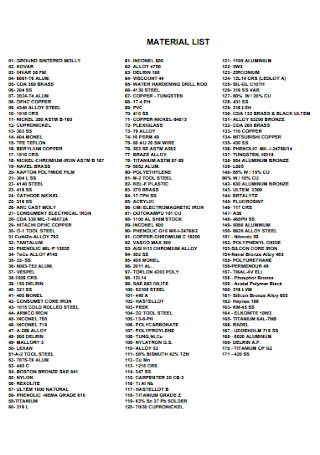

Standard Material List Template

download now -

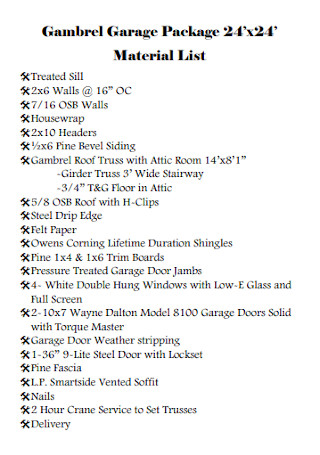

Garage Material List Template

download now -

Simple Material Liist Template

download now -

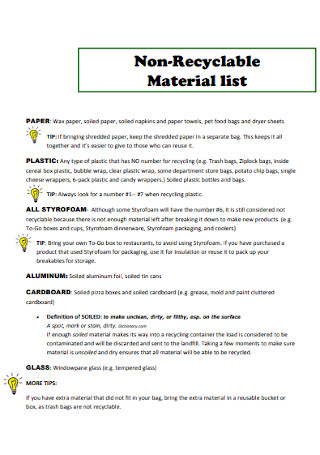

Non-Recyclable Material List Template

download now -

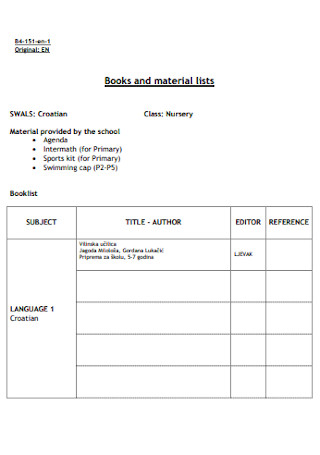

Books and Material Lists Template

download now -

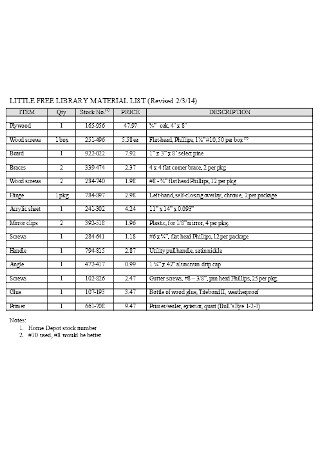

Library Material List Template

download now

What Is a Material List?

Planners and those who implement initiatives in practice frequently utilize a materials list. These may include the chief of the department of planning, project promoters, engineers, and others involved with the project. In essence, the inventory list template greatly assists all involved parties. Even the client must have access to these documents to estimate the total cost of the process. A statement is required for any job that requires various materials, whether for construction, cleaning, or other purposes. A material list is of utmost significance to those involved in the task’s execution. They must obtain the correct list on time to plan the budget report and material availability.

Benefits of Material List

Money does not grow on trees, nor do building materials materialize out of thin air. Material administration is a crucial and intricate aspect of every construction undertaking. Material management encompasses a broader range of activities, from planning and procurement to waste management and disposal, although many people associate it predominantly with the purchasing and delivery phase. Investing in your materials management system enhancements can significantly positively affect your overall construction management efforts, given its impact on workflows and profitability. Among the numerous advantages of construction material management are the following:

How to Have a Successful Material Management

Modern supply chain management is quite complex. There are numerous perspectives on which areas of expertise are most crucial to the success of a production, and each has compelling justifications for the top spot; materials management is one of them. Similar to the importance of oxygen to life, material flow is a driving factor in industrial performance. With adequate materials management, proper material flow and good inventory management often occur, resulting in dissatisfied customers, shutdowns, disgruntled employees, etc. Material and inventory difficulties can make or break a launch from consumer products to driverless vehicles. One missing component is all it takes to ruin the entire thing. A proper materials management system is crucial to the success of a launch and the organization, so ensuring it is appropriately in place and functioning is of the utmost importance. For this reason, we recommend that organizations focus on the five areas listed below to achieve materials management success: strong leadership and communication, proper systems and bill of material routing, inventory management, production reporting, and material flow chart and organization.

1. Strong Leadership

As with any department in a business, success is driven by top-down leadership and executed daily. A team must have faith in its leader and be motivated to complete duties on its behalf. Leaders must be willing to work alongside their team rather than simply dictating from a desk. Materials management requires leadership due to the moving parts and coaching proposal possibilities; materials are the foundation of all other sections inside a plant or manufacturing facility. Although every department should have strong leaders, materials management may be the most crucial due to the numerous ramifications of the process and flow. Strong materials leadership will reduce the likelihood of material difficulties in an organization.

2. System and Bill of Materials Scheduling

Whether a full-fledged ERP or a custom system, maintaining the correct technique and routing of the BOM is essential to the success of the program and materials. This is also BOM or Plan for Every automated Part software. The BOM or BOMs must be entered into any of these locations to guarantee proper routing. A system that all team members trust is the primary objective. Team members need trust in an action plan to fully utilize it, producing a solid link in the chain.

3. Inventory Management

Inventory management is essential for any production site or program; nevertheless, the significance of effective processes, systems, control, and reporting is sometimes underestimated. A system catalyst, product organization, a cycle counting program, and, most significantly, regular production reporting and proper system part routing are the cornerstones of an effective inventory control system. A thorough approach that allows you to categorize your inventory will guarantee that you always have materials and, more significantly, that you always have to turn away a customer.

4. Production Reporting

Ensure that all team members are trained in producing a production report at each process stage until the finished product leaves the facility. Also, if not more crucial, is the correct routing of parts in the BOM. Due to poor backflushing, if any item in the part routing is erroneous, it will not be appropriately indicated in inventory sheets. Production reporting assesses, visualizes, and comprehends the current and historical performance of production activity. It comprises dashboards, reports, timeline charts, and graphs that make it easier for users to understand key performance indicators (KPIs) and identify problems like bottlenecks, unplanned downtime, and inefficient machine use.

5. Material Flow & Organization

Implement a plan or system that outlines the material flow from raw to formed to WIP to final. Understanding the relationship between each material and component is the foundation of a successful material flow. Ensure that material flow is engineered at the outset of a facility or program launch to control how things move smoothly, what causes them to move, and what occurs between processes. A well-constructed material flow system can assist individuals in organizing their work, adjusting to unforeseen changes, and solving difficulties.

FAQs

Why are lists so important?

Maintaining such a list ensures that all your tasks are written down in one location so you remember everything significant. By prioritizing a task list, you organize the sequence in which you’ll complete them, so you may determine which requires immediate attention and which can wait.

Why are lists effective in writing?

Lists enable you to underline key points. In addition, they improve the readability of text by shortening lengthy phrases and paragraphs and adding attractive passive space to make reading more enjoyable. However, employing the incorrect list type or improper formatting can help improve readability.

What is a material checklist?

A material inspection checklist is a document that construction workers use to keep track of the condition of materials as they arrive at a job site. Use a free Material Inspection Checklist template to note how things look before you use them in a building project.

A material list is of utmost significance to those involved in the task’s execution. They must promptly obtain the correct list to plan the budget and material availability. Additionally, you can alter the Supply List templates you find online.