19+ SAMPLE Excel Scorecard

FREE Excel Scorecard s to Download

What is an Excel Scorecard?

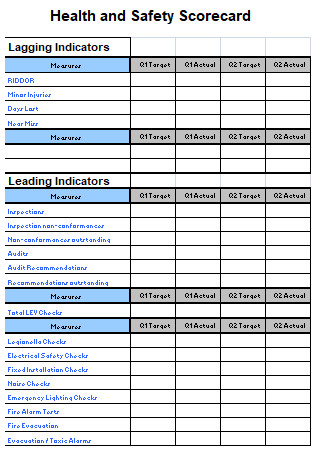

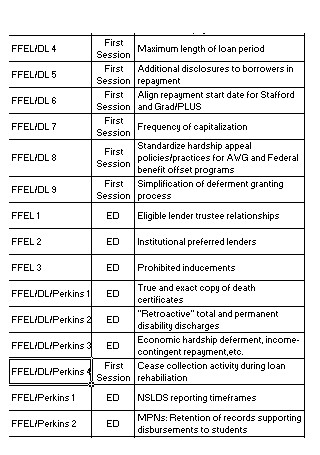

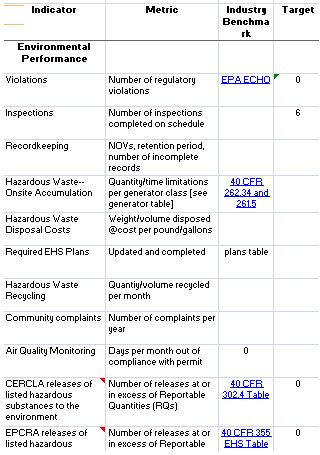

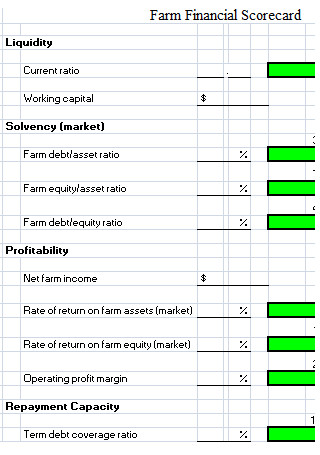

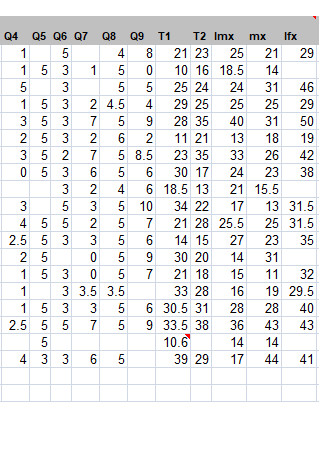

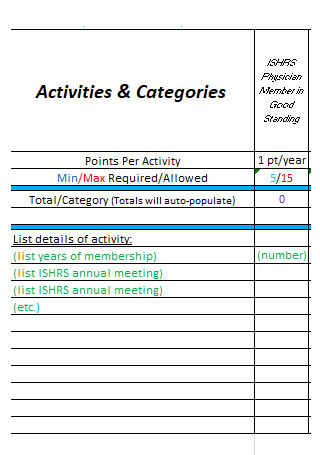

An Excel scorecard is a great tool where you can visualize the financial and learning growth of your business. It is like a professional balanced scorecard that focuses on the organizational performance of your business. Scorecards may vary according to the organization. You can take care of your customers and your internal business with this convenient tool. Some examples of an Excel scorecard are an Excel baseball scorecard, an Excel cricket scorecard, and an Excel call center agent performance scorecard. To create an Excel scorecard, an Excel scorecard example can help you. In case you wonder how to make an Excel scorecard, you can search for an Excel scorecard template or a Microsoft Excel scorecard template.

On the other hand, if you have the desire to know how to calculate scorecards in Excel, you must be familiar with any Excel scorecard formula. An Excel scorecard dashboard can also help you to manage your performance targets. Through the scorecard, you can measure the activities of your business with a long-term view. You can also decide on the best strategic operational plan to use. The philosophy of scorecards gives a global vision to your company. Just like a vendor scorecard, an Excel scorecard can be a balanced scorecard that can help you manage the business strategy. In the end, you will be able to achieve your business goals.

Points to Know in an Excel Scorecard

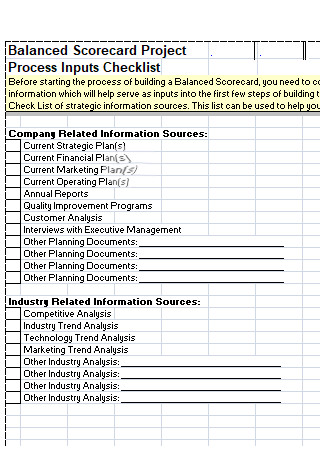

Before you can create an Excel scorecard, you must first have a good strategy for collecting the information. To start with, you need to know the following things so that you can construct a great Excel scorecard:

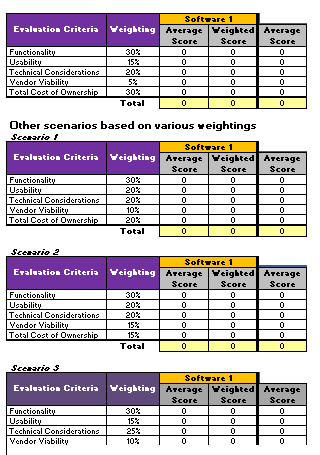

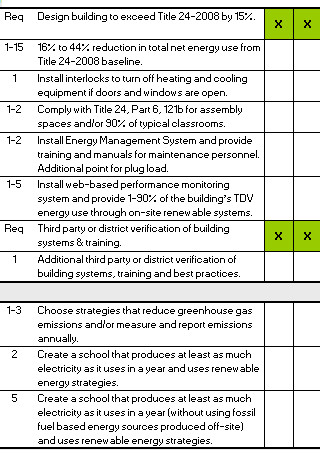

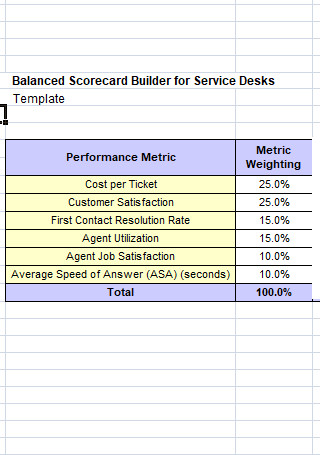

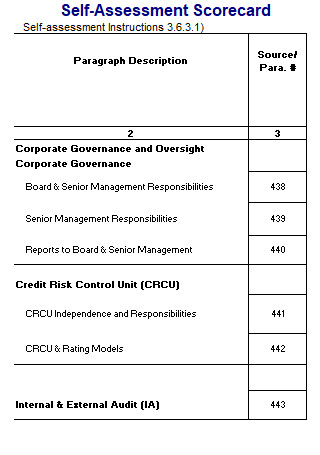

Responsibility: An Excel scorecard can be a part of the professional growth plan of your business. But it will not be effective unless all the team members know how to handle responsibilities. Designate a certain action plan for each team member to achieve your business goals. When everyone is responsible, you can be sure that your company can meet the performance targets. Everyone will work hard to give the best performance for the business. They will make sure that they keep the standards of the company with every task. But of course, you have to be good at delegating tasks. Be sure that you will assign the right roles to every team member. When work is properly assigned, you can expect success. Be sure that every worker is adept at every task that you are going to give. If not, make them attend training that can make them properly skilled in the tasks. Have the assurance that every team member can participate well in your projects. This way, you can be sure of great performance from every team member. The result will be great projects that will give success to your business.Schedule: You have to consider the schedule in your business when making an Excel scorecard. Be apt to monitor the daily schedule or weekly schedule of your business. The project timeline depends on the work schedule of your team members so you have to be sure that you have the right schedule. This way, you can be sure that you can finish every project. You can also ascertain that every project will be a success. If projects have the right timeline where team members will be given enough time to work well on the projects, you can make sure that they can deliver a great job. So as you can see, schedules truly matter in the performance targets of your business. If you want your employees to excel in all the tasks that you are going to give, you must allot proper time for their work. This way, they will not be in a hurry to finish a project. They can ensure that their work is accurate and they will have enough time to correct their mistakes. Workers are not mills that we can expect to work like a machine. There should be a good work schedule for every task so we can expect that they can accomplish every task so well. With a good schedule, everyone can attain the goals of their tasks.Target: Having targets is very important in business. Every business should have things like sales targets and performance targets. By having targets, we can have exact goals that we can strive for. It will be good to set a daily action plan for all your employees. They must be able to reach KPIs to achieve the goals of your business. When you have targets, your employees will work hard to keep up with them. Without targets, they may become too slack in work. But through targets, you can encourage them to strive harder in work. Every employee will not stop until he or she reaches the targets of your business. Because of this, you can expect every team member to be productive. You just have to assign some targets for their work schedule and you can expect perfect results, especially if your employees are capable. By having targets, you can be sure of the KPIs of your business. A great performance can be achieved and every quota can be met. With this, you can expect your business to generate more profits.Metrics: To ensure a great performance, you should have metrics for your performance targets. An Excel scorecard should have metrics so that you can be sure that you have achieved your purpose. By having metrics, you can check if your business is doing well. If your team members can keep up with the metrics of your business, then you know that they are working according to the standards of your company. Following metrics means reaching the performance targets of your business. So, your spreadsheet should use analytic tools that will show the quantitative growth of your company. By using the Excel scorecard, you can compare the objectives with the true results. So, you will know if you are keeping the KPIs of your business.Actions and Observations: The Excel scorecard will be effective if you will have the right actions and observations for it. Observations can make you know what you have to do to make implementation plans that can improve your business. By having observations, you can tell what deter the success of your business. You can be able to learn the strengths and weaknesses of your business. With this, you can strive harder to keep the strengths of your business and you can change your mistakes in your business. After having the right observations, you can make actions that will change your business for the better. So, you can have project action plans that can make you have better projects. By performing the right actions for your business, you can surely accomplish any goal of your business. It will be easy for you to reach even those goals that may seem unreachable.Strategic Goals: You should be able to define strategic goals to build an Excel scorecard. By doing this, you can consider every perspective of your business. Regarding the customer perspective, you may be able to succeed in the new customer acquisition. When it comes to your financials, you can have sustainability for the growth of your business. You can even reduce production costs and business process improvement costs. Strategic goals are needed so that you can have great innovation in your business. When you have new ideas for your business, you can be sure that you can find a way for your business to grow.Dashboard: The dashboard is something that you should consider in making an Excel scorecard. This can give you the big picture of your strategic vision. You can identify the needs of your customers through a dashboard. A sales dashboard can also make you know the business figures. You will know your earning and sales growth, even the risks in your business. Through a dashboard, an Excel scorecard can be more effective.

Benefits of an Excel Scorecard

Why is an Excel scorecard used by businesses? Is it because it can give better success to a business? This thing is sure when you create an Excel scorecard. It will be also good for you to know that an Excel scorecard has many benefits.

Gives Structure to Your Strategy: When you have an organizational strategic plan, you must have an Excel scorecard that can help you measure your strategy. With it, you can have strategic management where all areas of the organization will be easy to understand.Getting a Good View of Your Organization: Through an Excel scorecard, you will know where your business is going. Thus, you can have accurate insights for your business.Having Better Communication: To have an Excel scorecard is a good tool for your marketing communications plan. Through it, team members can find a good way to communicate about their performance.Knowing Cause and Effect: Through the Excel scorecard, you will know the cause and effect that affects the performance of your employees. Thus, you can do the necessary measures to solve any problems at hand.Gives Accountability: When your employees know that performance reports are given through the Excel scorecard, they can become accountable to work better. They will make sure that you can see the best performance from them.

How to Create an Excel Scorecard

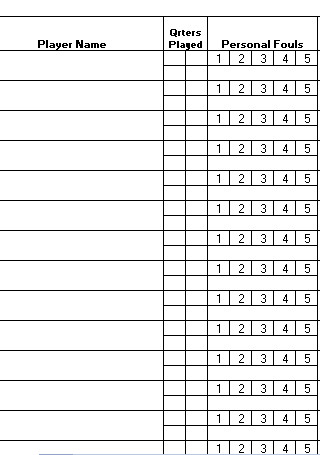

Making an Excel scorecard may not be that easy. You should need to follow some steps so that you can create an effective scorecard. Have the following steps:

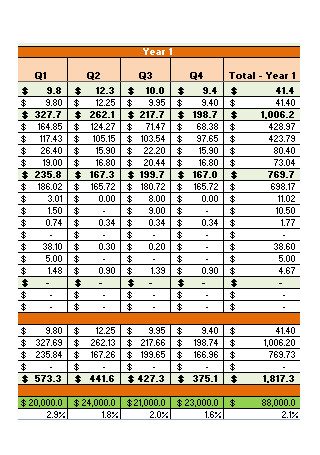

1. Visualize Your Sales

The first thing to do is to visualize your sales. Know that the Excel scorecard will be derived from the sales report. So, you must first diligently gather the sales report.

2. Create a Dashboard

It is necessary to create a sales dashboard to make the Excel scorecard effective. After that, you can input all the necessary information about the sales performance of your business.

3. Analyze the Scorecard

When you have included all the required information, you can start analyzing the Excel scorecard. By analyzing, you can make a data analysis report afterward if you want.

4. Make Recommendations

After analyzing the data, you can be able to make observations. Through your observations, make recommendations that can give improvement to your business. If you have not reached your KPIs, make strategies so you can achieve them next time.

FAQs

What are the tips for an Excel scorecard?

The tips for an Excel scorecard are to start simple, make a good framework, discuss everything with the upper management, use software, and be flexible.

What are the disadvantages of an Excel scorecard?

The disadvantages of an Excel scorecard are it has an overwhelming framework, it requires strong leadership to be successful, and it is difficult to manage.

Excel scorecards are implemented by businesses in different ways. But what matters is that you monitor the scorecard from the start to the end. Stick to your employee development plan to improve the performance targets of your company. Not only can you make the performance of the employees better, but you can also improve the performance of your business as a whole.