54+ Sample Quality Checklists

-

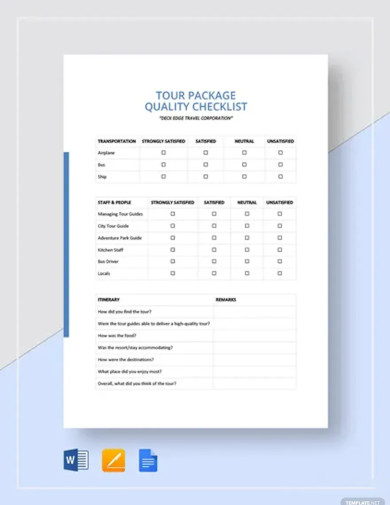

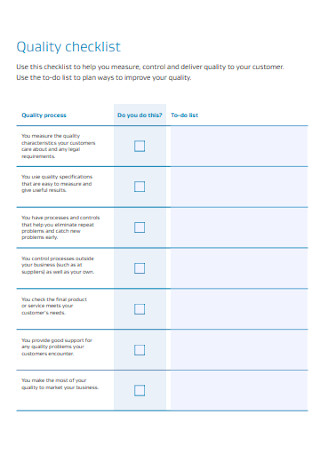

Quality Checklist Template

download now -

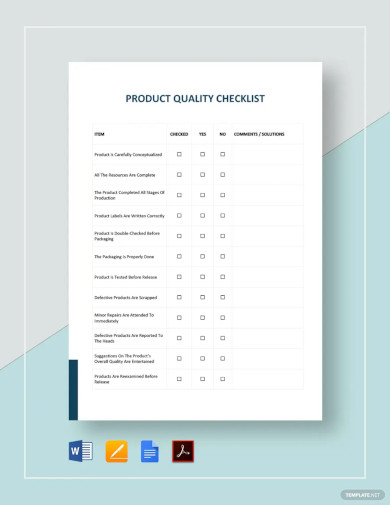

Product Quality Checklist Template

download now -

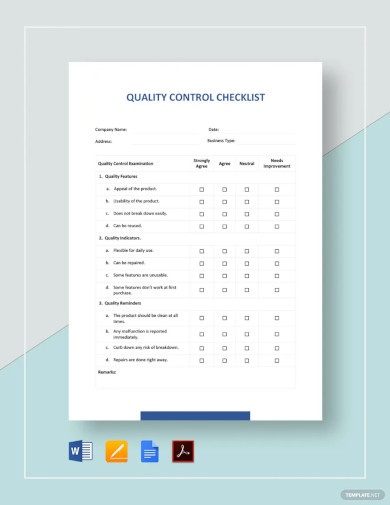

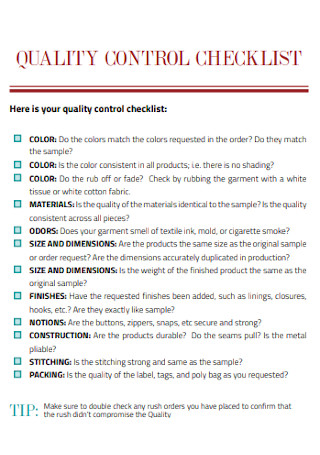

Quality Control Checklist Template

download now -

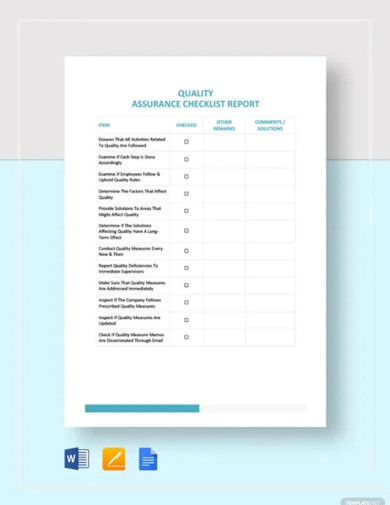

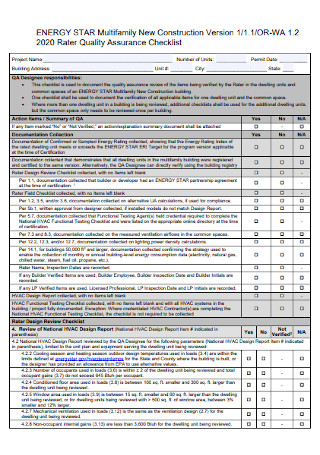

Quality Assurance Checklist Template

download now -

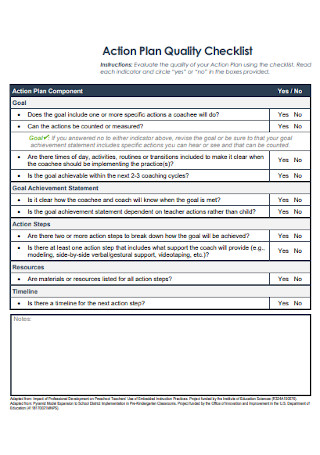

Action Plan Quality Checklist

download now -

Website Quality Assurance Checklist

download now -

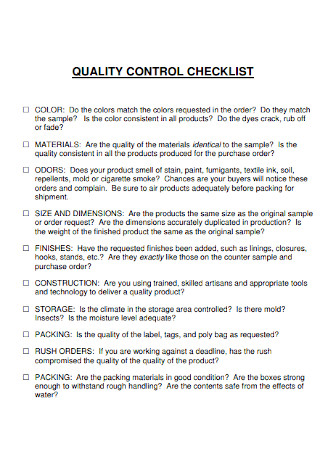

Quality Control Checklist

download now -

Point Quality Control Checklist

download now -

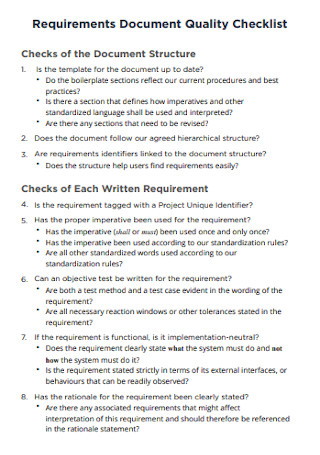

Requirements Document Quality Checklist

download now -

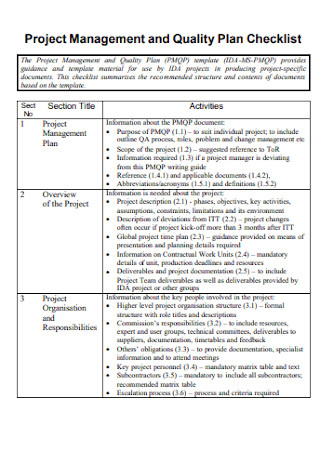

Project Management and Quality Plan Checklist

download now -

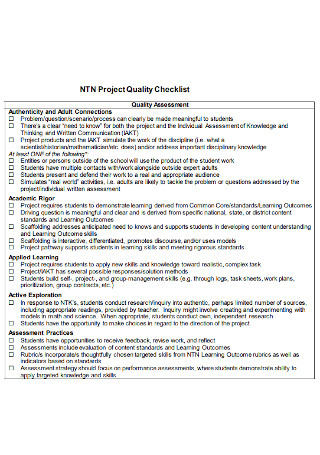

Project Quality Checklist Example

download now -

Course Quality Checklist

download now -

Simple Quality Checklist

download now -

Quality Assurance Checklist

download now -

Classroom Quality Checklist

download now -

Checklist for Quality Assessment

download now -

Standard Quality Control Checklist

download now -

Construction Quality Checklist

download now -

Quality Inspection Checklist

download now -

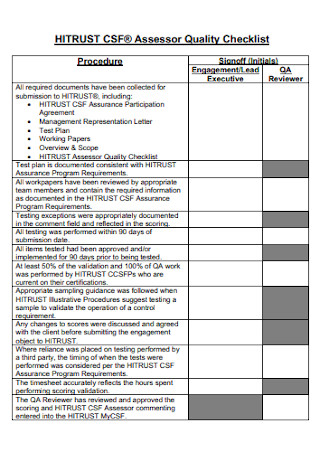

Assessor Quality Checklist

download now -

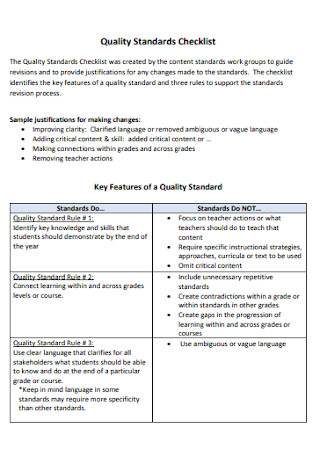

Quality Standards Checklist

download now -

Quality Sport Checklist

download now -

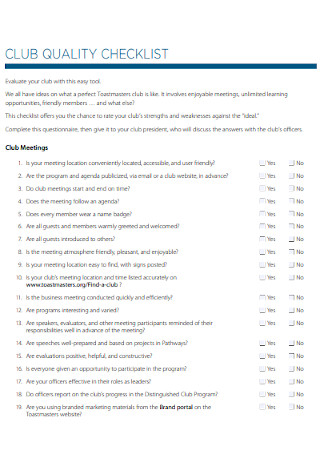

Club Quality Checklist

download now -

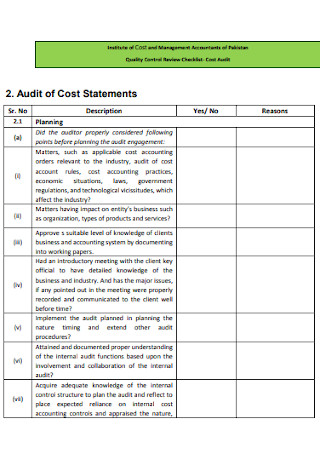

Quality Control Review Checklist

download now -

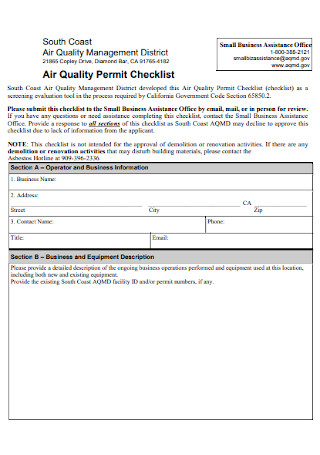

Air Quality Permit Checklist

download now -

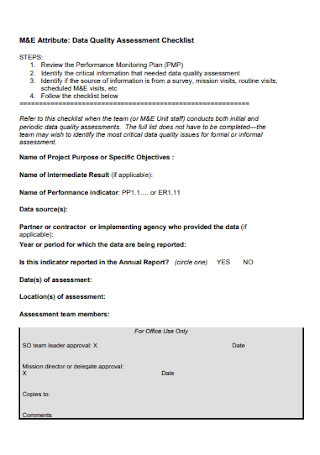

Data Quality Assessment Checkliist

download now -

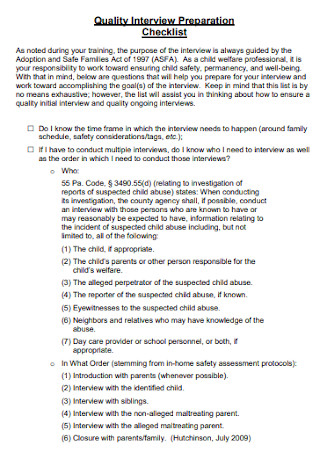

Quality Interview Preparation Checklist

download now -

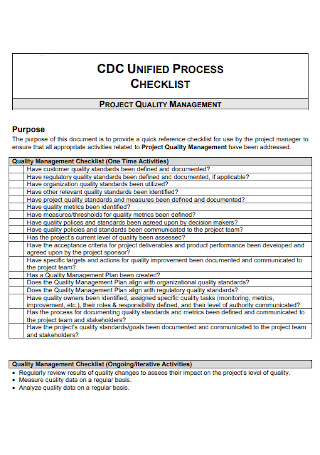

Project Quality Management Checklist

download now -

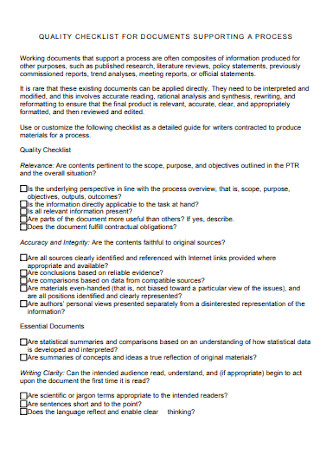

Quality Checklist for Documents

download now -

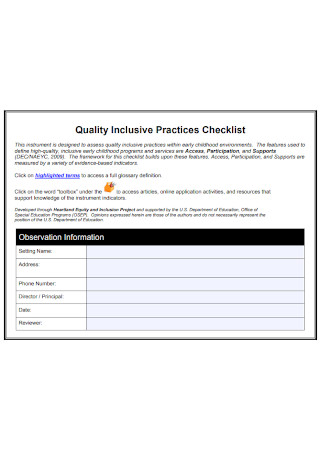

Quality Inclusive Practices Checklist

download now -

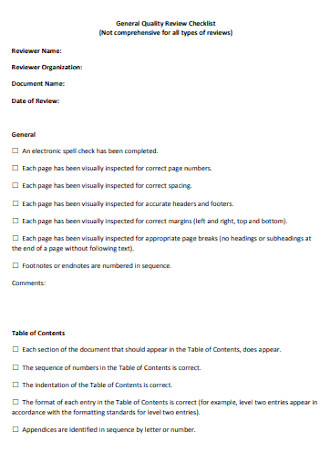

General Quality Review Checklist

download now -

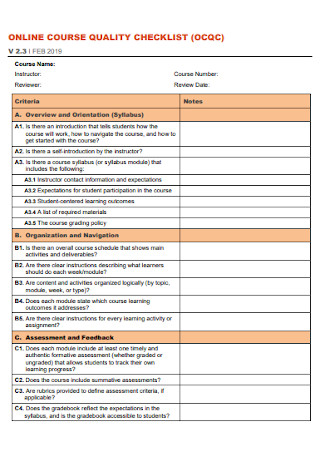

Online Course Quality Checklist

download now -

Quality Assurance Checklist for Digitising Records

download now -

Quality Requirements Checklist Example

download now -

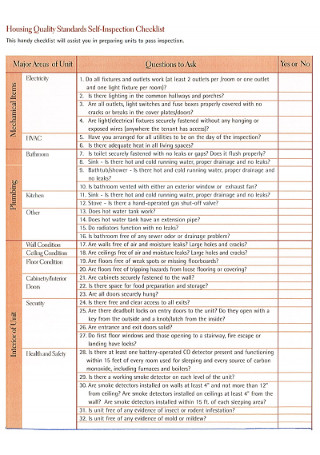

Housing Quality Checklist

download now -

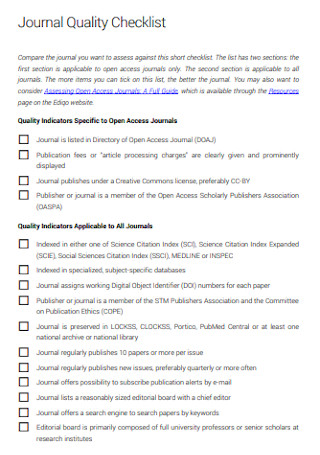

Journal Quality Checklist

download now -

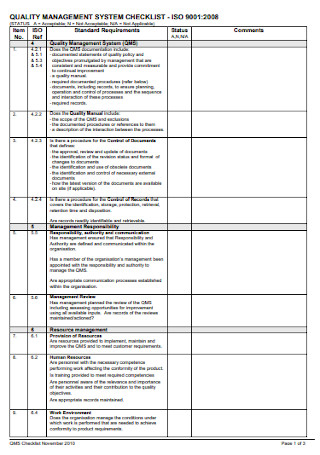

Quality Management System Checklist

download now -

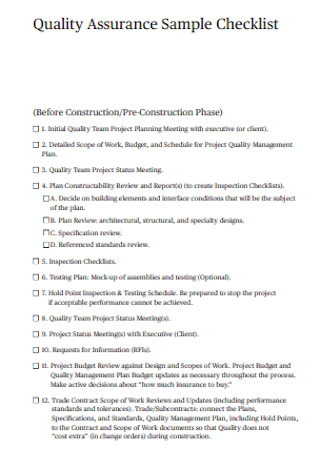

Sample Quality Assurance Checklist

download now -

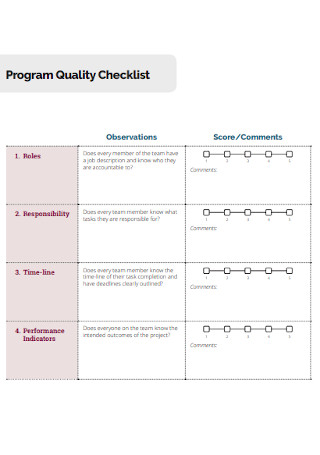

Program Quality Checklist

download now -

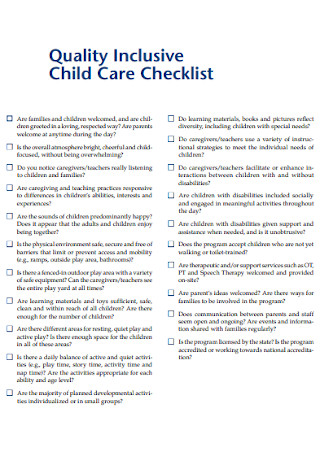

Quality Inclusive Child Care Checklist

download now -

Quality Monitoring Checklist

download now -

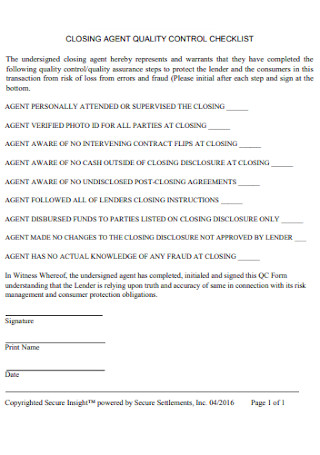

Closing Agent Quality Control Checklist

download now -

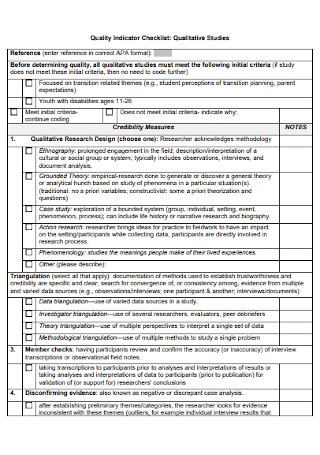

Quality Indicator Checklist

download now -

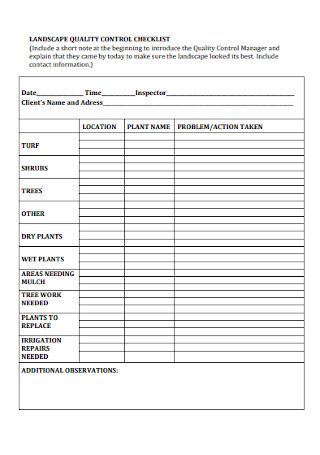

Landscap Quality Control Checklist

download now -

Quality Criteria Checklist for Project

download now -

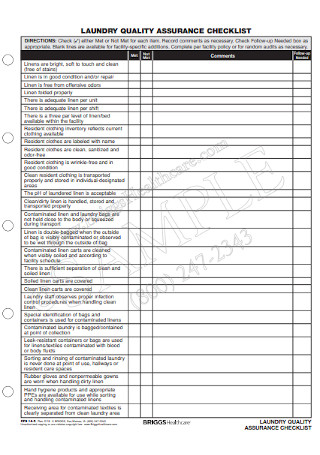

Laundry Quality Assurance Checklist

download now -

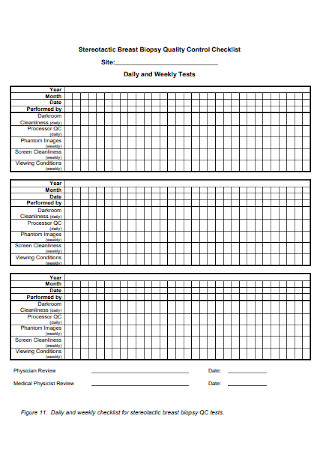

Stereotactic Breast Biopsy Quality Checklist

download now -

Milk Quality Checklist

download now -

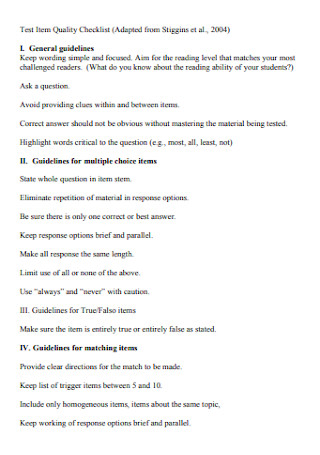

Test Item Quality Checklist

download now -

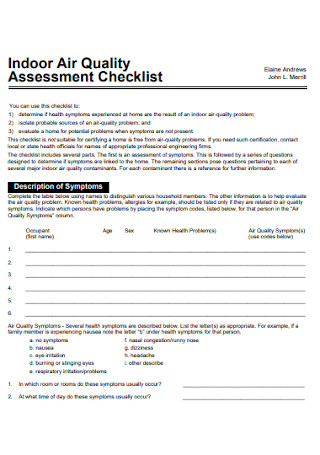

Indoor Air Quality Checklist

download now -

Quality Control Plan Checklist

download now -

Quality Improvement Checklist

download now -

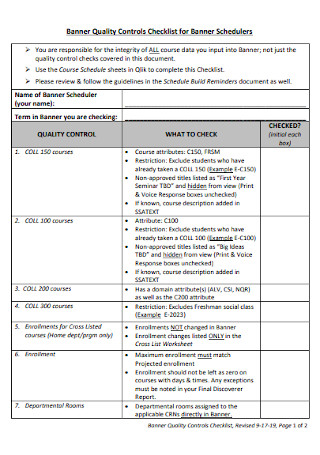

Banner Quality Checklist

download now -

Outcome Quality Checklist

download now -

Addendum Quality Assurance Checklist

download now

FREE Quality Checklist s to Download

54+ Sample Quality Checklists

Quality Checklists: What Are They?

The Different Elements of an Effective Quality Checklist

How to Create a Quality Checklist

FAQs

How to check product quality before shipment?

What are the different types of checklists?

Why is a checklist important?

Quality Checklists: What Are They?

A quality checklist is usually used when importers want to know what is the best way to clarify their product requirements, both to the supplier and any inspection staff that might check an order before shipping. In general, it is a written guide for product content, packaging, color, barcodes, appearance, possible defects, functions, and special requirements. Some call a quality checklist “inspection criteria sheet” or inspection checklist.

Meanwhile, 69% of Americans have shopped online, and 25% shop online at least once per month according to Optimonster.

The Different Elements of an Effective Quality Checklist

A quality checklist is composed of many different components. Commonly, the following elements are what should be included in your quality checklist. However, based on what type of item you need to ship, you may or may not need all that is listed below.

How to Create a Quality Checklist

Start by thinking about what things could possibly go wrong with your product during the shipment. This will help you come up with a list of specific potential hazards. From there, divide hazards into different categories: major, minor, and critical. Keep in mind that your list will differ whether you have sold the item before or not. To make your quality checklist more effective, follow the steps below.

Step 1: Select a Template

After completing the list of hazards, your next step is selecting the best template. But before that, make sure you fully understand the operation the items will go through in order for you to pick the most suitable template. Have you checked our templates above? If not, browse through our collections of printable templates fitting for your quality checklist.

Step 2: Modify the Template

To use the template of your choice, just click the download button. Then, open an editing tool that is compatible with your template’s file format. Begin modifying the template or leave the suggested content as is if it is precisely what you want your checklist to be all about. The best thing about working with a template is it gives you the option to customize or not.

Step 3: Add the Features

Refer to the list of elements above. What is listed there are the sections that should be present in your quality checklist. Put additional elements if it is necessary for your item. You can even add visual elements to neatly organize the content such as tables, bar charts, graphs, and so much more.

Step 4: Consider Electronic Checklist

Item production and shipment are made even more convenient with the help of electronic checklist forms. Also, if you want a sustainable operation that does not leave any trace, digital checklists can be your thing. And you create electronic quality checklists with our templates easily. Its best benefit is you are no longer required to produce printed copies as electronic checklists can be digitally used.

FAQs

How to check product quality before shipment?

- Inspection by an external inspector in the factory.

- Final inspection on a platform.

- Piece-by-piece inspection in the factory.

- Training plan and auditing internal inspectors in the factory.

What are the different types of checklists?

- Survey Checklist

- Safety Checklist

- Vacation Checklist

- Travel Checklist

- Chores Checklist

- Daily Checklist

Why is a checklist important?

A checklist is important because it contains the ultimate to-do list required to complete any task. With a good checklist, success is more likely to come through with everything you do.

The quality checklist is a foundation for ensuring good quality products and services. It also influences customer satisfaction and it dictates new clients whether to order again from you or not. Because a quality checklist keeps loyal customers, you should invest in creating one. For more sample templates that are useful, visit our website now to get a chance to sign up for any of our subscription plans.