9+ SAMPLE Warehouse Safety Inspection Checklist

-

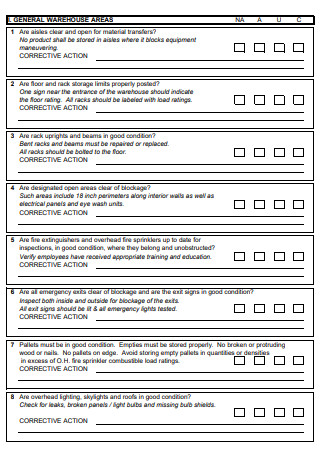

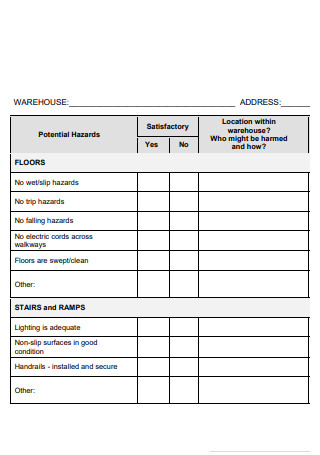

Monthly Warehouse Safety Inspection Checklist

download now -

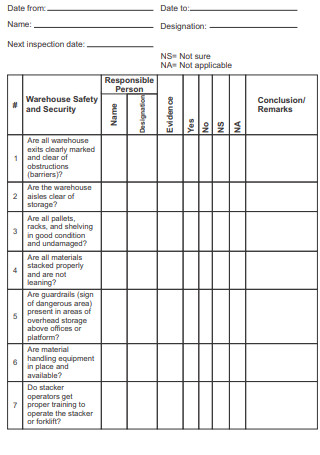

Warehouse Safety Inspection Checklist

download now -

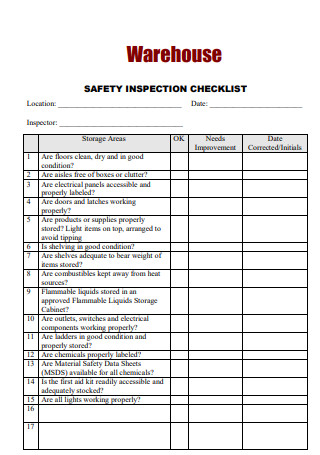

Sample Warehouse Safety Inspection Checklist

download now -

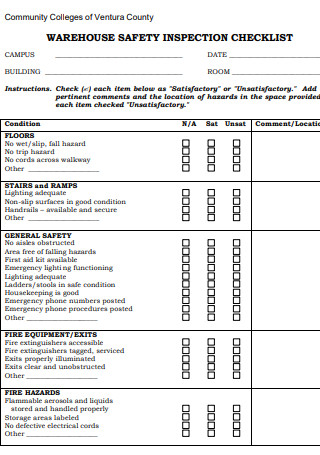

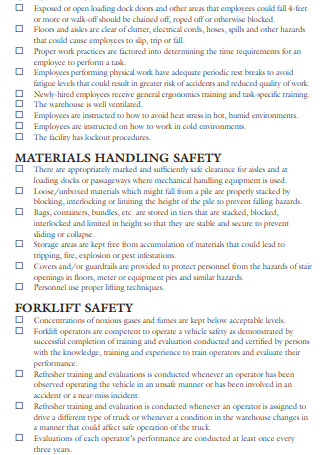

Formal Warehouse Safety Inspection Checklist

download now -

Bsic Warehouse Safety Inspection Checklist

download now -

Warehouse Staff Safety Inspection Checklist

download now -

Furniture Warehouse Safety Inspection Checklist

download now -

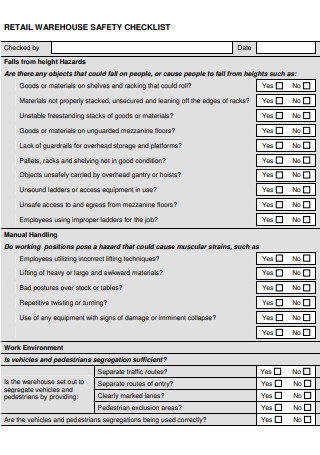

Retail Warehouse Safety Inspection Checklist

download now -

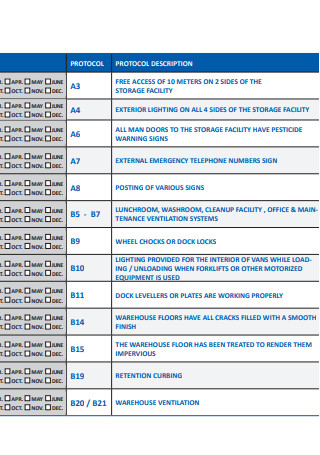

Warehouse Safety Inspection Checklist Example

download now -

Warehouse Workplace Safety Inspection Checklist

download now

FREE Warehouse Safety Inspection Checklist s to Download

9+ SAMPLE Warehouse Safety Inspection Checklist

What is Warehouse Safety?

What is a Warehouse Safety Inspection Checklist?

What are the Common Rules of Warehouse Safety?

What are Some Common Warehouse Issues?

What are the Typical Warehouse Hazards?

What are the OSHA Regulations and Standards?

Step by Step Guide in Preparing an Effective Warehouse Safety Inspection Checklist

FAQs

What are the kinds of Personal Protective Equipment in a Warehouse?

What is the objective of a warehouse safety inspection?

Why does warehouse safety matter?

What is Warehouse Safety?

By definition, warehouse safety is a formula of regulating guidelines and optimal industry practices to help warehousing personnel ensure a safe work environment and safe behavior while working inside the premises. It is an important matter for the workers to know about warehouse safety and practice good habits because any neglect, whether intentional or not, can lead to workplace incidents that lead to serious injuries, or in worse cases, death of a worker or multiple workers.

What is a Warehouse Safety Inspection Checklist?

A warehouse safety inspection checklist is a type of building inspection checklist that serves as an important record to be used when inspecting a warehouse for safety compliance and for identifying possible hazards or defects that may have emerged since the time the warehouse was last inspected. Frequent warehouse inspections can help the workers be always on top of all kinds of hazards and risks that are present during warehousing operations. These documents should be completed whenever a warehouse inspection takes place.

What are the Common Rules of Warehouse Safety?

The warehouse safety rules vary greatly depending on the warehouse and the business that operates it. Here are the common rules that can be observed to ensure safety:

What are Some Common Warehouse Issues?

As warehouse operations evolve along with time and technology, so do the safety problems that come with it. Here are some of the safety problems a typical warehouse faces in the modern era:

What are the Typical Warehouse Hazards?

Every work environment has a hazard that goes along with it. However, with adequate knowledge and safety training, the effects of a hazard can be mitigated. Here are some hazards one typically sees inside a warehouse:

What are the OSHA Regulations and Standards?

The Occupational Safety and Health Administration has some standards in place concerning general industries, which include warehousing operations. Here are those:

- Hazard Communication – A written Hazard Communication program must be written and properly implemented. In addition, workers who are frequently exposed to hazards should be properly trained about them and know how to deal with them.

- Emergency Action Plan – Warehouse owners should have a detailed action plan concerning the appropriate actions their employees should take in the event of an emergency.

- Fire Safety – If there are more than 10 workers employed in a warehouse, a written fire prevention plan must be kept in the warehouse and be readily available to the personnel for review.

- Exits – Warehouses should have multiple properly designed emergency exits available and they should be easily accessible in the event of an emergency. They should also be located as far away from each other as practically possible should a fire or an accumulation of heavy smoke render one exit unusable. Exits must also be frequently inspected and maintained to make sure that they are in optimal working condition.

- Walking/Working Surfaces – Warehouse and storage workers that work at heights should have the proper safety gear with them, such as a safety harness. This is done to protect them from falls, which is one of the leading causes of serious injuries or death in the workplace.

- First Aid – Warehouse operators should provide adequate medical personnel and first-aid supplies to their workers that are appropriate with the types of hazards that they usually face in the warehouse.

Step by Step Guide in Preparing an Effective Warehouse Safety Inspection Checklist

A good warehouse safety inspection checklist should be clear, concise, and above all, easy to complete. The checklist needs to be something one can run periodically to ensure that everything is in top condition and no discrepancies, no matter how small, is overlooked. Also, the checklist greatly varies from each warehouse. Here is a guide on how to prepare an effective checklist:

1. Planning.

In this step, plan on whether a very thorough inspection of the entire warehouse is to be done, or if just a section of it is needing one. Workers may also be informed ahead of time that an inspection of the workplace is due to happen anytime. This is done so no important work is interrupted when the inspection actually happens.

2. Create the checklist.

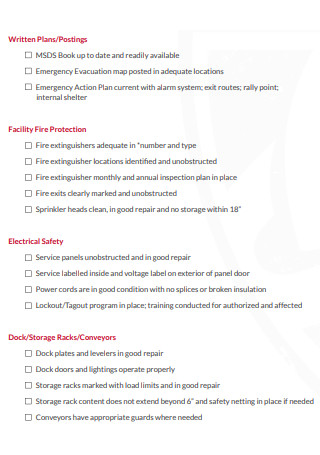

In this step, the proper creation of the checklist happens. It also depends on the type of inspection to be performed. The following are some of the items that should be included in the checklist if a thorough inspection is to take place:

- Damages in the building – no damage that can compromise the safety of the workers inside the warehouse

- Possible obstructions – clutter should be away from emergency exits and walkways

- Warehouse lighting – entire warehouse should be properly lit

- Cleanliness and proper hygiene – warehouse should be clean and workers should practice good hygiene

- Fire safety – fire extinguishers should be in the correct positions, and sprinklers and fire alarms should be working

- Ventilation – make sure it is not blocked

- Fire exits – clear markings and directional arrows should be present. The sign should also be properly lit

- Emergency signages – should be easily readable and in the correct place

- Labels on hazardous materials – should be clear and free of tampering

- Aisles and walkways – aisles must feature identification for clarity when storing materials

- Storage racks – should be clean and free of damage

3. Leave spaces for feedback.

It is also important to leave some spaces in the checklist for feedback or reports, problems found with the corresponding actions taken, and the recommendation reports from the people who conducted the warehouse inspection. The recommendations written will help the warehouse manager to know if any more components that will need replacing or restoring in the next maintenance interval. The actions taken will also let the manager know what the people who conducted the inspection did on the area they are inspecting.

4. Verification of the checklist.

When the creation of the checklist is done, make sure to verify it in order to make sure that everything is correct from the type of maintenance to be done down to the overall cost. Make sure that nothing of importance is overlooked, especially in areas that are already faded and show signs of decay. You should also check if there are areas of the warehouse that don’t even need inspection but you may have accidentally included. If you hand it over to the inspectors, it is also important to let them know about the type of warehouse inspection to be done, and the components that you have included in the checklist, so they can also verify your created checklist and also to avoid any confusion.

FAQs

What are the kinds of Personal Protective Equipment in a Warehouse?

Here are the types of PPE in a warehouse:

- Hard Hats

- Hi-vis vests or Jackets

- Safety glasses

- Earmuffs

- Safety shoes

- Safety gloves

- Overalls

What is the objective of a warehouse safety inspection?

Warehouse safety inspections are essential because they allow you to listen to the concerns of the warehouse workers and the managers, ensure that the warehouse and every worker adheres to safety regulations and standards, get a better knowledge of occupations and activities, and detect any hazards that have emerged or that will possibly emerge. establish the root causes of risks, provide recommendations for remedial action, and keep account of the measures done to remove or control the risks that are present in the warehouse.

Why does warehouse safety matter?

It matters because warehouses can contain various safety hazards which in turn serve as opportunities for accidents and incidents to happen that can lead to severe injuries. It is also important because the hazards that are present in a warehouse can change greatly from moment to moment, depending on the tasks inside. So the employees in the warehouse need to be frequently trained about warehouse safety and appropriately dealing with the hazards and safety issues they can encounter.

Having a warehouse safety inspection checklist is essential to make sure that everything that needs to be covered in the inspection is properly looked at. The checklist also helps streamline the process and helps prevent the inspection from going all over the place in case there’s any uncertainty if an item is already checked or not. It also helps avoid any situations where an item is unintentionally overlooked, which may evolve into a safety hazard if left unchecked. The data in the warehouse safety inspection checklist can be used to help improve the safety practices of the warehouse employees and also the condition of the warehouse itself. This article has examples provided above should you need to make one of your own.