15+ Sample Equipment Maintenance Plan

-

Equipment Maintenance Plan Template

download now -

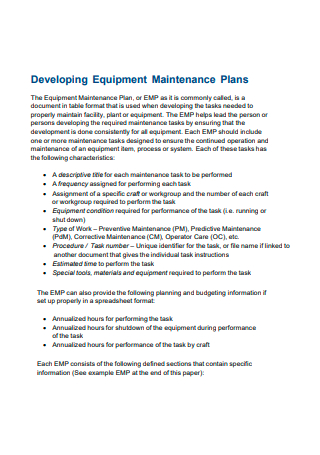

Developing Equipment Maintenance Plan

download now -

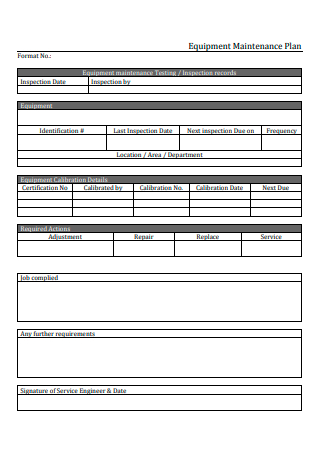

Equipment Maintenance Plan Format

download now -

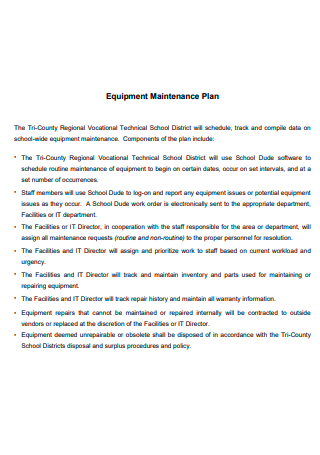

Printable Equipment Maintenance Plan

download now -

Operation and Equipment Maintenance Plan

download now -

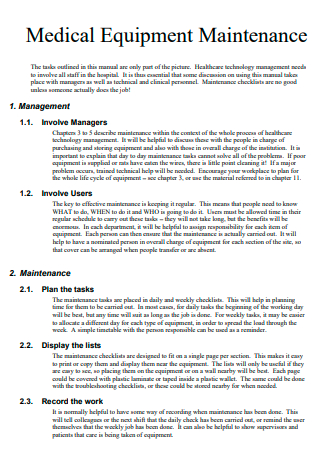

Medical Equipment Maintenance Plan

download now -

Equipment Maintenance Plan in PDF

download now -

Equipment For Preventive Maintenance Planning

download now -

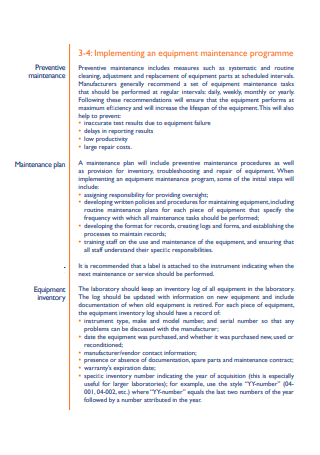

Equipment Maintenance Programme Plan

download now -

Equipment Maintenance Plan Example

download now -

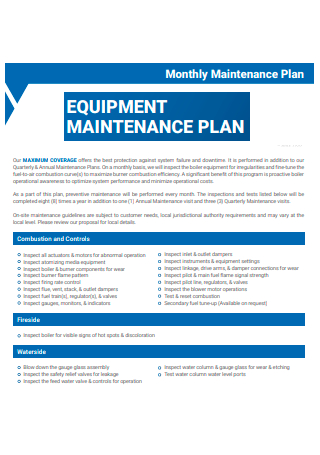

Equipment Monthly Maintenance Plan

download now -

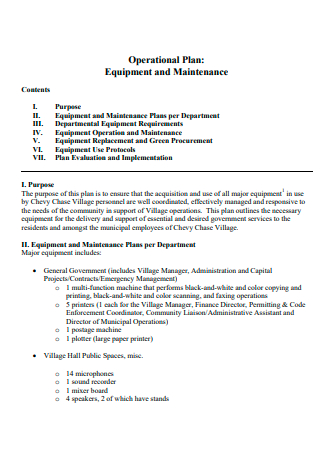

Equipment and Maintenance Operational Plan

download now -

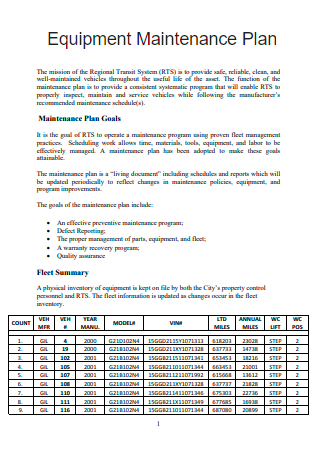

Formal Equipment Maintenance Plan

download now -

Equipment Maintenance Options Plan

download now -

Facilities Equipment Maintenance Plan

download now -

Standard Equipment Maintenance Plan

download now -

Equipment Maintenance and Reliability Plan

download now

FREE Equipment Maintenance Plan s to Download

15+ Sample Equipment Maintenance Plan

What Is An Equipment Maintenance Plan?

The Importance Of An Equipment Maintenance Plan

What Needs To Be Planned When Conducting Equipment Maintenance?

Types Of Equipment Maintenance

How To Create An Effective Equipment Maintenance Plan

FAQs

What are Maintenance Procedures?

How to determine the cost of planning equipment maintenance?

What happens if the equipment maintenance plan is incomplete?

What Is An Equipment Maintenance Plan?

An equipment maintenance plan refers to a business document that details all the types of equipment or machinery that is present in your company or production facility. This document describes the equipment down to the small details via a tabular format. This plan also assesses the type of maintenance that each piece of equipment needs, how frequently it needs to be maintained, and who will conduct the said maintenance on that equipment. When drafting an equipment maintenance plan, it is important to keep in mind that nothing of importance is to be overlooked for the maintenance process to function smoothly and effectively.

The Importance Of An Equipment Maintenance Plan

Have you ever worried about what could possibly happen when even the smallest component in your machinery breaks down? With an effective equipment maintenance plan, you will ensure that you are doing everything possible to avoid equipment breakdown and any halt in production – which could have far-reaching financial consequences and would necessitate hands-on crisis communications with all customers and stakeholders. Remember that your company’s reputation is its most valuable asset, so ensuring that your equipment is always fit for purpose should be a top priority.

What Needs To Be Planned When Conducting Equipment Maintenance?

Here are the numerous factors that should be planned when conducting equipment maintenance:

Types Of Equipment Maintenance

Here are the different types of equipment maintenance that can be done by your business or industry:

How To Create An Effective Equipment Maintenance Plan

Here are the following steps you can take in order to create an equipment maintenance plan; while it may be intimidating at first, once you go through it, you will notice that it follows a logical order and it gets easier.

-

1. Establish the People Involved In the Maintenance

Maintenance managers, your technical maintenance team, finance departments, and senior management may all be involved in the equipment maintenance plan. It is best for one or two people in each department to ‘own’ the project so that the management team always knows who is responsible for what. As a result, you’ll be able to make quick decisions and get them approved by management or your finance director.

-

2. Set the Goals

To ensure that the team you select is fully invested in the project it is critical to establish an Effective Goal right from the start. – the number of people will vary depending on the size of your facility. When it comes to equipment maintenance plans, the goals will most likely be to reduce reactive maintenance or corrective maintenance costs by a certain percentage or to reduce downtime by a certain percentage.

-

3. Create An Inventory

Once you’ve decided on your team, begin compiling a detailed inventory of all relevant equipment in your manufacturing process. This is by far the most time-consuming aspect of creating an equipment maintenance plan, but it is essential that it is done correctly because it ensures that every last piece of critical equipment is on the list for routine preventive maintenance.

It is also vital to consider how you record and store information. Usage of Spreadsheet Software is recommended because it allows you to create thousands of rows and columns, which should provide enough space to store large databases of text and data. Each piece of equipment’s make and model, as well as serial numbers, product specifications, asset identification numbers, and location information, must be entered.

-

4. Establish Preventive Measures

Make a note of the type of work required to keep the equipment running smoothly, as well as how long it will take. This can be estimated based on previous corrective maintenance experiences or by consulting owner’s manuals, manufacturer recommendations, and documented industry standards. You should be able to plan ahead and schedule maintenance for times when you’re less busy or naturally non-operational, such as overnight, if you record this alongside the frequency of maintenance work. There may be times when preventive maintenance can be performed during normal operating hours, which will be less expensive than bringing in maintenance engineers after working hours.

-

5. List the Required Materials

Ensure that your equipment maintenance plan includes a list of the specialized tools required to repair each piece of equipment. Include this in your list and make sure that you either acquire the tools or that your maintenance team or contractors have the tools they require. You must also consider the materials that will be required and ensure that you have them on hand or know where to get them in time for planned maintenance procedures.

-

6. Create the Maintenance Plan For Each Piece of Equipment

Begin by documenting the equipment’s condition, as this will help you prioritize its importance as part of your equipment maintenance plan. You’ll then need to have your expert technicians evaluate each component to determine when its next maintenance inspection is due and how frequently these inspections should be performed. All of this must be documented for future use. If you physically tag each part, asset tracking software may be useful for digitally tracking your equipment.

FAQs

What are Maintenance Procedures?

Maintenance procedures refer to a set of detailed instructions for doing maintenance tasks. Maintenance procedures must be up to date and easily accessible so that the maintenance personnel can follow them precisely. This ensures the reliability and good performance of the equipment.

How to determine the cost of planning equipment maintenance?

Equipment maintenance plans take time to develop, and it is best to prioritize high-priority maintenance before overburdening staff with lower-priority tasks. The initial preventive maintenance goals set will determine which assets should be prioritized. When evaluating each piece of equipment and the work required to keep it running, you should be able to estimate the number of hours for performing the task, shutting down the equipment, and determining which personnel are required in each case. This will allow you to calculate the cost of performing these tasks in the most efficient manner.

What happens if the equipment maintenance plan is incomplete?

Any omission being done in the document is likely to weaken the plan. If you leave out the work, there’s a chance you’ll do more than you need to and waste resources. You may have to work with less-experienced personnel on occasion and they will certainly struggle if you do not include instructions in your plan. Without a schedule, maintenance plans frequently place facilities in a ‘firefighting’ mode. You will not be able to optimize the performance of your assets throughout the year. You will have a difficult time budgeting for your maintenance program if you do not include a section indicating the spare parts required for maintenance tasks. The absence of sections in your plan dealing with workers and contractors predisposes your assets to poor maintenance.

Any company or industry that operates some sort of equipment whether it is heavy or not should have an effective equipment maintenance plan in place. They should also have one if they want to maximize their returns on investment. Scheduling a maintenance plan is considered critical to company operations since it involves time, energy, and various staff resources to complete. It is also essential because maintenance plans happen frequently. In creating this document, it is essential to make a list of different high-priority items as these will serve as starting points in the maintenance process. Maintenance activities should also be frequently and effectively done because when you neglect to perform maintenance on your assets, equipment, and machines in an effective manner, there is a very big chance that your company will end up at a loss.

In this article, examples of effectively made equipment maintenance plans are available for you to download and use as a reference in case you need to make one.