25+ SAMPLE Construction Management Plan

-

Construction Management Phase Plan

download now -

Construction Quality Management Plan

download now -

Construction Change Management Plan

download now -

Construction Risk Management Plan

download now -

Construction Cost Management Plan

download now -

Construction Schedule Management Plan

download now -

Construction Project Management Plan

download now -

Construction Quality Control Management Plan Checklist

download now -

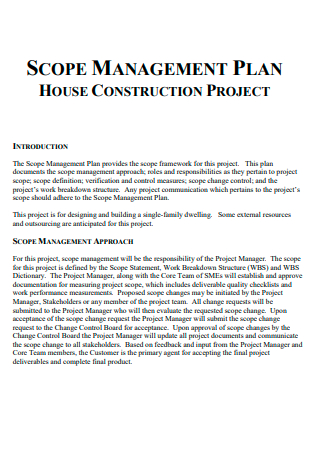

House Construction Project Scope Management Plan

download now -

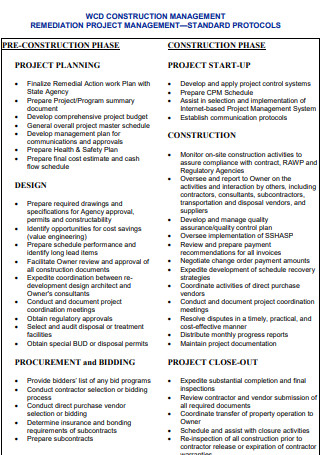

Project Construction Management Remediation Plan

download now -

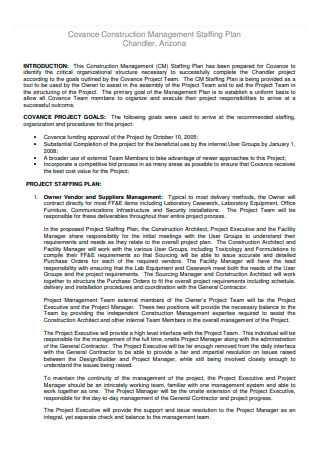

Staffing Construction Management Plan

download now -

Energy Project Construction Safety Management Plan

download now -

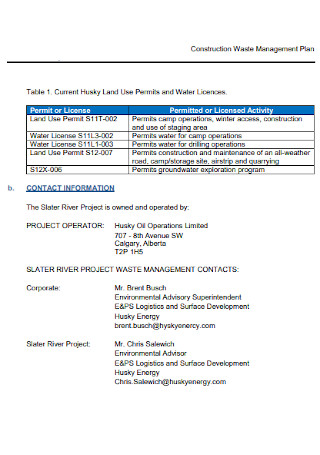

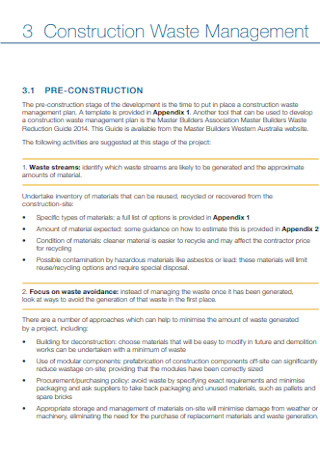

Sample Construction Waste Management Plan

download now -

Construction Waste Management Plan

download now -

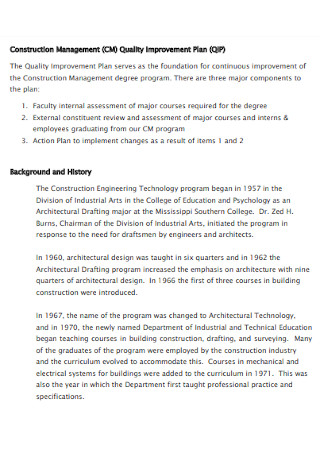

Construction Management Quality Improvement Plan

download now -

Construction Project Management Plan

download now -

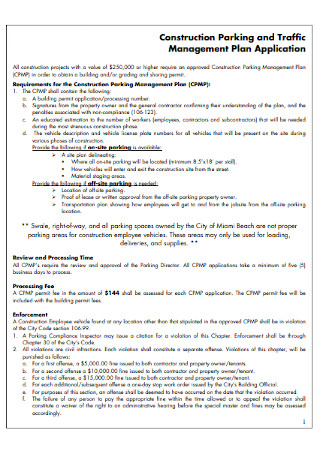

Construction Parking Management Plan

download now -

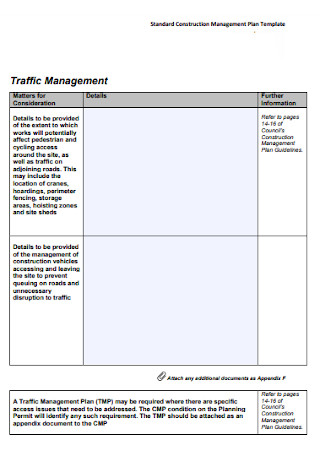

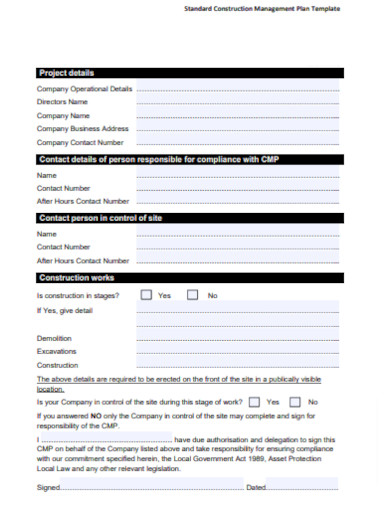

Standard Construction Management Plan

download now -

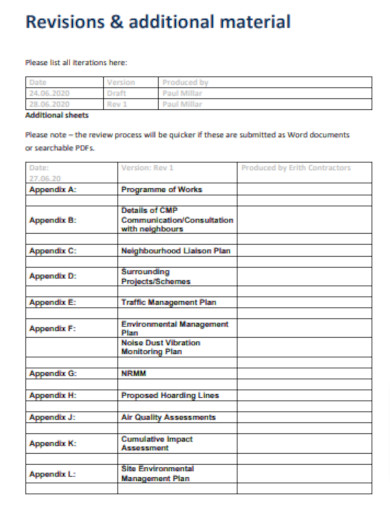

Construction Project Management Communication Plan

download now -

Construction Logistics Management Plan

download now -

Construction Demolition Management Plan

download now -

Construction Proposed Management Plan

download now -

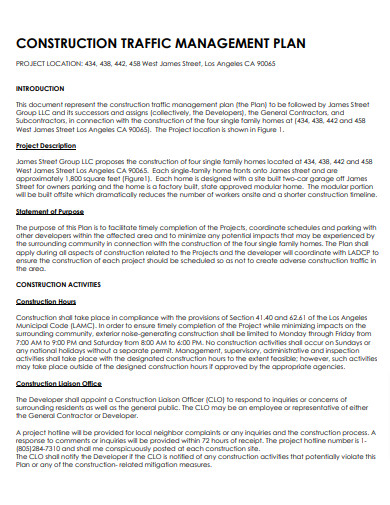

Construction Traffic Management Plan

download now -

Simple Construction Management Plan

download now -

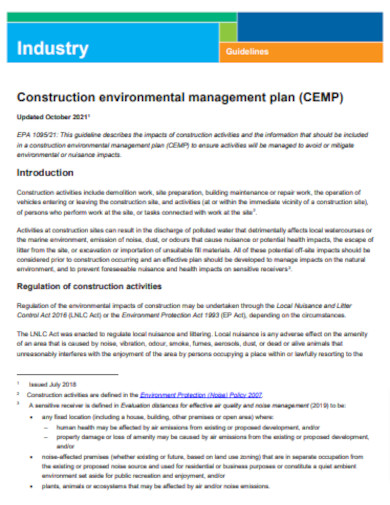

Construction Environmental Management Plan

download now -

Building Construction Management Plan

download now

FREE Construction Management Plan s to Download

25+ SAMPLE Construction Management Plan

What is a Construction Management Plan?

Key Components of a Construction Management Plan (CMP)

Why a Construction Management Plan (CMP) is Invaluable

Modern Trends in Construction Management

Challenges in Construction Management Plan

FAQ’S

Who is responsible for developing and overseeing the CMP?

How often should the CMP be reviewed and updated?

How does a CMP address environmental and community concerns?

Is a CMP legally required?

What is the difference between a CMP and a construction safety plan?

How does technology integrate into a CMP?

What is a Construction Management Plan?

A Construction Management Plan is the project roadmap that details the step-by-step logistics, management, and execution of a construction project. From initial sketches to the final coat of paint, the CMP steers the entire process, ensuring every decision aligns with the project’s objectives.

Key Components of a Construction Management Plan (CMP)

The Construction Management Plan serves as a comprehensive guide, directing the various phases and intricacies of a construction project. Each of its elements is crucial for ensuring the smooth flow of tasks, from initiation to completion. Here’s a more detailed exploration of these pivotal components:

1. Project Overview:

Description: This section provides a general outline of the project. It entails the project’s purpose, scope, objectives, and deliverables.

Location: A detailed specification of the project site, including its geography, neighboring structures, and accessibility.

Background: A brief history or any preliminary studies done regarding the project.

2. Roles & Responsibilities:

Organizational Chart: A visual representation showing the hierarchy and structure of the project team.

Stakeholder Identification: Listing of everyone involved, from clients to subcontractors, and their significance to the project.

Task Assignment: A detailed breakdown of duties for each team member or stakeholder.

3. Timeline:

Phases: Division of the project into specific stages, such as planning, design, construction, and handover.

Milestones: Key events or turning points that indicate significant progress.

Schedule: A detailed calendar highlighting start and end dates for each activity.

4. Budgeting:

Cost Estimation: Predicted expenses for every aspect, from labor to materials.

Funding Sources: Details on where the financial resources will come from.

Contingency Plan: A reserved budget for unforeseen expenses or overruns.

5. Risk Management:

Risk Identification: Spotting potential threats or challenges.

Risk Assessment: Evaluating the likelihood and impact of each risk.

Mitigation Strategies: Plans and actions designed to prevent or manage risks.

6. Communication Strategy:

Communication Channels: Platforms or methods (like meetings, emails, or software) for sharing information.

Feedback Mechanisms: Processes to gather feedback from stakeholders.

Reporting Structure: Hierarchical order of communication and how information flows.

7. Quality Control:

Standards: Established criteria that the project must adhere to.

Inspection Protocols: Scheduled checks to ensure quality is maintained.

Corrective Actions: Steps to rectify any deviations from the set standards.

8. Resource Management:

Inventory: A list of all resources, including tools, machinery, and human resources.

Allocation: Assigning specific resources to particular tasks or phases.

Resource Scheduling: Timelines for when and how long a resource will be utilized.

9. Waste Management:

Waste Identification: Recognizing different types of waste produced during construction.

Disposal Methods: Proper and environmentally responsible techniques for waste disposal.

Recycling: Identifying and managing resources that can be recycled or reused.

10. Stakeholder Engagement:

Stakeholder Analysis: Recognizing the interests and influence of each stakeholder.

Engagement Strategies: Plans to keep stakeholders informed and involved.

Feedback Collection: Methods to gather and incorporate stakeholder plan and feedback.

Each of these components, diligently crafted and seamlessly integrated, ensures that the CMP acts as a stable foundation, guiding the construction project toward successful completion.

Why a Construction Management Plan (CMP) is Invaluable

In the intricate world of construction, where precision meets practicality, a Construction Management Plan (CMP) emerges as a lighthouse, guiding projects through the storms of uncertainty to the shores of completion. The CMP’s value can’t be overemphasized, and here’s a deeper look into why it holds unparalleled significance:

1. Structure and Direction:

A CMP provides a blueprint for the entire project, laying out each phase’s specifics. With such a structured approach, every stakeholder knows the path ahead, reducing uncertainties and ambiguities.

2. Efficiency and Resource Optimization:

Resource allocation and scheduling, pivotal components of a CMP, ensure that manpower, machinery, and materials are used judiciously. This optimized utilization eliminates wastage, ensuring timely completion within the prescribed budget.

3. Risk Mitigation:

By identifying potential hazards and challenges in advance, the CMP allows for the development of proactive strategies. These mitigation plans can reduce delays, cost overruns, and potential legal issues.

4. Accountability and Responsibility:

The clear delineation of roles and responsibilities ensures every team member is aware of their duties. This clarity fosters accountability, ensuring everyone strives towards the common goal without overlaps or omissions.

5. Quality Assurance:

With strict quality control measures in place, the CMP ensures that the finished product meets or exceeds industry standards. This commitment to excellence safeguards the project’s integrity and the structure’s longevity.

6. Stakeholder Communication:

A CMP’s communication strategy guarantees a seamless flow of information between stakeholders. Regular updates, feedback mechanisms, and clear reporting structures maintain transparency, fostering trust and collaboration.

7. Financial Management:

The budgeting aspect of a CMP offers a clear financial framework. With detailed cost estimations and funding sources outlined, there’s a reduced risk of unexpected financial hurdles, ensuring the project remains financially viable.

8. Environmental Considerations:

Modern CMPs incorporate sustainable practices, especially in waste management. These environmentally-friendly protocols not only ensure regulatory compliance but also contribute to a project’s social responsibility and positive public perception.

9. Flexibility and Adaptability:

While a CMP provides structure, it’s also designed to accommodate changes. This adaptability ensures the project remains on track, even if unforeseen challenges arise.

10. Future Reference:

Completed CMPs serve as invaluable references for future projects, offering insights, lessons learned, and best practices.

Modern Trends in Construction Management

The construction industry, while rooted in age-old techniques and processes, is constantly evolving. Modern trends in construction management reflect a blend of technological advancements, societal shifts, and industry-specific needs. Here’s a detailed look at the prevailing trends transforming the way we manage and execute construction projects:

1. Digital Transformation:

Building Information Modeling (BIM): BIM provides a digital representation of a building’s physical and functional characteristics. It fosters collaboration, error detection, and efficient resource management.

Cloud-Based Management Software: Platforms such as Procore and PlanGrid allow real-time collaboration, document sharing, and project tracking, eliminating data silos and facilitating remote work.

2. Sustainable and Green Building:

The push for environmentally-friendly construction has intensified, leading to an emphasis on green certifications, energy-efficient materials, and sustainable construction practices.

3. Prefabrication and Modular Construction:

With an emphasis on reducing waste and speeding up construction timelines, more projects are using pre-built modules that are simply assembled on-site, ensuring quality and efficiency.

4. Advanced Analytics and Big Data:

Leveraging data from past projects can predict outcomes, optimize processes, and reduce costs. Predictive analytics help in forecasting potential delays, budget overruns, or safety incidents.

5. Drones and Robotics:

Drones are now frequently used for site surveys, progress monitoring, and safety inspections. Robotics, on the other hand, aids in tasks like bricklaying, concrete dispensing, and even site clean-up.

6. Augmented and Virtual Reality (AR & VR):

These technologies are increasingly used for virtual walkthroughs, design alterations in real-time, and training scenarios, offering stakeholders a more immersive experience.

7. 3D Printing:

Especially in custom or large-scale construction, 3D printing can produce complex architectural features, reduce material waste, and even create entire building sections.

8. Safety Enhancements with Wearable Tech:

Devices like smart helmets with AR capabilities, vests with built-in sensors, or boots that detect exhaustion levels are being integrated to enhance worker safety and well-being.

9. Lean Construction:

Adopted from manufacturing, this approach focuses on reducing waste in all forms (time, material, effort) and maximizing value, making construction processes more efficient.

10. Integrated Project Delivery (IPD):

IPD is a collaborative approach where all stakeholders (architects, contractors, and owners) work together from the project’s onset, sharing risks and rewards. This ensures more transparency and joint decision-making.

Challenges in Construction Management Plan

Crafting and executing a Construction Management Plan (CMP) might seem straightforward on paper, but in practice, numerous challenges can arise. Let’s explore some of the most common obstacles that construction managers and stakeholders often grapple with:

1. Scope Creep:

This is when the project’s objectives expand beyond its original goals without corresponding adjustments in resources, time, and budget. Uncontrolled changes or continuous addition to the project’s scope can derail its progress and lead to cost overruns.

2. Resource Constraints:

Procuring the necessary resources, be it materials, machinery, or manpower, in the right quantity and at the right time, can be a daunting task. Any mismatch in resource allocation can stall the project and increase costs.

3. Budget Overruns:

Sticking to a budget is a constant challenge, especially when unforeseen expenses arise. This could be due to market fluctuations, changes in project requirements, or unexpected site conditions.

4. Communication Barriers:

Effective communication is pivotal for a successful project. Miscommunication or lack of transparency among stakeholders can lead to misunderstandings, conflicts, and errors in execution.

5. Complex Regulatory Environment:

Navigating the maze of local, state, and federal regulations is not always straightforward. Non-compliance, whether inadvertent or overlooked, can lead to legal complications, penalties, and project delays.

6. Time Constraints and Delays:

Timely completion is often a significant pressure point. External factors like adverse weather conditions, delayed material deliveries, or unforeseen site challenges can disrupt schedules, leading to cascading delays.

7. Technological Integration:

While modern construction management tools and software offer immense benefits, integrating them seamlessly can be a challenge. This is especially true for teams accustomed to traditional methods or those lacking in tech-savviness.

8. Safety Concerns:

Ensuring the safety of the construction site, workers, and the public is paramount. Yet, accidents, oversights, or non-compliance with safety standards can pose grave risks.

9. Quality Maintenance:

Balancing speed with quality assurance is tricky. There’s always the temptation to cut corners to meet deadlines, but this can compromise the integrity and durability of the completed structure.

10. Stakeholder Management:

Different stakeholders (owners, contractors, suppliers, community members) may have varied expectations and interests. Aligning everyone towards a common goal while addressing individual concerns can be a diplomatic challenge.

11. Environmental and Social Impact:

Modern construction projects are expected to be environmentally responsible and socially sensitive. Managing waste, reducing carbon footprints, or addressing community concerns might pose challenges in the execution of the CMP.

FAQ’S

Who is responsible for developing and overseeing the CMP?

Typically, the construction manager or project manager, in collaboration with other key stakeholders, develops the CMP. Once developed, the construction manager is primarily responsible for its implementation and oversight, although input and cooperation from all project participants are essential.

How often should the CMP be reviewed and updated?

While the frequency might vary based on project size and complexity, it’s advisable to review the CMP at significant project milestones or whenever there’s a major change in project scope, resources, or timelines.

How does a CMP address environmental and community concerns?

Modern CMPs incorporate environmental management strategies, focusing on sustainable construction practices, waste management, and emissions control. Additionally, they might outline measures to address community concerns, like noise regulation adherence or traffic management around construction sites.

Is a CMP legally required?

While not always a legal requirement, certain jurisdictions or project types might mandate the development and submission of a CMP, especially for large-scale constructions or projects in environmentally sensitive areas.

What is the difference between a CMP and a construction safety plan?

While a CMP covers all aspects of project management, including resource allocation, timelines, and quality assurance, a construction safety plan specifically focuses on ensuring safety protocols, practices, and compliance on the construction site.

How does technology integrate into a CMP?

Modern CMPs often incorporate technological tools like project management software, Building Information Modeling (BIM), and other digital solutions to enhance efficiency, communication, and monitoring throughout the project lifecycle.

A well-structured CMP isn’t just paperwork; it’s the backbone of a successful construction project. As the industry advances and projects become more complex, the importance of a robust Construction Management Plan has never been more paramount. Stay ahead, and ensure your next construction endeavor stands tall, backed by a comprehensive CMP.