55+ SAMPLE HACCP Control Plans

-

HACCP Plan Template

download now -

HACCP Food Safety Plan Template

download now -

HACCP Audit Plan Template

download now -

Sample HACCP Audit Plan Template

download now -

Simple HACCP Plan Template

download now -

Health HACCP Plan

download now -

Food Safety HACCP Flow chart Plan

download now -

Restaurant Organic HACCP Plan

download now -

HACCP Seafood Control Plan

download now -

Retail Food Fresh Produce HACCP Plan

download now -

Guidelines for HACCP RecipePlan

download now -

HACCP Critical Cafe Control Plan

download now -

Retail Vegetable Food Establishments HACCP Plan

download now -

Sample ChickenHACCP Plan

download now -

Basic Monitoring HACCP Plan

download now -

Simple HACCP Bakery Plan

download now -

Determining Cheese HACCP Plan

download now -

HACCP Chocolate Plan Requirements

download now -

HACCP Beef System Plan

download now -

Pizza HACCP Plan Determination

download now -

Hazard Analysis and HACCP Pest Control Plan

download now -

Free HACCP Coffee Plan

download now -

HACCP Plan Beverage Implementation

download now -

Standard Storage HACCP Plan

download now -

HACCP Plan in Cold Storage Retail Facilities

download now -

Steps for Dairy HACCP Plan

download now -

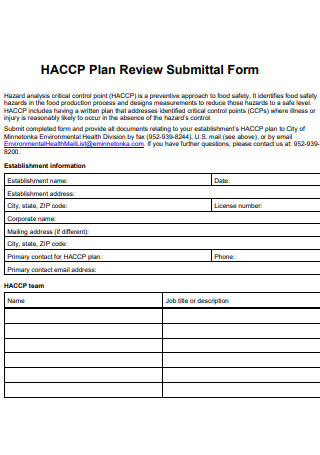

HACCP Plan Review Submittal Form

download now -

HACCP Operational Plan

download now -

HACCP Plan Review Application

download now -

HACCP Plan Principles

download now -

HACCP Plan Format

download now -

HACCP Control Plan

download now -

HACCP Hazard Assessment Control Plan

download now -

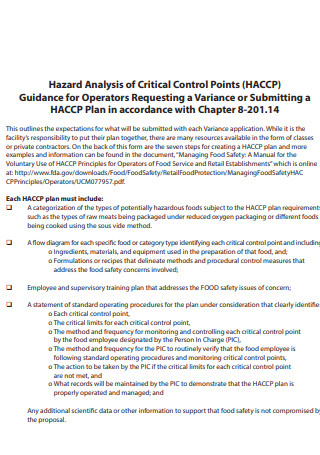

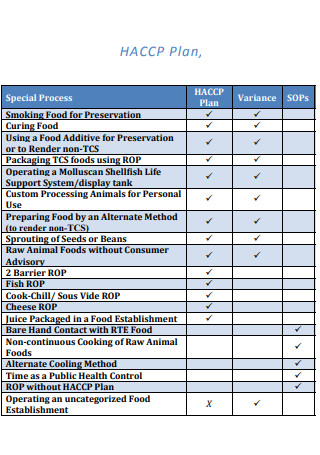

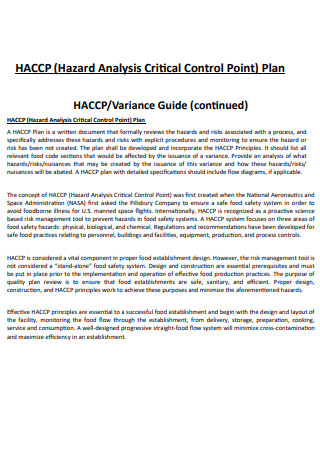

HACCP Variance Plan

download now -

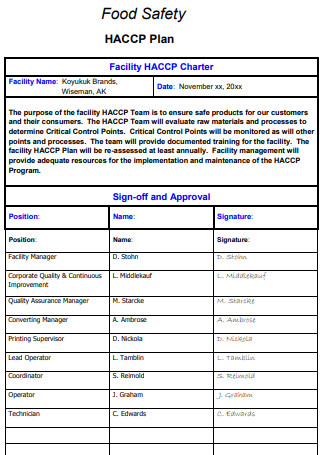

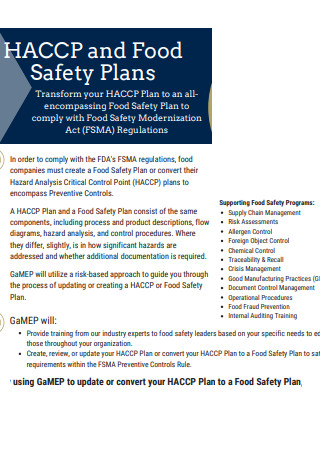

HACCP Food Safety Plan

download now -

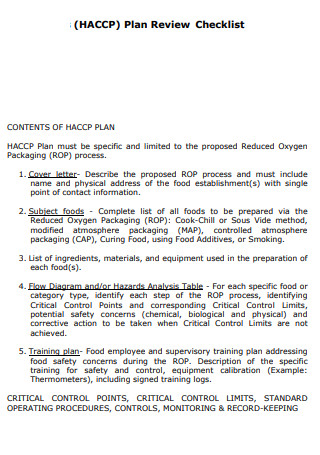

HACCP Plan Review Checklist

download now -

General HACCP Plan Development

download now -

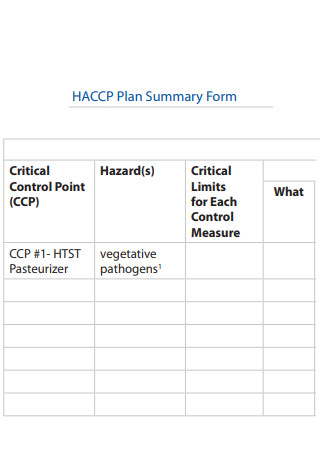

HACCP Plan Summary Form

download now -

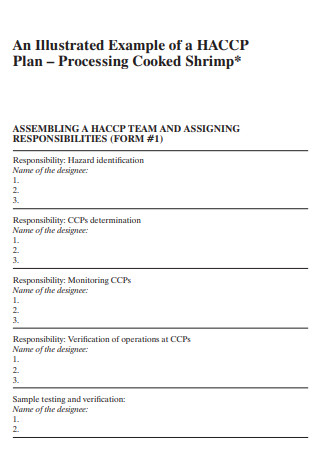

HACCP Plan for Processing Cooked Shrimp

download now -

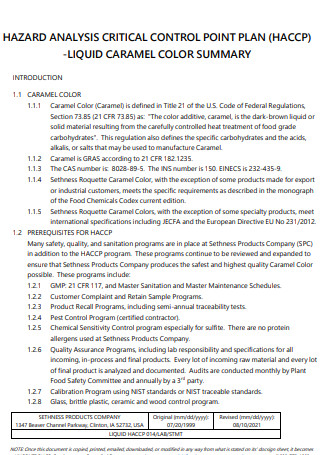

HACCP Plan for Liquid Caramel

download now -

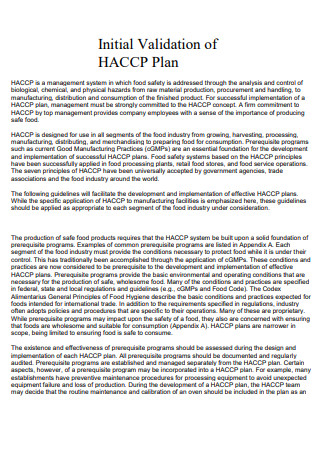

Initial Validation of HACCP Plan

download now -

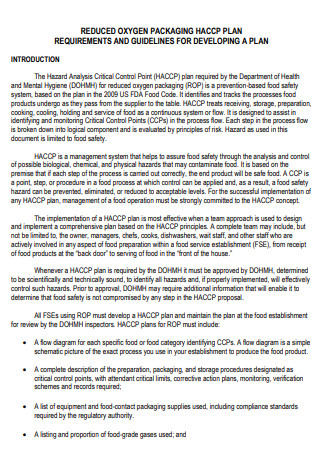

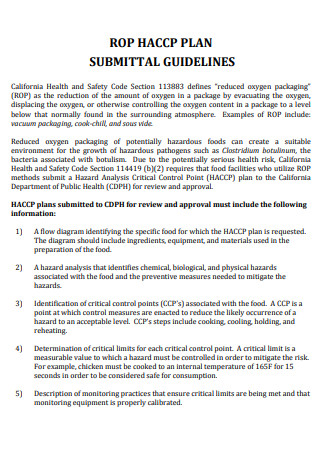

Reduced Oxygen Packaging HACCP Plan

download now -

Format HACCP Plan

download now -

6 Steps for HACCP Plan

download now -

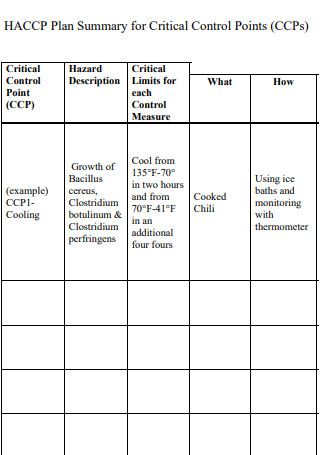

HACCP Plan Summary for Critical Control Points

download now -

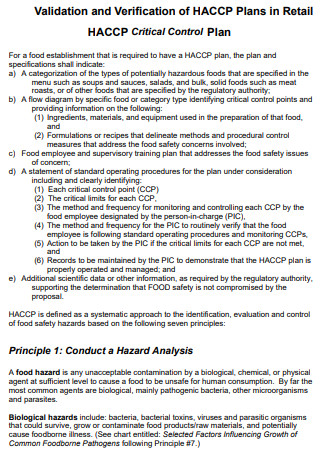

Validation and Verification of HACCP Plan

download now -

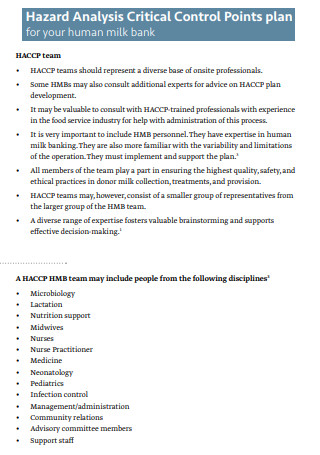

HACCP Plan for Human Milk

download now -

HACCP Safety Plan

download now -

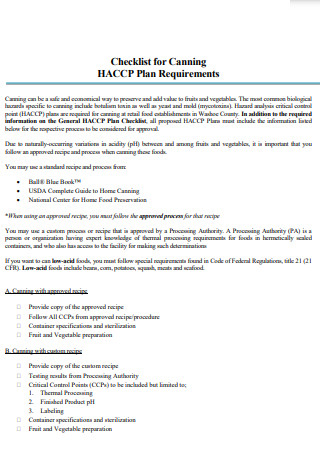

HACCP Plan Checklist for Canning

download now -

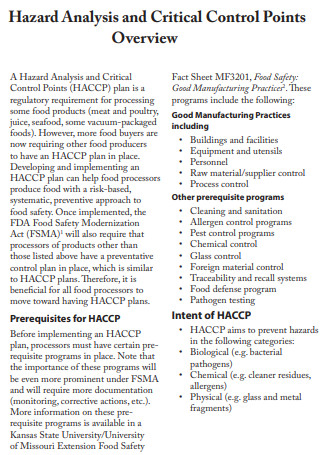

HACCP Plan Overview

download now -

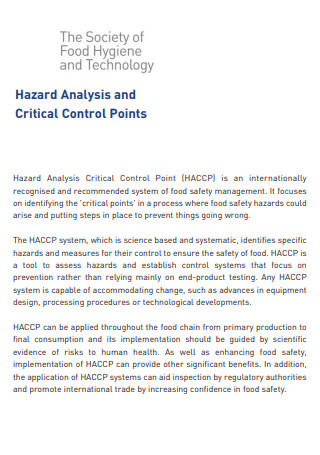

Food Hygiene And Technology HACCP Plan

download now -

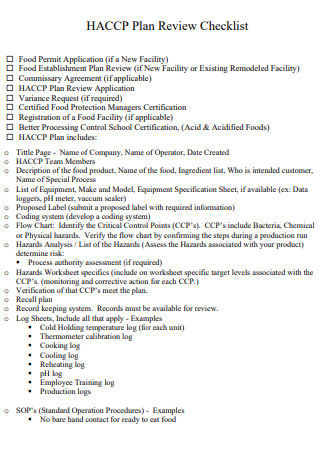

Food Safety HACCP Plan Review Checklist

download now -

Printable HACCP Plan

download now -

Editable HACCP Plan

download now -

HACCP Plan for Review And Approval

download now -

HACCP Plan Documentation Components

download now

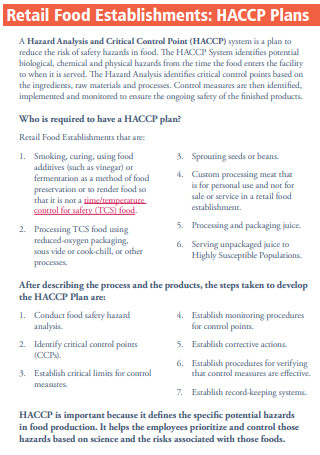

For food manufacturing and food services establishments, there is a mandatory system that they must fulfill to serve their customers and clients. HACCP systems serve a critical role in the food industry, and organizations must adhere to these standards. Set up a HACCP plan for your business today. What is a HACCP plan, and what safeguards does it provide to an organization, its employees, and customers. Continue reading the article below to find out more about a HACCP plan, including its definition, components, and construction process, with answers to frequently asked questions by different individuals. The article also contains samples for download to start a HACCP plan for your business.

What Is a HACCP Plan?

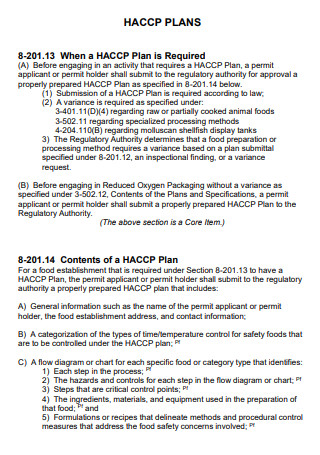

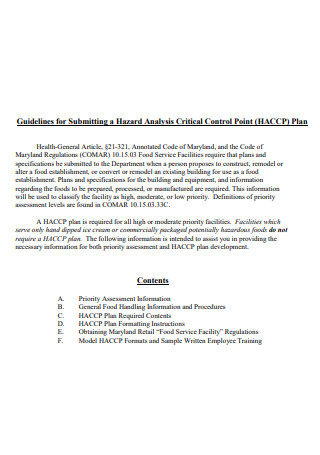

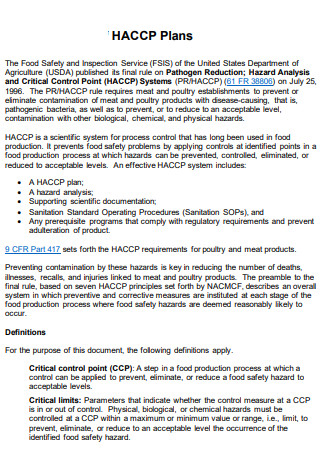

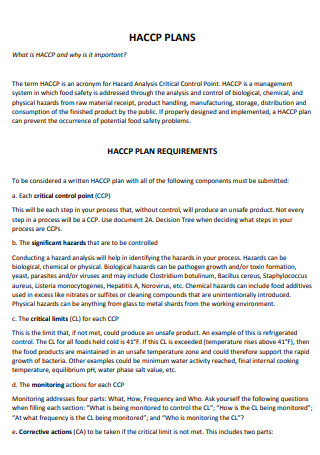

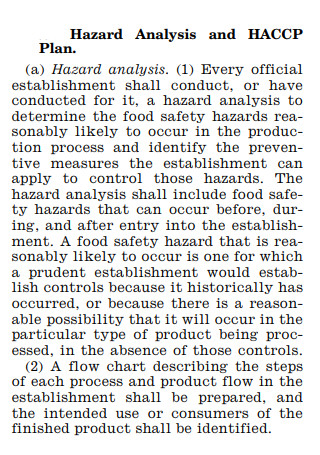

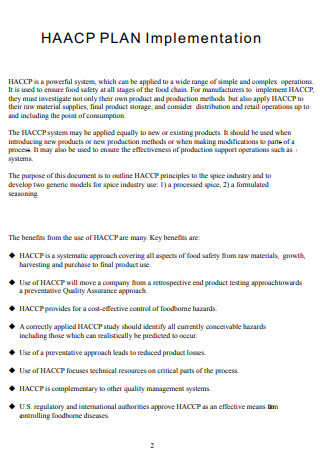

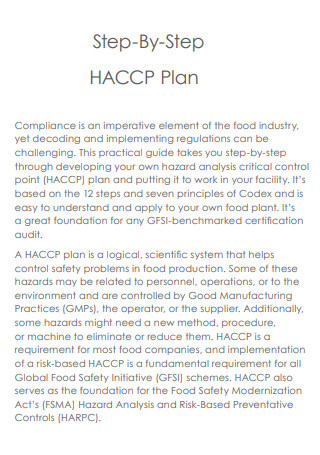

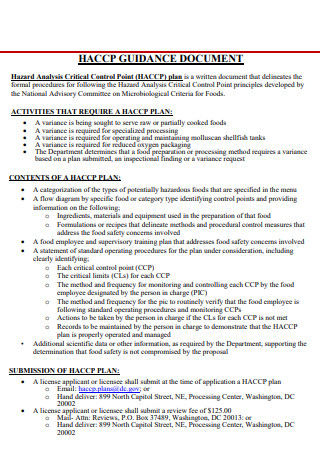

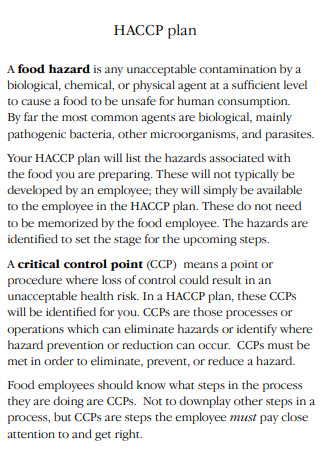

By definition, HACCP stands for Hazard Analysis Critical Control Points. HACCP serves a systematic and preventative approach stemming from a particular development by NASA (National Aeronautics and Space Administration) during the 1960s. Currently, the HACCP plan focuses on a systematic method that provides a structured framework for monitoring the entire food system of an establishment, ranging from food harvesting to consumption, to reduce the risk of hazards and diseases. Federal and state regulatory agencies adopt the HACCP plan and system to many businesses. They also look into the HACCP systems for inspections and require HACCP plans for particular food products. The Bureau of Food and Drug Administration recommends the HACCP system to different establishments as it is the most effective and efficient system and preventive control chart structure to guarantee the safety of all food items.

According to a research report from safefood.net entitled Assessing the Effectiveness of HACCP Implementation and Maintenance dated February 2004, with participating companies as food manufacturing plants, a total of 95 percent of participants possess formally documented food safety policies that are well communicated to its employees. About 93 percent of companies have a HACCP team that formulates HACCP plans and implements the processes.

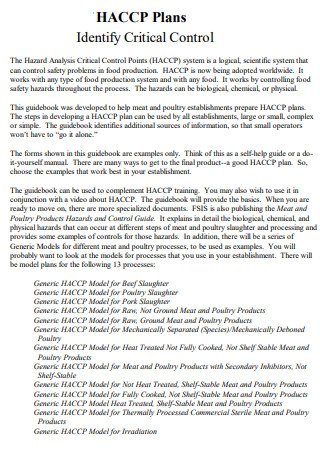

The Seven Principles of HACCP Plans

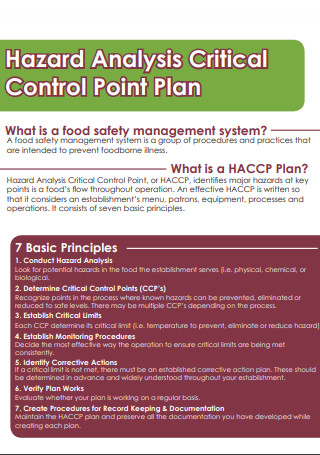

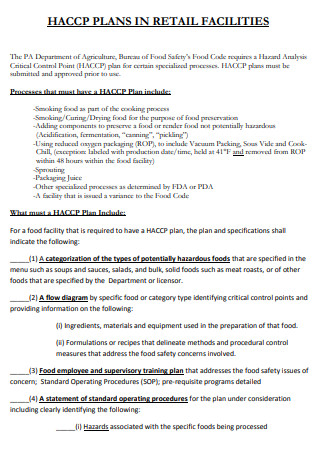

HACCP plans are standardized systems with recognition from the different state and federal regulatory agencies. The implementation of these plans follows specific components and principles. Below are the seven principles of HACCP that support the identification, evaluation, and control of food safety hazards, according to the United States Food and Drug Administration.

How To Develop a HACCP Plan

With a general understanding of the principles surrounding a HACCP plan, you can now start to develop a HACCP plan for your company. Like in any other planning process, it is essential to collect all the necessary information to include in the document. The fact-finding method or preliminary steps help settle the HACCP plan. Below are the five steps to follow.

-

Step 1: Establish the HACCP Team

The first step in developing a HACCP plan is to assemble individuals for your HACCP team. The role of the people working in the team is to gather the necessary information for the Planning Process. The HACCP team must be aware of the food product and process, food safety programs, food safety hazards of concern, and the seven principles of HACCP. HACCP teams don’t need to have many members. For smaller companies, having one individual in the team is enough. What matters is the team functions effectively and meets its responsibilities. The HACCP team begins to collect data from internal and external sources. External sources are available in state and federal agencies, trade and professional associations, consultants, universities, and libraries.

-

Step 2: Describe the Product

Before any hazard analysis process, a full description of the product, including its customer specifications, must include relevant information to a safe consumption. The safety information labeling must include details such as mycotoxin regulation, physical and chemical properties of ingredients, water, and pH levels. It must also indicate packaging, durability and storage conditions, and Transportation Requirements. The information must be visible on the labels of food products to help identify real health hazards in line with the product processing.

-

Step 3: Identify the Product’s Intended Use

The HACCP plan must include the intended use of the product. It must contain information on whether the Food Items are consumed directly, be cooked, or further processed. Identifying the intended use will have a significant impact on the hazard analysis and overall safety of food products. The nature of the target population also becomes relevant, especially if it specifies susceptible groups to hazards such as infants, elderly or malnourished individuals. Misuse of a product must also be on the product label.

-

Step 4: Draw Up the Commodity Flow Diagram

After identifying the composition and product use, the HACCP team must construct a detailed commodity Flow Diagram of the commodity system. The company can bring in the expertise of a commodity specialist to have the relevant knowledge in creating the document. Take note that commodity systems vary in different places and are present in different variants. For each manufacturing establishment, detailed secondary processing must be present using generic flows as a guide.

-

Step 5: On-Site Confirmation of the Commodity Flow Diagram

After the completion of the commodity flow diagram, members of the HACCP team must visit the manufacturing location for comparison on the available data in the document with the actual processes and practices happening on site. A step-by-step process practice is performed by the HACCP team to check if all the information on the commodity flow diagram is accurate, including the materials, practices, and controls. Information like drying procedures, storage conditions, grading systems, processing systems, and collection procedures are present in the diagram as necessary. The processing and manufacturing sites must have Daily Inspections to ensure that procedures and information are accurate.

FAQs

Do organizations need a HACCP plan?

The HACCP plan is necessary for each food and processing system that a food business employs because each food product and the processes of its production pose various risks and hazards to consumers that require appropriate risk management plan processes.

What are the four types of food hazards?

The four types of food hazards that companies must be aware of are microbiological hazards, chemical hazards, physical hazards, and allergens.

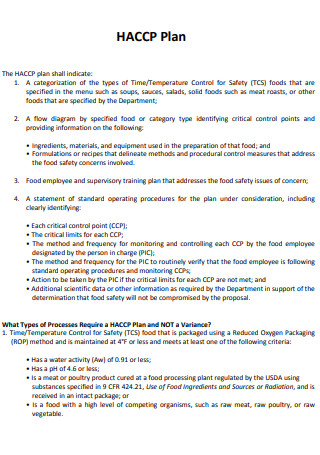

What foods require the HACCP plan?

HACCP requires processing for most food items, including meat, poultry, juice, seafood, and all other food processing business under the Food Safety Modernization Act 2010.

Creating a HACCP plan protects the food manufacturing business and its consumers. An organization geared toward preventing health hazards and risks to its customers will have loyal customers lining up to buy their products. Customer loyalty is one of the many factors that contribute to the success of large companies, and HACCP plans guarantee that businesses retain their market. Start the journey of reassuring consumers that the company follows all the necessary protocols for the food they consume. Download HACCP plan samples available in the article above today!