18+ Sample Contractor Safety Plan

-

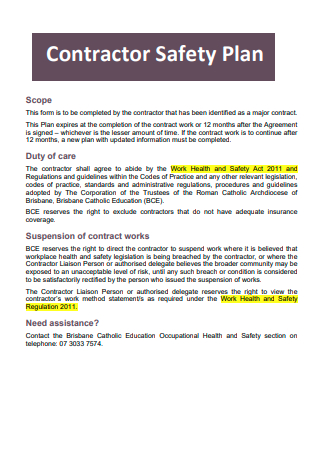

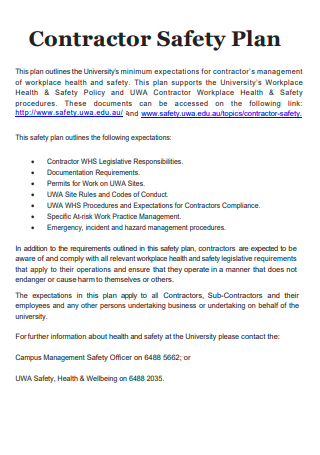

Contractor Safety Plan Template

download now -

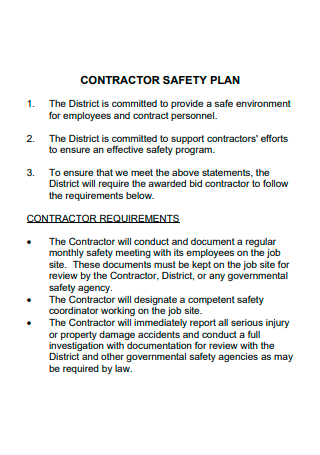

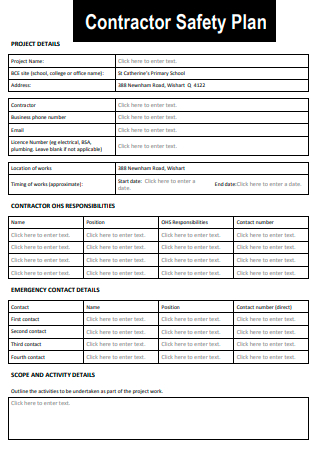

Basic Contractor Safety Plan

download now -

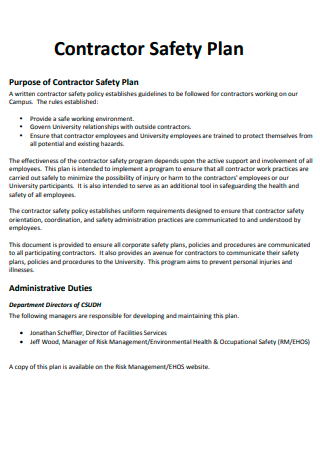

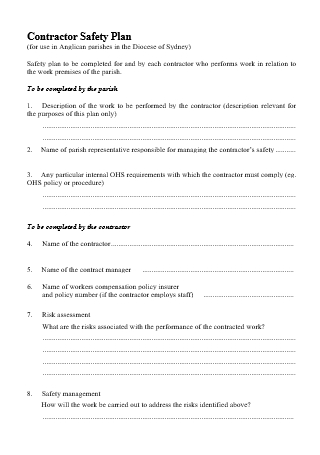

Contractor Safety Plan Review

download now -

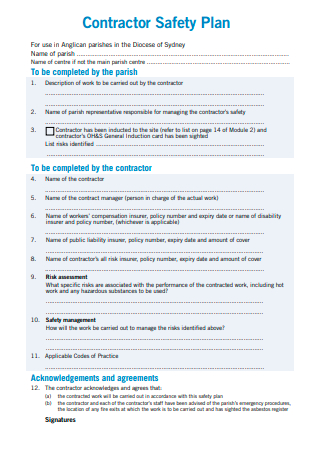

Contractor Safety Plan Example

download now -

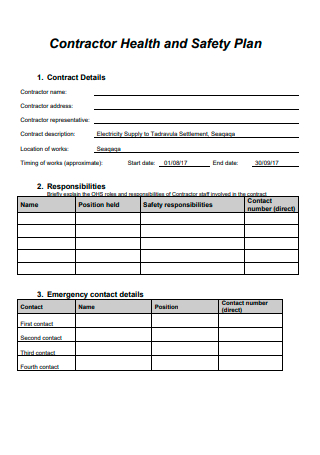

Contractor Health and Safety Plan

download now -

Contractor Hazard Assessment and Safety Plan

download now -

Printable Contractor Safety Plan

download now -

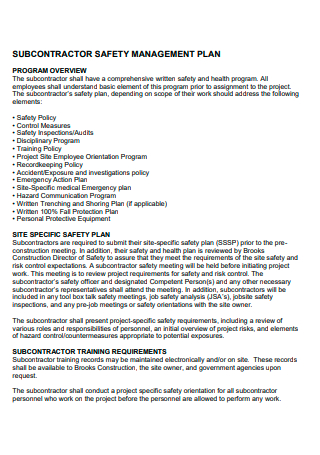

SubContractor Safety Management Plan

download now -

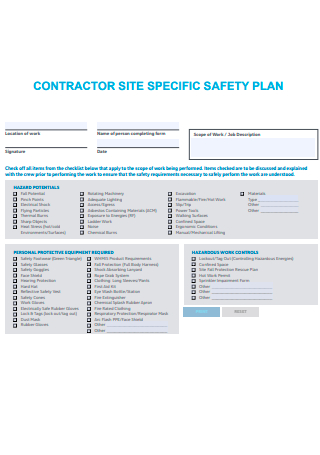

Contractor Site Specific Safety Plan

download now -

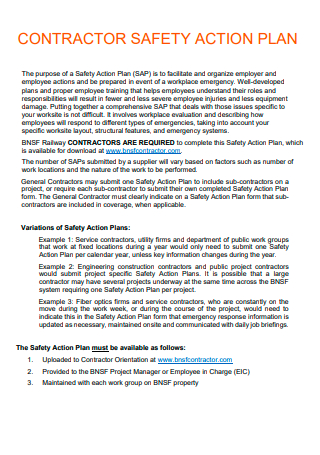

Contractor Safety Action Plan

download now -

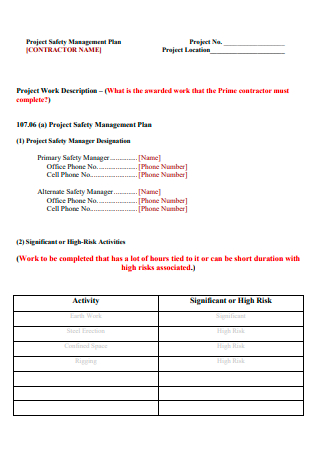

Contractor Project Safety Management Plan

download now -

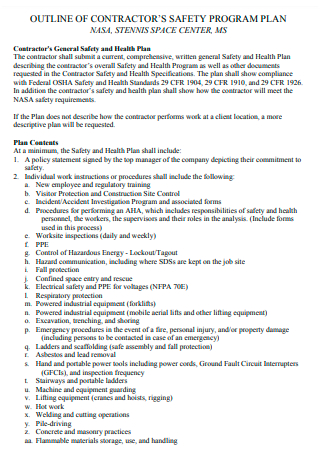

Contractor Safety Program Plan

download now -

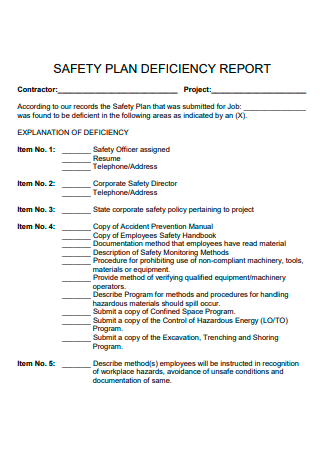

Contractor Safety Plan Deficiency Report

download now -

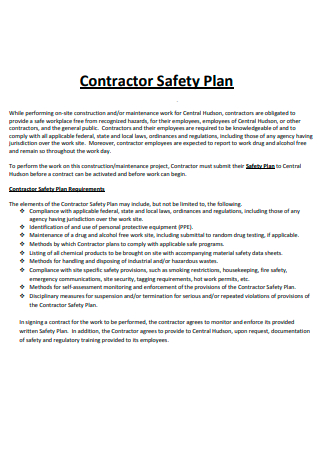

Contractor Site Safety Plan

download now -

Contractor Safety Plan in PDF

download now -

Sample Contractor Safety Plan

download now -

Formal Contractor Safety Plan

download now -

Contractor Safety Plan in DOC

download now -

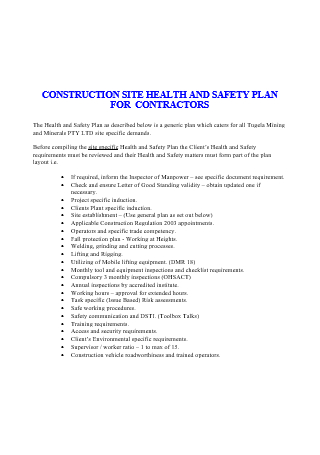

Construction Site Health and Safety Plan For Contractors

download now

FREE Contractor Safety Plan s to Download

18+ Sample Contractor Safety Plan

a Contractor Safety Plan?

Benefits of Construction Safety

Safety Tips for Construction Sites

How To Write a Construction Safety Plan

FAQs

Why is it necessary to have a construction safety plan?

What information is contained in the construction plan?

What is a phase plan for construction?

What Is a Contractor Safety Plan?

The contractor safety policy specifies uniform rules for communicating and educating personnel about contractor safety orientation, coordination, and administration processes. This document communicates all business safety strategies, regulations, and procedures to all participating contractors. Additionally, it enables contractors to share their safety plans, practices, and policies with the organization. This program is designed to help individuals avoid personal injuries and illnesses. Over 99% of all accidents are preventable, according to statistics.

Benefits of Construction Safety

Safety programs and policies help businesses stay competitive and effective in the construction industry, changing significantly. This is because projects are getting done and delivered in new ways. Making it easier for workers to do their jobs safely makes their jobs more accessible, making their work more efficient and better. It’s not enough to find the right construction skills for your business if you don’t also look for the right people. Below, we talk about the great things that construction safety can do for your business and how it can assist you to be more successful.

Safety Tips for Construction Sites

Construction sites are hazardous workplaces. Follow these seven easy safety regulations to keep yourself and others safe on a construction site. By wearing personal protective gear and adhering to protocols, you may make your workplace a safer place to work and prevent accidents. Also, thousands of individuals are harmed on building sites each year. Therefore, it is even more critical to incorporate health and safety into your activities if you work in construction.

-

1. Wear your PPE.

As you enter the site, ensure that you have the necessary PPE. PPE is critical; it serves as your final line of defense if you encounter a hazard on the job. High-visibility clothing helps ensure that you are spotted. Safety boots provide traction and protection for your feet. While hard helmets can be replaced, your skull cannot. It will not protect you unless you wear it. At a minimum, wear a hard hat, safety boots, a hi-viz vest, and any extra PPE required for the task at hand.

2. Do not begin work without first receiving an induction.

Each site has its own set of dangers and work procedures. No two places are identical. Ascertain that you are aware of what is occurring so that you may operate securely. Inductions are a legal obligation for everyone working on a construction site. Your initiation is critical. It directs you to the appropriate sign-in location, where to go, what to do, and what to avoid. Without one, do not begin work.

3. Maintain an orderly site

Construction work is inherently sloppy. Slips and trips may appear insignificant compared to other high-risk tasks occurring on the site, but do not be deceived. According to HSE figures, slips and trips accounted for 30% of identified significant injuries on construction sites. Maintain a neat work environment to minimize slip and trip hazards throughout your shift. Keep an eye out for locations such as access and escape routes.

4. Avoid putting yourself or others in danger.

Words speak louder than actions. Particularly on construction sites, where one incorrect step could endanger you. Set a good example on-site by thinking carefully and acting safely. You are accountable for your actions. Ensure that you maintain a safety-conscious attitude throughout your shift.

5. Never work in potentially hazardous areas.

Ascertain the safety of your work location. Recognize what is going on around you. Keep an eye out. According to HSE figures, 14% of construction fatalities result from anything falling or overturning, and 11% are the result of being struck by a moving vehicle. Never work at a height without using appropriate guard rails or other fall prevention measures. Avoid unsupported trenches. Ascertain that you have secure access. Avoid working beneath crane loads or performing other risky procedures.

6. Notify us of faults and close misses.

If you spot a problem, do not overlook it; immediately notify your supervisor. Complete a near-miss report, an incident report, or inform your supervisor directly. Utilize whatever mechanism your site has in place for reporting difficulties. Only after management has been made aware of the problem can action be taken immediately. The sooner issues are rectified, the lower the risk of an accident.

7. Never attempt to tamper with the equipment.

If something is broken or does not appear to be working correctly, follow rule 6 and report it. Do not attempt to coerce or alter something unless you have been trained or are required to. Remove guard rails and scaffold ties at all costs. Remove no machine guards. Unless you are competent, avoid attempting to repair damaged equipment. Never tamper with equipment without first obtaining authorization forms.

How To Write a Construction Safety Plan

Regardless of how effectively a construction job is completed, the ability to accomplish it safely is what matters. A comprehensive construction safety plan will direct your team in protecting everyone on the project site and reassuring the client that your organization can mitigate hazards and respond to crises. According to research, accident rates in construction are 71 percent higher than the national average for all industries. Construction can be far more dangerous than other forms of labor, so teams must develop comprehensive construction safety plans and supply training for operating heavy equipment to safeguard the health and safety of all personnel. Incorporate the recommendations below to assist you in developing a comprehensive plan for ensuring the security of your employees and community.

-

1. Allow For Adaptability And Flexibility

Safety plans should be adaptable and flexible enough to be used across numerous projects. Given the dynamic nature of construction and the high volatility of dangers and working circumstances, it is even more critical to establish a safety strategy that adapts to each type of project. For instance, a general safety plan often specifies who to contact and what actions to take in the event of an accident. On the other hand, a site-specific safety strategy tailors safety practices to each unique construction project.

2. Personal Protective Equipment Is Required

To demonstrate to clients that your business is devoted to the safety of all employees, ensure that your safety plan includes a list of personal protective equipment (PPE) supplied to each employee. Hard helmets, sunglasses, face masks, and earmuffs are personal protective equipment. Remind employees that they are accountable for and well-trained in the proper usage and care of their safety equipment.

3. Specific Construction Site Regulations

For example, smoking in undesignated areas is a standard safety issue on construction sites. Even though the Occupational Safety and Health Administration does not have regulations directly addressing smoking places on construction sites, companies should make establishing a hazard-free workplace a top concern.

4. Clarify Each Employee’s Role

Each employee is essential to the victory of a safety plan. As a result, all construction workers and subcontractors should grasp their job descriptions and responsibilities before starting a project. Employers should also establish the proper measures that each employee should take in the case of an emergency and assure that each employee is familiar with their duties in a safety plan.

5. Establish Protocols To Assist In Risk Mitigation

A safety plan’s primary objective is to illustrate the company’s risk management and occupational safety standards. Employers should incorporate rules and protocols into their plans to avoid accidents, such as operating procedures for heavy equipment and excavation safety precautions. When hazards become a reality, not only can construction projects be slowed down, but employees can sustain injuries. To avert these calamities, ensure that safety rules are followed.

6. Take Climate Conditions Into Consideration

Given that the bulk of building projects occur outdoors, weather conditions are another factor to consider while developing your strategy. Given that the weather cannot be controlled or manipulated, each construction site should have a contingency plan for dangerous weather conditions ranging from severe cold to excessive heat. Begin by assessing site-specific risks associated with a severe weather event. Then, tailor your safety strategy to the extreme weather in your location.

7. Include Contact Information for Emergency Personnel

A well-designed construction safety plan enables all on-site staff to respond quickly and effectively to any situation. One of the most valuable strategies to shorten emergency response time includes an emergency contact person or persons in the safety plan. Internal and external contacts should be included on this list of emergency contacts. Site supervisors and property managers, and emergency response services such as the fire department, paramedics, and police are included in this category.

FAQs

Why is it necessary to have a construction safety plan?

A comprehensive construction safety plan will direct your team in protecting everyone on the project site and reassuring the client that your organization can mitigate hazards and respond to crises.

What information is contained in the construction plan?

A building plan details the structure you intend to build and how it will look when completed. Construction plans are referred to by various terms, including blueprints, drawings, working drawings, and house plans. With their numerous strange symbols, construction blueprints can be intimidating to the untrained.

What is a phase plan for construction?

A construction phase plan is a critical document that explains the health and safety hazards inherent in the construction phase of a project and the control mechanisms that will be applied to mitigate or eliminate those risks.

It may not be comfortable for you to design and plan this coordination plan, particularly given that it contains details that should be pro-safety and pro-development. However, taking care of your contractor’s and its employees’ well-being is a worthwhile endeavor. This is a fantastic technique for you to alleviate the load of producing reports from scratch, as several materials and tools are available online.