25+ SAMPLE Construction Safety Plan

-

Construction Safety Training Plan

download now -

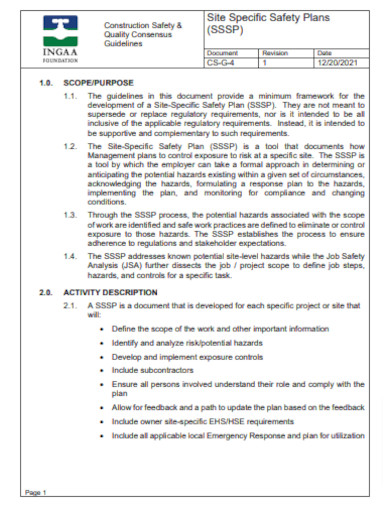

Construction Site Specific Safety Plan

download now -

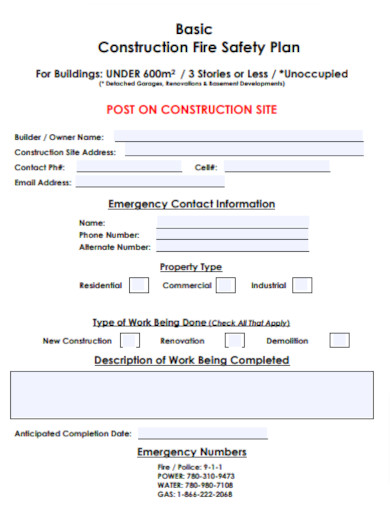

Construction Fire Safety Plan

download now -

Construction Safety Emergency Plan

download now -

Construction Workplace Safety Plan

download now -

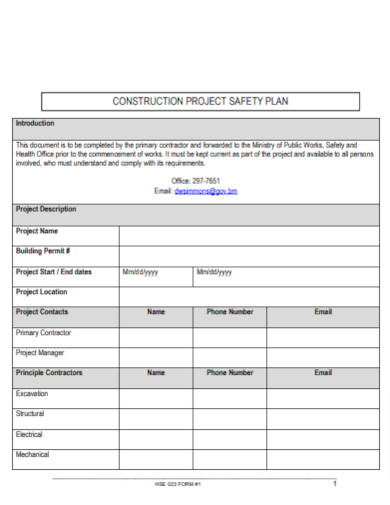

Construction Project Safety Plan

download now -

Energy Project Construction Safety Management Plan

download now -

Construction Site Health and Safety Plan For Contractors

download now -

Fire Safety Plan For Construction

download now -

Simple Construction Safety Plan

download now -

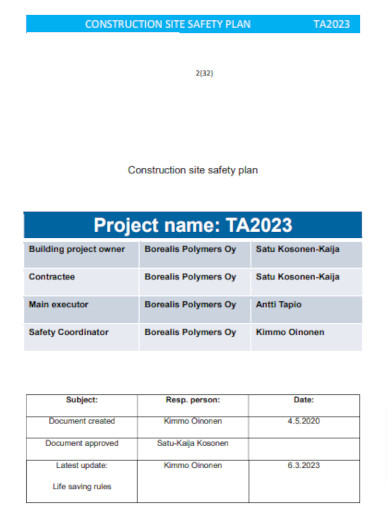

Construction Site Safety Plan

download now -

Basic Construction Safety Plan

download now -

Construction Safety Project Plan

download now -

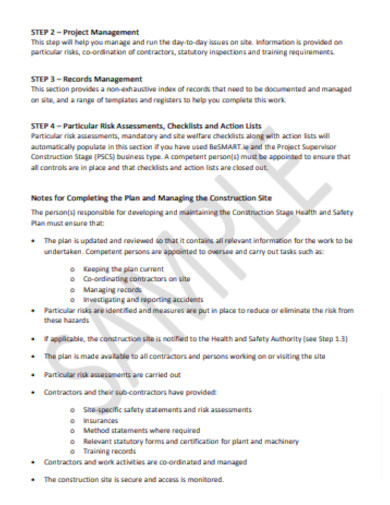

Construction Safety Stage Plan

download now -

Construction Safety Plan Requirement

download now -

Construction Safety Policy Plan

download now -

Construction Safety Checklist Plan

download now -

Construction Specific Safety Plan

download now -

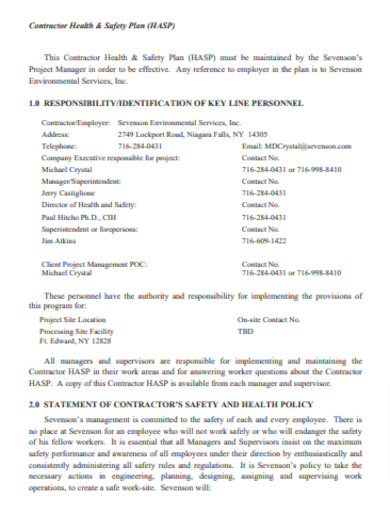

Construction Contractor Safety Plan

download now -

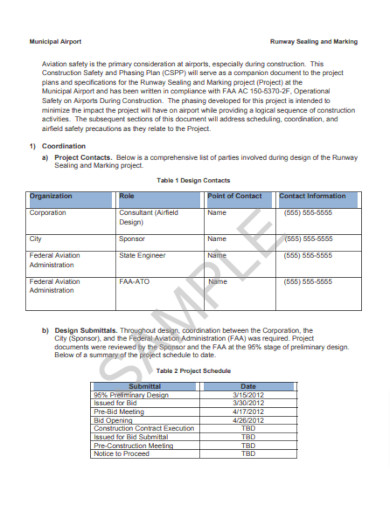

Municipal Airport Construction Safety Plan

download now -

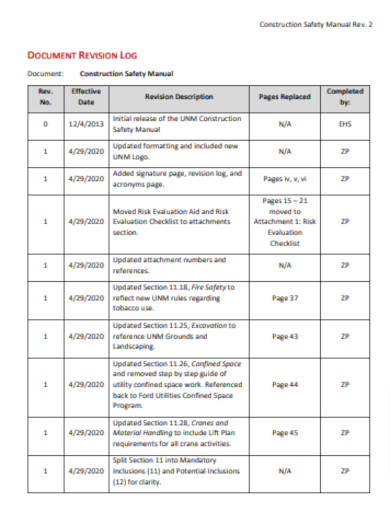

Construction Safety Manual Plan

download now -

Construction Site Health Safety Plan

download now -

Construction Safety Major Project Plan

download now -

On Site Construction Safety Plan

download now -

Construction Public Safety Plan

download now -

Construction Safety Plan Guidelines

download now

FREE Construction Safety Plan s to Download

25+ SAMPLE Construction Safety Plan

The Imperative of a Robust Construction Safety Plan

Why a Construction Safety Plan is Essential

Key Components of an Effective Safety Plan

Embracing a Safety-First Culture in Construction

How to Cultivate this Culture

How to write an OSHA Safety Plan?

FAQ’S

Who is responsible for creating and implementing the safety plan?

How often should the safety plan be reviewed?

Do all construction sites require a safety plan?

How do I ensure that all workers are familiar with the safety plan?

What happens if safety protocols in the plan are not followed?

How do I address language barriers in ensuring everyone understands the safety plan?

The Imperative of a Robust Construction Safety Plan

In the fast-paced world of construction, where towering skyscrapers and intricate infrastructures emerge from the ground, the safety of every individual on site is paramount. The very nature of construction, with its melding of heavy machinery, high-risk tasks, and often tight schedules, underscores the undeniable need for a detailed and comprehensive construction safety plan.

Why a Construction Safety Plan is Essential

In the intricate ballet of construction projects, where every detail counts and the margin for error is minuscule, the safeguarding of human life and the environment stands out as the paramount concern. The importance of a construction safety plan cannot be overstated, as it transcends mere regulatory obligations and delves into the very ethos of responsible and sustainable construction. Here’s a deeper dive into why a construction safety plan is indispensable:

Protection of Life and Health:

At its core, a construction safety plan is designed to protect everyone involved in the project—from site engineers to laborers. The construction environment is fraught with hazards, including falls from heights, machinery malfunctions, and exposure to harmful materials. A well-formulated safety plan anticipates these risks and creates measures to prevent or mitigate them.

Regulatory and Legal Compliance:

Governments worldwide have established stringent safety standards for construction sites. These regulations are in place not only to protect workers but also to safeguard the environment and the general public. Non-adherence can result in severe penalties, including project cessation, fines, or even legal prosecution.

Financial and Operational Continuity:

Workplace accidents can be financially crippling. From medical bills and compensation to project delays, the financial ramifications can quickly escalate. A proactive safety plan helps prevent these unexpected costs and ensures that the project timeline remains unaffected.

Reputation Management:

In today’s digital age, news travels fast. An accident or mishap on a construction site can tarnish the reputation of the construction firm. A strong commitment to safety enhances the company’s image, portraying it as responsible and trustworthy in the eyes of clients, partners, and the public.

Boosting Worker Morale and Productivity:

Workers perform at their best when they feel secure. A robust safety plan sends a clear message to the workforce that their well-being is a top priority. This not only boosts morale but also leads to higher productivity and a lower turnover rate.

Environmental Stewardship:

Modern safety plans also encompass environmental protection. Proper waste management, pollution control, and resource conservation methods ensure that the construction process treads lightly on the environment.

Proactive Risk Management:

Safety plans enable construction firms to be proactive rather than reactive. By anticipating potential challenges and hazards, teams can be better prepared, ensuring smoother project execution.

In essence, a construction safety plan is the bedrock upon which successful, sustainable, and responsible construction projects are built. It’s not just a document; it’s a testament to an organization’s commitment to excellence, responsibility, and care.

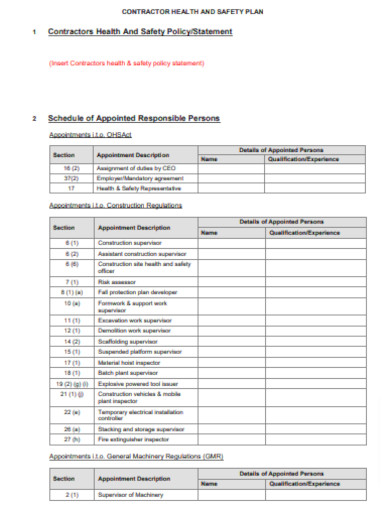

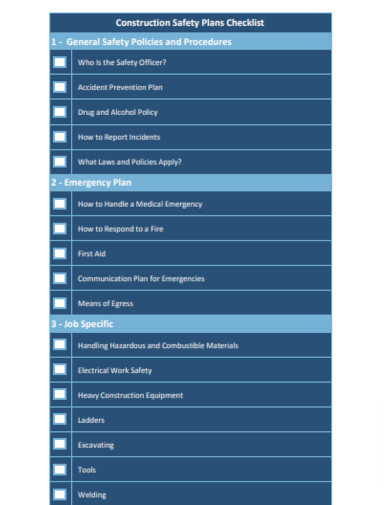

Key Components of an Effective Safety Plan

Constructing edifices, be it residential homes, towering skyscrapers, or expansive bridges, inherently comes with risks. To navigate the treacherous terrain of construction projects, a robust safety plan, serving as a beacon, is pivotal. So, what constitutes this protective shield that ensures workers return home unscathed and projects see the light of day without mishaps? Here are the fundamental components that breathe life into an effective safety plan:

Hazard Identification and Risk Assessment:

Before any shovel hits the ground, a thorough assessment of potential hazards linked to the project should be undertaken. This involves evaluating site conditions, understanding the nature of tasks, and identifying potential risks associated with tools, machinery, and materials.

Safety Protocols and Procedures:

This component elaborates on the specific actions required to mitigate identified risks. Whether it’s the correct procedure to operate a crane or the steps to safely handle hazardous materials, these protocols serve as a guide for workers.

Training and Education:

Knowledge is the first line of defense. Regular training sessions tailored to different roles ensure that every worker, regardless of their task, understands the safety measures in place and the reasons behind them.

Emergency Response Plan:

Despite best efforts, emergencies can arise. A well-defined emergency plan delineates the steps to be taken during crises, be it fires, structural collapses, or medical emergencies. This includes evacuation routes, first aid procedures, and communication systems.

Safety Equipment and Personal Protective Equipment (PPE):

The armor that stands between workers and potential hazards. This involves providing and mandating the use of safety gear like helmets, goggles, gloves, harnesses, and more, tailored to specific tasks.

Regular Inspections and Audits:

A static plan is of limited use. Regular inspections of the site, machinery, tools, and safety equipment ensure that standards are maintained and any new hazards are promptly identified.

Incident Reporting and Investigation:

In the unfortunate event of an incident, a clear reporting mechanism should be in place. This not only aids in providing timely assistance but also ensures that root causes are identified, preventing future recurrences.

Feedback Mechanism:

Workers on the ground often have firsthand insights into potential risks. A system where they can provide feedback or raise concerns ensures that the safety plan remains dynamic and evolves based on real-world feedback.

Continuous Review and Improvement:

The construction industry, tools, materials, and methods evolve. An effective safety plan isn’t set in stone. It adapts and morphs, integrating new best practices, technologies, and feedback.

Clear Communication:

From posters on site walls to digital platforms, clear communication ensures that every individual, whether they’re a day laborer or a site supervisor, is on the same page regarding safety protocols.

Embracing a Safety-First Culture in Construction

Amid the ever-evolving tapestry of construction, with its complex interplay of materials, machinery, and manpower, a singular ethos should always shine through: safety. It’s not enough to merely have safety protocols on paper; the essence of a truly secure construction environment is a deeply ingrained culture of safety. This transition from mere procedure to a pervasive philosophy can shape the destiny of construction projects and redefine an organization. Let’s delve into the nuances of embracing a safety-first culture in construction.

The Tangible Benefits

Enhanced Morale and Commitment: When workers realize that their safety is a non-negotiable priority, it boosts their morale and trust in the organization. This invariably leads to greater commitment, reduced turnover, and enhanced productivity.

Financial Savings:

Beyond the ethical imperative, a safety-first culture translates to fewer accidents, reduced medical expenses, lower compensation claims, and avoidance of legal ramifications and fines.

Reputation Amplification:

In a competitive market, a company known for its safety culture attracts more bids, better talent, and positive media attention.

How to Cultivate this Culture

Leadership By Example: Top management must not just preach safety but live it. When leaders demonstrate a commitment to safety, it resonates throughout the organization.

Continuous Training: Regular safety training sessions, both general and task-specific, ensure that the workforce is always equipped with updated knowledge.

Open Communication Channels: Create an environment where workers at all levels feel comfortable voicing their concerns, offering suggestions, and reporting near-misses without fear of retribution.

Reward and Recognition: Recognize and reward those who adhere to safety guidelines and contribute to a safer workplace. This could be in the form of bonuses, public recognition, or promotions.

Incorporate Safety in Induction: Right from day one, when a new employee joins, safety should be a significant part of their induction process.

Invest in Quality Equipment: Do not cut corners when it comes to safety equipment. Ensure the gear is of high quality, regularly inspected, and replaced when needed.

Review and Reflect: After any incident, even minor ones, conduct thorough investigations to determine root causes, learn from the mistakes, and make necessary changes.

How to write an OSHA Safety Plan?

Creating an OSHA (Occupational Safety and Health Administration) compliant safety plan is crucial for businesses that want to ensure the safety of their workers, maintain regulatory compliance, and foster a healthy work environment. Here’s a step-by-step guide to help you craft an effective OSHA safety plan:

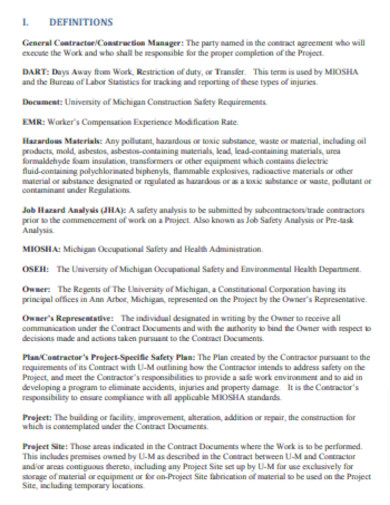

1. Understand OSHA Requirements

Begin by understanding the specific standards and regulations set by OSHA for your industry. Different industries may have varying requirements, so it’s essential to be knowledgeable about those relevant to you.

2. Define Your Scope

Specify the activities, procedures, sites, or tasks your safety plan will cover. This will be dependent on the nature of your business and the associated risks.

3. Identify & Assess Hazards

Conduct a thorough hazard assessment of your workplace. This involves:

- Surveying the workplace to identify potential hazards.

- Reviewing accident and injury logs.

- Talking to employees about perceived risks.

4. Develop Procedures to Control Hazards

Once hazards are identified, outline measures to eliminate or control them. This might involve:

- Implementing engineering controls, such as better equipment design or ventilation.

- Administrative controls, like rotating workers or scheduling regular breaks.

- Utilizing Personal Protective Equipment (PPE) for employees.

5. Define Safety Policies and Protocols

Clearly spell out your company’s safety policies, covering:

- Usage, maintenance, and storage of tools and equipment.

- Chemical handling and storage.

- Emergency procedures, including fire drills and evacuation plans.

- Reporting of injuries or unsafe conditions.

6. Training and Communication

Make sure that all employees:

- Understand the safety plan.

- Know how to use and maintain their PPE.

- Can identify hazards and know the appropriate response actions.

- Are aware of the emergency evacuation routes and procedures.

- Hold regular training sessions and refresher courses.

7. Emergency Response Procedures

Draft clear guidelines on what actions to take during emergencies, like fires, chemical spills, or electrical failures. Include details on emergency contact numbers, evacuation routes, and emergency assembly points.

8. Plan for Regular Inspections

Schedule routine safety inspections of the workplace to ensure that all safety measures are continually upheld and to identify any new potential hazards.

9. Accident Investigation

Outline clear procedures for reporting and investigating accidents or near-miss incidents. This helps identify the cause of accidents and prevents future occurrences.

10. Maintain Records

Document everything. Maintain logs of:

- All identified hazards.

- Training sessions and attendees.

- Inspection results.

- Incidents and subsequent investigations.

11. Regularly Review & Update the Plan

Safety plans aren’t static. Regularly revisit the plan, especially after significant changes to the workplace, introduction of new machinery, or after accidents. Update it as necessary to adapt to new situations or improved safety procedures.

12. Encourage Employee Participation

Involve employees in the safety plan creation and reviews. Their insights, being on the front lines, are invaluable.

FAQ’S

Who is responsible for creating and implementing the safety plan?

Typically, the primary responsibility falls on the employer or the main contractor. However, subcontractors and site managers also play crucial roles in enforcing and adhering to the plan.

How often should the safety plan be reviewed?

While it’s essential to review the plan regularly, it should definitely be revisited after any significant change to work processes, introduction of new equipment, or after a notable incident. Annual reviews are also recommended.

Do all construction sites require a safety plan?

While the size and scope of a project might influence the complexity of a safety plan, all construction sites should have a foundational safety plan in place to address potential hazards.

How do I ensure that all workers are familiar with the safety plan?

Regular training sessions, orientations for new employees, and periodic safety meetings can help ensure that all workers are aware of and understand the safety protocols.

What happens if safety protocols in the plan are not followed?

Failure to follow safety protocols can lead to worker injuries, regulatory fines, increased insurance premiums, potential legal action, and damage to the company’s reputation.

How do I address language barriers in ensuring everyone understands the safety plan?

Consider providing training and materials in multiple languages, utilizing visual aids, and employing bilingual safety supervisors or translators.

In conclusion, the value of a comprehensive construction safety plan is undeniable. It’s the line that separates organized, efficient projects from chaotic, hazardous ones. It’s not just a box to tick or a regulatory hurdle to clear; it’s the embodiment of an organization’s commitment to its most valuable asset—its people.