50+ Sample Corrective Action Plan

-

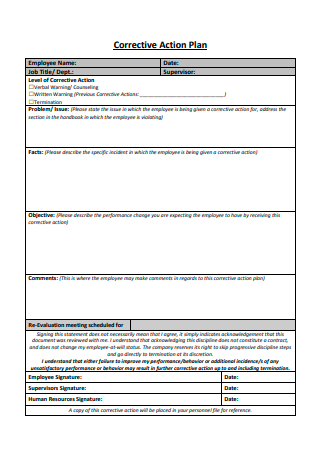

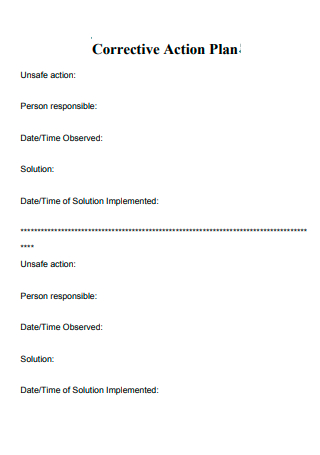

Corrective Action Plan Template

download now -

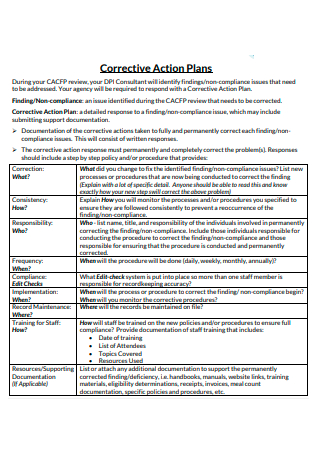

Basic Corrective Action Plan

download now -

Corrective Action Plan in PDF

download now -

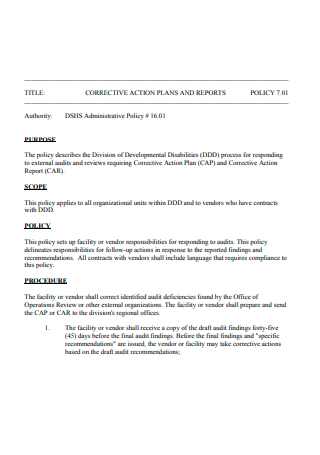

Corrective Action Plan and Reports

download now -

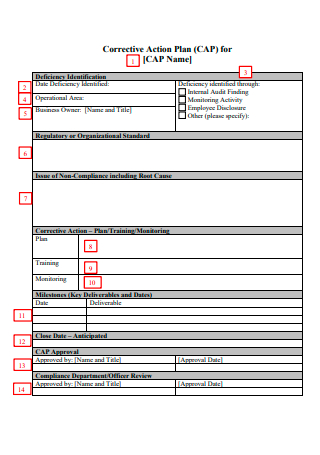

Corrective Action Plan Format

download now -

Corrective Action Plan Management

download now -

Corrective Action Plan and Summary

download now -

Corrective Action Plan Example

download now -

Corrective Action Plan Process

download now -

Office of Licensing Corrective Action Plan

download now -

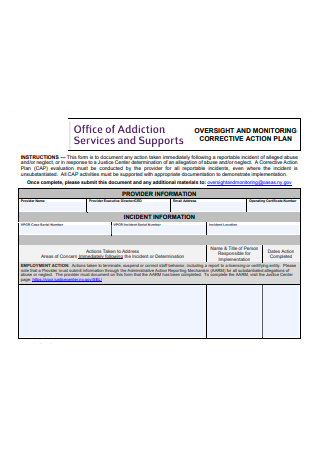

Monitoring Corrective Action Plan

download now -

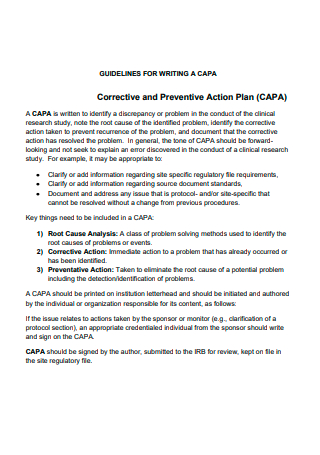

Corrective and Preventive Action Plan

download now -

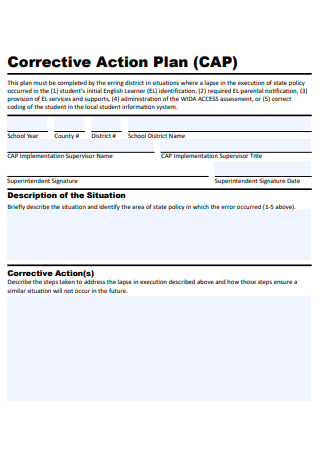

Formal Corrective Action Plan

download now -

Contractor Corrective Action Plan Evaluation

download now -

Draft Corrective Action Plan

download now -

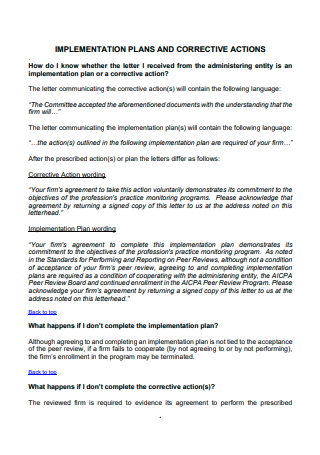

Corrective and Implementation Action Plan

download now -

High-Risk Corrective Action Plan

download now -

Prevention Program Corrective Action Plan

download now -

Participant Directed Services Corrective Action Plan

download now -

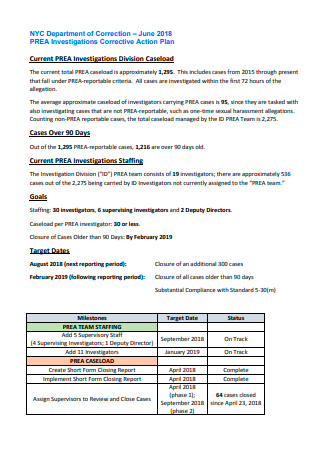

Investigation Corrective Action Plan

download now -

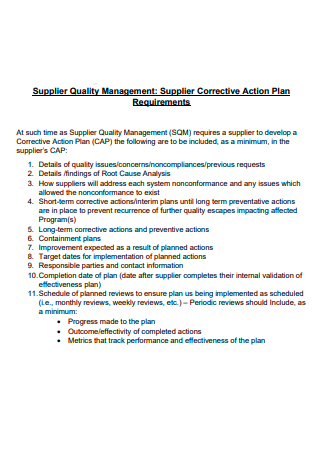

Supplier Corrective Action Plan

download now -

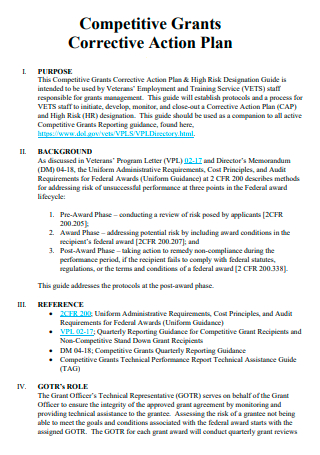

Competitive Grants Corrective Action Plan

download now -

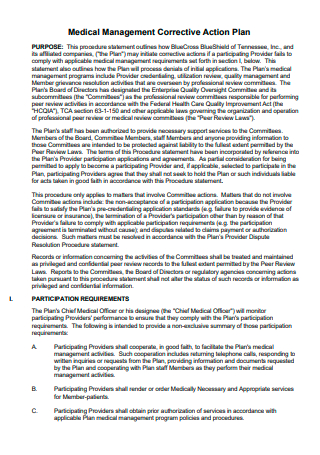

Medical Management Corrective Action Plan

download now -

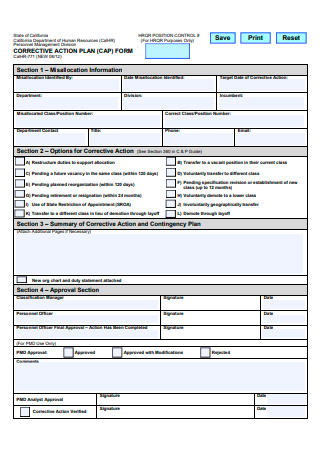

Corrective Action Plan Form

download now -

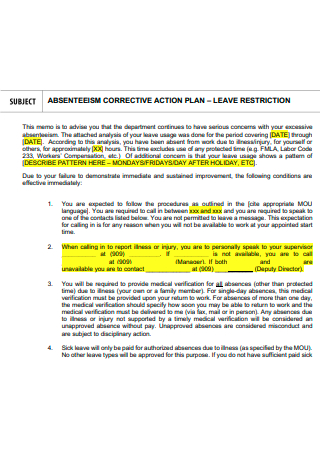

Absenteeism Corrective Action Plan

download now -

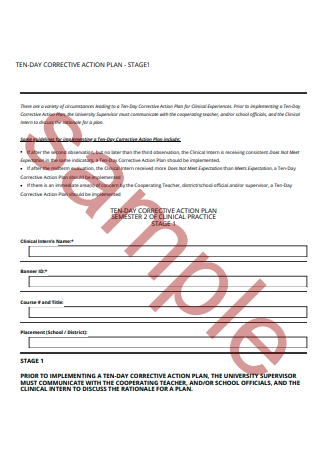

Professional Disposition Corrective Action Plan

download now -

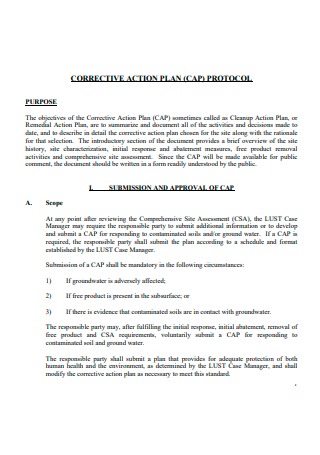

Corrective Action Plan Protocol

download now -

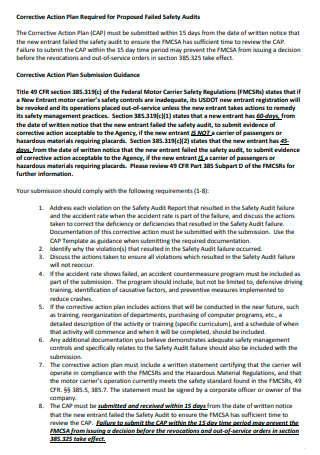

Failed Safety Audits Corrective Action Plan

download now -

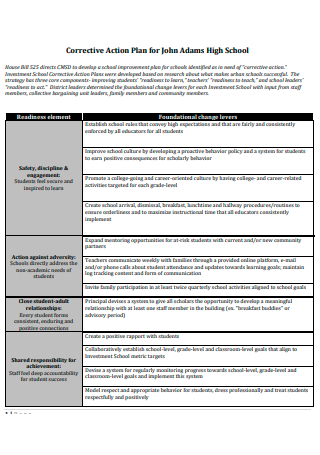

High School Corrective Action Plan

download now -

Sample Corrective Action Plan

download now -

Revised Corrective Action Plan

download now -

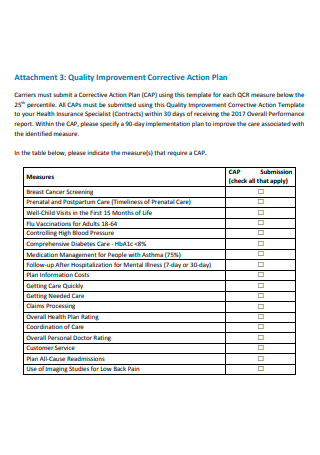

Quality Improvement Corrective Action Plan

download now -

Simple Corrective Action Plan

download now -

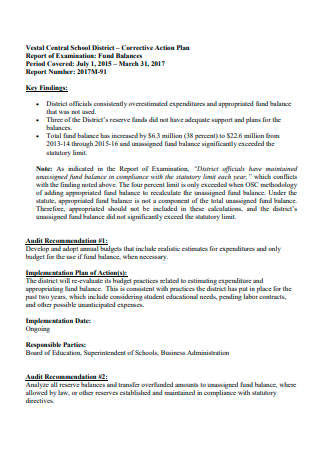

Fund Balances Corrective Action Plan

download now -

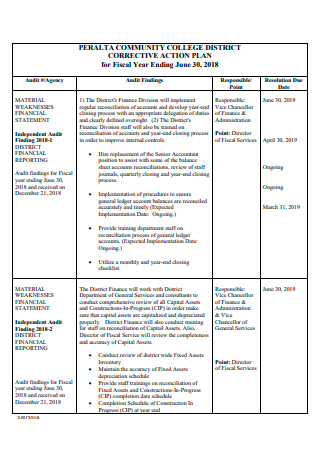

Community College District Corrective Action Plan

download now -

Standard Corrective Action Plan

download now -

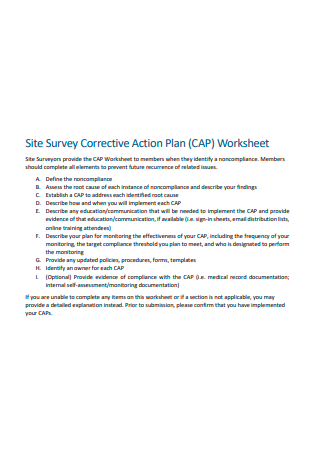

Site Survey Corrective Action Plan

download now -

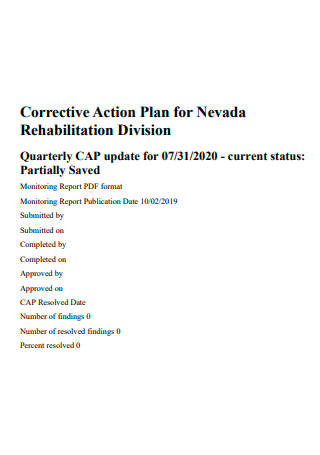

Corrective Action Plan For Rehabilitation Division

download now -

Program Corrective Action Plan

download now -

Non-Compliance Corrective Action Plan

download now -

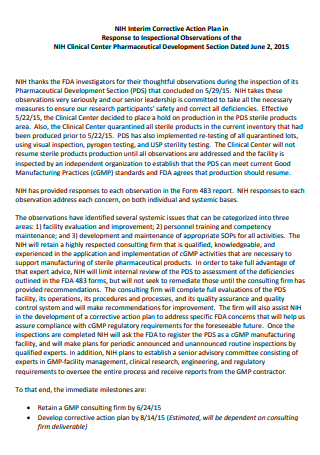

Responses and Corrective Action Plan

download now -

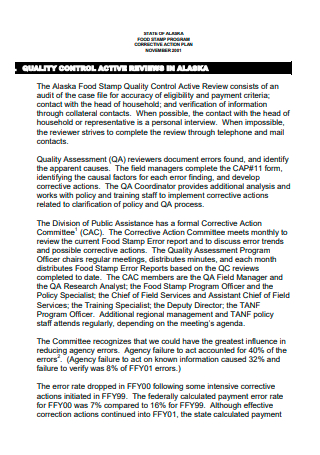

Food Stamp Program Corrective Action Plan

download now -

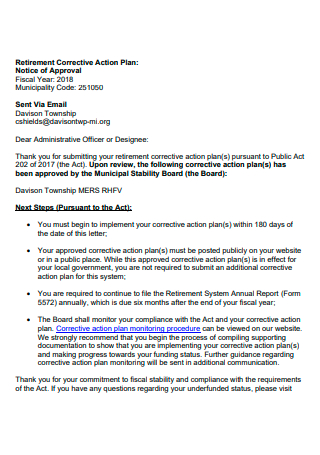

Retirement Corrective Action Plan

download now -

Interim Corrective Action Plan

download now -

Corrective Action Plan Procedures

download now -

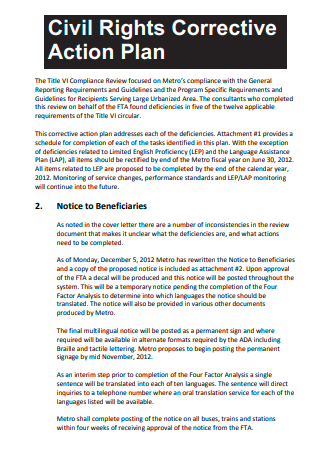

Civil Rights Corrective Action Plan

download now -

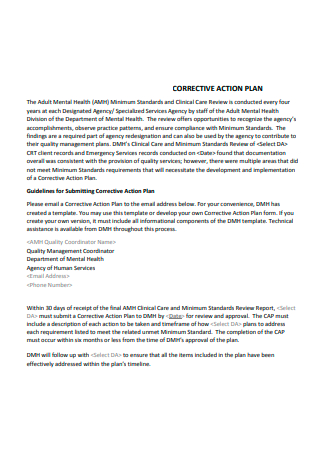

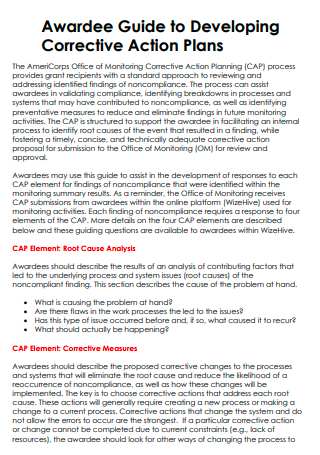

Developing Corrective Action Plan

download now -

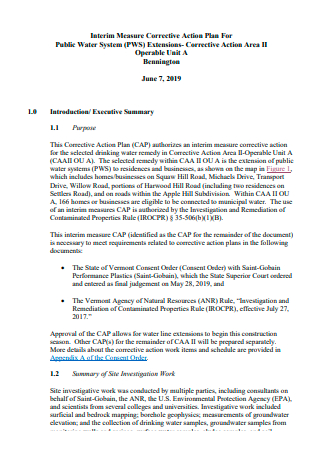

Interim Measure Corrective Action Plan

download now -

Department of Energy Corrective Action Plan

download now -

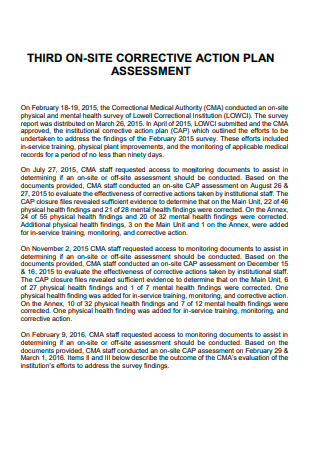

Corrective Action Plan Assessment

download now -

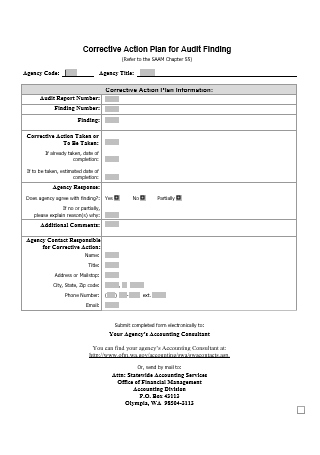

Corrective Action Plan For Audit Finding

download now

FREE Corrective Action Plan s to Download

50+ Sample Corrective Action Plan

What Is a Corrective Action Plan?

Components of a Corrective Action Plan

How To Implement the Corrective Action Plan

FAQs

What is the importance of a corrective action plan?

What does CAPAS do?

What is the primary goal of corrective action?

What Is a Corrective Action Plan?

A corrective action plan or CAP is a business document that seeks to complete targeted outcomes through a resolution of undesirable actions. It represents a step-by-step process that addresses specific issues, errors, and shortcomings of operations in the business. The record describes what designated individuals must do to rectify unforeseen situations. The implementation of a corrective action plan happens to facilitate workflow, identify the most cost-effective channels to resolve errors, improve procedures and techniques, increase efficacy and effectiveness of processes, and control and eliminate deficient and defective practices. An organization executes the corrective action plan when identified problems arise with the potential to have severe consequences and negative implications to the quality management system. The corrective action plan follows the SMART goal-setting process, making it systematic, manageable, achievable, relevant, and time-bound. The appropriate execution of the strategy aids to improve business performance, operations, and responses and address work-related problems. Corrective actions plans can be as simple as greeting customers that visit a store to more complex solutions like restructuring and revising accounting procedures.

According to IBIS World, 638,583 manufacturing businesses in the United States are active as of 2022. The number of organizations in the manufacturing industry has had an average increase rate of 1.7 percent over the past five years, starting from 2017 to 2022. As there are over a hundred thousand manufacturing companies in the United States, there are at least an equal number of corrective action plans in the entire country.

Components of a Corrective Action Plan

In writing a corrective action plan, it is critical to remember that the purpose of the document is to mitigate an unpleasant event to resume regular operations of the company. As such, several elements must be present in the action plan for it to function effectively. Below are the components of a corrective action plan that an organization uses.

How To Implement the Corrective Action Plan

When writing a corrective action plan for the organization, consider creating the document under the International Organization of Standardization (ISO) standards. In this way, implementing the solution to problems follow the standard operating procedures. For quality managers, the guidelines serve as an effective way to implement the corrective action plan. Below are the steps you can take as an organization to use the corrective action plan.

-

1. Determine if the Situation Call for Immediate Action

Not all problems and issues will need corrective action. The purpose of implementing the corrective action plan is to identify and resolve systematic issues or something that equates to putting the company in a difficult position and endangers the quality management system of the organization. It is the responsibility of the quality managers and their team members to conduct a risk analysis to determine the severity of the problem and determine the need for corrective action. An organization can look at different approaches, including Failure Mode and Effects Analysis (FMEA) or Hazard and Operability (HAROP). It is a sensible way to conduct risk management measures that qualify risk levels and impacts a problem brings to the organization, its products, and services. After these processes and an issue needs corrective action, the quality management team utilizes procedures under ISO standards and document its progress.

-

2. Conduct a Root Cause Analysis as Necessary

A root cause analysis is a methodological procedure that seeks to analyze a problem and identify possible root causes to resolve problems and issues that can cause unfavorable situations for the company. Conducting the analysis is critical to eliminate the root cause or causes, contradictory to just addressing a manifestation. The procedure best applies to repetitive, systematic, and requires time for resolution. It is essential to form cross-functional teams when planning corrective actions. Some of the techniques that organizations can use include the Five Whys and Eight Disciplines of Problem Solving to craft a reasonable problem statement, identify root causes, and brainstorm appropriate solutions for non-conformance.

-

3. Work on the Corrective Action Plan as a Team

After identifying the root cause of the problem and its possible effects on the organization, formulate the most appropriate corrective action. In every corrective action plan, there are two main actions. First is the recommended action to eliminate the problem, and second is the corrective action itself. Aside from including the recommended and corrective action, the action plan must contain specific information, indicate schedules and timeline implementation, key people and signatories, and corresponding costs. After the creation of the plan, the organization can communicate it to all involved parties for standardization.

-

4. Communicate and Implement the Plan

Improve and encourage management and leadership involvement when it comes to communication practices. Notify essential individuals along with their roles and responsibilities. Provide the necessary communication channels and ensure their availability at all times. These channels can also provide regular feedback on the implementation of corrective actions. These factors determine the efficacy of the implementation of the corrective action plan.

-

5. Conduct Follow-Up Meetings to Guarantee Effectiveness

ISO standards require organizations to review the efficacy of corrective action plans and revise and update risk management and levels to potential options. After the system implementation, process owners and quality teams must wait for a reasonable amount of time and perform follow-up reviews. Managers can input comments to the plan during the assessments. Document the results by attaching helpful documents like helpful notes and media as evidence of the outcomes of corrective actions.

FAQs

What is the importance of a corrective action plan?

Corrective action plans play a vital role in an organization for providing documentation of corrective actions. It allows companies to manage and revise systems to develop better solutions. Corrective action plans improve work processes and techniques, streamline workflows, increase efficiency and effectiveness of procedures, and find cost-effective methods to implement resolutions.

What does CAPAS do?

CAPAS stands for Corrective and Preventive Action Subsystem. Its purpose is to collect and analyze essential information, identify and investigate problems and issues, and take the appropriate corrective and preventive actions to prevent the reoccurrence of non-conforming events.

What is the primary goal of corrective action?

The primary goal of implementing any corrective action in an organization is to identify the root cause of issues and problems and utilize available resources to conduct appropriate measures to rectify the situation.

In every organization, setting up a corrective action plan becomes valuable in ensuring continuous daily operations of the business. Aside from identifying the root cause of problems that arise, it also provides a basis for future developments and needs of the company. instituting a corrective action plan allows the organization to react as soon as possible to prevent negative implications. Create the document for your company today, and download the samples available from the article.