39+ SAMPLE HACCP Audit Plan

-

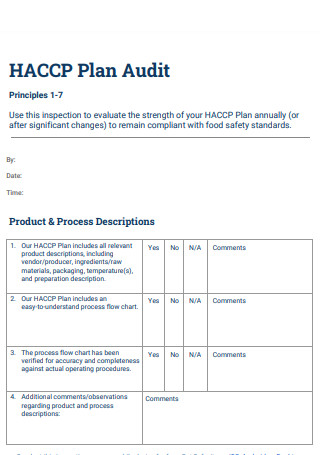

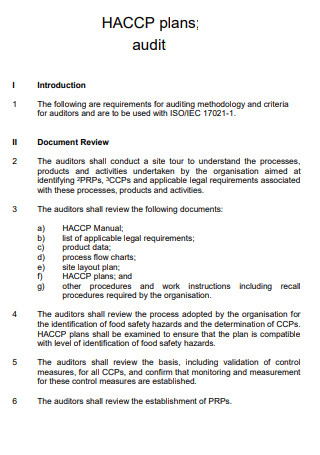

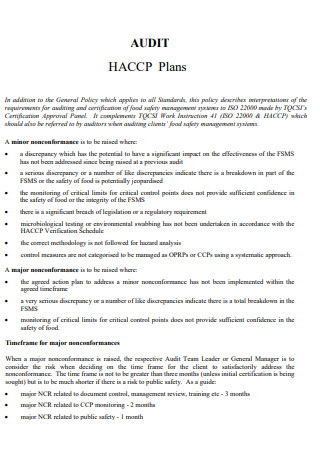

HACCP Audit Plan

download now -

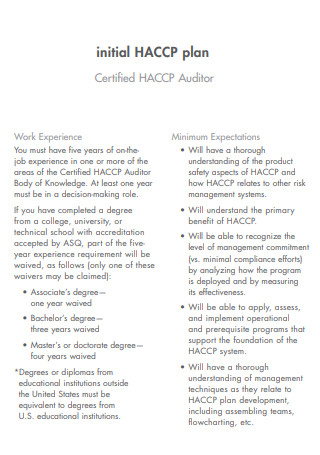

Initial HACCP Audit Plan

download now -

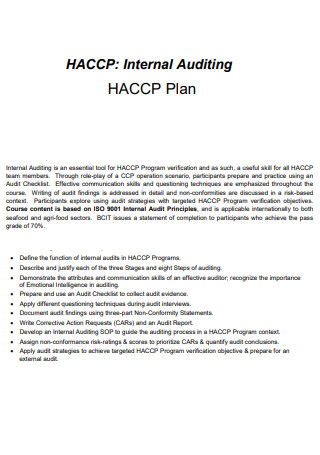

HACCP Internal Audit Plan

download now -

HACCP Certification Audit Plan

download now -

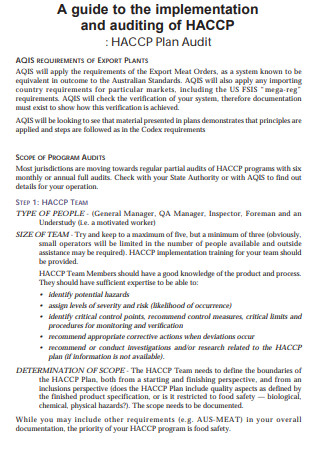

Implementation of HACCP Audit Plan

download now -

HACCP Audit Review Plan

download now -

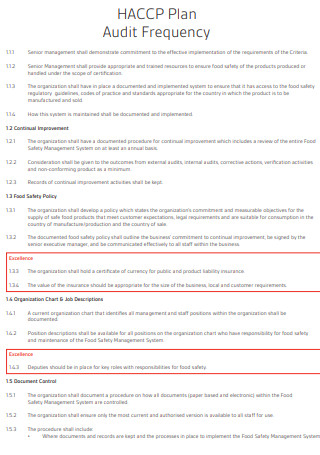

HACCP Audit Frequency Plan

download now -

HACCP Food Safety Audit Plan

download now -

Execution of HACCP Audit Plan

download now -

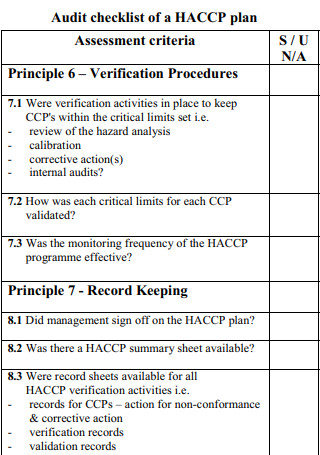

HACCP Audit Plan Checklist

download now -

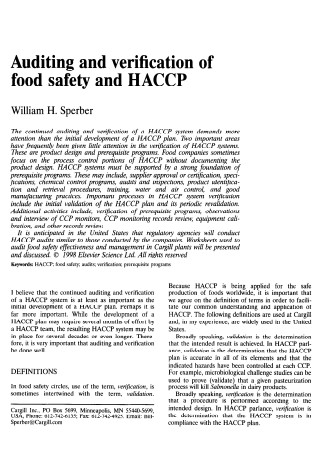

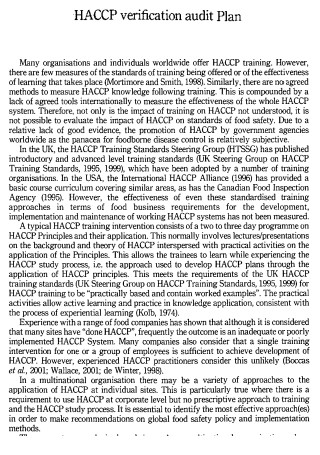

Verification of Food Safety HACCP Audit Plan

download now -

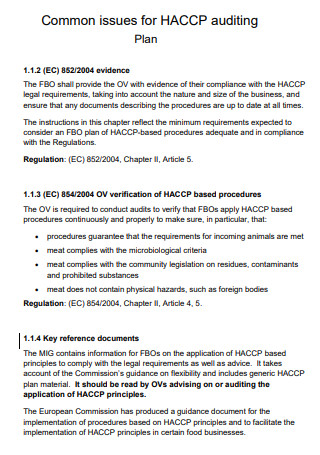

Common Issues for HACCP Audit Plan

download now -

HACCP Food Supplement Audit Plan

download now -

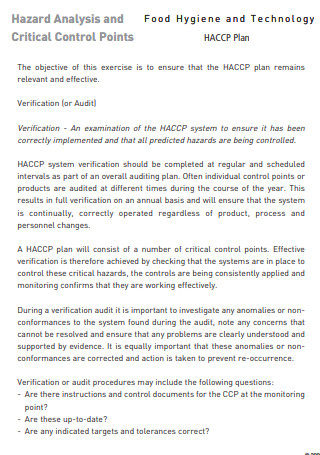

HACCP Food Hygiene Audit Plan

download now -

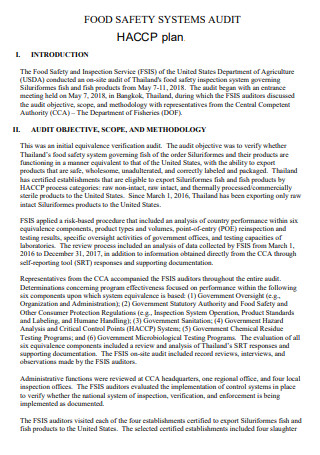

HACCP Food Safety System Audit Plan

download now -

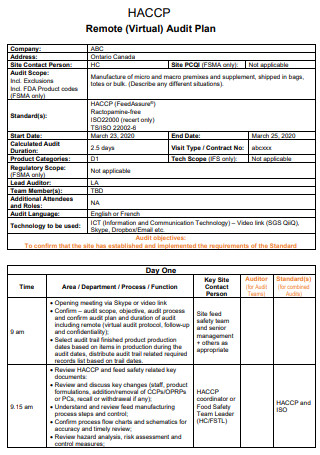

HACCP Virtual Audit Plan

download now -

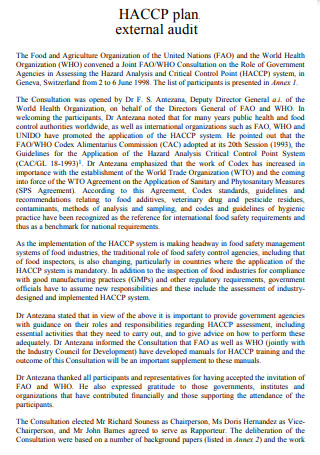

HACCP External Audit Plan

download now -

HACCP Verification Audit Plan

download now -

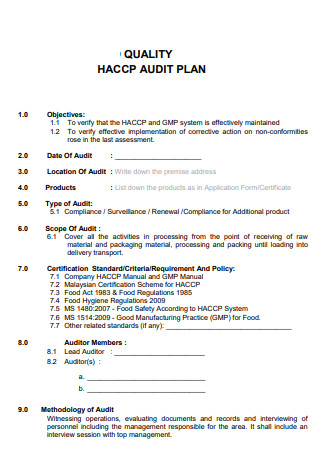

HACCP Quality Audit Plan

download now -

HACCP Audit Management Plan

download now -

HACCP Audit System Plan

download now -

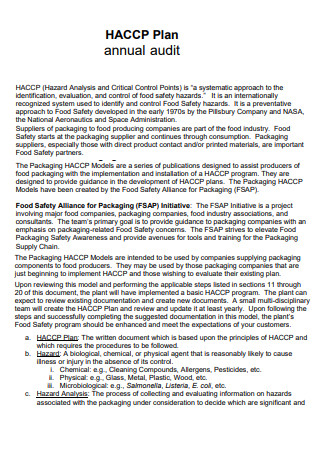

HACCP Annual Audit Plan

download now -

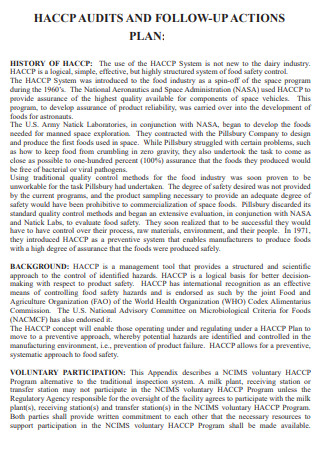

HACCP Audit Actions Plan

download now -

HACCP Audit Preparation Plan

download now -

HACCP Food Audit Plan

download now -

HACCP Safety Control Audit Plan

download now -

HACCP Audit Scoring Plan

download now -

HACCP Supply Audit Plan

download now -

Global HACCP Audit Plan

download now -

HACCP Audit And Training Plan

download now -

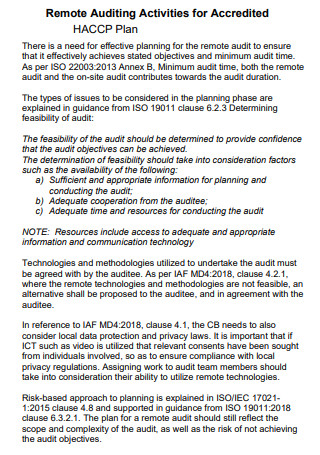

HACCP Remote Audit Plan

download now -

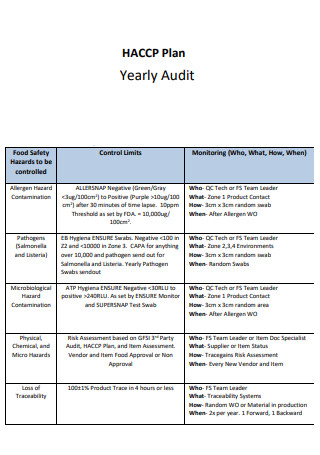

HACCP Yearly Audit Plan

download now -

Sample HACCP Audit Plan

download now -

HACCP Audit Plan Example

download now -

HACCP Audit Design Plan

download now -

HACCP Biosecurity Audit Plan

download now -

General HACCP Audit Plan

download now -

Standard HACCP Audit Plan

download now -

HACCP Audit Plan Template

download now -

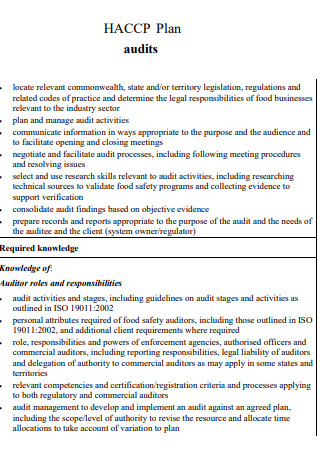

HACCP Internal Auditing Plan

download now

What Is a HACCP Audit Plan?

HACCP is incorporated into a management system to prevent food-borne hazards at all stages of the food chain, including production, manufacturing, storage, and distribution. It is derived from “Failure Mode and Effect Analysis,” an engineering system that asks what could go wrong with the entire system by examining a product’s components and manufacturing phases. Auditing is integral to most organizations because it serves as a system’s check and balance and can be a valuable improvement tool. According to statistics, 69% of manufacturers use HACCP systems, significantly more than the 13% and 15% in retail and catering, respectively.

Benefits of HACCP

Food poisoning is a severe issue; when the responsible business is identified, they are frequently held accountable. This can result in extreme penalties for the cultivator, food processor, or distributor. In addition to reputational harm, businesses may be forced to shut down. Now that we have a better knowledge of what HACCP is and how it protects companies and consumers let’s examine the additional advantages that HACCP can offer you as a business owner.

Principles of the HACCP Plan

HACCP’s objective is clear: it is a systematic approach to identifying, evaluating, and controlling food safety hazards. The system provides food production facilities and restaurants with uniform guidelines to ensure safe food storage and handling practices. To accomplish this, they must stick to the six fundamental principles of HACCP.

1. Conduct a hazard analysis

Create a list of food safety hazards that are a significant enough part of the process that, if not effectively controlled, could cause illness or injury to your consumers. This requires restaurants to create a list of food safety hazards associated with their menu. Include both the ingredients and their origin. This consists of the food’s storage, preparation, cooking, and equipment. It enables the creation, control, management, and tracking of specifications for raw materials, finished products, formulations, and ingredients, all from a single platform. To ensure that your HACCP plan is effective, you must identify all potential food safety hazards. Even if you meticulously adhere to the HACCP plan, overlooking a single potential risk could render it ineffective.

2. Determine the critical control points

Throughout the food preparation process, these are the points or steps where contamination is most likely to occur. While some techniques are included in prerequisite programs (PRPs), critical control points are those where control can be applied to prevent, decrease, or eliminate an acceptable level of food safety risk. Restaurants should be mindful of food safety risks that could result in contamination. Examine the food preparation process for each item on your menu and identify points where food safety is likely to be compromised.

3. Establish monitoring procedures

To ensure that the critical limits are attached, CCPs must be monitored frequently. These repeated and strategic observations/measurements must be documented and validated. For instance, restaurants should have established procedures and protocols for verifying the temperatures of cold-holding units and cooking temperatures for raw meat. This should also apply to test strips to confirm the sanitization chemical mixture. Having a schedule and assigning specific individuals eliminates ambiguity and increases accountability.

4. Establish corrective actions

Once noncompliance or unacceptable hazard has been identified, corrective actions must be developed and documented. Training and instructing your restaurant staff to take corrective action when a problem is discovered is essential to maintaining your food safety system. Disciplinary actions must be specified so that employees know which steps to take and how to carry them out.

5. Create verification processes

These are the activities used to evaluate the effectiveness of the HACCP plan. It is essential for restaurants to establish checklists, verification, and operational procedures for each daypart and shift throughout the week, as well as to test the effectiveness of their HACCP system regularly. Verifying your HACCP system establishes an “Operational and Quality Excellence” culture and reinforces expected behaviors. In addition, having the management team conduct routine self-evaluations aids in measuring overall compliance with regulatory bodies and brand standards.

6. Establish procedures for recordkeeping and documentation

A summary of the initial hazard analysis, the HACCP plan, the assignments, roles, and responsibilities, and the supporting documentation attesting that the procedures were followed. Restaurants must maintain detailed records for audits by state inspectors and third-party auditors and inspections by restaurant field managers. Compliance is demonstrated by maintaining temperature logs, equipment maintenance logs, operational documents, and completed corrective actions. It indicates that critical limits and procedures are in place to prevent food safety hazards and, thus, foodborne illnesses.

How To Complete a HACCP Plan

Developing a HACCP plan requires preparation and the right frame of mind. A HACCP is a written plan that addresses the food safety risks of your business, which requires concentration and knowledge of food safety and related manufacturing processes. Developing your own HACCP plan fosters a sense of ownership and a comprehensive comprehension of your food operations. In the event of problems, you can resolve unexplained system failures if you thoroughly understand your plan. While creating a HACCP plan from scratch can be time-consuming, some companies seek advice from independent experts, such as food safety consultants from regulatory agencies in the food industry. Before delving into the specifics of making a HACCP plan, there are a few fundamental preparation steps you must take to guarantee the success of your HACCP food safety system.

1. Examine your prerequisite courses.

The first step in making a HACCP plan is ensuring you have the needed programs. These programs are a crucial part of your HACCP initial plan and ensure that the basics of food processing are in place. They talk about the minimum quality standards for your sanitation design, food safety and hygiene practices in general, employee health, the right working conditions, and the proper training for your employees. By making sure that your food business follows basic rules and stays clean, you can make sure that low-risk health hazards are kept to an acceptable level. It also ensures that the food safety approach is built on a solid base.

2. Build your HACCP team

The individuals responsible for creating the HACCP plan are the company’s key personnel from each department. It is not the sole duty of a food business manager to develop a HACCP plan. Before you can execute a project, you must assemble your HACCP team. Your team must consist of individuals familiar with HACCP planning or its fundamental principles. Your HACCP plan-creating team members must come from various parts of your food production process to provide expert guidance in their respective fields. A group consisting solely of quality control personnel or a manager of a food manufacturing plant may lack the technical knowledge required for operating equipment. Also, a team consisting exclusively of food engineers may lack quality control expertise. There may be representatives from the quality assurance, engineering, manufacturing, logistics, and management departments on the team responsible for establishing your HACCP system. Each representative must have extensive knowledge of the business’s operations. They will be responsible for bringing up safety and quality concerns regarding the HACCP system as they pertain to their respective departments and contributing to their resolution.

3. Identify basic information about your organization

A HACCP plan is an organization-specific food safety management system. It establishes rules, standards, and controls for producing safe food products. Consequently, it is essential to identify the nature of your business, products, and processes, which will serve as the foundation for your HACCP system. By describing the product you are analyzing, you give your team an idea of the potential risks involved. This process entails providing a comprehensive product description, including its ingredients, allergen information, specifications, processing methods, storage method, physical dimensions, and visual appearance, among other specifics. Your product description will be more valuable if it contains specific details. Information such as parameters of the raw materials and the titratable acidity level, moisture level, water activity, salt concentration, formulation control, and chemical composition of the finished product will contribute to hazard identification and analysis. This information may also have specifications from suppliers, such as a microbiological pathogen load minimum.

4. Verify all preparatory steps

Traditionally, this step of the commodity flow chart requires on-site monitoring and verification. We recommend applying all comprehensive verification activities to the aforementioned preparatory measures. These verification steps are essential for preparing your entire food business to create a HACCP plan conventionally. Check the preparation plan for any missed areas during any verification activity.

FAQs

What is the HACCP flow chart?

A HACCP flowchart is a graphical representation of your company’s entire manufacturing process. A HACCP flowchart depicts the movement of food materials in your food business, from receiving raw materials to distributing finished products.

What is project Flow?

The project flow is the predetermined order of activities required to plan, produce, deliver, and maintain the project’s product and the information, materials, and resources needed. Project flow is a practical method for defining and organizing projects.

What is an audit checklist?

Auditors use an internal audit checklist to test a company’s financial, operational, or information technology (IT) systems, applications, procedures, and security.

As a participant in the food chain, it is your responsibility to eliminate safety risks from your processing plan. Developing and implementing a HACCP plan can assist you in not only achieving your safety objectives, expanding into new markets, and potentially increasing your profitability. It also ensures compliance with local, state, and national food safety regulations, which increasingly recommend HACCP programs to food businesses worldwide.