9+ Sample Validation Plans

-

Validation Project Plan

download now -

Validation Master Plan

download now -

Calibration and Validation Plan

download now -

Software Validation Plan

download now -

Validation Program Plan

download now -

Micro-plan for Validation

download now -

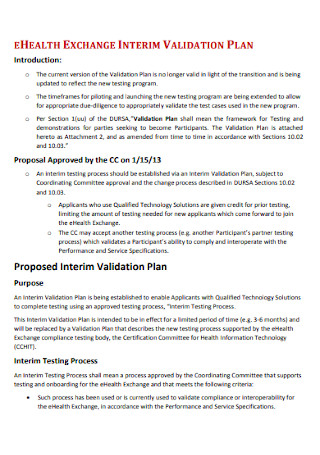

Health Exchange Interim Validation Plan

download now -

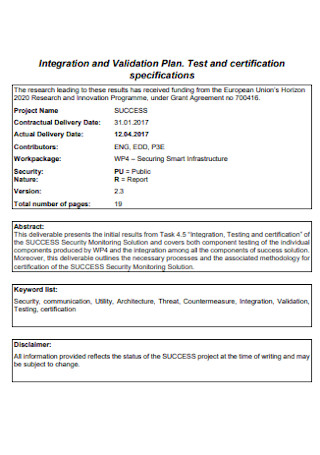

Integration and Validation Plan

download now -

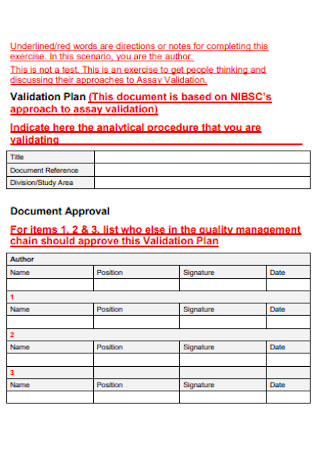

Simple Validation Plan

download now -

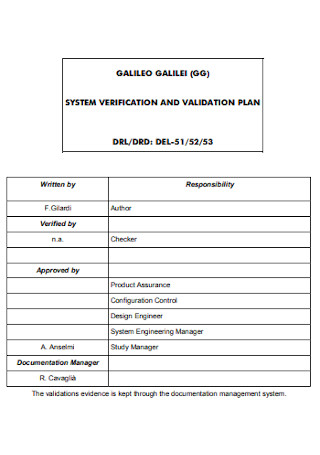

System Verification and Validation Plan

download now

FREE Validation Plan s to Download

9+ Sample Validation Plans

What Is a Validation Plan?

Elements Of a Validation Plan

Factors Contributing To a Validation Project Failure

Step by Step Process In Writing an Effective Validation Plan

FAQs

What is the difference between verification and validation?

What is the difference between a Validation Plan and a Validation Master Plan?

What are deliverables?

What Is a Validation Plan?

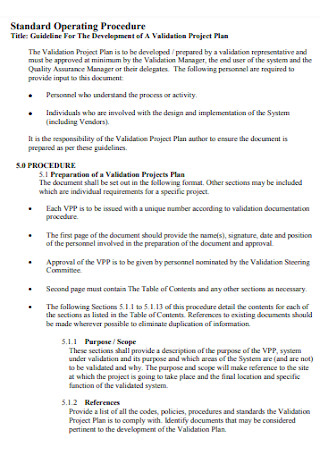

A Validation Plan is defined as a management document that describes a project’s approach. The plan typically describes the work to be done, the resources needed, the methods to be used, the configuration management and quality assurance procedures to be followed, the schedules to be met, the project organization, and so on. It serves as a central part of the Process Qualification documentation. These plans also define the scope and goals of a validation project. A validation plan is usually written at the beginning of the project and is usually specific to a single validation project.

It is important to note that a validation plan is significantly different from a validation master plan. Although they sound and seem so similar in wording, validation master plans govern the validation activities of an entire site or organization while a validation plan only focuses on a single project.

Elements Of a Validation Plan

Here are some of the elements that should be included whenever you’re writing a validation plan:

Factors Contributing To a Validation Project Failure

The failure of a validation project can be traced to the following factors:

- Unclear project objectives – The project sponsor must clearly define the validation project objectives. At the start of the project, the project manager should create a clear and concise Project Execution Plan (PEP) and train each project team member on the PEP. A clear, unambiguous, and concise set of system requirements and user requirements developed at the start of the project by the appropriate stakeholders is also essential to the success of the project. The validation lead is responsible for creating a solid Validation Project Plan (VPP), which should outline the scope of validation activities, the testing approach, the testing team and their responsibilities, and the acceptance criteria. Failure to plan in the aforementioned areas lays the groundwork for a validation project’s failure.

- Stakeholders are inconsistently engaged – Successful projects are the result of the ongoing involvement of a group of stakeholders that includes the project sponsor, business unit executives, quality personnel, members of the IT, QC laboratory, and engineering groups, among others. It ensures continuous adjustment and alignment in response to changing situations such as scope changes, human errors, and so on. A well-defined set of goals and objectives that are reviewed throughout the project’s duration is a recommended best practice.

- Absence of a proactive risk management – This is the most frequently overlooked aspect of project management. Teams fail to proactively identify, analyze, and mitigate project risk to scope, schedule, and budget during project setup and team formation. Doing so upfront will prevent project risks from being addressed reactively, giving management the impression that the project team has lost control of the project. It is prudent to create and distribute a Project Risk Management Plan, as well as to educate the entire project team on the risks.

- Poor training or lack of training of team members – A validation project is a business-centric activity in which business processes comprised of a series of activities are used to produce an outcome, such as a validated system. Because of this, it is critical to train people on the principles and methods of validation, as well as the associated regulations that validation must satisfy. A project onboarding training program for new project members joining the team during the course of the project should also be established. Many of these risks due to human factors can be eliminated by using paperless validation, also known as validation automation in the industry.

- Lack of project status in real-time – Executives frequently complain about not having real-time visibility into the current status of all projects. Unfortunately, they are made aware of critical issues only when the implications for costs, timeliness, and scope are significant or irreversible. Because they are the last line of defense against project failure, it is critical that they are given this visibility in real-time in a concise and clear format, such as a dashboard.

- Communication gaps – Regular standing meetings of project team members, timely release of meeting minutes so that issues identified are satisfactorily addressed and reported out during the next meeting, ensuring regular attendance of all stakeholders at these meetings, and publishing a RACI (Responsibility, Accountability, Consult, Inform) chart are also methods for achieving real-time visibility into project status. These methods can be used to bridge the gaps of communication between the team members of a validation project.

Step by Step Process In Writing an Effective Validation Plan

Since the validation plan is considered by professionals to be a comprehensive evaluation of the validation process it needs to be written effectively. With that being said, here are the steps needed to make one:

-

1. Start With the Introduction

The introduction in a validation plan is an overview of the process, product, or equipment validation that should be consistent with the validation request. It will detail the steps necessary to complete the validation. Conformance to regulations and internal policy; the impact of a change on maintaining the validated state; any impact on regulatory submission; the impact of the change on procedures, drawings, and other documents; and notifications to internal and external groups impacted by the validation are all the steps or requirements necessary to complete the validation.

-

2. Write the Technical Information

A description of the product, process, or equipment, as well as any relevant formulae and specifications, will be included in the Technical Information. Any technical aspects of the validation or qualification, as well as any references to technical reports from the previous stage of process validation, must also be included in this section. The total validation approach should be included as well. This is based on what is known from experimental studies and previous data. This section will also include anything that will strengthen one’s validation process. Also, this section should include the total number of lots to be sampled as well as the associated risk to be described.

-

3. State the Testing and Validation Strategies

The general types of testing that will be performed, such as regulatory specifications, internal controls, and process tests, will be included in the validation strategy and testing and should be clearly stated in this step. The rationale for the test, as well as the sampling, will be described, and all of this should be based on a risk assessment. This step should include a description of how the data will be statistically treated with confidence limits, as well as a general overview of the acceptance criteria. It is critical to remember that the specifics of the topics covered in this section will be covered in the validation protocols. Remember that the validation plan is high-level and provides a bird’s-eye view of the process validation.

-

4. Include Any Validation Documentation

The plan should include a list of required documents for the entire validation. Identifying and assigning a number to each document required for validation will ensure that no protocols are overlooked. This section will provide administrative assistance in understanding what needs to be done to complete the validation and ensuring that those in charge do so. This section will primarily assist validation practitioners in organizing and determining the steps in a validation process that must be identified and documented.

-

5. Cite Any References

The reference section will contain a list of all documents that support validation. This is the link between the previous and current stages of the lifecycle approach to process validation. R&D technical reports, formulation and process development reports, and technology transfer or scale-up reports are some examples of documents included in the references.

-

6. Finalize and Proofread

When the writing of the validation plan is completed, take the time to carefully analyze it and proofread it. Any mistakes or shortcomings found must be corrected and remedied because any kind of mistakes in the validation plan can derail the entire validation process resulting in its complete failure. When everything is done, take the time to finalize the document and make it look professionally written.

FAQs

What is the difference between verification and validation?

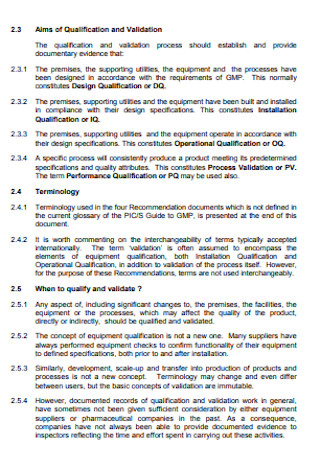

Verification is the process of checking whether the product is built according to the specifications that are given and meet all the quality requirements. If the product meets the requirements, it does not matter if it meets the needs of the customer. It is an internal process and is done by the quality control department. Validation, on the other hand, is the process of checking whether the product built is acceptable to the customers or not. It is an external process and the customer or customers will be the party doing the checks before the product is accepted by them. As implied, the suitability to customer needs is important in this step. The only way these two terms are similar is that they are both processes that involve checking all deliverables.

What is the difference between a Validation Plan and a Validation Master Plan?

Validation Plans specify the scope and objectives of a validation project. The Validation Plan is typically written at the beginning of the validation project (sometimes concurrently with the user requirement specification) and is unique to a single validation project. Validation Master Plans, on the other hand, discuss validation activities across an entire site or within an organization. The validation strategy is summarized in the Validation Master Plan. The Validation Master Plan’s purpose is to document the site’s compliance requirements and to ensure that adequate resources are available for validation projects.

What are deliverables?

The term “deliverables” is a project management term that traditionally refers to the quantifiable goods or services that must be provided upon project completion. Deliverables can be both tangible and intangible. For example, in a project aimed at improving a company’s technology, a deliverable could be the purchase of a dozen new computers. A deliverable in a software project, on the other hand, could refer to the implementation of a computer program aimed at improving a company’s accounts receivable computational efficiency.

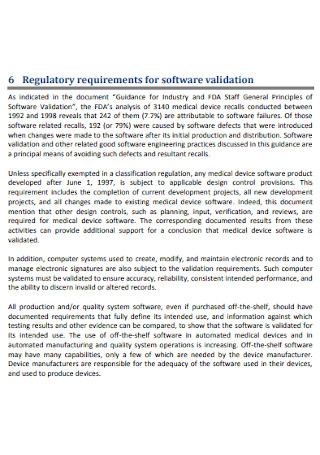

The process of validation plays a great role in quality assurance and cost reduction of the product being made. It also ensures that the product being produced is fit for its intended use. It also serves as a key element of assuming the quality of the product. Therefore, having a validation plan in hand is essential for the entire validation project since it outlines what should be done (the goals and the entire scope) and keeps the project from going all over the place. In this article, examples of ready-made validation plans are available for you to download and use as a reference.