8+ Sample HACCP Development Plan

-

HACCP Development Plan and Implementation

download now -

HACCP Development Retail Plan

download now -

HACCP Development Plan Form

download now -

HACCP Development Plan Example

download now -

HACCP Development Planning in PDF

download now -

Printable HACCP Development Plan

download now -

HACCP Development Plan in PDF

download now -

Simple HACCP Development Plan

download now -

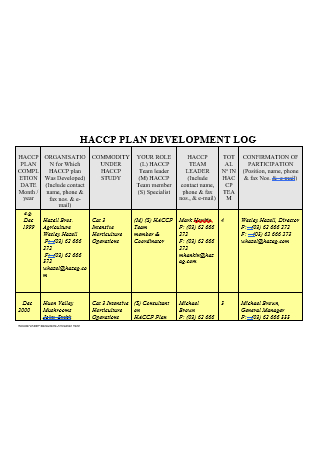

HACCP Development Log Plan

download now

FREE HACCP Development Plan s to Download

8+ Sample HACCP Development Plan

What is a HACCP Development Plan?

Types of Hazards and Control Methods

Benefits of a HACCP Development Plan

How to Write a HACCP Development Plan

FAQs

What are the essential steps to write for the HACCP development plan?

What are the primary stages of HACCP development?

What is a HACCP process flow chart?

What are some examples of HACCP development plans?

Why is it essential to develop a HACCP development plan?

What is a HACCP Development Plan?

A HACCP development plan is a detailed and well-structured action documentation plan and output of the HACCP study that contains major goals, initiatives, activities, processes, and tasks to support the HACCP or Hazard Analysis and Critical Control Point system. The HACCP team manager and staff use this document so that they are able to identify possible hazards and minimize risks in food safety management. It outlines a practical and preventive approach to ensuring a high level of food safety through hazard analysis, critical control points (CCP), CCP monitoring system, corrective actions, and documentation of all HACCP procedures and records based on the principles.

One of the drivers for competitive advantage in food safety is keeping up with the latest food trends. According to a 2022 food safety trend report, food deliveries, healthier options, and plant-based foods are the top food trends currently dominating the food industry. Food deliveries in the US reached around $18.5 billion in 2020. During the COVID-19 pandemic, most consumers prefer to eat healthier food products like keto versions of everyday food products and plant-based meats. The Information Resources, Inc revealed in a report that products with nutritional claims increased in sales by 10%. Thus, all team leaders and members of HACCP teams including food safety specialists should effectively create a compelling and effective HACCP development plan.

Types of Hazards and Control Methods

The team leader and members of a HACCP team need to have proper knowledge and understanding of the types of hazards that could happen, as well as preventive control methods. That’s why each one of them must have both academic backgrounds in microbiology or food-science-related subjects and professional food industry experience. Consider the different types of hazards and control methods when constructing a HACCP development and project assessment plan.

1. Biological Hazards

The major biological health hazards or biohazards are bacteria, fungi, parasites, molds, spores, bioactive substances, pathogenic microorganisms, and toxins from biological sources. These are disease-producing agents that can be transmitted to people through different modes of transmission. For example, hepatitis B virus, hepatitis C virus, and human immunodeficiency virus (HIV) can be acquired from blood and body fluids, while SARS-CoV-2, influenza virus, and measles can be transferred in more than one mode like contact, droplet spray, or small particle aerosol. Some control methods commonly used for biological hazards are proper ventilation, microbiological safety cabinets, pest prevention/extermination, requiring safety equipment to be used and worn, and proper storage, transport, and disposal of biologically hazardous materials.

2. Chemical Hazards

There are many hazardous chemical products that can harm and threaten human health when being ingested, inhaled, or absorbed through the skin such as cleaning chemicals, chlorine, ammonia, disinfectants, gas cylinders, glues, lead, asphyxiants, irritants, sensitizers, and paint. All employers with hazardous chemicals in their businesses and chemical manufacturers need to be informed about the specific identities and hazards of the chemicals to convey the hazard information to customers and protect everyone. To control chemical hazards and toxic substances, safety team managers and members need to use a hazard assessment checklist and follow these control methods: elimination/substitution, engineering controls, administrative and work practice controls, and personal safety equipment.

3. Food Allergens

The Food Allergy & Anaphylaxis Network (FAAN) reported that around 200 people die from anaphylaxis due to food allergies each year in the United States. Food allergens can significantly affect the health of individuals allergic to certain foods like milk, peanuts, tree nuts, fish, shellfish, eggs, soy, and wheat. These food allergens cause about 90% of food-allergenic reactions in the U.S. Businesses and organizations in the food industry need to set up proper HACCP food safety plans and allergen control programs to manage allergens in their facilities. Some control methods used by businesses are transporting and storing allergens in safe locations to prevent cross-contact and making sure that allergenic ingredients are controlled to prevent accidental usage.

4. Physical Hazards

These hazards can be classified as environmental hazards or occupational hazards as they include ergonomic hazards, heat and cold stress, radiation, noise hazards, and vibration hazards. Glass containers, blades, metal utensils, plastic fragments, stones, wood structures, wooden pallets, and sharp food parts like shells in nut products are some of the common sources of physical food hazards. To prevent and control physical hazards, the HACCP team should provide safety equipment to employees, reduce houses and vibrations, provide proper ventilation and air conditioning, and ensure that workers spend less time in areas of exposure.

Benefits of a HACCP Development Plan

Establishing clear and effective HACCP-based procedures and HACCP projects provide business firms and organizations with a cost-efficient system for facilitating food safety control. So, HACCP procedures and plans also integrate with other quality management systems and quality development plans. What are the main benefits of writing a HACCP development plan?

How to Write a HACCP Development Plan

Preparing a clear and effective HACCP development plan and a HACCP management plan is fundamental to increasing food safety standards and food quality standards. It helps business firms and facilities to streamline their food production processes to make safe and high-quality food and organize their staff to promote efficiency and teamwork. Try your best in writing an impeccable HACCP development plan.

Step 1: Create an Overview of the Product

Write a comprehensive overview of the product while writing a full description of the product and specifying the purpose or intended use of the product. Include some information related to safety such as composition, physical/chemical properties of the raw materials, and the final product and how the product is to be packaged, stored, and transported. Then, explain how the product is intended to be used and whether it will be consumed directly, or be cooked, or processed.

Step 2: Draw and Confirm a Process Flow Chart

The HACCP team must draw a detailed process flow chart or process map of the commodity system. Each food business has its own commodity system and even within one country may have a variety of commodity systems. After completing the process flow chart, the HACCP team members need to visit the commodity system to make comparisons demonstrated on the process flow chart with what really takes place in practice. Include in the process flow chart details such as harvest time, drying procedures, storage conditions, and grading systems.

Step 3: Examine the Hazards and Determine the Critical Control Points

The next step is to identify and examine the potential hazards that may happen in each ingredient and each phase of the commodity system must be considered. The major types of hazards are biological, chemical, physical, and food allergens. Conduct a hazard analysis to understand the health risk posed by the hazard. Then, use a decision tree to determine critical control points.

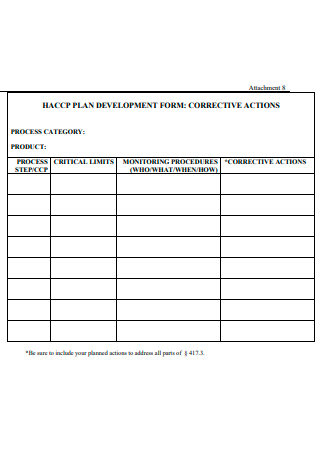

Step 4: Set Critical Limits, Monitoring Procedures, and Corrective Actions

Specify and validate the critical limits for each critical control point. Include measurements of time, temperature, moisture level, pH, water activity, and sensory parameters. Select appropriate monitoring procedures to confirm that critical limits at each CCP are being reached. If the monitoring shows that critical limits failed, you need to present corrective actions that must be taken right away based on the hazard assessment, risk and severity, and final product usage.

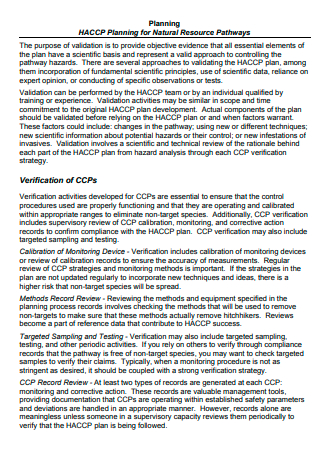

Step 5: Verify the HACCP System

The HACCP system can be verified by collecting samples for analysis using a method different from the current monitoring procedure, asking questions of staff, observing operations at critical control points, and formal auditing. Determine the appropriateness of the CCPs and preventive control measures, as well as the effectiveness of monitoring.

Step 6: Proofread and Prepare the Final HACCP Development Plan

Review your overall HACCP development plan and make sure that you fully demonstrate all the correct procedures and major points in your document. Skim it as you quickly scan the content of your HACCP plan to analyze if you overlook important areas or if there exist some grammatical or typographical errors in your document. If you see some errors, proofread, edit, and revise the plan immediately.

FAQs

The essential steps to write for the HACCP development plan are assembling the HACCP team, making a complete listing of all the products and processes to be covered, reviewing and listing all of the ingredients, recipes/ formulations, materials, and equipment used, and creating a document to develop and verify a process flow chart.

The primary stages of HACCP development are performing a hazardous analysis and supplier quality analysis, determining critical control points, setting critical limits, developing monitoring procedures, enacting corrective actions, creating verification procedures, and establishing record-keeping and documentation procedures such as time logs, checklists, forms, flowcharts, and employee training records.

A HACCP process flow chart is a comprehensive diagram or visual representation of a business’s overall manufacturing process. It demonstrates the flow of food materials in the food business which includes any raw materials and completed products.

Some examples of HACCP development plans are the HACCP development plan and assessment implementation plan, HACCP development retail plan, printable HACCP development plan, manufacturing HACCP development plan, and food safety HACCP development plan.

A HACCP development plan is essential to develop because it helps business firms and organizations to establish a cost-effective system for food safety and preventive control that covers ingredients, products, and recipes, as well as production, storage, and distribution. It can help managers and staff to take control of the food safety risks in the business and protect customers. Plus, it is a vital tool in maintaining a clean record to strengthen the public image of the company or organization.

What are the essential steps to write for the HACCP development plan?

What are the primary stages of HACCP development?

What is a HACCP process flow chart?

What are some examples of HACCP development plans?

Why is it essential to develop a HACCP development plan?

Writing a well-integrated HACCP development while using a food safety inspection checklist is important to assess possible hazards and critical control points and design effective preventive controls that will be implemented to prevent problems. Throughout the food supply chain coming from primary production to the consumer, HACCP principles and steps are applied to prevent waste and incident costs and to demonstrate due diligence where required. Thus, we offer a unique selection of sample HACCP development plan templates, HACCP development retail business plan templates, and other HACCP development plan templates that you can download and use for your food safety management work.