24+ Sample Quality Control Plans

-

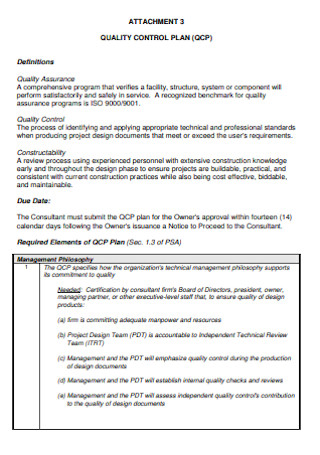

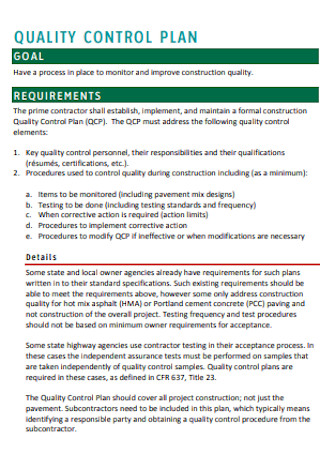

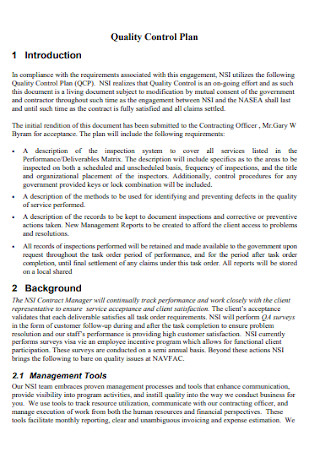

Sample Quality Control Plan

download now -

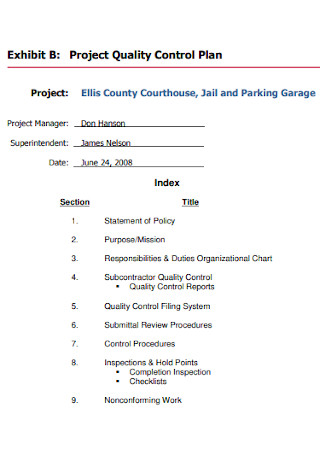

Project Quality Control Plan

download now -

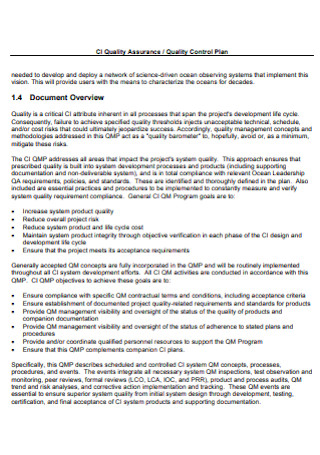

Quality Assurance and Control Plan

download now -

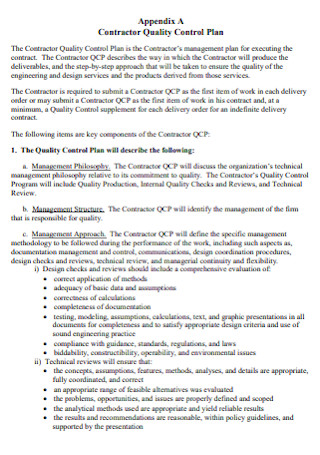

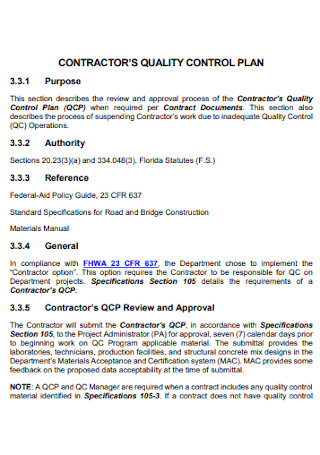

Contractor Quality Control Plan

download now -

Production Quality Control Plan

download now -

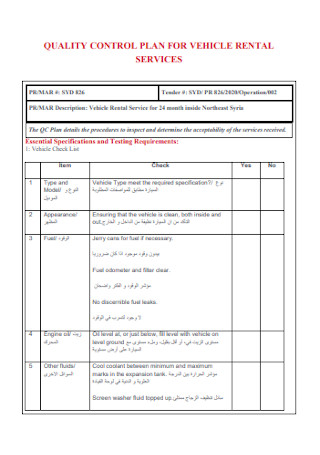

Quality Control Plan for Vehicle Rental

download now -

Quality Control Plans for Highway Bridges

download now -

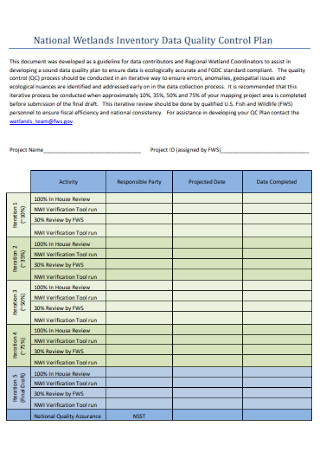

Inventory Data Quality Control Plan

download now -

Highway Safety and Quality Control Plan

download now -

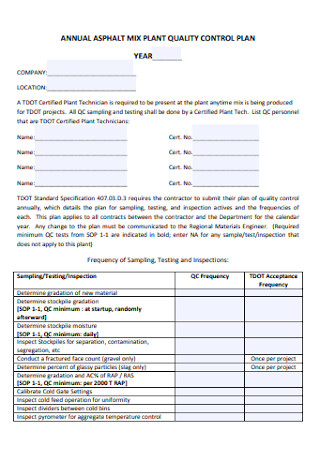

Plant Quality Control Plan

download now -

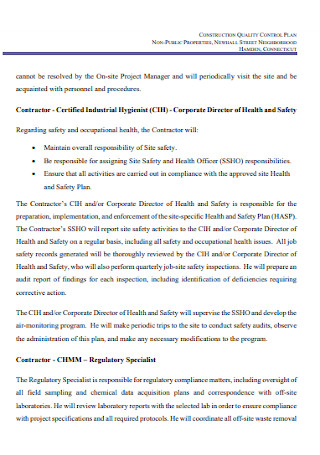

Construction Quality Control Plan Template

download now -

Simple Quality Control Plan

download now -

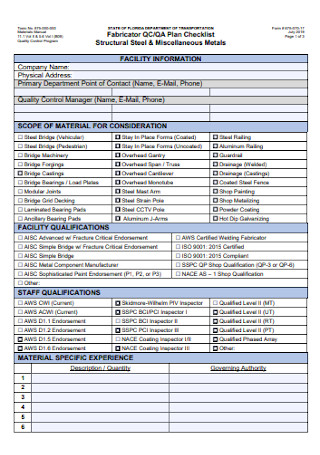

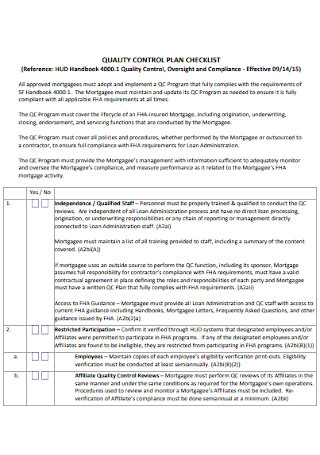

Quality Control Plan Checklist

download now -

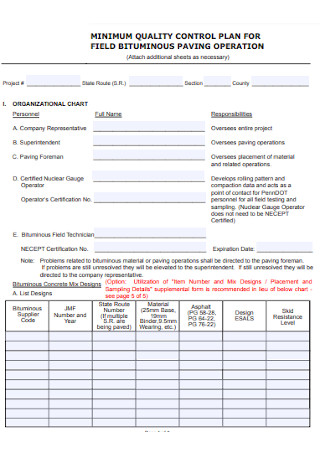

Minimum Quality Control Plan

download now -

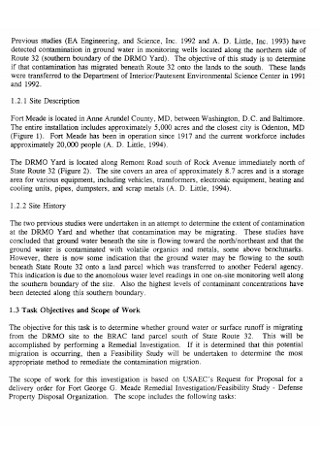

Final Quality Control Plan

download now -

Contractor Quality Control Plan

download now -

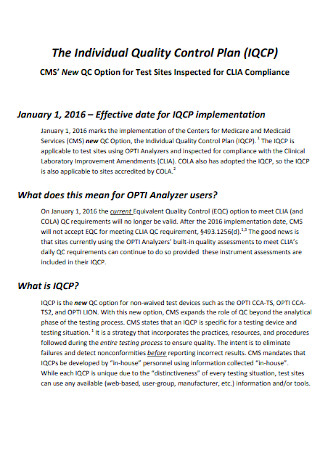

Individual Quality Control Plan

download now -

Individualized Quality Control Plan

download now -

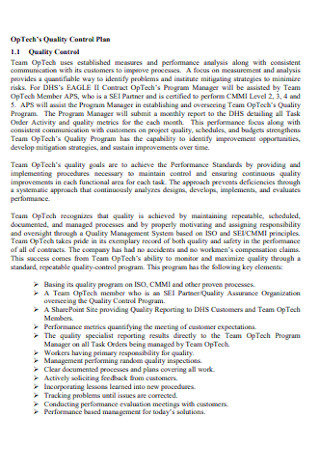

Technology Quality Control Plan

download now -

Quality Control Plan Checklist Format

download now -

Survey and Quality Control Plan

download now -

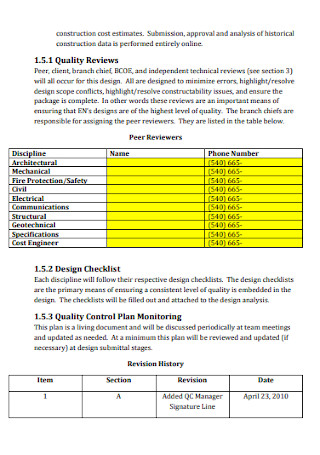

Design Quality Control Plan

download now -

Simple Quality Control Plan

download now -

Sample Quality Control Plan

download now -

Individualzed Quality Control Plan

download now

FREE Quality Control Plan s to Download

24+ Sample Quality Control Plans

What Is a Quality Control Plan?

Why Should You Prepare a Quality Control Plan?

The Elements of a Quality Control Plan

The Two Main Types of Quality Control Plans

How to Build an Excellent Quality Control Plan

FAQs

What are activities worth adding to a quality audit checklist?

What are highly recommended quality control tools?

What are the other types of quality control?

What Is a Quality Control Plan?

A quality control plan refers to the entire strategic plan that your company observes to ensure the stellar quality of the products, services, or business in general. This essential document contains everything you need to know about how to meet the quality standards of a project, service, product, or any other subject until operations go according to plan. Thanks to the QCP, a company can retain excellent quality goods and services to satisfy clients and eventually boost sales.

Why Should You Prepare a Quality Control Plan?

Quality control plans are a systematic framework that will help any organization strive to produce top-quality goods, services, and outcomes no matter what. In case you doubt the importance of a quality control plan, here are the most striking reasons to remind you that preparing a QCP is worth it for your business:

Poor Quality Identification

Expect your quality control plan’s purpose statement to look for potential sources of dismal quality in any aspect. With the QCP, you would know how to prepare for possible elements that would cause poor quality on a product or service as well as where to look for those potential quality control issues. Then, it would be easier for you and your company to recognize these issues before they actually get worse.

Prevention Tips and Improvement Plans

A quality control plan is not all about identifying potential issues alone because the main point is to figure out ways how to prevent and solve such quality control problems. The QCP eventually leads you to come up with a quality improvement plan so that outcomes of impressive quality can be maintained at work.

A Detailed List of Criteria and Tools

The sheet used as your quality control plan is not just for display, especially when it houses a bunch of critical details about your business and how to keep up with the quality requirements. The checkpoints or criteria used to assess quality during or after an inspection will be stated in the QCP. Also, the quality control plan opts to suggest a number of quality control tools such as a quality control checklist, quality assurance to-do list, quality management schedule, and more.

A Must-Have for Any Type of Industry

Something you can’t ignore about quality control plans is that they are a must for any type of business. Whether you run a restaurant, manufacturing warehouse, steel fabrication service, internal design company, mechanical engineering business, mortgage subcontractor service, software development program, automotive inspection company, electrical construction enterprise, or even a janitorial service, a QCP aims to ensure you deliver top-notch quality products and services. Just make sure your QCP is tailored according to your industry’s needs.

A Plan for a Better Future

Always keep in mind that quality control plans think about the future of your company. In fact, creating the QCP is done first before even considering production and inspection reports. A quality control plan is reusable for regular quality inspections while, at the same time, you can develop it anytime to optimize quality management and hope for a better outcome.

The Elements of a Quality Control Plan

Although quality control plans differ in purpose, layout, and content, there is no denying that you can still identify common denominators from each QCP. These are the standard elements that make up a proper quality control plan:

The Two Main Types of Quality Control Plans

Before even considering constructing your own quality control plan, it helps to determine what type of quality control plan you should observe. These are the two basic types of QCPs you should know:

Product Quality Control Plan

From the name itself, product quality control plans concern the manufacturing of a product or item. For example, you conduct a quality inspection of a newly released product to check if it goes in line with the manufacturing and supply agreement. Whether products have incorrect colors, misprinted labels, and other manufacturing defects, the product QCP should aim to prevent such matters.

Process Control Plan

When the issue comes from the production process or any step of a project measured for quality, it should fall under the process control plan. Also referred to as a production control plan or simply a control plan, this type of QCP reassures that quality standards still apply to the production or any essential process in your organization. This example is how you manage the different processes of a project and ensure they go according to quality requirements rather than focusing on a product’s quality.

How to Build an Excellent Quality Control Plan

A quality control plan is very detailed and its content would either make or break your organization. Now for the real deal, these are the ultimate steps you need to formulate a quality control plan effectively and efficiently:

Step 1: Get to Know Your Industry and Its System

First of all, how well do you know your business project or organization? Study your industry including how the system works before deciding to create a quality control plan. By familiarizing everything you need to know about your business, you can eventually figure out which aspects must be evaluated in terms of quality. The key is to refer to your original quality control agreement so that the QCP goes in line with the agreement.

Step 2: Use a Premade Quality Control Plan Sample

Check out the full collection of sample quality control plan templates on this site and click on any template you want to edit. Customize the QCP sample so you can only fill out the details, change the format, alter the design, or insert your content rather than making a QCP right from the very beginning, which would have been very time-consuming. Then, the process runs along smoothly because each template is a guide on how you can come up with a professional-looking QCP.

Step 3: Complete the Elements of a QCP

Denote the essential elements of the quality control plan in your template such as the project overview’s introductory statement, background, scope, etc. Then, complete the rest of the elements such as organizational structure, work verification, and down to the quality development plan. You can even add other parts to the QCP that you think are relevant to your purpose, so insert them one by one.

Step 4: Produce a Straightforward and Easy-to-Read Plan

As much as possible, organize the details inside your quality control plan. During the part where you insert a bunch of elements in the QCP, changes are the data could become too much that things are harder to read and understand. Just like any business plan, the key is to write professionally, meaning you write in a way that is easy to understand, straightforward, yet informative enough. Poorly written QCPs would not help you that much during actual quality inspections.

Step 5: Set a Regular Quality Inspection Formally

Most importantly, set the quality inspection schedule. Don’t simply make the quality control plan and lock it on a shelf after using it one time. Quality inspections should be done regularly since quality management should never be overlooked in business. You may decide whether to set a daily schedule, weekly schedule, quarterly schedule, or annual schedule for the quality inspection. Go for the schedule that works best in operations so that quality is assured no matter what.

FAQs

What are activities worth adding to a quality audit checklist?

Your quality audit checklist could use some process checklists, peer reviews, product or service inspections, software testing, and overall documentation.

What are highly recommended quality control tools?

The following quality control tools can certainly help you during quality inspections: quality control checklists, organizational charts, flow charts, scatter diagrams, quality assurance schedules, stratification, and fishbone diagrams.

What are the other types of quality control?

Besides the two main types of QCP which are product quality control and process control, other types you can incorporate are control charts and acceptance sampling.

Indeed, outlining a robust quality control plan assures any organization of implementing high-quality products, services, performances, and processes; however, the QCP is not a one-document-fits-all type of situation. You have to come up with your own criteria and tailor the plan according to the quality needs of your business. Thankfully, you can produce the QCP in the best layout possible and insert your unique set of data using sample quality control plan templates.