9+ SAMPLE Manufacturing Corrective Action Plan

-

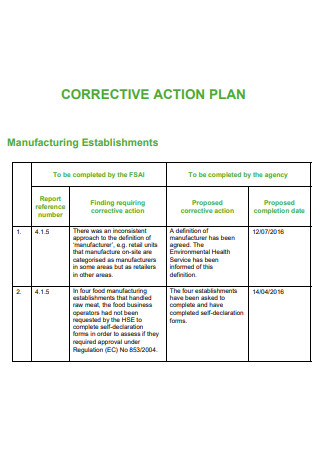

Manufacturing Health Corrective Action Plan

download now -

Manufacturing Development Corrective Action Plan

download now -

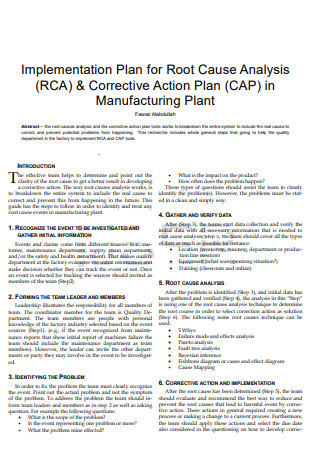

Manufacturing Plant Corrective Action Plan

download now -

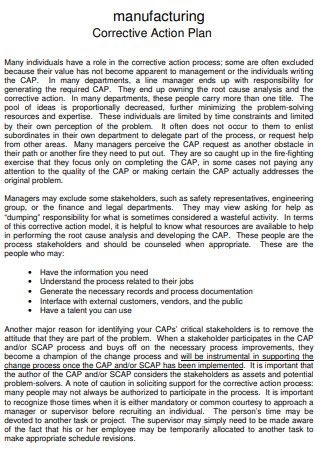

Manufacturing Corrective Action Plan

download now -

Manufacturing Management Corrective Action Plan

download now -

Sample Manufacturing Corrective Action Plan

download now -

Manufacturing Corrective Preventive Action Plan

download now -

Manufacturing Interim Corrective Action Plan

download now -

Standard Manufacturing Corrective Action Plan

download now -

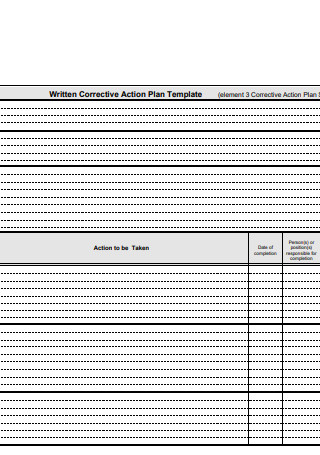

Basic Manufacturing Corrective Action Plan

download now

FREE Manufacturing Corrective Action Plan s to Download

9+ SAMPLE Manufacturing Corrective Action Plan

What Is a Manufacturing Corrective Action Plan?

What Makes Up an Effective Manufacturing Corrective Action Plan?

What are the Different Types of Product Defects?

Steps in Creating a Manufacturing Corrective Action Plan

FAQs

What is the difference between a correction and a corrective action?

What is lean manufacturing all about?

What is a corrective action request?

What Is a Manufacturing Corrective Action Plan?

First of all, what is manufacturing all about? By definition, it refers to the act or process of transforming different types of raw materials into usable finished products through the use of different methods, such as tools (manual or powered), human labor, machinery (simple or complex), and chemical processes. This can be beneficial to companies since it allows them to sell the finished products at a higher cost compared to the raw materials. More importantly, manufacturing procedures that are efficient allow producers to take advantage of economies of scale, generating more units at a cheaper cost. However, as advanced as it may seem due to the continuous evolution of technology, manufacturing is still susceptible to various imperfections or inconsistencies.

A manufacturing corrective action plan is a document that specifies the duties and procedures for recognizing nonconformities, performing corrective actions, and following up to confirm that the corrective actions performed were effective and successful in preventing the cause of the nonconformance. In layman’s words, this is used to discover and correct systemic flaws so that they do not reoccur. Corrective action plans are used by businesses, particularly those involved in manufacturing when a discovered problem has the potential to significantly impact the company’s quality management system. When effectively executed, these strategies can aid in the improvement of manufacturing operations and the resolution of work-related challenges.

What Makes Up an Effective Manufacturing Corrective Action Plan?

Corrective action plans provide the companies with an opportunity to create a process for implementing corrective actions that begin with research and end with a thorough review. And for the manufacturing corrective action plan to be effective, it needs to have the following elements in place:

What are the Different Types of Product Defects?

For every perfect and up-to-standard product that made the store shelf, there are the ones that didn’t make it through the quality control process, and there are also some that may have sneakily made it through the shelf. With that being said, here are the different types of product defects:

Steps in Creating a Manufacturing Corrective Action Plan

Now that the elements that make up an effective corrective action plan have been identified, here are the following steps that you need to take in order to make an effective manufacturing corrective action plan:

1. Identifying the Issue

This is the first step that needs to be performed when creating the corrective action plan. An issue is detected when someone finds a nonconformance or fault in a product or during the manufacturing process. Complaints are filed through internal or external methods such as a consumer complaint helpline, the management evaluation process, a staff suggestion box, or an audit. Explaining what is involved, what has really happened compared to what was intended to happen, where the event was witnessed, and where the event occurred are all important things to accomplish when diagnosing the problem.

2. Evaluating the Severity

Once the issue has been properly identified, it’s time to determine how severe it actually is in this step. The major goal of this stage is to determine whether the problem requires a corrective action plan to be resolved or whether a moderate method is adequate. This phase is critical since both over-and under-escalating situations are considered to be unproductive. Treating every problem as worthy of a corrective action plan will overwhelm you and leave you under-resourced, whereas elevating zero issues risks written warnings, penalties, and serious harm to workers or consumers. This choice is better managed by assessing the issue’s severity, damage, and complexity. If the occurrence was low-risk, try a different approach to rectifying it. If the situation is high-risk, a corrective action plan may be required.

3. Analyzing the Root Cause of the Issue

After evaluating the severity of the issue and determining it to be worthy of a manufacturing corrective action plan, proceed to this step. The source of the detected issues or dangers is the root cause, and it is critical knowledge in the effort to avoid their recurrence or reoccurrence. Determining underlying reasons can be difficult for a range of factors, including the possibility of several probable causes, and it’s difficult to be confident that one factor is more accountable than another. It is critical at this phase not to point fingers without doing a thorough investigation, even if the cause and effect seem to be evident, because wasting time addressing a false cause may be frustrating.

4. Identifying Options for Resolution

After the root cause has been analyzed, it is time to identify options for resolving the issue. The goal of this step is to develop a plan to resolve the issue and its root cause. Resolving issues can be done in multiple ways, which include performing a correction/band-aid fix, performing a corrective action, and performing a preventive action. Corrections/band-aid fixes involve quickly resolving a problem that arises, corrective actions involve fixing the root cause to prevent its reoccurrence, and preventive actions involve risk management to prevent a problem’s reoccurrence.

5. Implementing the Resolution Plan

After identifying the options for resolving the issue, it’s time to implement them. They can be corrective or preventive methods. If you want to execute corrective actions, you must first identify the systemic flaws that are affecting your organization, service, or product. Corrective measures might be knee-jerk at times, but they are a vital step in fixing and controlling an issue. Preventive interventions are sometimes preferable because they are proactive, prediction-based approaches that strive to prevent or monitor probable dangers before they evolve into big, possibly dangerous ones.

6. Monitoring Your Actions

After implementing the necessary actions for resolving the issue, it’s time to see how effective they actually are in this step. This is the most crucial phase since it guarantees that the action is not only suitable but also that it will fix the issue and prevent it from happening or reoccurring in the future. Surprise audits are a fantastic way to check for efficiency. The audit will check that all machinery, people, and processes are operating in accordance with the corrective action plan.

FAQs

What is the difference between a correction and a corrective action?

The difference between the two is that correction is a more reactive and rapid response to an issue or problem containment, while corrective action is a more deliberate response to a problem, in which you analyze the underlying reason, create a remedial strategy, and then record and implement the plan.

What is lean manufacturing all about?

Lean manufacturing is a type of manufacturing that may be employed by businesses that seek to minimize production system time in order to boost efficiency. When a corporation implements a lean manufacturing strategy, it indicates that it intends to increase production while removing as much waste as feasible. This might imply reducing operational costs and lead times.

What is a corrective action request?

A request for corrective action is a specific request to address the source of a nonconformity. The nonconformity might be in a product, process, or service. Frequently, such as when a manufacturer engages with a supplier, the source agency first addresses the issue before issuing a corrective action request. A corrective action request might involve several levels of concern, and it is most commonly seen in manufacturing or production environments.

Manufacturing companies can make use of this type of corrective action plan if there are issues present in their company that can severely threaten their operational safety or the quality of the products that they manufacture. And in order for the document to do its job, it must be constructed effectively. In this article, various sample templates of this document are available for you to have a look at and use as a reference when you need to make one.