50+ SAMPLE HACCP Management Plan

-

HACCP Management Plan

download now -

HACCP Management Sponsorship Plan

download now -

HACCP Management System Plan

download now -

HACCP Management Program Plan

download now -

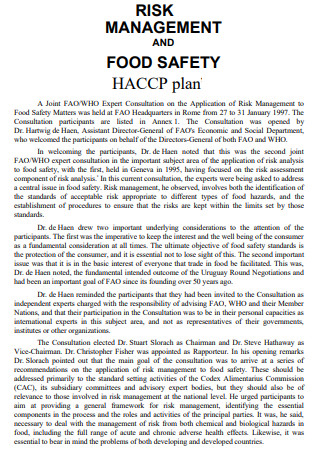

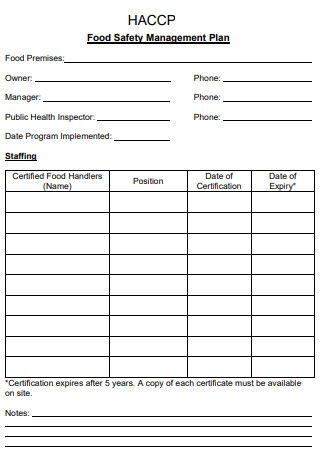

HACCP Food Safety Management Plan

download now -

Development of HACCP Management Plan

download now -

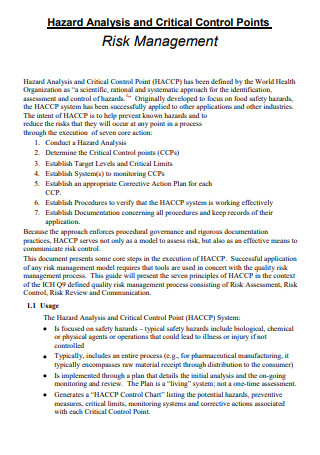

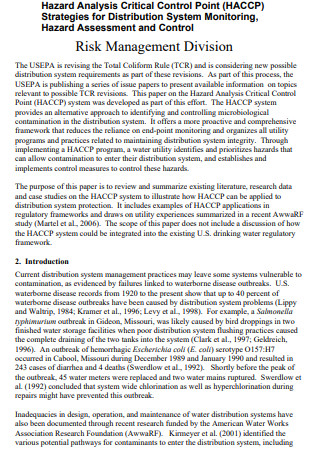

HACCP Risk Management Plan

download now -

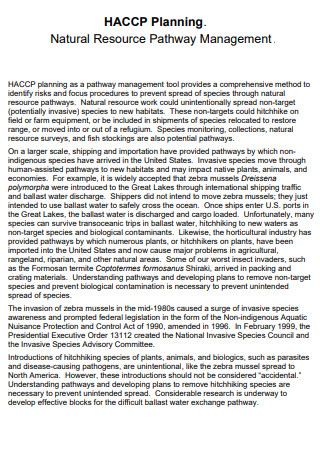

HACCP Natural Resource Management Plan

download now -

HACCP Management Training Plan

download now -

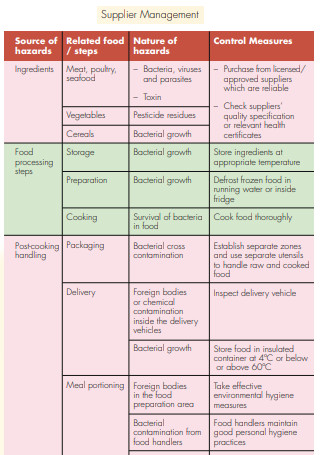

HACCP Supplier Management Plan

download now -

HACCP Food Safety Management System Plan

download now -

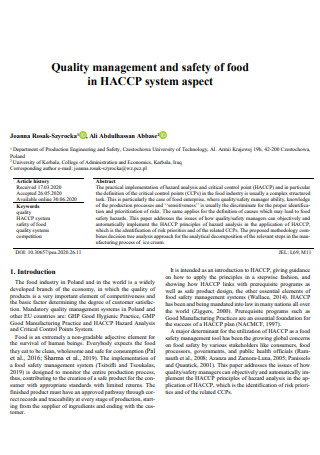

HACCP Quality Management Plan

download now -

HACCP Management Division Plan

download now -

Implementation of HACCP Management Plan

download now -

HACCP Risk Management Food Safety Plan

download now -

Creating HACCP Management Plan

download now -

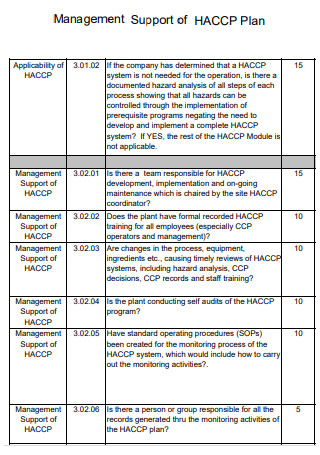

HACCP Management Support Plan

download now -

HACCP Quality Management Food Plan

download now -

HACCP Revalidation Management Plan

download now -

Effective HACCP Management Plan

download now -

HACCP Waste Management Plan

download now -

Sample HACCP Management Plan

download now -

HACCP Quality Assurance Management Plan

download now -

HACCP Management Commitment Plan

download now -

HACCP Food Processing Management Plan

download now -

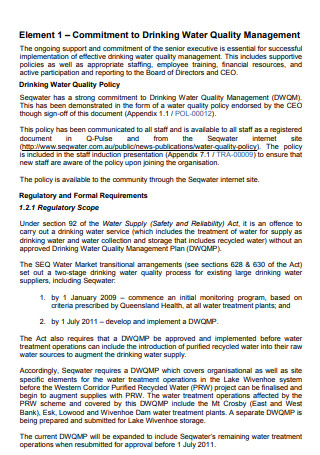

HACCP Water Quality Management Plan

download now -

HACCP Food Safety Management Plan Example

download now -

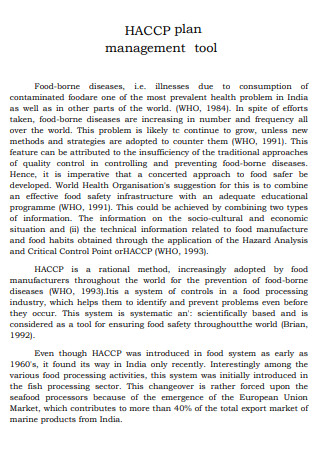

HACCP Management Tool Plan

download now -

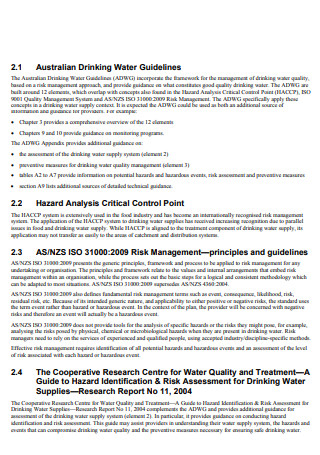

HACCP Drinking Water Quality Management Plan

download now -

HACCP Review Management Plan

download now -

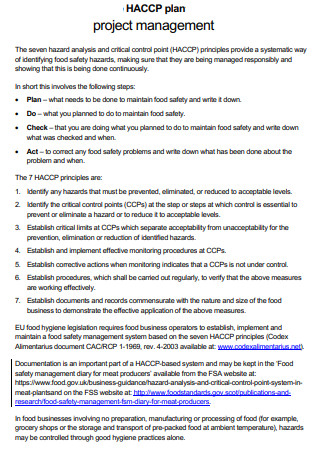

HACCP Project Management Plan

download now -

Simple HACCP Management Plan

download now -

HACCP Cake Management Plan

download now -

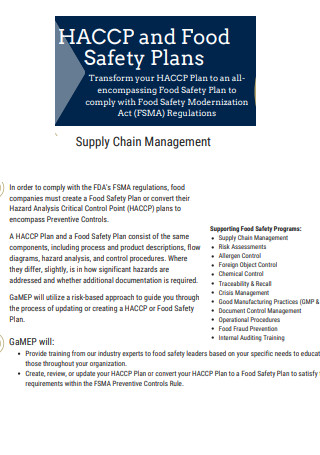

HACCP Supply Chain Management Plan

download now -

HACCP Safety Management Plan

download now -

HACCP Resource Management Plan

download now -

HACCP Organisational Management Plan

download now -

HACCP Food Service Management Plan

download now -

HACCP Water Operations Management Plan

download now -

Steps for HACCP Management Plan

download now -

HACCP Audit Management Plan

download now -

HACCP Reduced Oxygen Management Plan

download now -

Formal HACCP Management Plan

download now -

Preliminary HACCP Management Plan

download now -

HACCP Pollution Management Plan

download now -

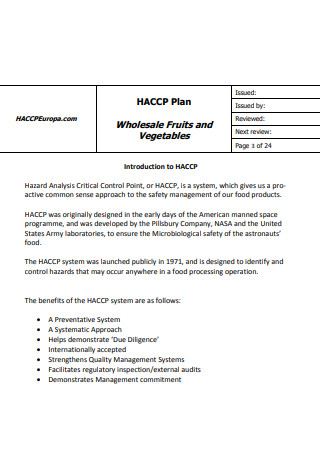

HACCP Management Plan in Meat Processing

download now -

Standard HACCP Management Plan

download now -

HACCP Retail Food Management Plan

download now -

HACCP Food Chain Management System Plan

download now -

HACCP Farm Management Plan

download now -

HACCP Food Service Operation Management Plan

download now

FREE HACCP Management Plan s to Download

50+ SAMPLE HACCP Management Plan

What is an HACCP Management Plan?

Different Types of HACCP Management Plans

Basic Components of a HACCP Management Plan

How to Write a HACCP Management Plan

FAQs

How to do HACCP plan?

How many steps are there in a HACCP Plan?

What are the HACCP management plan guidelines?

What foods require a HACCP plan?

What is the difference between the HACCP plan and food safety plan?

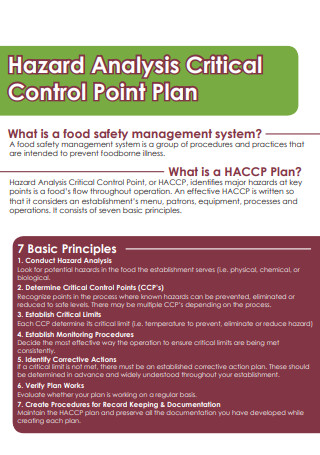

What are the major principles of HACCP?

What is an HACCP Management Plan?

A HACCP management plan is a clear, comprehensive, and well-designed written document that is typically used for the implementation of food and product safety management. It is an effective strategic management tool that helps various individuals, companies, groups, professionals, and others to guide them in making informed judgments concerning safety matters and removing bias. It can be transferred to the suppliers to help in guaranteeing raw material safety and to assist in showing effective food safety management using documented evidence.

According to a statistical report, 1 in 6 people which is 17% or about 48 million people in the United States have experienced a foodborne illness eacy year. Project managers, operational managers, supervisors, HACCP and crisis managers, and other professionals in all companies and organizations should prioritize HACCP management because it provides an effective way to improve food or product quality and safety, prevent hazards, and enhance processes. Thus, all kinds of project managers, operational managers, program managers, project supervisors, and other managers should effectively create a complete and well-coordinated HACCP management plan.

Different Types of HACCP Management Plans

Many companies and institutions in the food industry use HACCP to detect, examine, and control hazards that are significant for food safety inspection. That’s why food producers, manufacturers and retailers focus on ensuring product origin, integrity, and quality. They run risk management systems to mitigate risks and manage issues immediately. What are the different types of HACCP management plans?

1. HACCP Management Plan for Restaurant

If you are a restaurant owner or manager, a HACCP management plan for restaurant is an essential tool included in a restaurant development plan to keep control of food safety in your restaurant business. It is an accurate and well-detailed plan to demonstrate your committed approach to food safety for your customers. It can help in the prevention of any unacceptbale health risks and the occurence of any severe disease due to the consumption of your restaurant food. When writing this HACCP plan, create an interdisciplinary team, provide product and market details, draw a commodity flow diagram, specify and examine all hazards, identify the CCPs or Critical Control Points, establish critical limits, cosntruct a monitoring procedure system, define corrective action procedures, and keep a record of your HACCP system. This plan requires a sufficient amount of knowledge and time of food safety, so a HACCP plan example from our website will help you to build your plan.

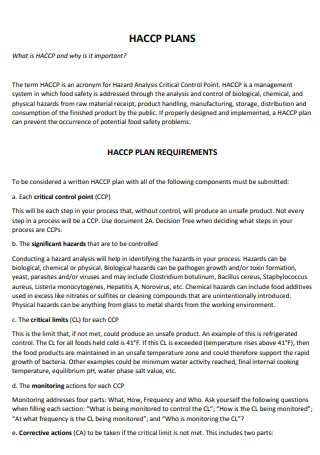

2. HACCP Food Safety Management Plan

This type of HACCP plan is included in a fast food business plan and it is used to evaluate and manage the operations in food safety management regarding the products and procedures of a business firm. When preparing this document, use a pre-made HACCP plan template to help you complete the necessary documents based on the food safety HACCP guidelines. The first page of the HACCP food safety management plan contains the details of the company, the process to be covered by the plan, and the names of the people assigned to develop the plan or the HACCP food safety management team. Then, outline the scope and the process flow on the second page. Explain the production process that the plan is to cover including the start and end points of the process being covered, the type of food safety hazards to be solved, the proudct and its intended use, the customers and product end users, product packaging, storage and distribution details, and safety information.

3. HACCP Management Training Plan

HACCP managers create a compelling and well-structured HACCP management training plan to guide their team members about all food safety compliance standards. It contains the course information which includes the preliminary steps and major principles required in the HACCP plan development. For example, this plan contains brief summary about the training course agenda such as the importance of food safety, the need for HACCP food safety management procedures, consequences of poor food safety, history of HACCP, HACCP methodology, HACCP team, identifying potential food safety hazards, product and process areas of risk, and implementing HACCP food safety systems.

4. HACCP Management Plan for Meat Processing

A HACCP management plan for meat processing is a scientific and systematic plan to control food safety management systems properly. It outlines the preventive system for safer production of meat products to prevent possible biological, chemical, and physical food safety hazards that can naturally occur due to a change in production processes or other reasons or issues. Plus, it helps in addressing multiple products within one processing category, as well as assessing only one product passing rhoguh multiple processing categories such as heat treated-shelf-stable, products with secondary inhibitors, raw product-ground, thermally-processed commercially sterile, slaughter, etc.

Basic Components of a HACCP Management Plan

Construct an integrated and well-written HACCP management plan while highlighting the fundamental elements of the plan. Include the following elements for you to create a professional document:

Structure the monitoring methods and procedures that the HACCP team are responsible to implement in order to document a sequence of observations for CCPs. This serves as a record after the food operations in proper monitoring logs. Corrective Actions and Verification Procedures: Indicate the corrective actions and verification procedures that will be carried out in the HACCP plan. Corrective actions are necessary to have control over the food safety management operations, address the remaining food safety risk, and maintain food safety when a CCP fails to control a specific hazard. Explain the verification and validation procedures that your HACCP system will execute such as product testing, CCP evaluation, and comprehensive review of monitoring records.

How to Write a HACCP Management Plan

Businesses and institutions in the food industry are responsible for making sure that the food they put on the marketplace or that are served in food service establishments are safe, suitable for human consumption and reach regulatory requirements of the country where they are marketed. If you are having difficulties in writing a clear and systematic HACCP management office action plan for your business or organization, we have some easy-to-follow tips below that indicate how to write a clear and structured HACCP management plan:

1. Conduct a Hazard Analysis

You need to know what are the potential food hazards that may exist in your business or company. Examine the hazards of the ingredients that you use in your food products such as the equipment used, meat and seasonings, chemicals that come in contact with the food, and individuals in your staff who are assigned in food preparation.

2. Identify Critical Control Points and Establish Critical Limits

Go through your food processes to identify which hazards can be controlled. Then, establish specific critical limits on the critical control points (CCPs). For instance, you might mention that you will cook the meat to 155℉ (68℃) and if you need to perform bacteria testing, establish the limits clearly.

3. Set a Monitoring System and Corrective Actions

Build a monitoring system to help you ensure the critical limits. So, if the critical limit for pepperoni making is cooking it to 155℉ (68℃), you will place in the monitoring system that it is required to use a thermometer to check the temperature and listing it in the temperature log.

4. Outline Verification Procedures

Describe the key verification procedures that will be used to see the effectiveness of your HACCP plan. Some examples of verification procedures that you may add are observing the actions of your employees like measuring the temperatures of the foods and documenting them in a temperature log.

5. Create Procedures for HACCP System Documentation

Describe the important procedures that must be implemented for the documentation of your HACCP system. Incorporate the hazard analysis, HACCP risk management plan, and other supplemental documents for the critical limits.

6. Proofread and Prepare the Final HACCP Plan

Review your overall HACCP management plan and make sure that you fully indicate all the major points in your document. Highlight the connection between specific HACCP management goals, objectives, and procedures used for the fulfillment of the HACCP objectives, and the evaluation of the HACCP crisis and health and safety inspection project managers involved in the HACCP management plan. If you notice that you forgot some portions that need more important information, edit and revise the document immediately.

FAQs

First, you need to gather the HACCP Management Team and define the food and its distribution. After that, specify the major use and consumers of the food. Construct and verify a simple process flow diagram. Then, perform an in-depth hazard analysis and identify the critical control points.

There are seven steps that must be done in a HACCP plan to solve the biological, chemical, and physical hazards analysis and control.

The HACCP management plan guidelines are fundamental guidelines intended for new and prospective owners and operators of food businesses such as fish products, poultry, bread and pastries, and processed food product establishments. These guidelines explain the best practices and regulations to meet regulatory requirements.

Dairy, fruit juice, meat, poultry, egg products, and seafood are some of the foods that require a HACCP plan.

HACCP plan is a critical post-process management planning tool to prevent food safety risks for an extensive range of products through the identification of possible hazards in major areas in the process. On the other hand, a food safety plan is an essential tool that takes a more preventive focus on detecting potential risks and executing proper controls to minimize food contamination proactively.

The major principles of HACCP are CCP identification, hazard analysis, setting critical limits, corrective actions, monitoring procedures, record-keeping, documentation, and verification procedures.

How to do HACCP plan?

How many steps are there in a HACCP Plan?

What are the HACCP management plan guidelines?

What foods require a HACCP plan?

What is the difference between the HACCP plan and food safety plan?

What are the major principles of HACCP?

Thus, HACCP is an important foundation for product safety management that connects with other management systems. Being a logical and straightforward system of control based on the prevention of certain issues, a HACCP system is integrated when the HACCP team observes the process or product from start to end, determines possible hazards, places controls to monitor them, documents them, and makes sure that it continues to work properly. To assist you while developing a comprehensive HACCP plan, we have included several HACCP management plan samples, HACCP management plans for high school, HACCP management plans for middle school, HACCP audit plans, and other HACCP management plan template that you can download and use for your HACCP management work.