50+ Sample Quality Assurance Plans

-

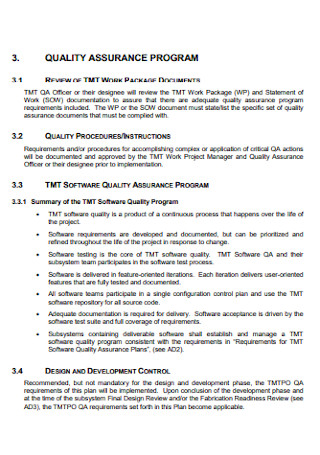

Software Quality Assurance Plan

download now -

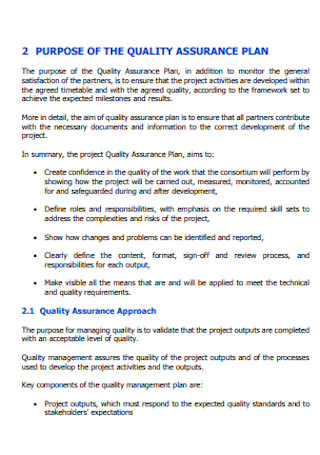

Purpose of Quality Assurance Plan

download now -

Gartner Quality Assurance Plan

download now -

Quality Assurance Plan Checklist

download now -

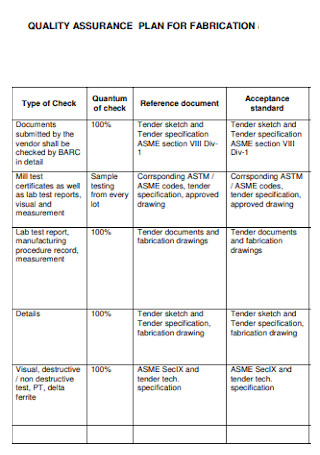

Quality Assurance Plan for Fabrication

download now -

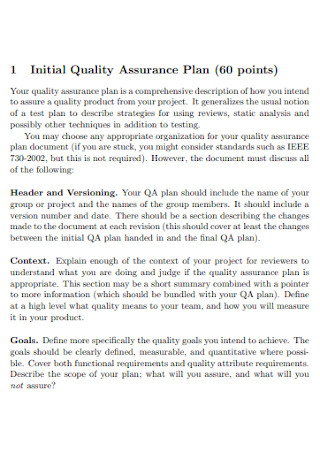

Initial Quality Assurance Plan

download now -

Quality Assurance Plan Example

download now -

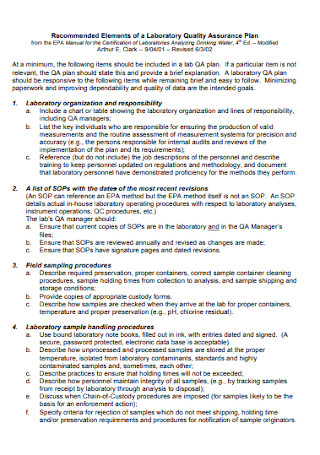

Laboratory Quality Assurance Plan

download now -

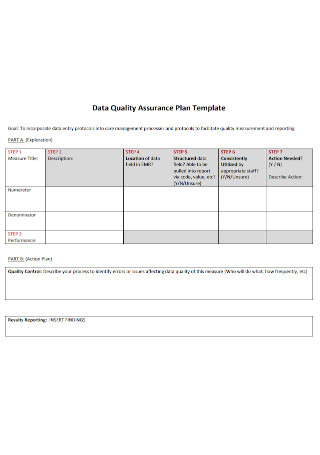

Data Quality Assurance Plan

download now -

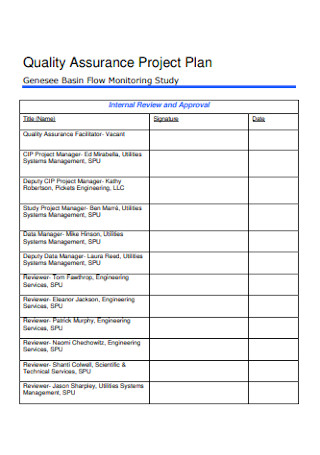

Quality Assurance Project Plan

download now -

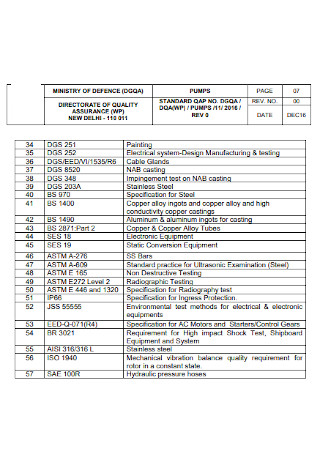

Quality Assurance Plan for Pumps

download now -

Construction Quality Assurance Plan

download now -

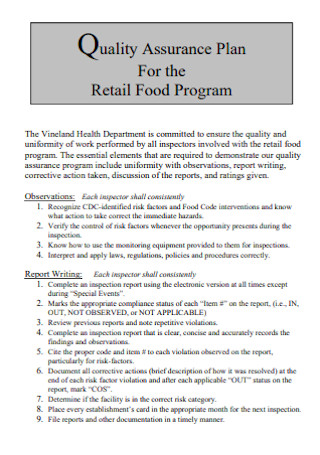

Quality Assurance Plan for Retail Food Program

download now -

Quality Assurance Plan for MediSmarts

download now -

Quality Assurance Plan Format

download now -

Laboratory Quality Assurance Plan

download now -

Final Construction Quality Assurance Plan

download now -

Quality Assurance Training Plan

download now -

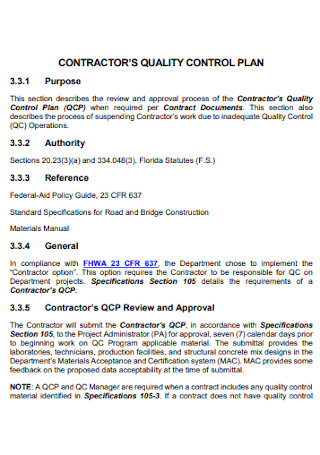

Contractor Quality Assurance Plan

download now -

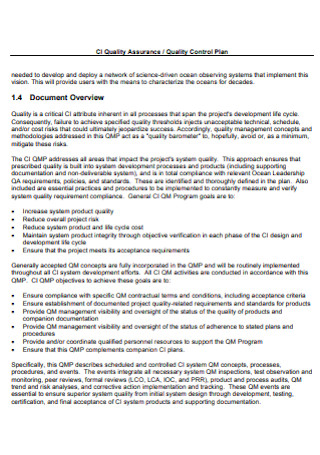

Network Quality Assurance Plan

download now -

Quality Assurance and Control Plan

download now -

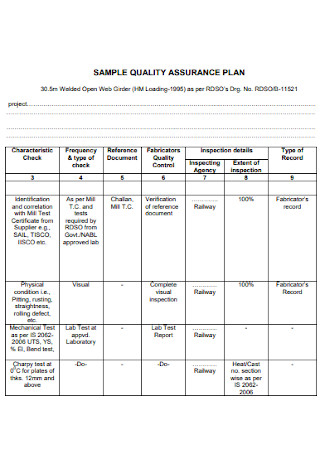

Sample Quality Assurance Plan Example

download now -

Basic Quality Assurance Plan

download now -

Preliminary Quality Assurance Plan

download now -

Product Quality Assurance Plan

download now -

Individual Quality Assurance Plan

download now -

Materials Quality Assurance Plan

download now -

Quality Assurance Program Plan

download now -

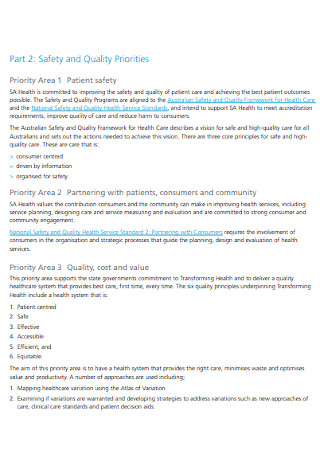

Safety and Quality Assurance Plan

download now -

Quality Improvement Assurance Plan

download now -

Scientific Quality Assurance Plan

download now -

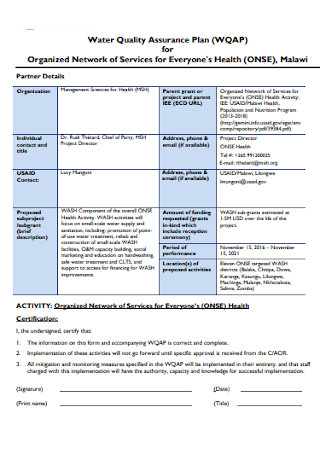

Water Quality Assurance Plan Template

download now -

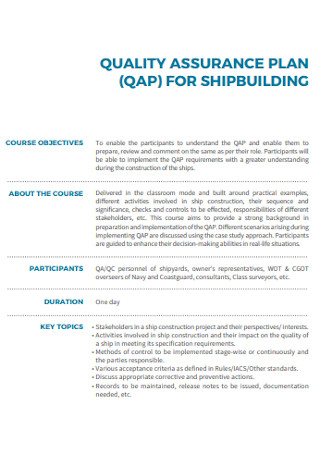

Quality Assurance Plan for shipbuilding

download now -

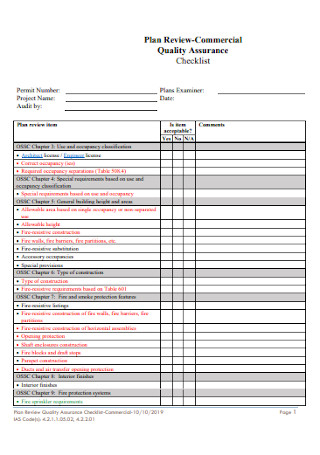

Commercial Quality Assurance Plan Checklist

download now -

Farm Water Quality Assurance Plan

download now -

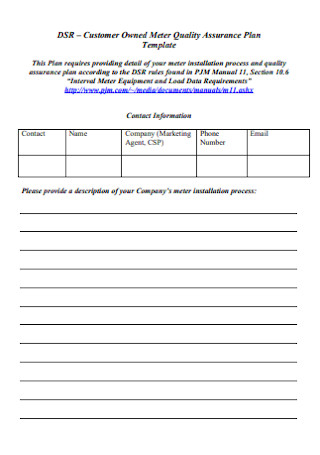

Customer Owned Meter Quality Assurance Plan

download now -

Quality Assurance Action Plan

download now -

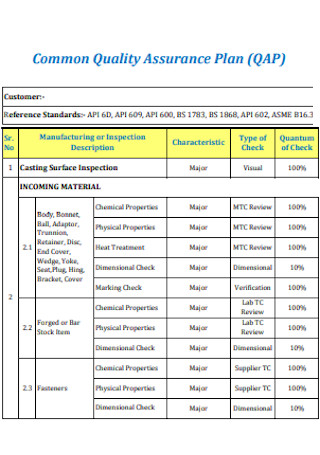

Common Quality Assurance Plan

download now -

Model Quality Assurance Plan

download now -

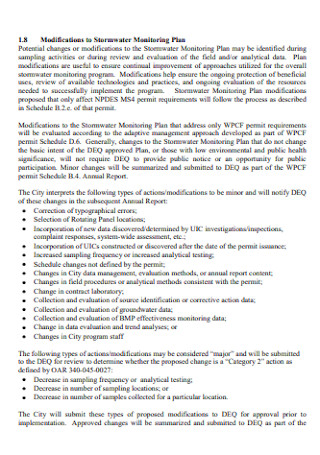

Stormwater Monitoring and Quality Assurance Plan

download now -

Quality Assurance Strategic Plan

download now -

Standard Manufacturing Quality Assurance Plan

download now -

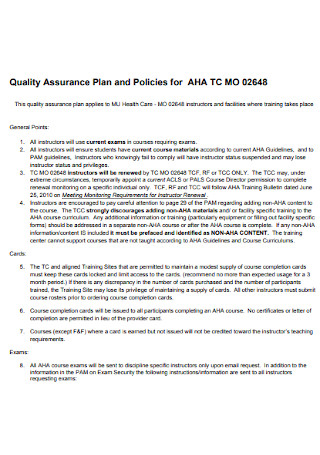

Quality Assurance Plan and Policies

download now -

Research Integrity and Quality Assurance Plan

download now -

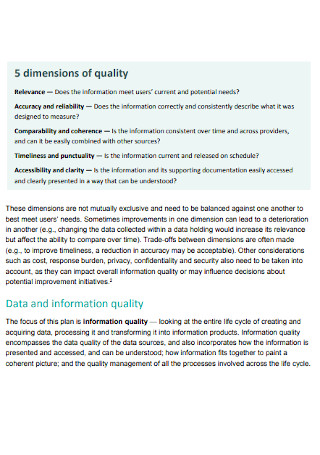

Quality Assurance Information Plan

download now -

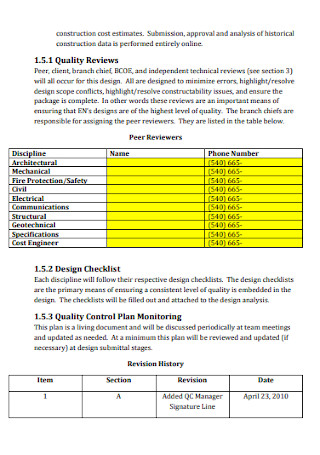

Desiign Quality Assurance Plan

download now -

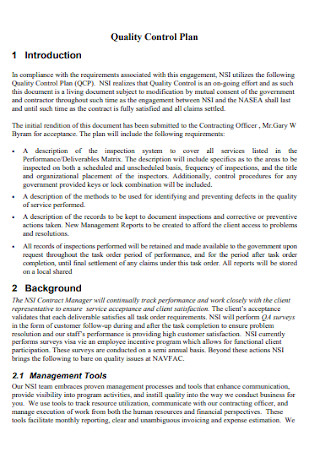

Quality Assurance Control Plan

download now -

Quality Assurance Work Improvement Plan

download now -

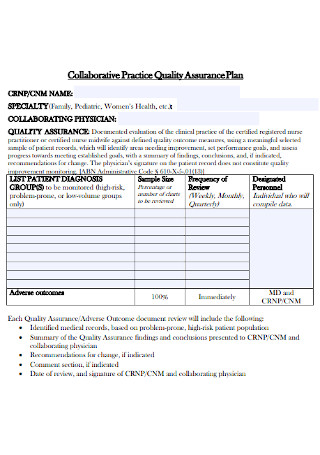

Collaborative Practice Quality Assurance Plan

download now -

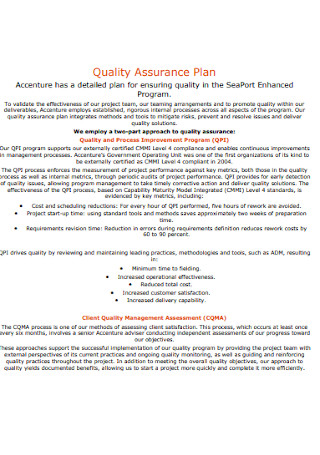

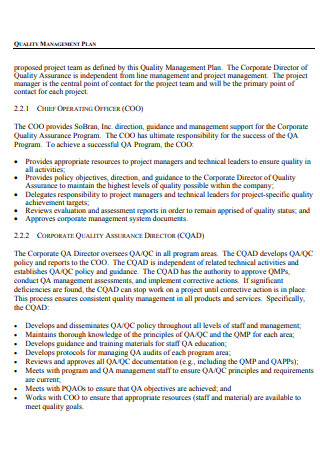

Sample Corporate Quality Management Plan

download now -

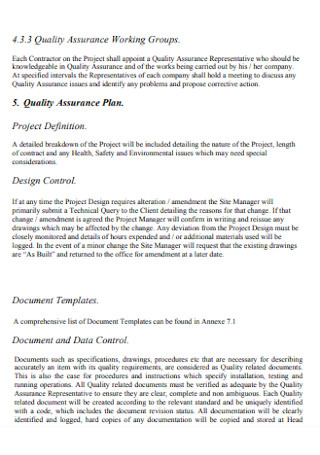

Quality Assurance Working Group Plan

download now

FREE Quality Assurance Plan s to Download

50+ Sample Quality Assurance Plans

What Is a Quality Assurance Plan?

Why Are Quality Assurance Plans Important?

The Standard Quality Assurance Plan Format

How to Build an Exemplary Quality Assurance Plan

FAQs

What are the other names of the quality assurance plan?

What is the difference between quality assurance and quality control?

What are the four steps of the quality assurance cycle?

What Is a Quality Assurance Plan?

Quality assurance plans (QAP) are the official documents organized by project teams. Just like a quality plan, the document must be strictly observed to ensure that the final output of products and services follows the given criteria that make up top-notch quality products or services. With assurance, you will not only listen to the consumers’ needs but also run according to your company’s target objectives.

It was reported in a 1981 HBR survey that three of five chief executives of the biggest businesses said that quality was improving. On the contrary, 49% of their 7,000 clients mentioned that American product quality had lessened.

Why Are Quality Assurance Plans Important?

While it is easy to say that quality assurance plans are there to deliver top-quality products and services, how exactly are they important to businesses, customers, and projects in general? In this section, discover the many advantages that prove how essential the QAP is.

Quality Maintenance Guaranteed

Quality assurance plans denote all the necessary strategies and procedures to implement quality maintenance effectively. It is more than just evaluating if a product is good or not because product or service quality is being maintained at specified levels. So whether you handle a construction project, healthcare laboratory, contractor software, or even manufacturing equipment, you can treat QAP as your quality maintenance plan.

Detailed and Easy-to-Follow Steps

What is responsible to ensure excellent quality in operations is the detailed step-by-step procedures enlisted in the quality assurance plan. The plan itself is expected to be easy to read until no issue takes place from pre-planning down to the final stage of production or delivery. So rather than trying to memorize all the steps for quality assurance, you won’t forget a thing by using this strategic plan for your reference.

Balance in Business and Customer Satisfaction

Another positive attribute of the QAP is to balance meeting the business and customer needs. Indeed, any business would want to make their customers happy as much as possible. But if that means their satisfaction is giving the company low profits, arduous operations, and a bad rep, then something must be changed. Thanks to the quality management plan, there is room to consider the customers’ needs as well as the businesses’ specific goals. That is how you recognize which practice works best for quality and which ones must be avoided.

Risk Reduction

Most importantly, quality assurance plans are made to mitigate the chances of costly errors. You can’t deny that any product, service, or project has its own set of risks. Hence, quality assurance is around to prevent possible defects and improve product quality in the best approach possible. In other words, there is also some room to incorporate a risk assessment plan in your QAP.

The Standard Quality Assurance Plan Format

Quality assurance plans deal with a myriad of processes such as planning, evaluating, monitoring, reporting, and more. Although the QAP helps assure the whole project team to comply with the necessary procedures and standards, part of what makes it possible is the plan’s organized outline. And here is the standard format for an effective quality assurance plan that you can follow:

How to Build an Exemplary Quality Assurance Plan

First things first, you don’t need to write a quality assurance plan from scratch. There are sample templates provided to you already, as seen above in this article. You may opt for a quality assurance plan sample for construction, quality assurance plan checklist, or just a simple quality assurance plan template. And once you find your preferred QAP template, be sure to apply these steps:

-

Step 1: Set Your Quality Objectives

Every company doesn’t have the same quality objectives, so defining the goals must be personalized. And the best approach to defining quality objectives is by adapting to SMART goals. That means the objectives must be specific, measurable, appropriate, realistic, and timely. And besides basing on your organization’s objectives, listen to customer expectations as well. This will help you realize that low-quality products can also make you lose clients.

-

Step 2: Assign Specific Roles and Duties

The whole quality assurance plan is not expected to be carried out by one person. And in a company, a number of team members are expected to manage certain responsibilities. Hence, listing and assigning duties with the help of a task checklist shall make this second step pay off. Also, don’t bother to send tasks immediately without training the staff yet. Training helps ensure that the roles given to the team meet their skills. And standardized responsibilities will set a clear motion towards meeting quality objectives and project expectations.

-

Step 3: Follow the Quality Assurance Plan per Se

You will eventually complete your quality assurance plan by following the standard QAP format being discussed earlier. From general data to risk management, they will all collaborate to make an effective QAP. Then, observe your company’s new quality assurance processes. Besides being trained, the whole team must have the necessary resources to reach each target too. However, following the guidelines of the business plan doesn’t mean the process is over. You still have three more steps to go.

-

Step 4: Evaluate the Results

While following the quality assurance plan marks the testing procedure of your plan, the next concern is to come up with a detailed evaluation report of the QAP’s results. So in testing and following the plan, did it work or not? State the reasons clearly in the evaluation report. The QAP will give you the criteria already on how to assess and ensure that expectations are met, including what to do to improve next time.

-

Step 5: Create Adjustments and Improvement Plans

Evaluating leads to a number of realizations, especially in listening to any feedback openly. So come up with the proper adjustments for a better quality management plan in the coming months or auditing reports to come. When a plan is effective, it is likely that companies will maintain in using that plan. However, change is constant for any industry. And you even need to change big time when the plan itself fails. So aim to have a proper development or improvement plan whether it involves better management, a more organized customer service, or any goal. You will surely look forward to your products’ successes.

-

Step 6: Update the Team Regularly

Besides knowing why the entire team should observe the quality management plan, keep everyone in the loop with what has been done from time to time too. For example, announce to everyone if the plan worked or improved at the moment. Productive meetings with the team will help manage this last step, especially when you welcome their feedback. As everyone stays updated, the whole plan will surely sail smoothly.

FAQs

What are the other names of the quality assurance plan?

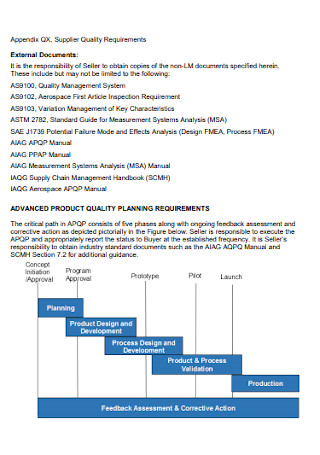

A quality assurance plan is also referred to as an advanced quality plan (AQP) in the US. In the automotive sector, quality assurance plans may be regarded as advanced product quality plans (APQP). Or, you can simply say quality assurance (QA).

What is the difference between quality assurance and quality control?

First of all, quality assurance and quality control are not the same. Quality assurance deals more with preventing possible defects of a product while quality control is more on determining those product defects.

What are the four steps of the quality assurance cycle?

Quality assurance involves planning, doing, checking, and acting. And this cycle will reassure you that quality management runs effectively in your organization.

The next time you aim to retain high standards for your product or service quality, save time and money, and ensure continuous business success, you can’t go wrong with a well-made quality assurance plan. Indeed, anyone can think of a way to make a product sell. But failing to prepare quality standards can bring down that idea’s value. Hence, depend on a quality assurance plan to organize all aspects of your product development, from how to observe top-notch quality standards down to how to make the appropriate changes for the sake of quality. Download now!