5+ Sample Project Safety Management Plan

-

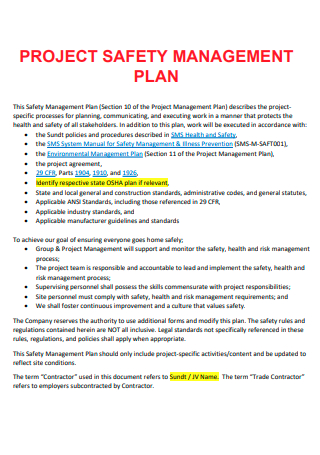

Project Safety Management Plan Template

download now -

Project Health and Safety Management Plan

download now -

Basic Project Safety Management Plan

download now -

Energy Project Construction Safety Management Plan

download now -

Project Safety Management Plan Format

download now -

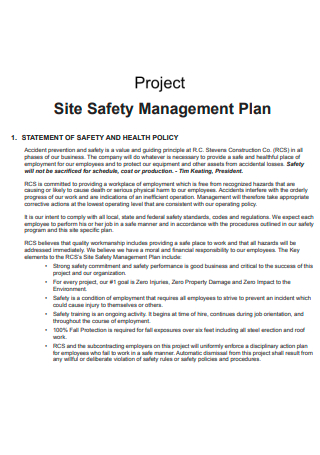

Project Site Safety Management Plan

download now

FREE Project Safety Management Plan s to Download

5+ Sample Project Safety Management Plan

What Is a Project Safety Management Plan?

The Four Pillars of a Construction Safety Management System

How to Make a Project Safety Management Plan

Tips for a Successful Construction Health and Safety Management

FAQs

What is the purpose of a safety management plan?

What is the importance of project management?

Why is safety management important?

What Is a Project Safety Management Plan?

A project Safety Plan is a written document that outlines everything a worker needs to know about working safely on a construction site. It’s as easy as that, yet it’s also as comprehensive. A project safety plan should be an all-in-one reference for personnel to evaluate before starting work on their first day on the job. Furthermore, site safety plans must be used as a reference whether a worker has a query about working safely or in the event of an emergency. Continue reading the article to be knowledgeable of the importance and steps in writing your own. There is a guide as you scroll down below.

The Four Pillars of a Construction Safety Management System

Policy and goals, safety risk management, safety assurance, and safety promotion are four pillars or components of a successful safety management system. These pillars enable senior management and safety personnel to create and administer a successful, comprehensive, and life-saving safety program. As a result, these safety management system pillars may and should be adapted to other industries, such as the construction industry, which is fraught with hazards. The four pillars, or components, can be used in building in the following ways. Check out the construction Project safety management plan we have provided for you.

How to Make a Project Safety Management Plan

Now that we have established the definition of a project safety Management Plan, it is time for you to start the process of writing your own. If you are pressed for time and have other tasks to manage, then use a safety management plan template to save time and prioritize other things to do. At least you have a template ready at your disposal which you can adjust at any given time. With that being said, you can now begin to follow along the process of making your own project safety management plant.

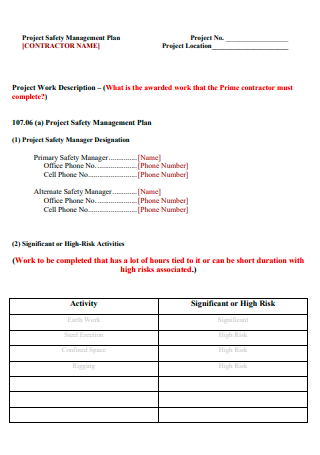

Step 1: Write the Project Description

A description of the important features of the project based on the main stages, as well as potential hazards and risks, should be included in this portion of the plan. This section of the plan should be project-specific, outlining important facts such as the project’s name, purpose, duration, phases, and safety issues at each stage. This also involves the specification of the project’s site location and layout design, as well as the interfaces to be considered. Project signs must include information such as the major contractor’s name and contact information, including after-hours phone numbers, as well as the location of the project’s site office. Safety in design considerations, including any applicable work health and safety hazards and risks reported by the designer, should also be described in this part.

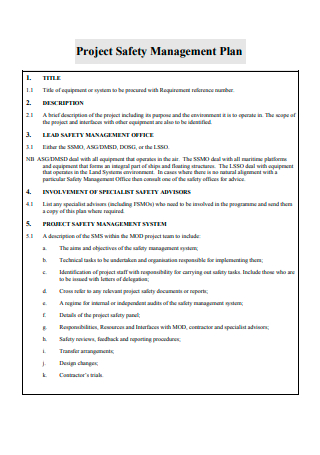

Step 2: State the Responsibilities

This section should define the work health and safety responsibilities of all project personnel from the tender process to the completion of a contract. In particular, this section should define who can make decisions and take actions on work health and safety issues, and in what circumstances. The description of the responsibilities must include the name, position, and appropriate authority of all personnel such as the corporate management such as the managing director and project director, project and site managers, workers, contractors and subcontractors, and many more. Specific aspects for responsibilities may include consultation arrangements, managing design issues, hazard identification, Risk Assessment and control measures, inspections, tests and compliance with site safety rules, and many more.

Step 3: Make sure to Complete Consultations

Pre-start briefings, toolbox discussions, and meetings are examples of consultation arrangements. Topics covered, meeting dates, and names of those in attendance should all be documented. The plan should specify how consultation and communication needs are accomplished, such as by establishing a health and safety committee or designating a health and safety representative or other consultation procedures agreed upon by management and workers. Where committees and health and safety representatives are in place for consultation, the procedure must be followed as prescribed.

Step 4: Ensuring Induction and Training

Induction and training are critical components in ensuring that employees are well-informed about workplace health and safety risks. The plan must detail how employees will be trained on health and safety regulations. A unique site induction protocol should be specified in this section, indicating the process for inducting personnel, visitors, and subcontractors. It should also state how records will be kept for three years after the project is completed. Prior to starting work on-site, the primary contractor must guarantee that all personnel, contractors, and subcontractors have attended general construction induction training. This is an obligatory requirement for the primary contractors, even if it is not part of the management plan.

Step 5: Managing Subcontractors

This section of the work health and safety management plan should identify the project’s important subcontractors and how the lead contractor will manage their safety plans and safe work procedure declarations. The mechanism for engaging subcontractors, as well as monitoring and analyzing their performance, must be included in the major contractor’s plan. All subcontractor risk assessments, as well as their safety performance, must be collected, assessed, monitored, and reviewed. A register will aid in the administration of insurances, licenses, accreditation information, and document verification. To reduce risk and assure compliance with contract requirements and project safety protocols, the major contractor will outline how subcontractors will be monitored.

Step 6: Document Control and Record-Keeping

This part also requires a strategy to indicate how project safety documentation is kept up to date. Control, approval, retention duration, distribution, storage, and destruction of papers and records should all be part of a protocol. Training records, individual qualifications, inspection reports, plant and equipment records, work licenses, safety equipment records, incident investigation reports, risk assessments, minutes of safety meetings, audit reports, and workers compensation records are all examples of safety records. A copy of the plan must be preserved by the principal contractor until the project is finished. If a notifiable incident happens, the plan must be retained for a period of two years following the incident. Anyone working on the project should have a copy of the plan on hand at all times.

Tips for a Successful Construction Health and Safety Management

In the administration of a building site, health and safety are extremely important. They are important criteria in determining whether the task will be done on time and at the desired quality. Although health and safety policies have improved in recent years, it is still critical for construction companies to adequately manage these areas. This will not only help to ensure that employees have safe working conditions, but it will also help to mitigate the impact on company performance, such as project delays.

FAQs

What is the purpose of a safety management plan?

In compliance with the safety planning standards, safety management plans enable project managers, construction crews, and their teams to define and communicate work health and safety arrangements, as well as set and prioritize targets to improve performance in an organized manner. A safety management plan is necessary to ensure the awareness of the workers involved in the project or construction. This helps avoid unnecessary issues, complications, or accidents from endangering their lives and the progress of the construction or project. A project with an integrated safety management plan will have fewer complications in the long run.

What is the importance of project management?

The relevance of Project Management in businesses cannot be emphasized. It boosts the efficiency of every part of the company when done appropriately. It frees up your team to focus on the job that matters, rather than being distracted by projects that go off course or budgets that spiral out of control. Managing a project is important because it helps the team stay ahead of issues that they may face as they go through the process of the project.

Why is safety management important?

There is more openness when everything is combined into one system. That is why a safety management system is so important as it provides supervision of safety procedures, ensures that a site complies with applicable rules and laws, and saves lives by fostering a strong safety culture. Safety should be upheld no matter the situation and project in order to avoid facing accidents or incidents. You can check out available project safety plan samples which you can use as a reference when your company is in need to better manage safety in the current projects they are working on.

Companies will perform risk analysis on the project they are planning to push through with before committing to it. This ensures the safety of the situation and in a way Project Managers are able to address potential risks before they begin to have a bigger role in the situation. An implementation of a project health and safety management plan will be useful and important for any given project supervised by a company.